Homemade, cheap, plasma CNC

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

linux configuration safe height 20 (as per tommy suggestion), Sheet cam rapid clearance 30mm.

Z axis drives down, slows to probe, probes and cuts, goes up 8.4mm ( no idea why it only goes this high) travels to next cut, goes up, begins probe.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21192

- Thank you received: 7241

Jog the torch down to just under where the slats start (no material on table) then click on the "touch off" button, make sure Z axis is selected.

Also the Z axis and joint section of the ini file would help.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

This SheetCam setting is not used, all Z settings are internal and set from the parameters tab.Still not working,

linux configuration safe height 20 (as per tommy suggestion), Sheet cam rapid clearance 30mm.

It goes up because your Probe Height may be higher than your Safe Height.Z axis drives down, slows to probe, probes and cuts, goes up 8.4mm ( no idea why it only goes this high) travels to next cut, goes up, begins probe.

Are you still getting the Safe Height warning? If you do when exactly are you getting it?

Can you post a backup of your config.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

z axis from .ini.

#******************************************

[AXIS_Z]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 80

MAX_ACCELERATION = 1000.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -150

MAX_LIMIT = 15

[JOINT_3]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 40.0

MAX_ACCELERATION = 500.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 50

STEPGEN_MAXACCEL = 600

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 10000

STEPSPACE = 10000

STEP_SCALE = -160.0

MIN_LIMIT = -150

MAX_LIMIT = 15

HOME_OFFSET = 0

HOME_SEARCH_VEL = 25

HOME_LATCH_VEL = -5

HOME_FINAL_VEL = 20

HOME_IGNOR_LIMITS = YES

HOME_SEQUENCE = 1

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21192

- Thank you received: 7241

Safe height is where the torch is retracted to before G0 or before it moves from cut to cut.

I have it at 120 as my travel is 180 in total after homing, so i have space to spare.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

I have changed the safe height to 100 and still get the same error.

The z axis only goes up to 8.4mm before travel. And gives the warning after the first cut of a job.

No doubt I have set something, somewhere and now I can’t find it to fix it.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Can you post the backup of your config.

Can you post a Gcode file it errors with.

Can you pinpoint exactly on the Gcode file where it errors.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

- Posts: 244

- Thank you received: 54

config

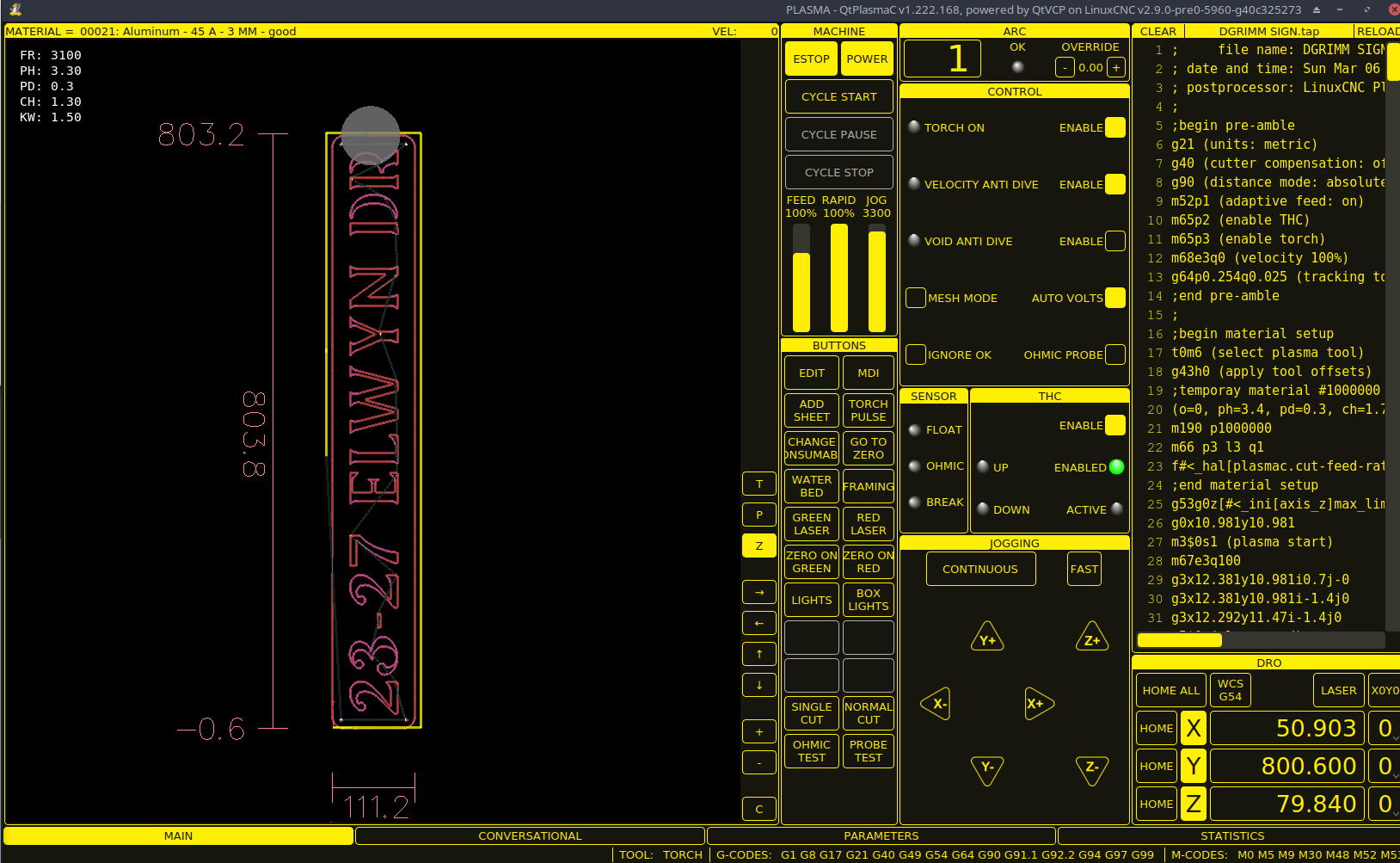

G code. error happens at line 17. once touchoff has been completed.

Attachments:

Please Log in or Create an account to join the conversation.