Homemade, cheap, plasma CNC

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

27 Dec 2021 05:49 #230045

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

You can achive what both of your laser buttons do by using the built in laser button:

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

27 Dec 2021 06:15 #230049

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

Yeh, that was suggested in an earlier post here but James wanted to do it his way. Not a bad way to learn about hal and QTP really.You can achive what both of your laser buttons do by using the built in laser button:

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

27 Dec 2021 12:35 #230061

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Rod,

Did have some luck tonight getting spotting to work.

I followed some instructions from arclightdynamics on youtube, they did a clip called 'plasma center punch training video'. this made a little bit of sense to me for some reason, then coupled with your advice I'm getting somewhere now. Currently in the GUI I have 1V and 2ms. this is working and not punching through 1.2mm steel. I'll mess around with it some more tomorrow.

Philc54, Thank you. I had looked into this previously, however I wasn't at this level yet to fully appreciate how this would work. I am getting there and this will be my next hurdle. I do use it to some capacity using "mark edge' & 'set origin' to align my material if I can't be bothered to set it on the machine correctly or if it's a small bit for a quick cut. Hopefully soon I'll have this setup.

Cheers

Did have some luck tonight getting spotting to work.

I followed some instructions from arclightdynamics on youtube, they did a clip called 'plasma center punch training video'. this made a little bit of sense to me for some reason, then coupled with your advice I'm getting somewhere now. Currently in the GUI I have 1V and 2ms. this is working and not punching through 1.2mm steel. I'll mess around with it some more tomorrow.

Philc54, Thank you. I had looked into this previously, however I wasn't at this level yet to fully appreciate how this would work. I am getting there and this will be my next hurdle. I do use it to some capacity using "mark edge' & 'set origin' to align my material if I can't be bothered to set it on the machine correctly or if it's a small bit for a quick cut. Hopefully soon I'll have this setup.

Cheers

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

27 Dec 2021 13:00 #230065

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

27 Dec 2021 17:58 #230070

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

Looks perfect! Time to move on to the next challenge!

Just watch that the torch voltage does not flicker over the 1 V threshold when its not cutting.

Just watch that the torch voltage does not flicker over the 1 V threshold when its not cutting.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

01 Jan 2022 01:16 - 01 Jan 2022 01:23 #230427

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Rod,

Next challenge is the torch mount properly, even with 10 'strong' magnets, it still breaks away too easily, and I don't have. micro switch on it yet to pause the machine when it does breakaway.

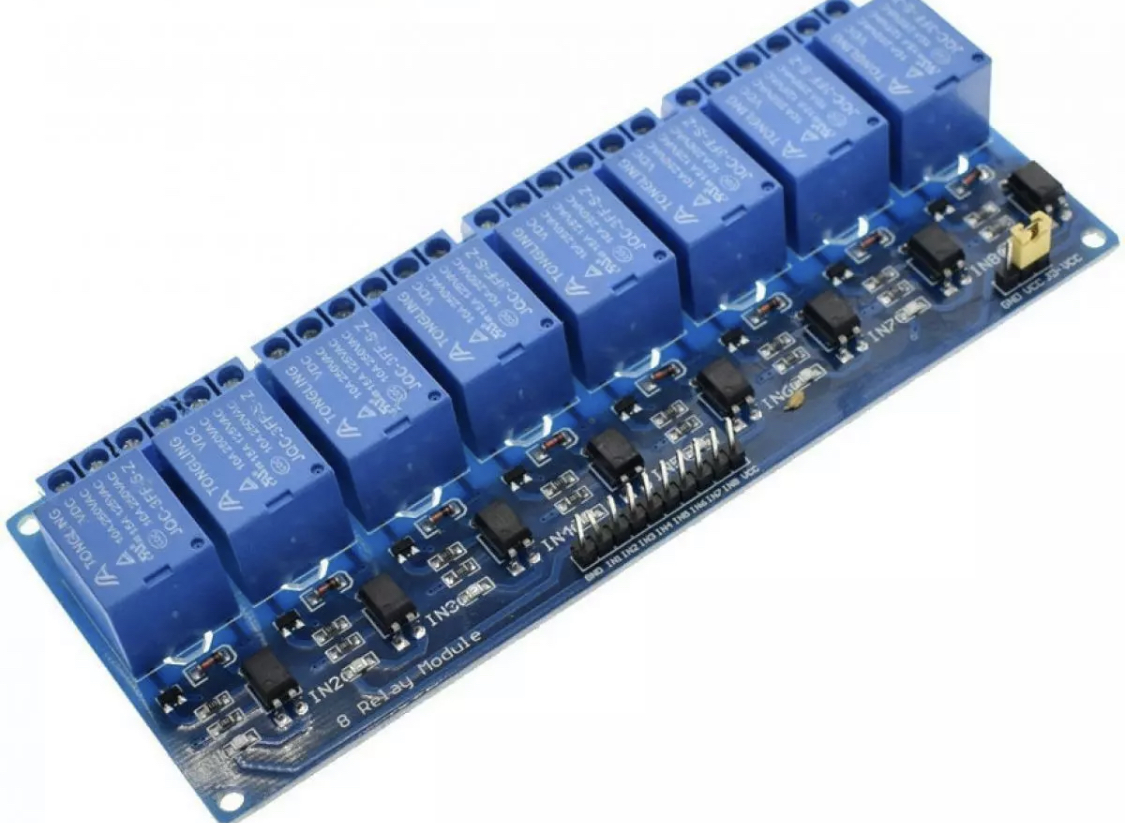

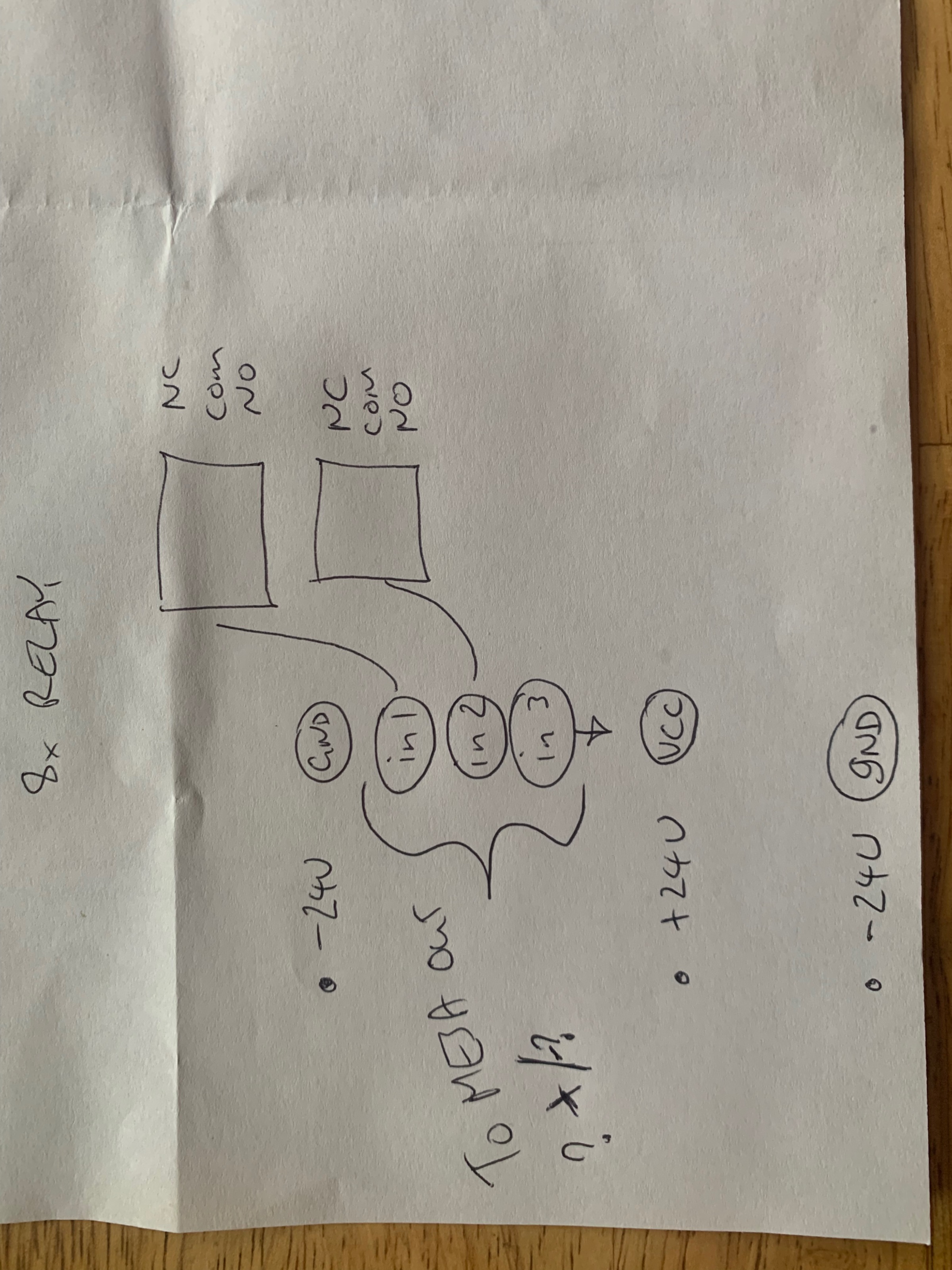

Also brains trust, I want to upgrade the 2 relay's I have to a set of 8. however I'm struggling to find a correct wiring diagram on getting it connected to the MESA board.

Pics to follow of current setup, new 8x relays, current wiring diagram. I need help on how to connect this all in properly, I'll also put up my attempt at connections.

Next challenge is the torch mount properly, even with 10 'strong' magnets, it still breaks away too easily, and I don't have. micro switch on it yet to pause the machine when it does breakaway.

Also brains trust, I want to upgrade the 2 relay's I have to a set of 8. however I'm struggling to find a correct wiring diagram on getting it connected to the MESA board.

Pics to follow of current setup, new 8x relays, current wiring diagram. I need help on how to connect this all in properly, I'll also put up my attempt at connections.

Attachments:

Last edit: 01 Jan 2022 01:23 by RNJFAB.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

01 Jan 2022 01:43 #230428

by rodw

I found vicegrips solved this

Replied by rodw on topic Homemade, cheap, plasma CNC

Thanks Rod,

Next challenge is the torch mount properly, even with 10 'strong' magnets, it still breaks away too easily, and I don't have. micro switch on it yet to pause the machine when it does breakaway.

I found vicegrips solved this

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

01 Jan 2022 06:16 - 01 Jan 2022 06:17 #230435

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Attachments:

Last edit: 01 Jan 2022 06:17 by RNJFAB.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11611

- Thank you received: 3905

01 Jan 2022 06:22 - 01 Jan 2022 06:23 #230436

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

So looks perfect to me!

Actually have found Linuxcnc so good, I don't even think a magnetic breakaway is required.

EDIT: Been thinking of drilling and tapping a hole to make it permanent!

Actually have found Linuxcnc so good, I don't even think a magnetic breakaway is required.

EDIT: Been thinking of drilling and tapping a hole to make it permanent!

Last edit: 01 Jan 2022 06:23 by rodw.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

02 Jan 2022 01:44 #230511

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Rod,

I was thinking of doing the same, however I'm having issues if I have VOID A/DIVE on. This will from time to time cause the torch to crash, with it off I have had no problems. Also if I have AUTO VOLTS on it can be a bit hit and miss, sometimes a perfect cut, sometimes crash every 20mm or less. The torch just keeps diving.

Currently with the volts set for each material and a bit of tweaking, I have nice cuts for all the material I normally use.

I was thinking of doing the same, however I'm having issues if I have VOID A/DIVE on. This will from time to time cause the torch to crash, with it off I have had no problems. Also if I have AUTO VOLTS on it can be a bit hit and miss, sometimes a perfect cut, sometimes crash every 20mm or less. The torch just keeps diving.

Currently with the volts set for each material and a bit of tweaking, I have nice cuts for all the material I normally use.

Please Log in or Create an account to join the conversation.

Time to create page: 0.204 seconds