Inconsistent values from Versaprobe

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

17 Oct 2024 18:05 #312420

by gardenweazel

Inconsistent values from Versaprobe was created by gardenweazel

I'm using QTDragon HD and having issues when probing.

I am using the steps as outlined in the qt_auto_probe_tool.ngc file start off with.

From machine_log.dat (VIM line numbers precede each line)

17 17:11:22 Loaded tool 0

18 17:11:22 Tool 0: PROBE

19 17:11:28 Cannot switch pages while in AUTO mode

20 17:11:39 Versa Probe: Start Cycle: Go to Tool Setter

21 17:12:08 Versa Probe: Start Cycle: Probe Tool Setter Z Height

22 17:12:17 HISTORY Tool Setter height Z[-148.426]

23 17:13:17 Versa Probe: Start Cycle: Probe Z Height of material

24 17:13:27 HISTORY Probe Material Top Z[-115.031]

25 17:14:47 Cannot switch pages while in AUTO mode

26 17:14:52 Versa Probe: Start Cycle: Probe Outside Edges, Finish At Corner

27 17:15:17 HISTORY Outside XPYP Xp[0.302] Lx[0.000] Yp[0.027] Ly[0.000]

28 17:15:56 Started program from line 1

29 17:17:30 Tool 16: whiteside router bits - whiteside rd210

30 17:17:47 Tool 16: whiteside router bits - whiteside rd210

31 17:17:47 Probe Height: -148.4200

32 17:17:47 Run timer stopped at 00:01:50

33 17:17:47 Loaded file /home/andy/uploads/Large-Serving-Tray-REVISED-V2-POCKET-2.ngc

34 17:17:47 Block Height: -115.0300

35 17:17:47 Probe Result: 229.0947

36 17:17:47 Calculated Offset: 262.4847

37 17:17:47 Linear move on line 231 would exceed Z's positive limit

38 17:17:47 Linear move on line 231 would exceed joint 3's positive limit

39 17:17:47 invalid params in linear command

40 17:17:47 Abort Parameter is [3]

41 17:17:55 Started program from line 1

42 17:18:17 Tool 16: whiteside router bits - whiteside rd210

43 17:18:17 Probe Height: -148.4200

44 17:18:17 Block Height: -115.0300

45 17:18:17 Probe Result: 229.0912

46 17:18:17 Calculated Offset: 262.4812

47 17:43:20 Run timer stopped at 00:25:24

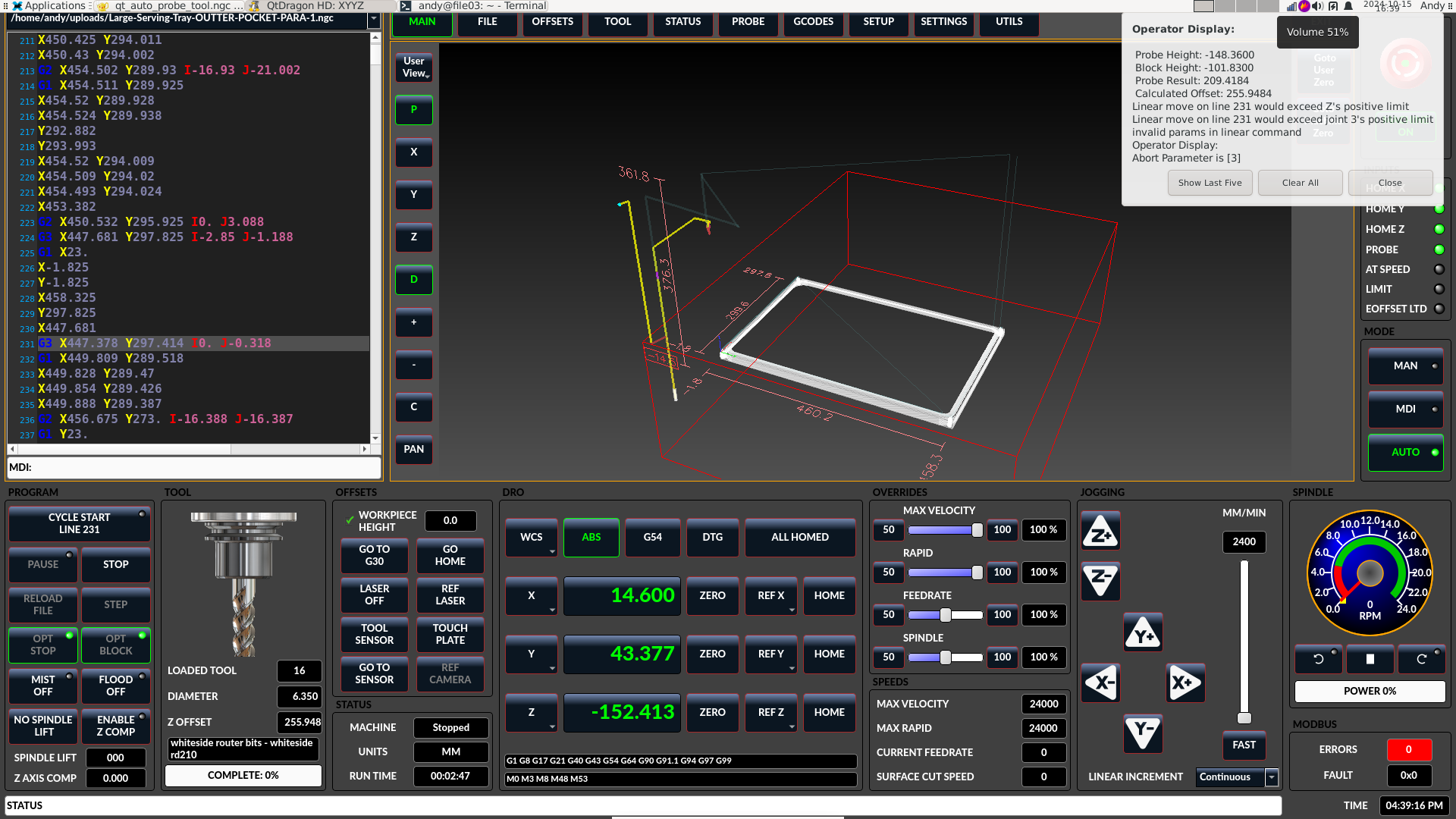

Here's the popup message: NOTE the MDI line number 231 has no Z axis movement and the program file has not even started to execute. At this point the new tool change has already taken place and the new tool is being measured.

Not sure what is causing this but, after I "Clear all" the and restart the file from the beginning it runs as expected without the error.

Finally, worth noting is that I noticed my tool table appears to have been altered and is NOT from previous runs. Has many missing columns.

It appears as if something has written to the tool table when it should have not.

Here's a couple of lines in my current tool table that reflects this issue, note that tool 16 has the Z set.

T15 P15 D+6.350000 ;whiteside router bits - whiteside ru210

T16 P16 D+6.350000 Z+258.012190 ;whiteside router bits - whiteside rd210

T17 P17 D+6.350000 ;whiteside router bits - whiteside rd207

And here is a backup that I took a week or so ago:

T15 P15 X0 Y0 Z0 A0 B0 C0 U0 V0 W0 D6.35000 I0 J0 Q0 ;whiteside router bits - whiteside ru2100 -- 1/4 inch upcut spiral- solid carbide

T16 P16 X0 Y0 Z0 A0 B0 C0 U0 V0 W0 D6.35000 I0 J0 Q0 ;whiteside router bits - whiteside rd2100 -- 1/4 inch downcut spiral- solid carbide

T17 P17 X0 Y0 Z0 A0 B0 C0 U0 V0 W0 D6.35000 I0 J0 Q0 ;whiteside router bits - whiteside rd2074a --o-flute 1/4 inch downcut spiral - solid carbide

Any ideas?

I am using the steps as outlined in the qt_auto_probe_tool.ngc file start off with.

From machine_log.dat (VIM line numbers precede each line)

17 17:11:22 Loaded tool 0

18 17:11:22 Tool 0: PROBE

19 17:11:28 Cannot switch pages while in AUTO mode

20 17:11:39 Versa Probe: Start Cycle: Go to Tool Setter

21 17:12:08 Versa Probe: Start Cycle: Probe Tool Setter Z Height

22 17:12:17 HISTORY Tool Setter height Z[-148.426]

23 17:13:17 Versa Probe: Start Cycle: Probe Z Height of material

24 17:13:27 HISTORY Probe Material Top Z[-115.031]

25 17:14:47 Cannot switch pages while in AUTO mode

26 17:14:52 Versa Probe: Start Cycle: Probe Outside Edges, Finish At Corner

27 17:15:17 HISTORY Outside XPYP Xp[0.302] Lx[0.000] Yp[0.027] Ly[0.000]

28 17:15:56 Started program from line 1

29 17:17:30 Tool 16: whiteside router bits - whiteside rd210

30 17:17:47 Tool 16: whiteside router bits - whiteside rd210

31 17:17:47 Probe Height: -148.4200

32 17:17:47 Run timer stopped at 00:01:50

33 17:17:47 Loaded file /home/andy/uploads/Large-Serving-Tray-REVISED-V2-POCKET-2.ngc

34 17:17:47 Block Height: -115.0300

35 17:17:47 Probe Result: 229.0947

36 17:17:47 Calculated Offset: 262.4847

37 17:17:47 Linear move on line 231 would exceed Z's positive limit

38 17:17:47 Linear move on line 231 would exceed joint 3's positive limit

39 17:17:47 invalid params in linear command

40 17:17:47 Abort Parameter is [3]

41 17:17:55 Started program from line 1

42 17:18:17 Tool 16: whiteside router bits - whiteside rd210

43 17:18:17 Probe Height: -148.4200

44 17:18:17 Block Height: -115.0300

45 17:18:17 Probe Result: 229.0912

46 17:18:17 Calculated Offset: 262.4812

47 17:43:20 Run timer stopped at 00:25:24

Here's the popup message: NOTE the MDI line number 231 has no Z axis movement and the program file has not even started to execute. At this point the new tool change has already taken place and the new tool is being measured.

Not sure what is causing this but, after I "Clear all" the and restart the file from the beginning it runs as expected without the error.

Finally, worth noting is that I noticed my tool table appears to have been altered and is NOT from previous runs. Has many missing columns.

It appears as if something has written to the tool table when it should have not.

Here's a couple of lines in my current tool table that reflects this issue, note that tool 16 has the Z set.

T15 P15 D+6.350000 ;whiteside router bits - whiteside ru210

T16 P16 D+6.350000 Z+258.012190 ;whiteside router bits - whiteside rd210

T17 P17 D+6.350000 ;whiteside router bits - whiteside rd207

And here is a backup that I took a week or so ago:

T15 P15 X0 Y0 Z0 A0 B0 C0 U0 V0 W0 D6.35000 I0 J0 Q0 ;whiteside router bits - whiteside ru2100 -- 1/4 inch upcut spiral- solid carbide

T16 P16 X0 Y0 Z0 A0 B0 C0 U0 V0 W0 D6.35000 I0 J0 Q0 ;whiteside router bits - whiteside rd2100 -- 1/4 inch downcut spiral- solid carbide

T17 P17 X0 Y0 Z0 A0 B0 C0 U0 V0 W0 D6.35000 I0 J0 Q0 ;whiteside router bits - whiteside rd2074a --o-flute 1/4 inch downcut spiral - solid carbide

Any ideas?

Attachments:

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

18 Oct 2024 00:55 #312454

by gardenweazel

Replied by gardenweazel on topic Inconsistent values from Versaprobe

So, the call to save the tool offset is in the qt_auto_probe_tool.ngc on or around line 202-203 seems to be mangling the tool.tbl format.

203 G10 L1 P#<tool> Z[#<calculated_offset>]

Which occurs after the OKAY click of the tool change prompt. I've checked it before and after.

203 G10 L1 P#<tool> Z[#<calculated_offset>]

Which occurs after the OKAY click of the tool change prompt. I've checked it before and after.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7272

- Thank you received: 2115

19 Oct 2024 00:10 #312566

by cmorley

Replied by cmorley on topic Inconsistent values from Versaprobe

Tool table problem first

I believe linuxcnc will just not write the axes that are zero.

The comment line is probably limited to a certain length in linuxcnc - though I can't find that limit at the moment. QtDragon is less limiting on comment length.

As for the Error message.

Am I understanding right, if you cancel the G54 offsets the process works once?

Chris

I believe linuxcnc will just not write the axes that are zero.

The comment line is probably limited to a certain length in linuxcnc - though I can't find that limit at the moment. QtDragon is less limiting on comment length.

As for the Error message.

Am I understanding right, if you cancel the G54 offsets the process works once?

Chris

The following user(s) said Thank You: gardenweazel

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

19 Oct 2024 15:06 #312612

by gardenweazel

Replied by gardenweazel on topic Inconsistent values from Versaprobe

"I believe linuxcnc will just not write the axes that are zero."

I noticed in the Wiki there was a comment that the format had changed in previous versions. So I assumed that the table is in correct format and not corrupted.

"The comment line is probably limited to a certain length in linuxcnc - though I can't find that limit at the moment. QtDragon is less limiting on comment length."

The reference to line 231 appears to be coming from the qt_auto_probe_tool.ngc file. This is lines in that file with preceding line numbers:

225 ; return to original tool-tip position, but using new z-offset

226 ; (DEBUG, Return to original tool-tip position using new z-offset: #<local_start_x> , #<local_start_y> , #<local_start_z> )

227 G53 G0 Z[#<_ini[VERSA_TOOLSETTER]Z_MAX_CLEAR>]

228 ; now use original (modal)coord system to go over to xy

229 G0 X[#<local_start_x>] Y[#<local_start_y>]

230 ; and finally down to the (already offset) z coord

231 G0 Z[#<local_start_z>]

"Am I understanding right, if you cancel the G54 offsets the process works once?"

My gcode file has a G54 line in it from Fusion 360 but that is after the tool change. So once it fails, I click "Clear all" the error gets cleared and I click start at line 1 it runs without error.

I believe that this INI line may be part of the problem(no G43)??

RS274NGC_STARTUP_CODE = G17 G21 G40 G80 G90 G94 G54 G97 G64 P0.025 S5000

Here's the lines of the gcode that I am running:

%

( WHITESIDE RD2100 -- 14 INCH DOWNCUT SPIRAL- SOLID CARBIDE )

G90 G94 G17 G91.1

G21

G53 G0 Z0.

(2D POCKET4)

T16 M6

S20000 M3

G94 G4 P8.

G17 G90

G54

G64 P0.01 Q0.01

M8

G0 X206.261 Y146.152

Z29.5

G0 Z-8.5

G1 Z-11.365 F1354.67

Thanks for your help Chris!

I noticed in the Wiki there was a comment that the format had changed in previous versions. So I assumed that the table is in correct format and not corrupted.

"The comment line is probably limited to a certain length in linuxcnc - though I can't find that limit at the moment. QtDragon is less limiting on comment length."

The reference to line 231 appears to be coming from the qt_auto_probe_tool.ngc file. This is lines in that file with preceding line numbers:

225 ; return to original tool-tip position, but using new z-offset

226 ; (DEBUG, Return to original tool-tip position using new z-offset: #<local_start_x> , #<local_start_y> , #<local_start_z> )

227 G53 G0 Z[#<_ini[VERSA_TOOLSETTER]Z_MAX_CLEAR>]

228 ; now use original (modal)coord system to go over to xy

229 G0 X[#<local_start_x>] Y[#<local_start_y>]

230 ; and finally down to the (already offset) z coord

231 G0 Z[#<local_start_z>]

"Am I understanding right, if you cancel the G54 offsets the process works once?"

My gcode file has a G54 line in it from Fusion 360 but that is after the tool change. So once it fails, I click "Clear all" the error gets cleared and I click start at line 1 it runs without error.

I believe that this INI line may be part of the problem(no G43)??

RS274NGC_STARTUP_CODE = G17 G21 G40 G80 G90 G94 G54 G97 G64 P0.025 S5000

Here's the lines of the gcode that I am running:

%

( WHITESIDE RD2100 -- 14 INCH DOWNCUT SPIRAL- SOLID CARBIDE )

G90 G94 G17 G91.1

G21

G53 G0 Z0.

(2D POCKET4)

T16 M6

S20000 M3

G94 G4 P8.

G17 G90

G54

G64 P0.01 Q0.01

M8

G0 X206.261 Y146.152

Z29.5

G0 Z-8.5

G1 Z-11.365 F1354.67

Thanks for your help Chris!

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

21 Oct 2024 17:17 #312776

by gardenweazel

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Adding some additional relevant logging info:

[QTvcp.QTVCP.WIDGETS.DIALOG_WIDGET][ERROR] No callback or STATUS message specified for: toolDialog_ (dialog_widget.py:317)

[QTvcp.QTVCP.WIDGETS.DIALOG_WIDGET][DEBUG] Button pressed is: &OK (dialog_widget.py:561)

USRMOT: ERROR: invalid command

Linear move on line 231 would exceed Z's positive limit

[QTvcp.QTVCP.WIDGETS.GCODE_EDITOR][VERBOSE] editor: highlight line 226 (logger.py:38)

[QTvcp.QTVCP.WIDGETS.GCODE_EDITOR][DEBUG] should reload the display (gcode_editor.py:713)

[QTvcp.QTVCP.WIDGETS.GCODE_EDITOR][VERBOSE] Line changed: 0 (logger.py:38)

Linear move on line 231 would exceed joint 3's positive limit

invalid params in linear command

[QTvcp.QTVCP.WIDGETS.DIALOG_WIDGET][ERROR] No callback or STATUS message specified for: toolDialog_ (dialog_widget.py:317)

[QTvcp.QTVCP.WIDGETS.DIALOG_WIDGET][DEBUG] Button pressed is: &OK (dialog_widget.py:561)

USRMOT: ERROR: invalid command

Linear move on line 231 would exceed Z's positive limit

[QTvcp.QTVCP.WIDGETS.GCODE_EDITOR][VERBOSE] editor: highlight line 226 (logger.py:38)

[QTvcp.QTVCP.WIDGETS.GCODE_EDITOR][DEBUG] should reload the display (gcode_editor.py:713)

[QTvcp.QTVCP.WIDGETS.GCODE_EDITOR][VERBOSE] Line changed: 0 (logger.py:38)

Linear move on line 231 would exceed joint 3's positive limit

invalid params in linear command

Attachment not found

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

21 Oct 2024 17:19 #312777

by gardenweazel

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Attachments:

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7272

- Thank you received: 2115

24 Oct 2024 05:27 #313033

by cmorley

Replied by cmorley on topic Inconsistent values from Versaprobe

I have not forgotten you, but have been too busy to test on my machine.

line 231 returns the tool to the start position, but with the new tool length.

52 #<local_start_z> = #<_z>

<snip>

probe

set tool table offset

return to Z location:

231 G0 Z[#<local_start_z>]

If the new tool is longer then the original, and the machine cannot go up anymore to get to that position, you would get that error.

you could add this just above line 231 so we can see where it is trying to go:

(DEBUG, moving to Z: %f#<local_start_z>)

line 231 returns the tool to the start position, but with the new tool length.

52 #<local_start_z> = #<_z>

<snip>

probe

set tool table offset

return to Z location:

231 G0 Z[#<local_start_z>]

If the new tool is longer then the original, and the machine cannot go up anymore to get to that position, you would get that error.

you could add this just above line 231 so we can see where it is trying to go:

(DEBUG, moving to Z: %f#<local_start_z>)

The following user(s) said Thank You: gardenweazel

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

24 Oct 2024 16:30 #313105

by gardenweazel

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Thanks Chris for your response.

The 3d probe is almost always going to be shorter than the tool length.

Here's what I have added:

225 ; return to original tool-tip position, but using new z-offset

226 (DEBUG, Return to original tool-tip position using new z-offset: #<local_start_x> , #<local_start_y> , #<local_start_z>)

227 G53 G0 Z[#<_ini[VERSA_TOOLSETTER]Z_MAX_CLEAR>]

228 ; now use original (modal)coord system to go over to xy

229 G0 X[#<local_start_x>] Y[#<local_start_y>]

230 ; and finally down to the (already offset) z coord

231 G0 Z[#<local_start_z>]

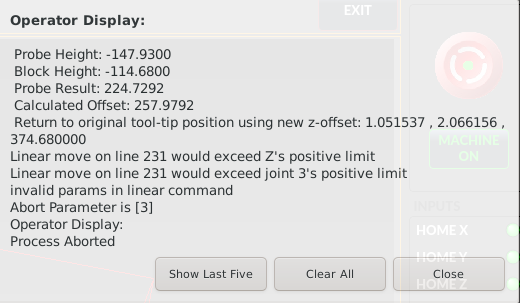

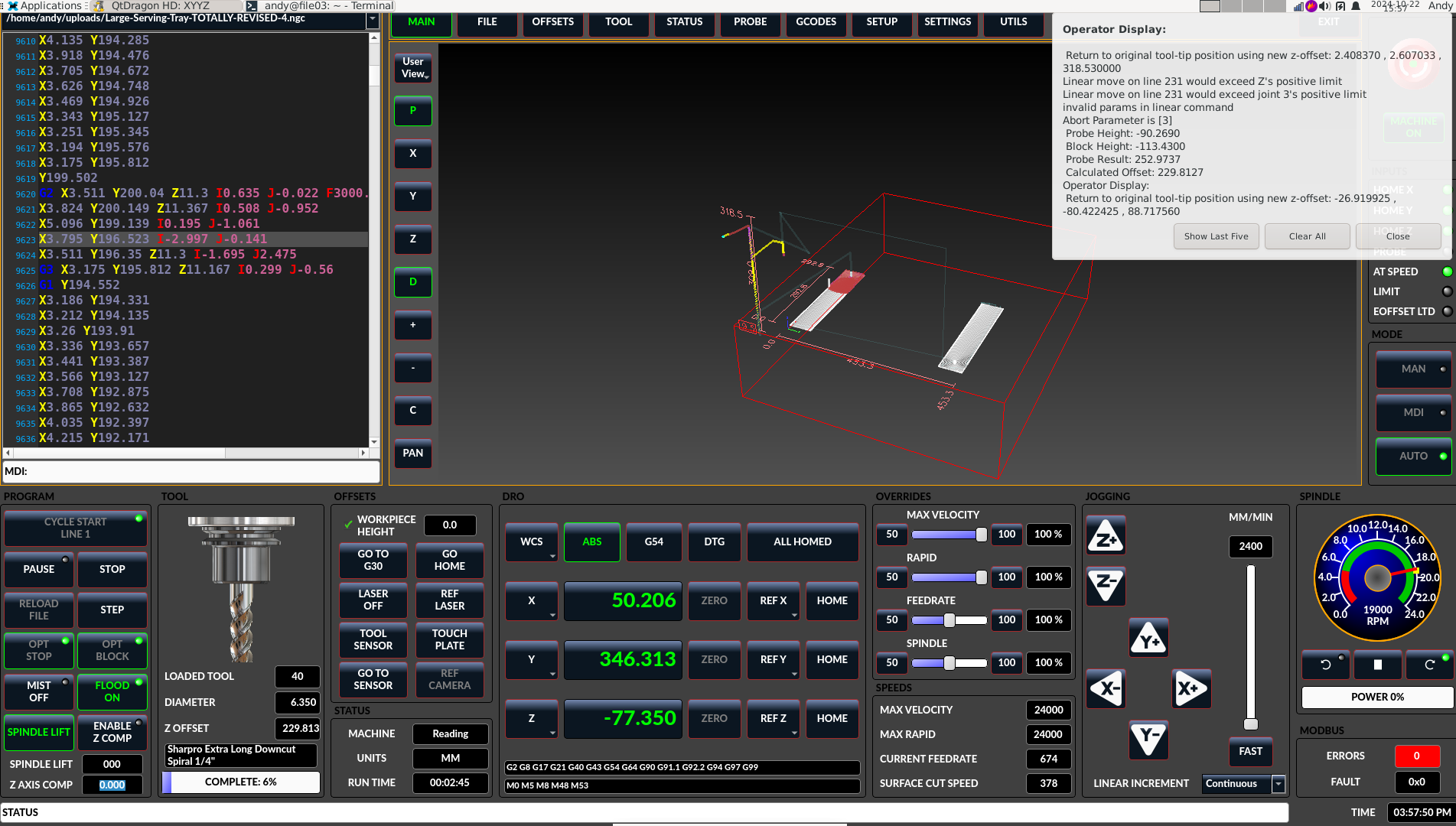

In the attached/inline image you can see the values of local_start_z of 318.53 which fails. At the end the local_start_z it is set to 88.717560 and the program then moves forward.

I believe that the msg "invalid params in linear command" I believe is actually coming from this line:

203 G10 L1 P#<tool> Z[#<calculated_offset>]

and there after a G43.

There is mention of another forum post by @sou528 here that mentions the same however there's no follow up to that post .

He does refer to the documentation that indicates an example zworkoffset . If you scan the github repository for the word zworkoffset you will see mention to this.

I'd really like to get this one behind me if at all possible.

The 3d probe is almost always going to be shorter than the tool length.

Here's what I have added:

225 ; return to original tool-tip position, but using new z-offset

226 (DEBUG, Return to original tool-tip position using new z-offset: #<local_start_x> , #<local_start_y> , #<local_start_z>)

227 G53 G0 Z[#<_ini[VERSA_TOOLSETTER]Z_MAX_CLEAR>]

228 ; now use original (modal)coord system to go over to xy

229 G0 X[#<local_start_x>] Y[#<local_start_y>]

230 ; and finally down to the (already offset) z coord

231 G0 Z[#<local_start_z>]

In the attached/inline image you can see the values of local_start_z of 318.53 which fails. At the end the local_start_z it is set to 88.717560 and the program then moves forward.

I believe that the msg "invalid params in linear command" I believe is actually coming from this line:

203 G10 L1 P#<tool> Z[#<calculated_offset>]

and there after a G43.

There is mention of another forum post by @sou528 here that mentions the same however there's no follow up to that post .

He does refer to the documentation that indicates an example zworkoffset . If you scan the github repository for the word zworkoffset you will see mention to this.

I'd really like to get this one behind me if at all possible.

Attachments:

Please Log in or Create an account to join the conversation.

- gardenweazel

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 10

30 Oct 2024 20:20 #313510

by gardenweazel

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Here's another similar post:

forum.linuxcnc.org/qtvcp/40992-qtdragon-...tion?start=10#212164

I don't understand how or why var #5223 is being set to -321.00 in my VAR file. Makes no sense since my entire travel along Z is much less.

Still searching for a fix on this issue.

I don't understand how or why var #5223 is being set to -321.00 in my VAR file. Makes no sense since my entire travel along Z is much less.

Still searching for a fix on this issue.

Please Log in or Create an account to join the conversation.

- seebaer1976

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

02 Nov 2024 15:31 #313662

by seebaer1976

Replied by seebaer1976 on topic Inconsistent values from Versaprobe

I'll join in because I have the same problem.

When I touch the probe, the g54 z values are correct.

When I start the program, insert the new tool and it then measures it, the numbers for g54 z are over 200. And the program stops because the z axis is exceeded.

But the strange thing is that in the linuxcnc.var, the correct value is under #5223 (e.g. -98.816)

When I touch the probe, the g54 z values are correct.

When I start the program, insert the new tool and it then measures it, the numbers for g54 z are over 200. And the program stops because the z axis is exceeded.

But the strange thing is that in the linuxcnc.var, the correct value is under #5223 (e.g. -98.816)

The following user(s) said Thank You: gardenweazel

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 1.130 seconds