QTPlasmaC mode2 - valid arc lost

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 69

- Thank you received: 17

Problem is I'm getting "valid arc lost". I guess it happens after THC starts sending UP/DOWN to QTPlasmaC, because if I set THC "Delay Arc" to 1.5 sec, arc lost happens at 1.5 sec. In the video below THC setting "Delay Arc" was 0.5s (I know, too low, but it happens no matter the value, it only postpones the error)

I'm also getting "Probe tripped during non-probe move" but I think that is because the THC is making the torch go DOWN.

If I disable THC, it cuts ok.

The test material is 0.8mm galvanized steel. Tried several combinations of pierce height and cut height. Using 20Amps and 5 cfm.

My Arc-OK UP and DOWN cable is shielded and grounded.

Could you point me the things I should try setting and testing ? Thanks.

Attachments:

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 69

- Thank you received: 17

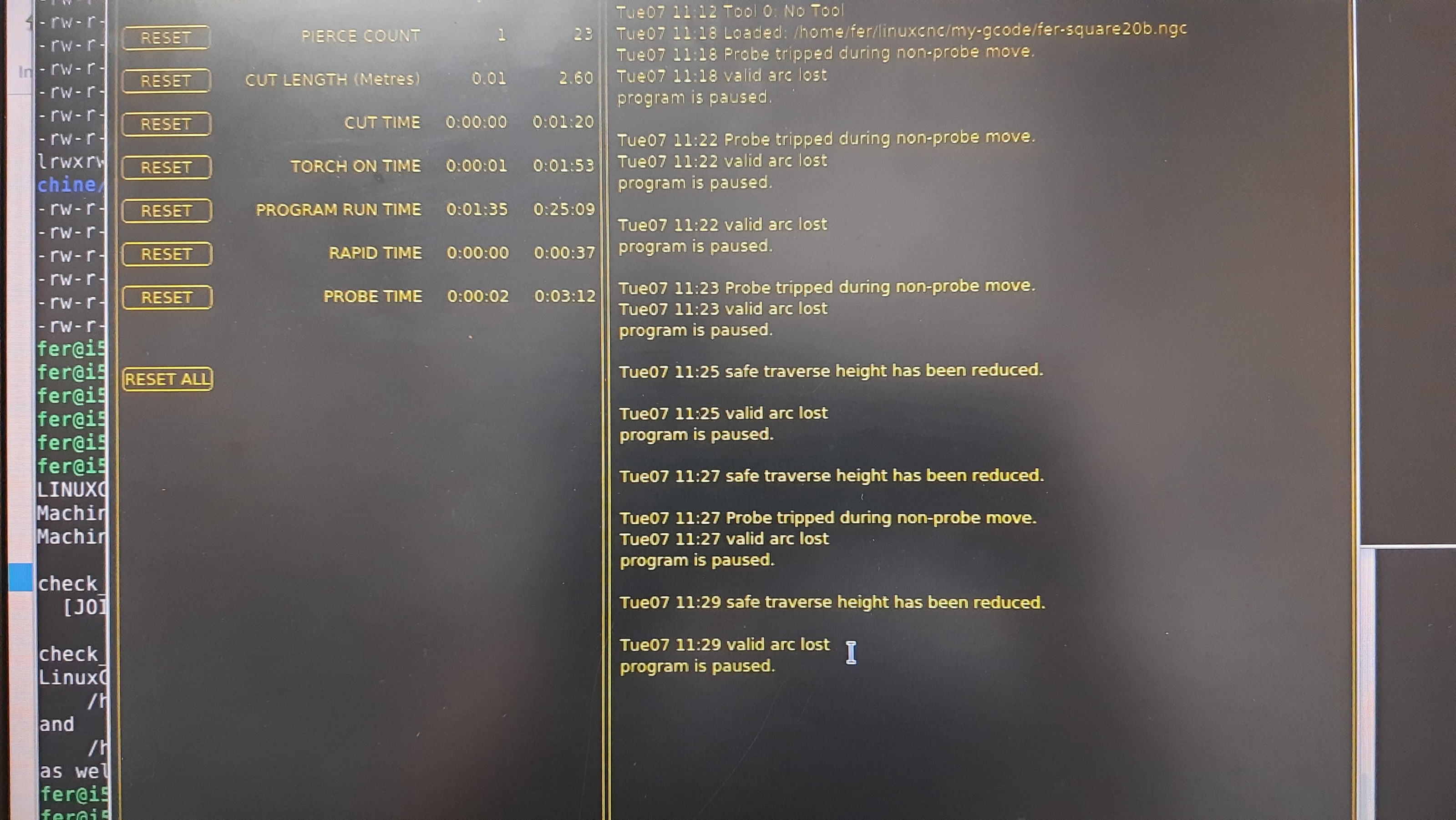

This is the QTPC view:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 69

- Thank you received: 17

Thanks for looking at it.

The last messages:

were because I had turned the controller off and put Linux to hibernate without shutting down QTPCTue07 12:39 joint 0 on limit switch error

Tue07 12:39 joint 1 on limit switch error

Tue07 12:39 joint 2 on limit switch error

Tue07 12:39 joint 3 on limit switch error

Wed08 06:57 Unexpected realtime delay on task 0 with period 40000

This Message will only display once per session.

Run the Latency Test and resolve before continuing.

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 69

- Thank you received: 17

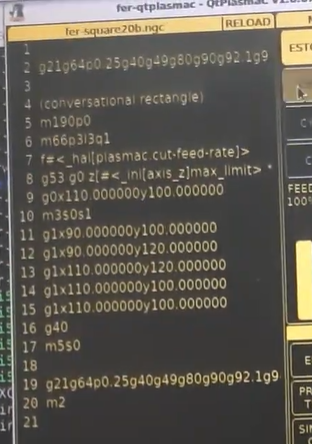

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Do you have any information on the THC.

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 69

- Thank you received: 17

It's from macrol.com.br (a local company here).

English manual is at:

macrol.com.br/wp-content/uploads/2020/10...WII-V3_4-english.pdf

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

net torch-off-probe <= parport.0.pin-13-in-not => motion.probe-input The pierce and cut heights look to be ok, is the gas pressure good, here is a link to some other things that require checking:

forum.linuxcnc.org/38-general-linuxcnc-q...blem?start=50#218185

The THC says it has optocouplers for the outputs, do you have the polarity correct as shown in the diagram.

If all the above are good then you could possibly try one of the following:

Set a small time for lost arc delay:

linuxcnc.org/docs/devel/html/plasma/qtpl...html#_lost_arc_delay

setp plasmac.arc-lost-delay 0.1Increase the debounce for arc ok in custom.hal, it is currently 5.

setp db_arc-ok.delay 5Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 69

- Thank you received: 17

I will follow your advices and also start fresh with a new config, migrating block by block. I had some merges in the past that may be causing problems.

Will get back and share the findings.

Please Log in or Create an account to join the conversation.