Workshop update

- HiioHoi

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 4

09 Jan 2020 20:53 #154489

by HiioHoi

Replied by HiioHoi on topic Workshop update

Hi,

I have to contribute to this topic also. My workshop size is 1,4x2,1m and I have done some progress today. Added Kallax shelf and workdesk which is of course extra supported from back. Next thing to do is clean up milling machine wiring and move computer and controlbox to top of the milling machine enclosure. Currently I am waiting to arrive beefy 24v power supply to remove all laptop power supplies. I will add another photo when all things are done.

I have to contribute to this topic also. My workshop size is 1,4x2,1m and I have done some progress today. Added Kallax shelf and workdesk which is of course extra supported from back. Next thing to do is clean up milling machine wiring and move computer and controlbox to top of the milling machine enclosure. Currently I am waiting to arrive beefy 24v power supply to remove all laptop power supplies. I will add another photo when all things are done.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

09 Jan 2020 21:12 #154492

by tommylight

Replied by tommylight on topic Workshop update

Neat little shop, thank you.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

10 Jan 2020 23:08 #154589

by machinedude

Replied by machinedude on topic Workshop update

thanks to tommy i have my eyes set on some peg board organization solutions  for some reason i do better with keeping track of stuff if it's all out in the open

for some reason i do better with keeping track of stuff if it's all out in the open  i need all the help i can get

i need all the help i can get

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

27 Jan 2020 08:47 #155880

by bbsr_5a

Replied by bbsr_5a on topic Workshop update

is the BOX Noice or Dust related

the HF Spindel doesent like closed frames on long time part millings

the HF Spindel doesent like closed frames on long time part millings

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11624

- Thank you received: 3911

27 Jan 2020 10:00 #155887

by rodw

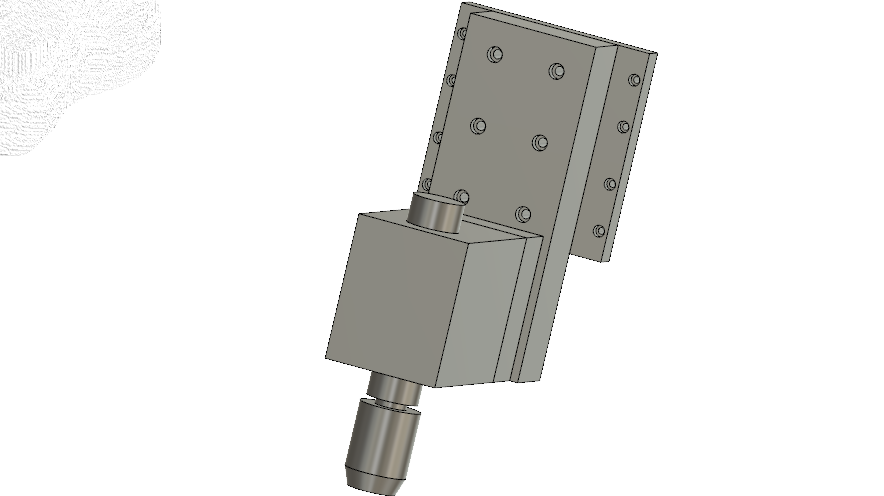

Small spaces are fun. My shed was 2.4 x 4.8mm. I'd love to se a few more photos of your optimum Conversion. Very nice with linear rails and all!

Replied by rodw on topic Workshop update

Hi,

I have to contribute to this topic also. My workshop size is 1,4x2,1m and I have done some progress today. Added Kallax shelf and workdesk which is of course extra supported from back. Next thing to do is clean up milling machine wiring and move computer and controlbox to top of the milling machine enclosure. Currently I am waiting to arrive beefy 24v power supply to remove all laptop power supplies. I will add another photo when all things are done.

Small spaces are fun. My shed was 2.4 x 4.8mm. I'd love to se a few more photos of your optimum Conversion. Very nice with linear rails and all!

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

- Visitor

-

27 Jan 2020 11:39 - 27 Jan 2020 11:40 #155893

by BeagleBrainz

Replied by BeagleBrainz on topic Workshop update

I'd add a picture of my shed...but I'm in the process of trying to remove all traces of my last attempt to swing a cat. (I hate playing "Where is that smell coming from")

Maybe once I finish off the chip tray for the mill I might be able to get in there to take a pic or 2.

HiioHoi a tip of the hat for being able to get organised in such a small space.

Maybe once I finish off the chip tray for the mill I might be able to get in there to take a pic or 2.

HiioHoi a tip of the hat for being able to get organised in such a small space.

Last edit: 27 Jan 2020 11:40 by BeagleBrainz.

Please Log in or Create an account to join the conversation.

- HiioHoi

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 4

31 Jan 2020 19:41 #156273

by HiioHoi

Replied by HiioHoi on topic Workshop update

Here is few photos of my conversion and my new 90% finished workshop.

I used original leadscrew for z-axis and banjo for easy stepper motor mounting. I hope pics will tell full story but if you have questions please ask.

I used original leadscrew for z-axis and banjo for easy stepper motor mounting. I hope pics will tell full story but if you have questions please ask.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

01 Feb 2020 11:34 #156297

by machinedude

Replied by machinedude on topic Workshop update

i bought a lathe of this size a long time ago. the model i bought is actually discontinued now so i guess that makes it old now even though it seem like i just bought it not to long ago.

i converted mine a while back but kept the basic machine untouched other than adding motors and a ball screw on the z azis. i'm actually going to try to mount the milling head on the 4' x 8' gantry table i'm working on to see if i can gain a light duty gantry mill. i know it will work on aluminum the rest is to be determined still. the one i got was a combo machine and had the milling head attachment and it should end up looking something like this when i get done with it.

the lathe is going to get redone soon as well i would like to loose the step pulley v belt drive and switch to a servo motor instead.

i converted mine a while back but kept the basic machine untouched other than adding motors and a ball screw on the z azis. i'm actually going to try to mount the milling head on the 4' x 8' gantry table i'm working on to see if i can gain a light duty gantry mill. i know it will work on aluminum the rest is to be determined still. the one i got was a combo machine and had the milling head attachment and it should end up looking something like this when i get done with it.

the lathe is going to get redone soon as well i would like to loose the step pulley v belt drive and switch to a servo motor instead.

Attachments:

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

01 Feb 2020 11:57 #156301

by machinedude

Replied by machinedude on topic Workshop update

Attachments:

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

01 Feb 2020 11:59 #156302

by bbsr_5a

Replied by bbsr_5a on topic Workshop update

this will give you nice Part option when it is finished

are you under suggestion to get the Spindle to a indexed CAxis as well

with a 2Way Setup as Lathe mill combination

a good modern stepper Driver can reach 2000U/min at 800steps/rev

consider this to be a Hybrid

are you under suggestion to get the Spindle to a indexed CAxis as well

with a 2Way Setup as Lathe mill combination

a good modern stepper Driver can reach 2000U/min at 800steps/rev

consider this to be a Hybrid

Please Log in or Create an account to join the conversation.

Time to create page: 0.271 seconds