Probing Revisited

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

From memory (yes I do have some left) when PlasmaC was young and John (islander261) kindly donated a lot of his time (plus consumables and stock) he mentioned that as he almost exclusively cut thin sheet he had previously had these issues and he would clamp the sheet down to minimize any problems. We tried several ideas during this testing phase and ended up with the result we have today.

It has been suggested that PlasmaC should be able to handle these changes in the sheet.

So if anyone has any suggestions or knowledge of how other systems work around this issue now is the time. You do need to bear in mind that there are both ohmic and float type probing and we need to be able to cater for both.

Even if you have had probing issues and don't have a solution it would be good to know exactly what issue you are having.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21178

- Thank you received: 7235

I do make the Z axis as fast as possible as that saves time when lots of probing is involved. Last machine i finished had a Z axis that could do 12m/m, but that was way to fast, so it would trip the switch and continue pushing or stalled the Z axis stepper motor, so i had to set it to 6m/m. It could successfully probe up to 7.2m/m, but i left some margin there.

For most plasma cutters, having it at 2m/m is more than enough, and what you loose in time (if any) you gain in reliability, since those 5 to 10cm of travel are not long by any stretch. Never mind me that last 2 machines i built, one had 2 separate floating heads for two plasma torches or plasma and oxy/accetylene with both at 32cm moving down, and that last fast one had 28cm.

Also they all have instant homing on Z axis, so i set the home in 5cm above material. At 6m/m the probing takes a bit over 1 second, or some 5 seconds if the home/torch is set at 25cm above material. 1000 pierces per day = 1000 seconds, or roughly 20 minutes.

I doubt anyone does 1000 pierces per day, the cost of consumables would ruin him/her.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

This is why I thought we had it right, there is a lot of probe testing here.

forum.linuxcnc.org/plasmac/38521-gui-for...smac?start=60#160119islander261 wrote:

I actually have routine cutting that is over 1500 pierces one single sheet with some actually using up a new set of consumables (over 3,000 pierces) on a single sheet

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21178

- Thank you received: 7235

I feel sorry for him, 3000 probes = 1 hour a day gone never to come back.

Not a joke, that really is to much waiting, so any small gain in speed is money and time saved and more produced.

On a side note, The ESAB Ultrarex i retrofitted has a stepper motor mounted on the back of the existing DC motor, through a gearbox, so it is slow at 900mm/m, last month he asked if it could be sped up. He has been using it for 2 years (i think), never complained. That got left that way since he was not interested in making custom mounting and fittings for it, it came to bite him !

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I took some more time to read through this again and one of the proposals a while back is similar to this but it didn't go anywhere, I think it just got lost in that massive thread.I do make the Z axis as fast as possible as that saves time when lots of probing is involved. Last machine i finished had a Z axis that could do 12m/m, but that was way to fast, so it would trip the switch and continue pushing or stalled the Z axis stepper motor, so i had to set it to 6m/m. It could successfully probe up to 7.2m/m, but i left some margin there.

For most plasma cutters, having it at 2m/m is more than enough, and what you loose in time (if any) you gain in reliability, since those 5 to 10cm of travel are not long by any stretch.

My intention was to probe down at full Z speed, if material is detected back off until material not detected plus a mm or two (actually I said 10 back then) then probe down at the slower probe speed until material detected, back off at 0.001mm (0.00003937") per thread period until material not detected then call that the top of material.

This should put top of material within 0.001mm plus 0.001mm multiplied by the debounce value. This way Probe Height could be relegated to the offcut bin

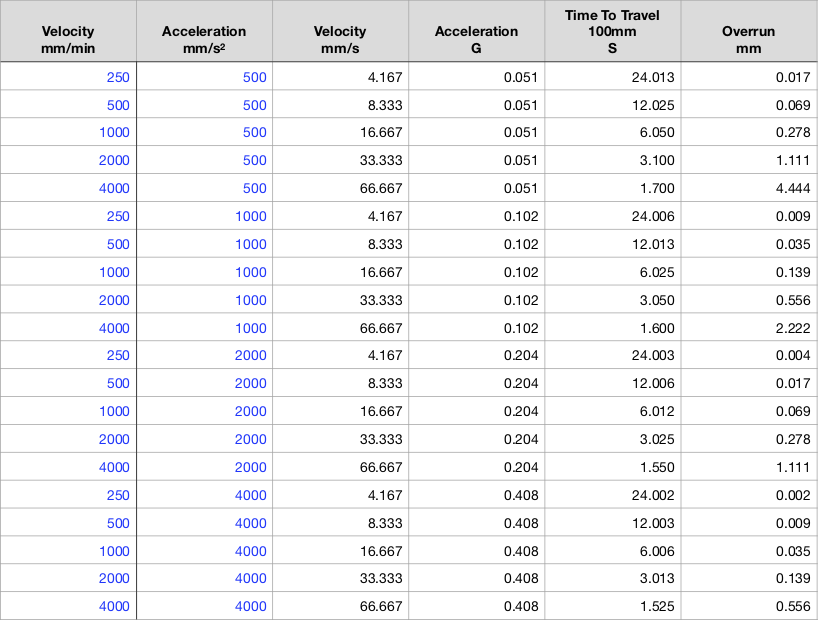

The main issue for users is that you would need a floating head with enough movement to soak up any overrun on the first probe. I did a quick spreedsheet of overrun figures (metric only) and it shows at 2m/min it takes roughly 3 seconds to move 100mm (provided my calculations are correct).

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

You guys can try this out if you want.

The only change is that if ohmic/float detects something before Probe Height is reached it will retract a short distance then probe at Probe Speed as before.

If Probe Height is reached before ohmic/float then the behaviour should be as it always was.

It should also work for Probe Test.

It still gives the error message but I can rip them out if they are a PITA.

I guess if your machine is suited to the fast probes then you could set Probe Height really low and use it this way for all probing (assuming it works)

EDIT: After thinking a bit more, if this works out I should remove the error message from normal probing but leave it in for Probe Testing as it may be of assistance when setting up the Probe Height for some folk.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11641

- Thank you received: 3918

And nowhere do we reference g forces in Linuxcnc configs. ...

Its been discussed previously on this forum that Newtons apple was accelerating at 9.81 m/s/s when it hit him on the head! (so 0.051g = 0.051 * 9.81 = 0.500 m/s/s = 500mm/sec/sec (in Aussie Device units)

Anyway, your efforts deserve a reprieve so I am prepared to overlook your dalliance!

Thanks for taking this on board Phill. I'll test when I can but I think it will be a few days before I can try this out. You did really well finding that earlier post. Hopefully ideas like that can be broken out into separate threads now Plasmac has its own forum section.

Its interesting you mentioned the float switch. A few times I noticed that probing was really slow last week but then I observed exactly what you said. A bowed sheet must have resulted in slow ohmic connection so I noticed when this happened the probe upwards was taking up the overshoot on the float switch.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

And nowhere do we reference g forces in Linuxcnc configs.

No but Jim Colt throws it around so I thought that if I did as well then some folk may think that I know what I am talking about.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11641

- Thank you received: 3918

And nowhere do we reference g forces in Linuxcnc configs.

No but Jim Colt throws it around so I thought that if I did as well then some folk may think that I know what I am talking about.

Phill, you are the master kenobi of plasma cutting now. Jim is just an influential user. You actually make this stuff work!

With the collective knowledge on this forum for guidance, you have done amazing work! We don't need any other disciples to follow!

I have to try and resume my void crossing research as once this probing is mastered, thats about all that is left to conquer

Did I tell you thats really hard?

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11641

- Thank you received: 3918

Thanks Tom.

This is why I thought we had it right, there is a lot of probe testing here.forum.linuxcnc.org/plasmac/38521-gui-for...smac?start=60#160119islander261 wrote:

I actually have routine cutting that is over 1500 pierces one single sheet with some actually using up a new set of consumables (over 3,000 pierces) on a single sheet

I think my last job was up there too. I must work it out!

Please Log in or Create an account to join the conversation.