IHS sensing with laser sensor

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

24 Sep 2020 18:02 - 24 Sep 2020 18:02 #183613

by AgentWD40

I feel like I remember reading something from Jim Colt about machines using air directly from the torch to blow surfaces dry/clean before ohmic sensing when using a water table...

Replied by AgentWD40 on topic IHS sensing with Capcitive sensor

Very expensive, no dobut i just showed it because i think they blow air to keep clean

I dont think they clean it often.

You guys already have compressors but like Mike told this have a cost.

I feel like I remember reading something from Jim Colt about machines using air directly from the torch to blow surfaces dry/clean before ohmic sensing when using a water table...

Last edit: 24 Sep 2020 18:02 by AgentWD40.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21157

- Thank you received: 7224

24 Sep 2020 20:36 #183621

by tommylight

Replied by tommylight on topic IHS sensing with Capcitive sensor

PlasmaC has a button exactly for that, named "torch pulse" on the main GUI screen.I feel like I remember reading something from Jim Colt about machines using air directly from the torch to blow surfaces dry/clean before ohmic sensing when using a water table...

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

24 Sep 2020 22:03 #183634

by Himarc3D

Replied by Himarc3D on topic IHS sensing with Capcitive sensor

The water i think is the most difficult thing to pass. The hard stuff is to make one algorithm (its beyond my mind).Sensors, camera for harsh environment already have in market.

Yes, I believe its possible to use couple arduino and LCNC but I dont have the knowledge to code that.

Here is one example for use camera and laser to detect arc, at pag 3 some camera models but all in japanese.

If you dig for papers i think you find many ideas for you.

www.jstage.jst.go.jp/article/qjjws1943/70/7/70_7_674/_pdf

www.nipponsteel.com/tech/report/sm/pdf/1a138001.pdf

Yes, I believe its possible to use couple arduino and LCNC but I dont have the knowledge to code that.

Here is one example for use camera and laser to detect arc, at pag 3 some camera models but all in japanese.

If you dig for papers i think you find many ideas for you.

www.jstage.jst.go.jp/article/qjjws1943/70/7/70_7_674/_pdf

www.nipponsteel.com/tech/report/sm/pdf/1a138001.pdf

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

24 Sep 2020 22:06 #183635

by Himarc3D

Replied by Himarc3D on topic IHS sensing with Capcitive sensor

At pag 2 in the image is talking about the laser and camera angle, probabily you find this stuff in english.

www.jstage.jst.go.jp/article/qjjws1943/70/7/70_7_674/_pdf

www.jstage.jst.go.jp/article/qjjws1943/70/7/70_7_674/_pdf

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

25 Sep 2020 07:17 - 25 Sep 2020 07:21 #183687

by pinder

Replied by pinder on topic IHS sensing with Capcitive sensor

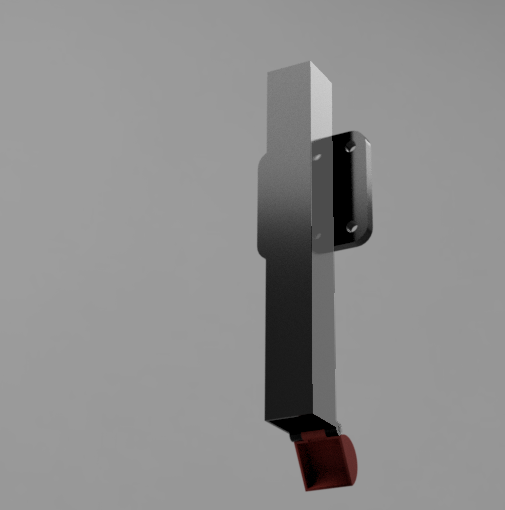

Sensors can be mounted like this.

To make sensing fast offset should be minimum and in one direction only x or y.

protective cover open

cover closed

opening and closing of the lid can be made pretty fast.

sensor mounted at the bottom can be protecting from dross easliy.

I want to clarify, this is only for IHS. still Voltage THC will be needed.l

To make sensing fast offset should be minimum and in one direction only x or y.

protective cover open

cover closed

opening and closing of the lid can be made pretty fast.

sensor mounted at the bottom can be protecting from dross easliy.

I want to clarify, this is only for IHS. still Voltage THC will be needed.l

Attachments:

Last edit: 25 Sep 2020 07:21 by pinder.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

25 Sep 2020 07:43 - 25 Sep 2020 07:46 #183689

by taloot

Replied by taloot on topic IHS sensing with Capcitive sensor

i will make ur life easier,,

u can use 2 encoder input

one for real THC other for capacitacne... normally the capacitance is accurate,, but not very accurate. but for probing its very fast compare to proximity or mechanical switch

even proximity sensor have lag/ (and or motor deacceleration speed... so

ur idea is gr8

solving 2 main issue,, with current system

1st u sense the sheet so u have time to stop the motor. unlike the tip complete touch

2nd u reduce the probing time, and u can protect the torch better as it will retract if its about to hit something

for design u can use my code its works well

and for circuit u need resistors. 2m ohm to 4m ohm depend of the destance of detection u want

and for antenna u need the tip to be 1 pole and the machine is the other

u can use mechanical relay to disconnect the tip while ark is on

in my qtpy i have the feature virtual float switch based on encoder value..

its OVERKILL as float switch even if its dirty

and while machine is rrepositiong .. it will trigger estop if value reach,, ur specifc value ,,,

so very good idea

u can use 2 encoder input

one for real THC other for capacitacne... normally the capacitance is accurate,, but not very accurate. but for probing its very fast compare to proximity or mechanical switch

even proximity sensor have lag/ (and or motor deacceleration speed... so

ur idea is gr8

solving 2 main issue,, with current system

1st u sense the sheet so u have time to stop the motor. unlike the tip complete touch

2nd u reduce the probing time, and u can protect the torch better as it will retract if its about to hit something

for design u can use my code its works well

and for circuit u need resistors. 2m ohm to 4m ohm depend of the destance of detection u want

and for antenna u need the tip to be 1 pole and the machine is the other

u can use mechanical relay to disconnect the tip while ark is on

in my qtpy i have the feature virtual float switch based on encoder value..

its OVERKILL as float switch even if its dirty

and while machine is rrepositiong .. it will trigger estop if value reach,, ur specifc value ,,,

so very good idea

Last edit: 25 Sep 2020 07:46 by taloot.

The following user(s) said Thank You: pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

25 Sep 2020 08:03 - 25 Sep 2020 08:03 #183691

by pinder

Now I am going to use laser sensor for two reeasons,

1) those are accurate, IMHO atleast for IHS.

2) we dont have to move z axis for probe.

steps:

z moves rest height

offset applies and sensor comes at plasma position,

lid opens, sensor takes reading, close the lid

offset removes and plasma torch comes at its postion

reading is sent to plasmac

it calculates current work position, applies pierce height

torch starts cutting

I know, not for sure, this is less than 2 second process.

Replied by pinder on topic IHS sensing with laser sensor

thankyou taloot.i will make ur life easier,,

u can use 2 encoder input

one for real THC other for capacitacne... normally the capacitance is accurate,, but not very accurate. but for probing its very fast compare to proximity or mechanical switch

even proximity sensor have lag/ (and or motor deacceleration speed... so

ur idea is gr8

solving 2 main issue,, with current system

1st u sense the sheet so u have time to stop the motor. unlike the tip complete touch

2nd u reduce the probing time, and u can protect the torch better as it will retract if its about to hit something

for design u can use my code its works well

and for circuit u need resistors. 2m ohm to 4m ohm depend of the destance of detection u want

and for antenna u need the tip to be 1 pole and the machine is the other

u can use mechanical relay to disconnect the tip while ark is on

in my qtpy i have the feature virtual float switch based on encoder value..

its OVERKILL as float switch even if its dirty

and while machine is rrepositiong .. it will trigger estop if value reach,, ur specifc value ,,,

so very good idea

Now I am going to use laser sensor for two reeasons,

1) those are accurate, IMHO atleast for IHS.

2) we dont have to move z axis for probe.

steps:

z moves rest height

offset applies and sensor comes at plasma position,

lid opens, sensor takes reading, close the lid

offset removes and plasma torch comes at its postion

reading is sent to plasmac

it calculates current work position, applies pierce height

torch starts cutting

I know, not for sure, this is less than 2 second process.

Last edit: 25 Sep 2020 08:03 by pinder.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

25 Sep 2020 08:58 #183694

by taloot

u dont need all this hassle,,

u can use ohmic connector, on the torch tip... no need for all this,,

and u can do all of this in plasmac... i make it the same way in my laser

but in plasma u have to use 2 encoder one for float and one for thc voltage,,,

u dont need all this mechanical things,, u add,

if u have extra power,, invest ur time in laser head cleaning and nozzle changing,,,, it worth ur efforts...

and i will be ur 1st client

Replied by taloot on topic IHS sensing with laser sensor

thankyou taloot.i will make ur life easier,,

u can use 2 encoder input

one for real THC other for capacitacne... normally the capacitance is accurate,, but not very accurate. but for probing its very fast compare to proximity or mechanical switch

even proximity sensor have lag/ (and or motor deacceleration speed... so

ur idea is gr8

solving 2 main issue,, with current system

1st u sense the sheet so u have time to stop the motor. unlike the tip complete touch

2nd u reduce the probing time, and u can protect the torch better as it will retract if its about to hit something

for design u can use my code its works well

and for circuit u need resistors. 2m ohm to 4m ohm depend of the destance of detection u want

and for antenna u need the tip to be 1 pole and the machine is the other

u can use mechanical relay to disconnect the tip while ark is on

in my qtpy i have the feature virtual float switch based on encoder value..

its OVERKILL as float switch even if its dirty

and while machine is rrepositiong .. it will trigger estop if value reach,, ur specifc value ,,,

so very good idea

Now I am going to use laser sensor for two reeasons,

1) those are accurate, IMHO atleast for IHS.

2) we dont have to move z axis for probe.

steps:

z moves rest height

offset applies and sensor comes at plasma position,

lid opens, sensor takes reading, close the lid

offset removes and plasma torch comes at its postion

reading is sent to plasmac

it calculates current work position, applies pierce height

torch starts cutting

I know, not for sure, this is less than 2 second process.

u dont need all this hassle,,

u can use ohmic connector, on the torch tip... no need for all this,,

and u can do all of this in plasmac... i make it the same way in my laser

but in plasma u have to use 2 encoder one for float and one for thc voltage,,,

u dont need all this mechanical things,, u add,

if u have extra power,, invest ur time in laser head cleaning and nozzle changing,,,, it worth ur efforts...

and i will be ur 1st client

The following user(s) said Thank You: Clive S, pinder

Please Log in or Create an account to join the conversation.

- pinder

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 196

- Thank you received: 128

25 Sep 2020 09:08 - 25 Sep 2020 09:09 #183695

by pinder

I will try that.

Sure, This will be like ATC in milling machines.

Cleaning can be done en route to tool change.

Cheers,

Pinder

Replied by pinder on topic IHS sensing with laser sensor

you are suggesting to use torch tip to use as capacitive sensor?u dont need all this hassle,,

u can use ohmic connector, on the torch tip... no need for all this,,

I will try that.

Hahaif u have extra power,, invest ur time in laser head cleaning and nozzle changing,,,, it worth ur efforts...

and i will be ur 1st client

Sure, This will be like ATC in milling machines.

Cleaning can be done en route to tool change.

Cheers,

Pinder

Last edit: 25 Sep 2020 09:09 by pinder.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

25 Sep 2020 09:08 #183696

by Himarc3D

Replied by Himarc3D on topic IHS sensing with laser sensor

Taloot is in another level with your toys hahaha, i dont have idea really.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 5.681 seconds