Valid arc lost & top limit is reached while THC moving up

- sharp_reaper

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 7

I've been away from the machine yesterday.If you click "Ignore ArcOK" and run a test cut, what happens?

Tested today with ArcOk "Valid Arc Lost".

Tested with "Ignore ArcOK" it cuts fine with no errors in 5 cuts

But I have some irregular slats that it needs THC

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2526

- Thank you received: 857

But I have some irregular slats that it needs THC

Yep, the goal is to get the works working with THC.

The fact that it cuts fine with the ArcOK ignored tells me that you're losing the ArcOK signal (obviously) and we need to figure out why.

I am going to assume you went back to Mode 1. I watched your video in slow-mo, and it appears that as your voltage goes up, the torch goes down and vice versa, so that is correct.

I would be curious to see a halscope plot of the ArcOK signal while you are cutting with ArcOK Ignored, to see if the ArcOK signal cuts in and out.

Otherwise, here are some things I would check:

1. Have you verified that the scale for your Z axis is correct? Meaning verify with a dial indicator, or some other means, that when commanded to move 50mm, the z axis moves 50mm?

2. Check the connections for the arcok circuit. Could be as simple as a loose wire that is causing your issues. Especially because the lengths of cut appear to be random before it cuts out.

3. Some people with Hypertherms report needing to change the debounce value for the ArcOK signal to 10. After the above, if you dont find any issue, you could try that too.

Please Log in or Create an account to join the conversation.

- sharp_reaper

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 7

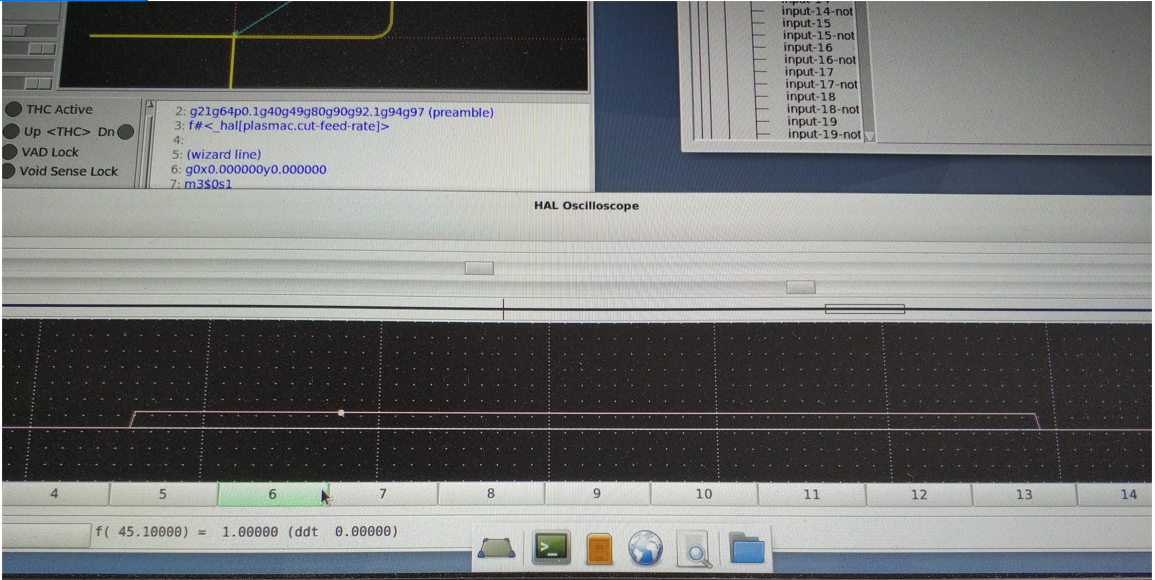

Sorry I doesn't understand how it works hal scope very well here is a photo:

1 - I have tripled checked the Z axis scale and it's corret.

The commanded movement equals the distance movement of Z axis.

2 - Checked the connection of ArcOK and it's well tighten.

The ArcOK signal is a dry contact from Hypertherm cutter.

I have one cable in 24VDC and the other in the Input-15 of 7I76E.

From the cuts I think it cuts aproximadately the same amount when it shows the error.

3 - Changed to "setp db_arc-ok.delay 10" with THC enabled

EDIT: I've noticed that when Ignored ArcOK the voltage drops too much from 63 V.

I'm doing more test with Ignore ArcOK ON. It happened more frequently now the torch shuts off with almost the same lenght of cut but shows no error and continues to the end of the cut with the torch off (no stopping)

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2526

- Thank you received: 857

Disconnect the torch voltage wires from the THCAD and take a known DC power source and hook to it (9v for example), verify that when 9 volts are supplied, 9 volts show on the GUI.

After that, it's silly questions, like does Page Up make the torch go up, and Page Down makes it go down.

I doubt anyone here has any experience with the new SYNC cartridges, but perhaps the THC delay needs to be longer for the voltage to settle with those. Try 1.0s, or 1.5s.

Otherwise, you could try changing the P value for the PID to 20, in case the reaction is too slow.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11566

- Thank you received: 3884

There are two ways to fix this, one is to use a pull down resistor between the 7i76e input and field power 0 volts to ensure the minimum current is exceeded. (What I do)

The other way is to add a capacitor to create a "spark" each time it operates to burn off the oxide.

Some others are vehmently opposed to my views and I am not interested in creating an argument. All I can say I have personal experience of the frustration this causes. I am assuming that Hypertherm has used the same relay they have used in all their previous plasma cutters which is rated between 100 mA and 10 amps.

My recommendation is to use a HS10 100 Ohm 10 Watt resistor as the pull down. This will result in about double the minimum current. Expect a few cycles to burn off the oxide before reliable operation is restored.

If others propose a different method or resistor value, just ask them if thy have any first hand experience with this particular issue before adopting their suggestions.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2526

- Thank you received: 857

This is starting to sound awfully like intermittent behaviour due to oxidisation of the dry contacts inside the plasma cutter because the high impedance circuit from the 7i76e input to ground (check the mesa manual).

I hope so, that'd be a really easy solution for OP!

A further explanation, and the calculations for resistance value are listed here, using the exact relay found inside a Powermax 65 (may be prudent to double check your arc ok relay is the same) as an example: linuxcnc.org/docs/devel/html/plasma/qtpl...html#qt-contact-load

No one here has first hand experience with your exact hardware configuration and one-size-fits-all advice on the forum comes with no warranty nor promise to replace the conformally coated relay inside of your power source. So it's best to start at the relay manufacturer's recommendation, do your own calculations, and work your way up if necessary.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21084

- Thank you received: 7197

Easy to check, clamp a DVM set to buzzer to ARCOK on the plasma.

I am almost certain of issues with shielding or loose THCAD wires, hard to see from the video but the voltage just disappears.

Monitoring encoder velocity might help

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2526

- Thank you received: 857

Pretty sure he said he gets that even in mode 0, so .....

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21084

- Thank you received: 7197

Forgot about that snowwy, busy day with a bit of headache, the latter messes badly with my ability to think and process informations.

Please Log in or Create an account to join the conversation.