New day new problem

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21024

- Thank you received: 7163

19 Aug 2021 16:39 #218155

by tommylight

Replied by tommylight on topic New day new problem

Can you please give us more details on at what stage is the arc getting lost?

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

19 Aug 2021 17:59 #218166

by acourtjester

Replied by acourtjester on topic New day new problem

It seemed to be in the middle of a cut operation. The test was to cut 3 rounds in 3 squares, and it happened in the square cutting part of the operations. These were about 1.5" square, it was intermittent not consistent.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21024

- Thank you received: 7163

19 Aug 2021 23:21 #218185

by tommylight

Replied by tommylight on topic New day new problem

Things that cause intermittent arc loss:

-to low pressure

-to high pressure

-worn consumables

-charred consumables on the inside from oil/water

-grid voltage drop

-oil/water from moisture in air supply

-bad ground clamp connection to work piece

-torch to high

-torch to low

-to low pressure

-to high pressure

-worn consumables

-charred consumables on the inside from oil/water

-grid voltage drop

-oil/water from moisture in air supply

-bad ground clamp connection to work piece

-torch to high

-torch to low

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

20 Aug 2021 12:55 #218237

by acourtjester

Replied by acourtjester on topic New day new problem

thanks for the reply I fully understand these causes. I have used 3 different brands of THC before using the LinuxCNC/THCAD equipment. And all used the 50:1 divider without the lost arc signal. From what I see from others is using either 30:1 or 20:1 is with the THCAD setup is the way to go. Thus the reason for my wanting to change the setting in both the hypertherm and software.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

20 Aug 2021 15:20 #218244

by robertspark

Replied by robertspark on topic New day new problem

Tom, changing the voltage divider setting within the plasma cutter or the voltage divider scale "should" not change the transfer signal.....

could it be maybe.... you need a bit of debounce on the transfer signal.....

It may be useful if you could log some readings / cuts (I am not sure how to do this yet, but would like to know how to set it up [if someone is willing to explain please / could point a noob like me in the right direction])

then you may be able to see at what point / when / what transfer signal is being lost.

I know you can use software transfer (Mode 0), but I chose to use Mode 1, given the hypertherm (like you and I use) provides a good transfer signal..... it knows when the arc has transferred and toggles a relay internally.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_mode

could it be maybe.... you need a bit of debounce on the transfer signal.....

It may be useful if you could log some readings / cuts (I am not sure how to do this yet, but would like to know how to set it up [if someone is willing to explain please / could point a noob like me in the right direction])

then you may be able to see at what point / when / what transfer signal is being lost.

I know you can use software transfer (Mode 0), but I chose to use Mode 1, given the hypertherm (like you and I use) provides a good transfer signal..... it knows when the arc has transferred and toggles a relay internally.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_mode

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

20 Aug 2021 16:28 - 20 Aug 2021 16:33 #218246

by acourtjester

Replied by acourtjester on topic New day new problem

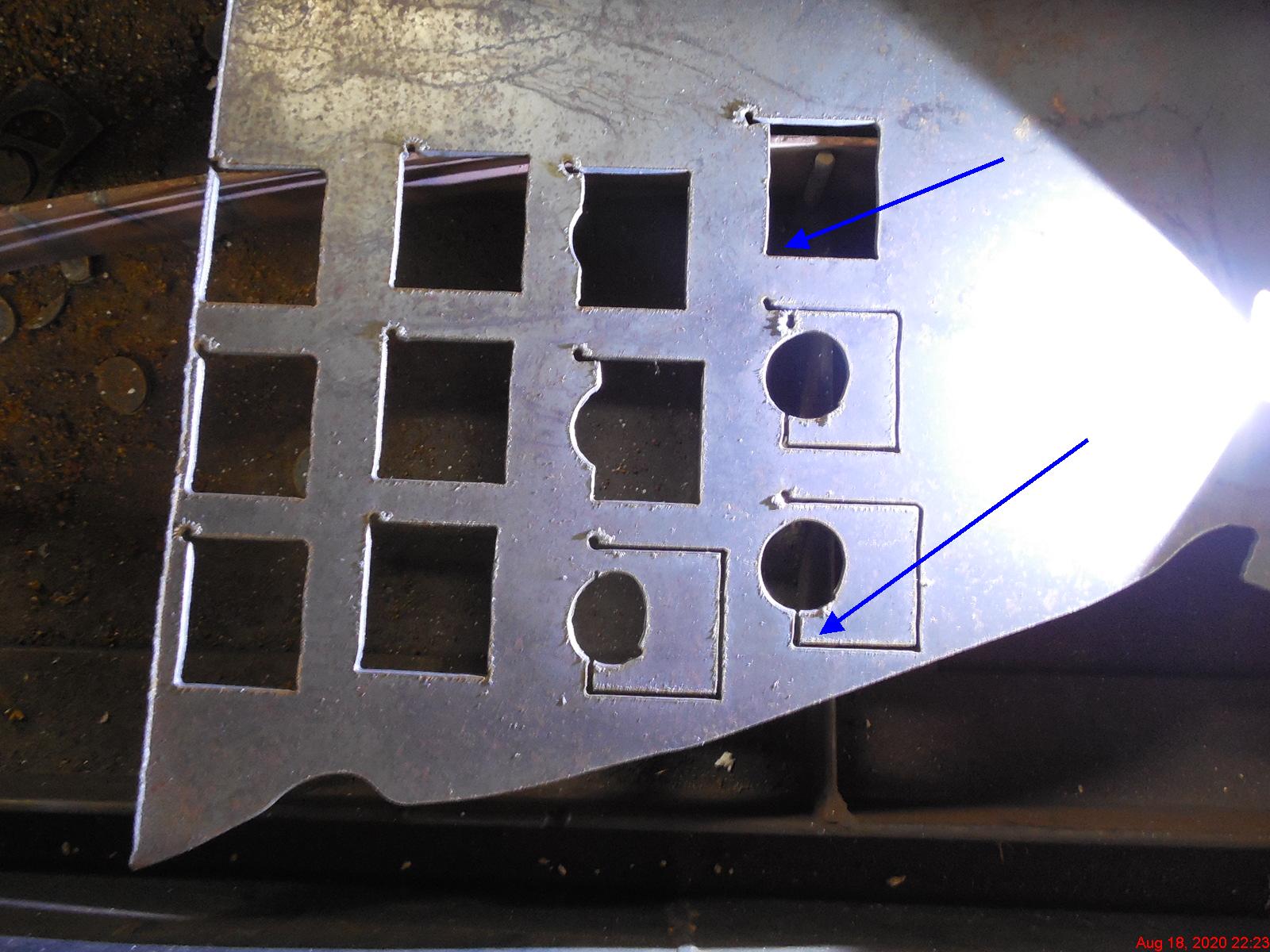

Not sure if this will help but here is the cut where the problem happened. The arrows show where the stop happened. A resume cut message cam up and I clicked on it. This in turn cause the position of G-code to shift as you can see the first row cut ok ( I know the cut shape is wacko, I have since recalibrated the motor travel). It seemed the position of the cutter does not return to the correct restart position, when the resume cut is clicked.

Understand this is the first attempt at cutting to see what works. Now to the debounce, I have not changed those setting and they all seem to be at 5. I my way of looking at the change of voltage divider change from 50:1 to 20:1 may get a wider range of sample for the software to work with. I did replace the consumables when the problem started without a good result, I clamp the work lead directly to the metal being cut. I have not had a chance to make the changes to the Hypertherm or the Arc Voltage Scale value. the Arc Ok signal is wired with the pull/down resistor as published and worked fine with Hal show when checked.

Understand this is the first attempt at cutting to see what works. Now to the debounce, I have not changed those setting and they all seem to be at 5. I my way of looking at the change of voltage divider change from 50:1 to 20:1 may get a wider range of sample for the software to work with. I did replace the consumables when the problem started without a good result, I clamp the work lead directly to the metal being cut. I have not had a chance to make the changes to the Hypertherm or the Arc Voltage Scale value. the Arc Ok signal is wired with the pull/down resistor as published and worked fine with Hal show when checked.

Attachments:

Last edit: 20 Aug 2021 16:33 by acourtjester. Reason: adding info

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

20 Aug 2021 17:09 #218247

by robertspark

Replied by robertspark on topic New day new problem

I am not using hypersensing with a THCAD5 as I already had / have an ohmic sensor that is adjustable and it has worked find for me.

But It do use a THCAD5 for my voltage divider from the Hypertherm 45 (non XP) which is fixed (in my case) at 50:1 with a 100K and 2K resistor arrangement internally.

The resistor ratio is 50:1 (100K : 2K) but the voltage divider is actually 51:1 .... or the output is 1/51 of the input signal. so 5V on the THCAD (full scale = 255V). I have tested it with a couple precision voltage sources I have and it is accurate.

LM4040

2.048V

2.5V

4.096V

www.ti.com/lit/ds/symlink/lm4040-n.pdf?t...Fwww.google.com%252F

Are you using a THCAD 5 or THCAD 10 for cutting voltage sensing?

But It do use a THCAD5 for my voltage divider from the Hypertherm 45 (non XP) which is fixed (in my case) at 50:1 with a 100K and 2K resistor arrangement internally.

The resistor ratio is 50:1 (100K : 2K) but the voltage divider is actually 51:1 .... or the output is 1/51 of the input signal. so 5V on the THCAD (full scale = 255V). I have tested it with a couple precision voltage sources I have and it is accurate.

LM4040

2.048V

2.5V

4.096V

www.ti.com/lit/ds/symlink/lm4040-n.pdf?t...Fwww.google.com%252F

Are you using a THCAD 5 or THCAD 10 for cutting voltage sensing?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21024

- Thank you received: 7163

20 Aug 2021 18:09 #218254

by tommylight

Replied by tommylight on topic New day new problem

Asuming those are all the same shapes, i would look at grounding first, then wiring.

Shifting position is always a sign of interference or loss of power to the drives due to voltage drop from plasma cutter draw.

Shifting position is always a sign of interference or loss of power to the drives due to voltage drop from plasma cutter draw.

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

20 Aug 2021 18:29 #218258

by acourtjester

Replied by acourtjester on topic New day new problem

I am using the THCAD-10 for voltage sensing, but also have a THCAD-5 mounted in the controller, switching the wiring would be easy.

You comment " with a 100K and 2K resistor arrangement internally" are you saying you modified the original configuration or they are in the original circuits. I would be very happy to leave the hypertherm as it is set, as I have not had any problems with that on any of the tables I have built. And that is using other THC assemblies.

I also have another setup for the Ohmic sensor that was successful another tables too.

You comment " with a 100K and 2K resistor arrangement internally" are you saying you modified the original configuration or they are in the original circuits. I would be very happy to leave the hypertherm as it is set, as I have not had any problems with that on any of the tables I have built. And that is using other THC assemblies.

I also have another setup for the Ohmic sensor that was successful another tables too.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

20 Aug 2021 18:32 #218259

by robertspark

Replied by robertspark on topic New day new problem

Tom has been doing this a while, just not with linuxcnc / Mesa hardware.

I am not sure what CNC table build number he is at at the moment, but is is more than 9.

when logging, is their a way to log gcode motion to align with logged data?

and output the data to a log file?

I am not sure what CNC table build number he is at at the moment, but is is more than 9.

when logging, is their a way to log gcode motion to align with logged data?

and output the data to a log file?

Please Log in or Create an account to join the conversation.

Time to create page: 0.099 seconds