Suggestion QtPlasma and PlasmaC

- crowloy

- Offline

- Premium Member

-

Less

More

- Posts: 80

- Thank you received: 17

03 Mar 2021 22:45 #200951

by crowloy

Suggestion QtPlasma and PlasmaC was created by crowloy

I use a program called lightburn for my CO2/diode lasers. One feature that I use alot is the frame button. This basically runs the nozzle around what you are cutting in a square to make sure you have room on the material to cut that particular item. I noticed linuxcnc has a extents display on screen giving the location of the start as well as the length/width. I know I missed this feature as I was cutting some items and missed the plate on the one

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

03 Mar 2021 23:39 #200956

by snowgoer540

Replied by snowgoer540 on topic Suggestion QtPlasma and PlasmaC

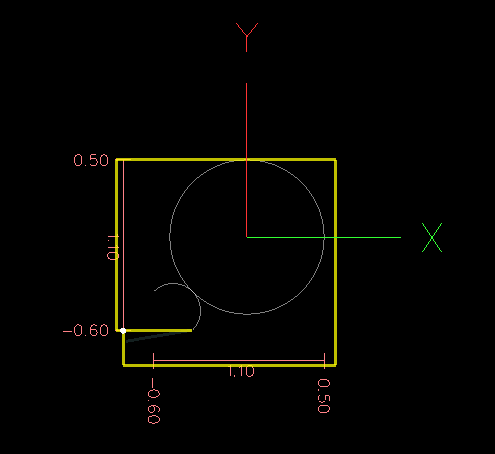

Interesting. Normally I just look at the preview window and jog the torch around the extents of the program's movements (white/grey lines) and then jog the torch down at each critical point and make sure it will have enough material to eat.

Seems to work well. Though it's not automated like you're saying.

Take this for example, the yellow is my jog path prior to running the program:

Seems to work well. Though it's not automated like you're saying.

Take this for example, the yellow is my jog path prior to running the program:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21156

- Thank you received: 7223

04 Mar 2021 00:30 #200970

by tommylight

Replied by tommylight on topic Suggestion QtPlasma and PlasmaC

Pretty sure this was discussed here before, but my google-foo if failing me !

Also pretty sure there was some kind of solution, most probably python checking the extents in the gcode file and generating the test pattern.

Also pretty sure there was some kind of solution, most probably python checking the extents in the gcode file and generating the test pattern.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

04 Mar 2021 00:34 #200971

by phillc54

Replied by phillc54 on topic Suggestion QtPlasma and PlasmaC

I have seen that request before but forgot about it...

So there is no Z motion, just a rapid to X/Y start point then X/Y motion in a rectangle around extents at current material speed?

So there is no Z motion, just a rapid to X/Y start point then X/Y motion in a rectangle around extents at current material speed?

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

04 Mar 2021 00:54 #200973

by snowgoer540

I dont want to speak for OP, but it might be useful to just do it at cut height?

Maybe just treat it like a dry run, but instead of dry running the gcode, it just dry runs a rectangle around the program extents?

Replied by snowgoer540 on topic Suggestion QtPlasma and PlasmaC

I have seen that request before but forgot about it...

So there is no Z motion, just a rapid to X/Y start point then X/Y motion in a rectangle around extents at current material speed?

I dont want to speak for OP, but it might be useful to just do it at cut height?

Maybe just treat it like a dry run, but instead of dry running the gcode, it just dry runs a rectangle around the program extents?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21156

- Thank you received: 7223

04 Mar 2021 01:28 #200974

by tommylight

For what is worth, i have 5 Euro (very expensive, i know) "cross" laser pointers on all new machines, makes life much easier.

Replied by tommylight on topic Suggestion QtPlasma and PlasmaC

I would not, it will bump the torch to the material, very bad material here.......but it might be useful to just do it at cut height?

For what is worth, i have 5 Euro (very expensive, i know) "cross" laser pointers on all new machines, makes life much easier.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

04 Mar 2021 01:54 #200976

by snowgoer540

How do you do a dry run then?

I think I might get one of those lasers soon. Phill has a pretty nifty touchoff tool now that's native to QtPlasmaC. Seems pretty useful.

Replied by snowgoer540 on topic Suggestion QtPlasma and PlasmaC

I would not, it will bump the torch to the material, very bad material here.......but it might be useful to just do it at cut height?

For what is worth, i have 5 Euro (very expensive, i know) "cross" laser pointers on all new machines, makes life much easier.

How do you do a dry run then?

I think I might get one of those lasers soon. Phill has a pretty nifty touchoff tool now that's native to QtPlasmaC. Seems pretty useful.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7269

- Thank you received: 2115

04 Mar 2021 01:58 #200977

by cmorley

Replied by cmorley on topic Suggestion QtPlasma and PlasmaC

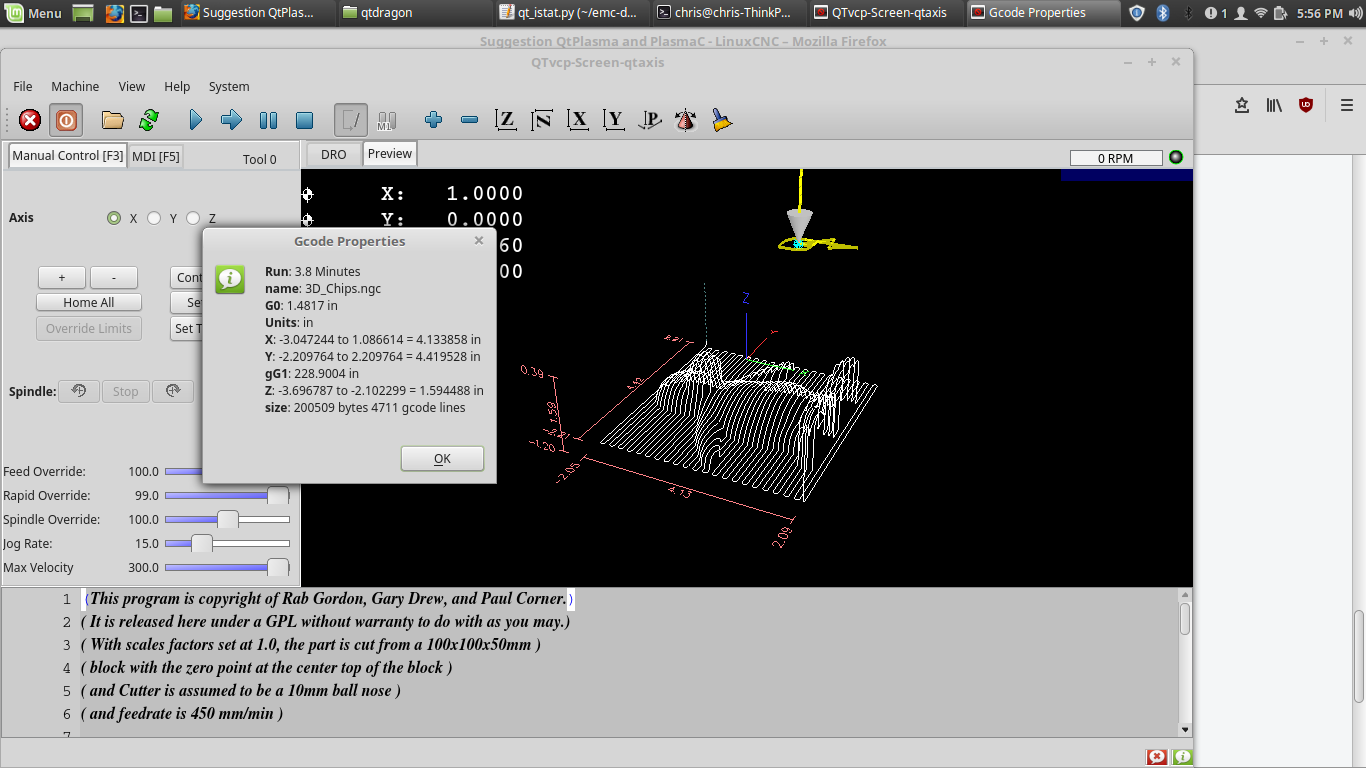

Attachments:

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

04 Mar 2021 02:01 #200978

by phillc54

Replied by phillc54 on topic Suggestion QtPlasma and PlasmaC

Thanks Chris, that is helpfull, I didn't know about that...I wonder if the 'gcode properties' info is useful for that - you could use the info to build a macro to rapid around the perimeter...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21156

- Thank you received: 7223

04 Mar 2021 09:14 #201005

by tommylight

Replied by tommylight on topic Suggestion QtPlasma and PlasmaC

I just watch the laser while jogging manually, leaving the torch up.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.108 seconds