Using Spotting with Sheetcam

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11568

- Thank you received: 3885

22 Jul 2020 10:56 #175384

by rodw

Replied by rodw on topic Using Spotting with Sheetcam

I found on my machine anything < 220 ms would not fire the torch. I thought when there were a few trying to get this going that mine was one of the quickest so I would start well above that..Have you set the threshold volts and delay time in the config panel.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

22 Jul 2020 11:27 #175386

by Clive S

Yes I have tried various settings. I have attached a slightly modified test prog

link to vid and pic. photos.app.goo.gl/VBYt32bv5eShEe6E6

It will do the first pierce but not the other 3. I noticed the arc goes up to 250V on the last three.

Also the code use tool 2 and it picks that from the tools from PlasmaC

It does the same for both files.

Replied by Clive S on topic Using Spotting with Sheetcam

Have you set the threshold volts and delay time in the config panel.

Yes I have tried various settings. I have attached a slightly modified test prog

link to vid and pic. photos.app.goo.gl/VBYt32bv5eShEe6E6

It will do the first pierce but not the other 3. I noticed the arc goes up to 250V on the last three.

Also the code use tool 2 and it picks that from the tools from PlasmaC

It does the same for both files.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Jul 2020 11:35 - 22 Jul 2020 11:49 #175387

by phillc54

Replied by phillc54 on topic Using Spotting with Sheetcam

The $2 is spindle #2, not tool #2. That is the correct spindle for spotting

It may be that your machine needs a bit of recovery time between torch on signals. Try putting a dwell (G4L between the spots.

Edit: (G4) not G4L, stupid phone...

It may be that your machine needs a bit of recovery time between torch on signals. Try putting a dwell (G4L between the spots.

Edit: (G4) not G4L, stupid phone...

Last edit: 22 Jul 2020 11:49 by phillc54.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11568

- Thank you received: 3885

22 Jul 2020 11:53 #175388

by rodw

Thats not unexpected when the torch turns on and off. Doing it so close together, might make it go higher... It won't hurt anything with a THCAD involved.

Replied by rodw on topic Using Spotting with Sheetcam

I noticed the arc goes up to 250V on the last three.

Thats not unexpected when the torch turns on and off. Doing it so close together, might make it go higher... It won't hurt anything with a THCAD involved.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

22 Jul 2020 12:22 - 22 Jul 2020 12:24 #175390

by Clive S

Ok I have tried a dwell of 4 secs. It is still the same. Then I tried a bolt hole 5Number 40mm dia from the extras. That worked perfectly But then that is using a different tool.

Replied by Clive S on topic Using Spotting with Sheetcam

The $2 is spindle #2, not tool #2. That is the correct spindle for spotting

It may be that your machine needs a bit of recovery time between torch on signals. Try putting a dwell (G4L between the spots.

Edit: (G4) not G4L, stupid phone...

Ok I have tried a dwell of 4 secs. It is still the same. Then I tried a bolt hole 5Number 40mm dia from the extras. That worked perfectly But then that is using a different tool.

Last edit: 22 Jul 2020 12:24 by Clive S.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Jul 2020 12:26 #175391

by phillc54

Replied by phillc54 on topic Using Spotting with Sheetcam

Do you mean that you spotted with the bolt circle or did a cut?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

22 Jul 2020 12:32 #175392

by Clive S

Sorry I should have said the bolt hole cut 5 5mm holes not spotted

Replied by Clive S on topic Using Spotting with Sheetcam

Do you mean that you spotted with the bolt circle or did a cut?

Sorry I should have said the bolt hole cut 5 5mm holes not spotted

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

22 Jul 2020 13:05 #175395

by phillc54

Replied by phillc54 on topic Using Spotting with Sheetcam

I seem to recall similar voltage issues when you were setting your machine up which required using a relay for arc ok. Maybe you machine is not suitable for the way we have spotting set up.

It may be possible to change spotting a bit by adding a value of -1 to the threshold which would mean start the delay when arc ok is established. If you are interested in this let me know and I will have a look tomorrow. This may be a bit heavy handed for spotting but then again it may suit your machine.

It may be possible to change spotting a bit by adding a value of -1 to the threshold which would mean start the delay when arc ok is established. If you are interested in this let me know and I will have a look tomorrow. This may be a bit heavy handed for spotting but then again it may suit your machine.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

22 Jul 2020 14:53 #175398

by Clive S

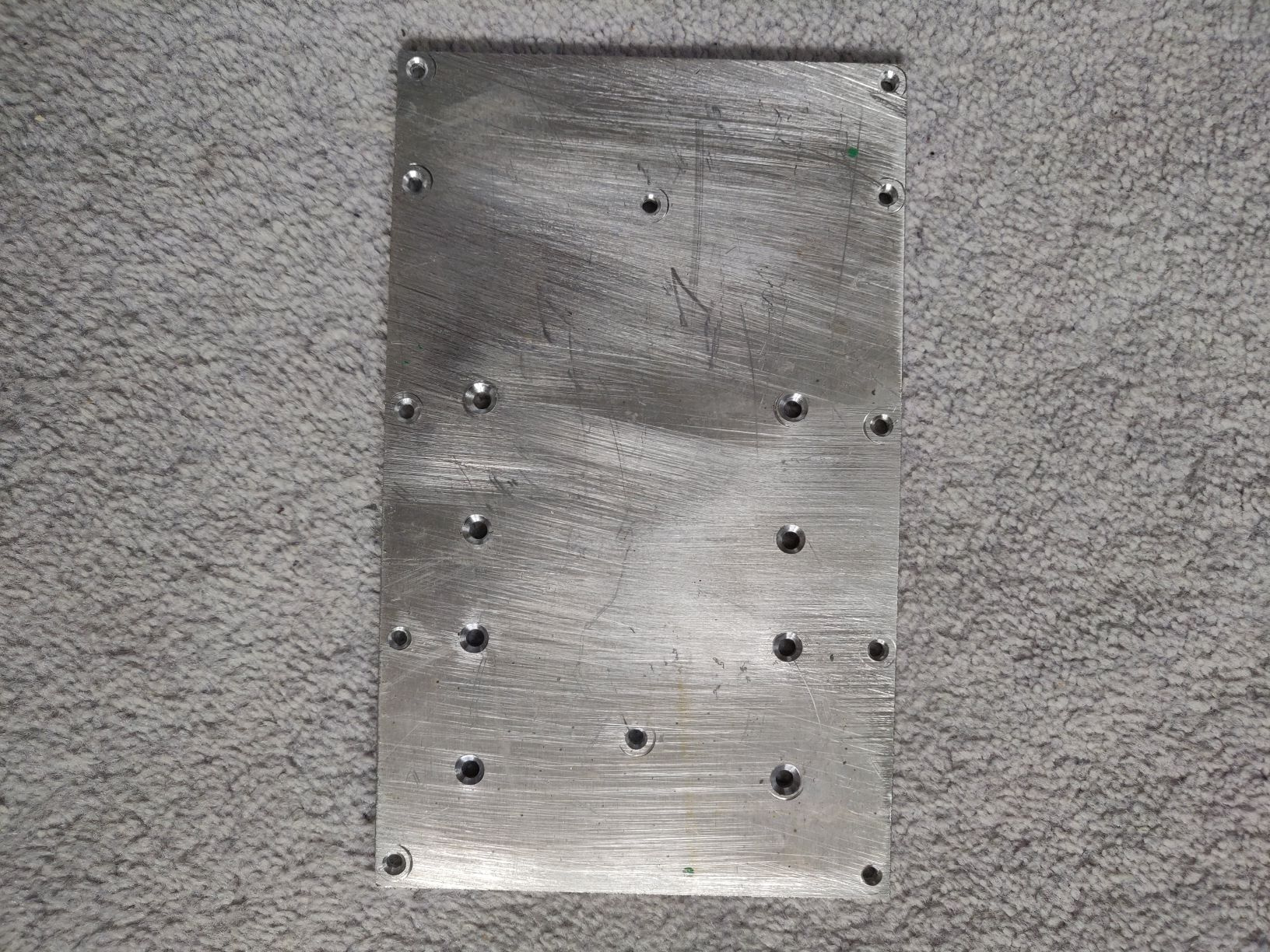

Phill I have managed to do what I wanted ie make a back plate to hold a 7i76e all done on the plasma drilling all the holes and cutting it out in one go All I had to do was stick a 3mm drill through each plasma hole

All I had to do was stick a 3mm drill through each plasma hole

I changed M3 $2 S1 (cut start) to M3 $0 S1 (cut start) through the file

Replied by Clive S on topic Using Spotting with Sheetcam

I seem to recall similar voltage issues when you were setting your machine up which required using a relay for arc ok. Maybe you machine is not suitable for the way we have spotting set up.

It may be possible to change spotting a bit by adding a value of -1 to the threshold which would mean start the delay when arc ok is established. If you are interested in this let me know and I will have a look tomorrow. This may be a bit heavy handed for spotting but then again it may suit your machine.

Phill I have managed to do what I wanted ie make a back plate to hold a 7i76e all done on the plasma drilling all the holes and cutting it out in one go

I changed M3 $2 S1 (cut start) to M3 $0 S1 (cut start) through the file

Attachments:

The following user(s) said Thank You: phillc54, tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21096

- Thank you received: 7204

22 Jul 2020 15:20 #175402

by tommylight

Replied by tommylight on topic Using Spotting with Sheetcam

Nice.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.992 seconds