New day new problem

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Aug 2021 09:00 #218315

by robertspark

Replied by robertspark on topic New day new problem

the hypertherm seems to have contacts that are rated at 120v AC / 1A.....

there is no need for 240mA of current flow to provide a wetting current.

if the relay is rated at 1A, then the wetting current will be LESS than 1mA

it's just to break the oxide layer, and is only applicable to open relays..... if they are sealed (such as a reed relay) then no wetting current is applicable given no oxide layer will form as their is no humidity for it to form.

I'll pull the cover off my pmx 45 later as I am curious what relay they have used as I'd expect it to be a quality relay..

using too much current will shorten the life span in my opinion than using just enough (above the minimum)

I tend to use Fujitsu relays personally as the data sheets are comprehensive.... TE / omron seem to kindly miss the minimum current rating .... Fujitsu clearly publish iteh 2A relay.... minimum current 0.01mA (ie 200 000 times less than the rated current)

www.google.com/url?sa=t&source=web&rct=j...zjjsvHT914D46NTBXYNC

some have a minimum current of 5000 times less than the rating 5A .... minimum 1mA

I am not saying it is a non issue.. just less of an issue than what is being portrayed.....

I always try to design for a 10mA at 24v signal current especially when their is potential for inductance about from other sources (plasma start signals ).... I also try to use quality relays (Fujitsu or coto [reed relays])

there is no need for 240mA of current flow to provide a wetting current.

if the relay is rated at 1A, then the wetting current will be LESS than 1mA

it's just to break the oxide layer, and is only applicable to open relays..... if they are sealed (such as a reed relay) then no wetting current is applicable given no oxide layer will form as their is no humidity for it to form.

I'll pull the cover off my pmx 45 later as I am curious what relay they have used as I'd expect it to be a quality relay..

using too much current will shorten the life span in my opinion than using just enough (above the minimum)

I tend to use Fujitsu relays personally as the data sheets are comprehensive.... TE / omron seem to kindly miss the minimum current rating .... Fujitsu clearly publish iteh 2A relay.... minimum current 0.01mA (ie 200 000 times less than the rated current)

www.google.com/url?sa=t&source=web&rct=j...zjjsvHT914D46NTBXYNC

some have a minimum current of 5000 times less than the rating 5A .... minimum 1mA

I am not saying it is a non issue.. just less of an issue than what is being portrayed.....

I always try to design for a 10mA at 24v signal current especially when their is potential for inductance about from other sources (plasma start signals ).... I also try to use quality relays (Fujitsu or coto [reed relays])

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

21 Aug 2021 09:05 #218316

by phillc54

Replied by phillc54 on topic New day new problem

I "think" the HT relay quoted 100mA @ 5V so roughly 21mA @ 24V

It is somewhere on the forum...

It is somewhere on the forum...

The following user(s) said Thank You: robertspark

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Aug 2021 10:05 - 21 Aug 2021 10:06 #218318

by robertspark

Replied by robertspark on topic New day new problem

Last edit: 21 Aug 2021 10:06 by robertspark.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

21 Aug 2021 10:16 #218319

by phillc54

Replied by phillc54 on topic New day new problem

The relay part number is in this post:

forum.linuxcnc.org/plasmac/39929-random-...lost?start=70#180876

forum.linuxcnc.org/plasmac/39929-random-...lost?start=70#180876

The following user(s) said Thank You: robertspark

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Aug 2021 11:24 #218320

by robertspark

Replied by robertspark on topic New day new problem

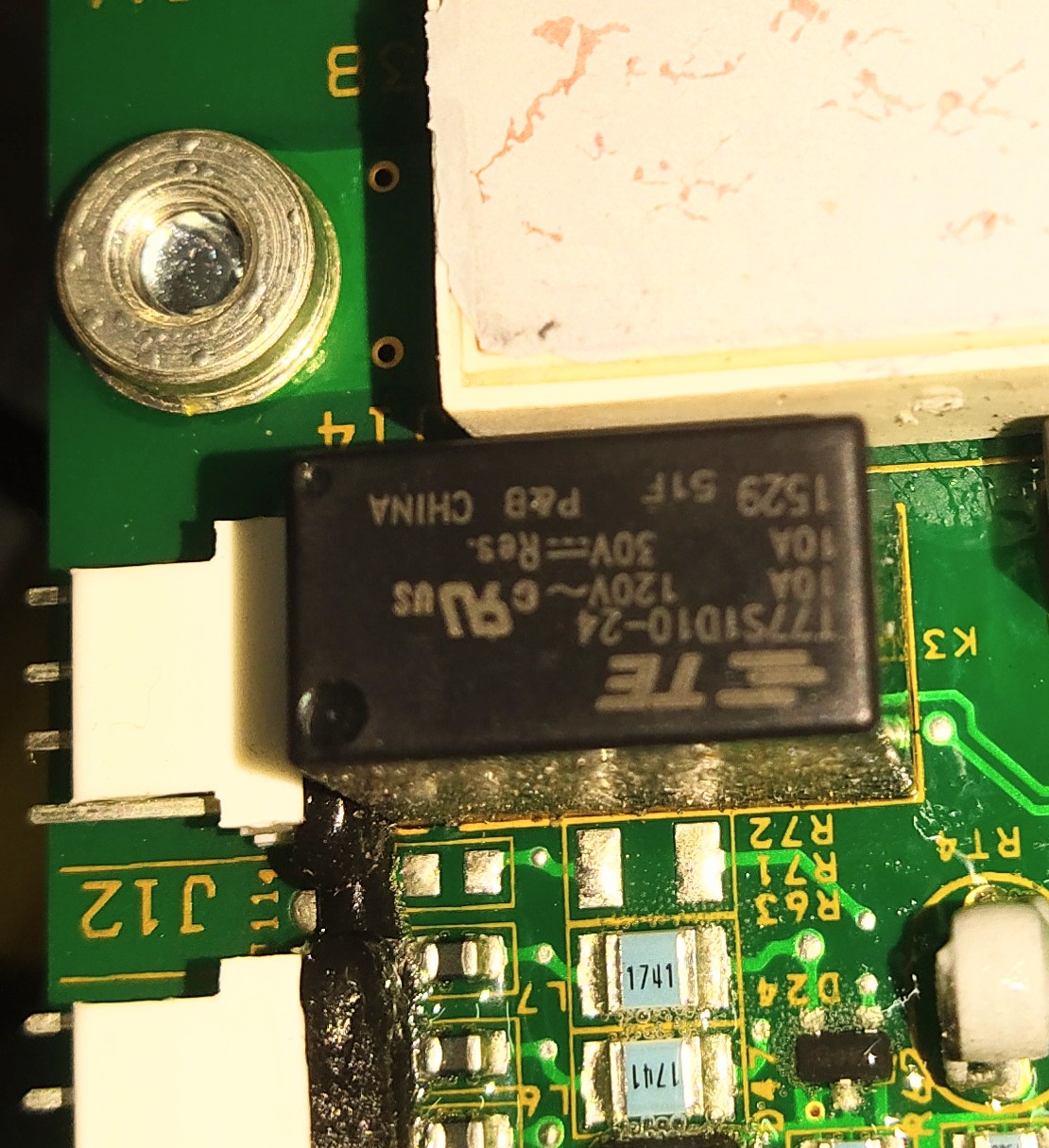

this is from my hypertherm powermax 45 (non XP).... surprised they did not use a better relay.... (faster + sealed)

TE T77S1D10-24

www.google.com/url?sa=t&source=web&rct=j...R2FFH8C10rLl-7avOTn1

www.google.com/url?sa=t&source=web&rct=j...QwAYWjZUUS8oF8MhKnd5

min recommended = 100mA @ 5V (0.5W)

so, at 24v => 0.5 / 24 = ~ 21mA

again... surprised they did not choose a better relay.... (360 operations per hour (for an arc transfer relay on a plasma cutter) 10msec operate and 4msec release time)

Min. recommended contact load ---- 100mA at 5VDC

Frequency of operation ---- 360 ops./h

Operate/release time max. 10ms/4ms

TE T77S1D10-24

www.google.com/url?sa=t&source=web&rct=j...R2FFH8C10rLl-7avOTn1

www.google.com/url?sa=t&source=web&rct=j...QwAYWjZUUS8oF8MhKnd5

min recommended = 100mA @ 5V (0.5W)

so, at 24v => 0.5 / 24 = ~ 21mA

again... surprised they did not choose a better relay.... (360 operations per hour (for an arc transfer relay on a plasma cutter) 10msec operate and 4msec release time)

Min. recommended contact load ---- 100mA at 5VDC

Frequency of operation ---- 360 ops./h

Operate/release time max. 10ms/4ms

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2513

- Thank you received: 848

21 Aug 2021 12:07 - 21 Aug 2021 12:34 #218322

by snowgoer540

Replied by snowgoer540 on topic New day new problem

Interesting to see they are the same relay in a 45 non XP and a 65 XP.

I agree on being surprised by their relay choice, I remember thinking the exact same thing when I took a picture of mine and looked up the data sheet.

I also agree that blindly following resistance value advice is a bad idea.

I live in hazy, hot, and humid Pennsylvania and have had no issue with not increasing the current for contact wetting. But I keep the knowledge stored away should the issue arise.

I agree on being surprised by their relay choice, I remember thinking the exact same thing when I took a picture of mine and looked up the data sheet.

I also agree that blindly following resistance value advice is a bad idea.

I live in hazy, hot, and humid Pennsylvania and have had no issue with not increasing the current for contact wetting. But I keep the knowledge stored away should the issue arise.

Last edit: 21 Aug 2021 12:34 by snowgoer540.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21024

- Thank you received: 7163

21 Aug 2021 13:13 #218324

by tommylight

But i disagree with Rod, not the most likely, not even the least likely cause.

Adding a resistor will only make it harder for interference to trigger the issue, not solve it.

It is always an interference issue, never a "wetting" issue, as can be proven by over 30 machines in daily use for several years and none of them use any "wetting" of any kind.

The OP is also loosing position during work, not just the arc, so all this discussion is not helping him.

Replied by tommylight on topic New day new problem

I agree with Phill.

I would expect that if it were a wetting issue then it would crop up at the start of the cut not in the middle of the cut.Because despite 20 posts on this thread, nobody else had thought to flag the most likely cause of the problem.

But i disagree with Rod, not the most likely, not even the least likely cause.

Adding a resistor will only make it harder for interference to trigger the issue, not solve it.

It is always an interference issue, never a "wetting" issue, as can be proven by over 30 machines in daily use for several years and none of them use any "wetting" of any kind.

The OP is also loosing position during work, not just the arc, so all this discussion is not helping him.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

21 Aug 2021 14:39 #218327

by robertspark

Replied by robertspark on topic New day new problem

I did ask Tom (the OP) to see if he can provide some logs maybe showing:

the arc OK / transfer input pin

the torch fire output pina motion pinthe plasma cutter voltage inputthe z axis machine DRO (not sure how that will read with out of bounds motion).... but if the thc is responding too fast / course or too slow and fine... it may be loosing the arc in height

is there a way that you could setup a long term logging file as the issue seems intermittent

the arc OK / transfer input pin

the torch fire output pina motion pinthe plasma cutter voltage inputthe z axis machine DRO (not sure how that will read with out of bounds motion).... but if the thc is responding too fast / course or too slow and fine... it may be loosing the arc in height

is there a way that you could setup a long term logging file as the issue seems intermittent

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

21 Aug 2021 21:19 - 21 Aug 2021 21:20 #218352

by acourtjester

Replied by acourtjester on topic New day new problem

Ok here is the word from the shop. I changed the voltage divider in the hypertherm to 20:1 and the Arc Voltage Scale in the QTPlasmaC.prefs file and bumped up the debounce to 7 (was 5). Ran test cuts fine only arc lost was cutting over an open space in the metal.DUH. I could not get a good image of the relay on the PM65, (middle image). Cut the wrench but dimensions are off need to redo the steps per.

thanks again

Tom

thanks again

Tom

Attachments:

Last edit: 21 Aug 2021 21:20 by acourtjester.

Please Log in or Create an account to join the conversation.

Time to create page: 0.144 seconds