QTPlasmaC Crashing bug report

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

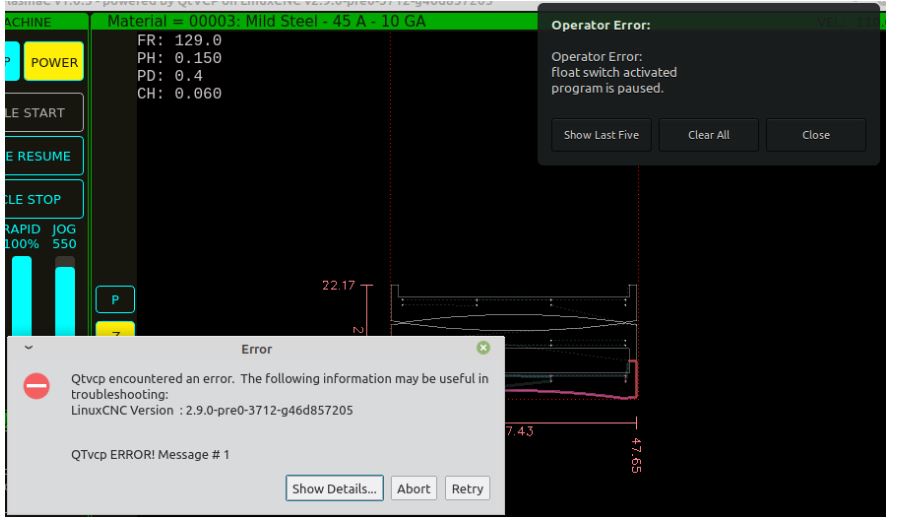

I am updated to version 1.0.5. (The latest at the time of writing this) I was cutting some stuff out tonight and I kept getting an error while cutting that would result in a complete crash of the software.

I switched over to PlasmaC (Not QT) and ran the same file. I got a pause program over there saying that my float switch activated. The big difference is it didn't crash the tool over in PlasmaC. It just paused, and would allow me to resume. So the fact it is crashing instead of pausing is the bug.

Now my question. I think the float switch activating during cut is an EMI issue that I don't have the expertise or equipment or knowledge to track down. Is there a way to deactivate the float switch during the cut, then reactivate it for the next pierce so the controller stops reading any signals coming from it while cutting? If not, is there a way to add debounce or something like that so that false signals don't interrupt? I didn't see anything in the config for that. I probably missed it. I saw the Arc OK debounce.

My controller is the 7i96. It is an awesome controller, but a little too sensitive for it's own good in my noisy, crappy cheap table, environment.

Thanks in advance.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

There is debounce on the float switch in the connections.hal file.

linuxcnc.org/docs/devel/html/plasma/qtpl...ml#_contact_debounce

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

Can you click "Show Details" on the error message and post the result.

There is debounce on the float switch in the connections.hal file.

linuxcnc.org/docs/devel/html/plasma/qtpl...ml#_contact_debounce

Thanks Phill. I will go find the debounce setting in the .hal. I figured you already had my back on this one. Haha

As far as clicking "show details". I tried. Any button I pressed would crash the software. Show details, about, retry, the little x at the top. All attempts resulted with a crash.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

If you were running from a terminal was the a error message in the terminal. If you weren't running from a terminal can you try that.As far as clicking "show details". I tried. Any button I pressed would crash the software. Show details, about, retry, the little x at the top. All attempts resulted with a crash.

This is untested but you may be able to enable ohmic sensing, this then has a hal pin plasmac.ohmic-enable which is only active while probing. You could connect this to a relay and run you float switch signal through the relay contacts.Is there a way to deactivate the float switch during the cut, then reactivate it for the next pierce so the controller stops reading any signals coming from it while cutting?

I would not recommend doing this if you don't have a breakaway switch for safety reasons.

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

Also I don't have a breakaway yet so I won't try the ohmic hack advice you offered.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

How much travel is in your float switch? I would recommend actually watching the floating head/switch while it's cutting to make sure it's not actually moving/getting tripped. It seems everything happens 10x faster while actually cutting

I will try to replicate your scenario this evening and see if it causes my QtPlasmaC to crash.

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

Now I will play with the debounce and see if I can eliminate the float switch falsely tripping. I don't think it is getting pushed by the material because the THC isn't doing it's job. Not outside of possibilities, but I was looking pretty close last night at that and it didn't appear to be happening.

Please Log in or Create an account to join the conversation.

- Nick7251

- Offline

- Senior Member

-

- Posts: 57

- Thank you received: 10

I have the issue resolved by adding time to the arc ok debounce value. So I don't want to get into that. It is working great now. But the tool still has the bug of crashing if arc ok is lost.

Also I had a crash tonight in the middle of a long job when I hit pause. Luckily it was easy to recover. But non the less the tool crashed and shut down.

Thought I would log my findings if you want to try to duplicate them. Maybe it is just my build, and not a bug at all.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

Help us help you

Please Log in or Create an account to join the conversation.