Homemade, cheap, plasma CNC

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11718

- Thank you received: 3966

21 Nov 2021 19:29 #227222

by rodw

Thats a side affect of having the gene!

Replied by rodw on topic Homemade, cheap, plasma CNC

Took some time to stop laughing !

Thats a side affect of having the gene!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21290

- Thank you received: 7267

21 Nov 2021 21:43 #227236

by tommylight

Replied by tommylight on topic Homemade, cheap, plasma CNC

I thought the chronic sleep deprivation was a side effect!

Took some time to stop laughing !

Thats a side affect of having the gene!

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

23 Nov 2021 11:08 #227393

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Rod,

Toolset moved.

Changed the settings in the PP ass well, however the tool set selected in the PP is the one that QtPlasmaC runs, and i'm unable to change it.

I'll stay tuned to see your PP come through in my e-mail when you get a chance.

Thanks

Toolset moved.

Changed the settings in the PP ass well, however the tool set selected in the PP is the one that QtPlasmaC runs, and i'm unable to change it.

I'll stay tuned to see your PP come through in my e-mail when you get a chance.

Thanks

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

12 Dec 2021 12:52 #228917

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

new problem just for fun. Any cut files loaded into QtPlasmac get turned 180deg.

Not sure why this has happened. just updated to the latest version and it still does it.

Any ideas?

Not sure why this has happened. just updated to the latest version and it still does it.

Any ideas?

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2537

- Thank you received: 867

12 Dec 2021 14:45 #228922

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

I dont see that here, on either the virtual machine, or my main machine.

But I do have two thoughts:

1. your origin point in the preview should be that Y is pointing up and X is pointing to the right. If not, a rotation probably got set accidentally.

You could set it back to zero by going to the MDI and entering:

You will have to click RELOAD to see the effect in the graphic preview window if you have g-code loaded.

2. If it's not that, you'll have to post your g-code for one of us to take a look.

But I do have two thoughts:

1. your origin point in the preview should be that Y is pointing up and X is pointing to the right. If not, a rotation probably got set accidentally.

You could set it back to zero by going to the MDI and entering:

G10 L2 P0 R0You will have to click RELOAD to see the effect in the graphic preview window if you have g-code loaded.

2. If it's not that, you'll have to post your g-code for one of us to take a look.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

12 Dec 2021 23:03 - 13 Dec 2021 00:31 #228957

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Snowgoer,

Just the rotation had been changed and i didn't know how it happened or how to get it back.

Did all my cutting last night by redoing the g-code and flipping the cut. Talk about an upside down nightmare !!

thanks again for all the help and behind the scenes work that you guys are doing.

Just the rotation had been changed and i didn't know how it happened or how to get it back.

Did all my cutting last night by redoing the g-code and flipping the cut. Talk about an upside down nightmare !!

thanks again for all the help and behind the scenes work that you guys are doing.

Last edit: 13 Dec 2021 00:31 by RNJFAB.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

27 Dec 2021 05:13 #230041

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

So post Christmas update 2021.

TB6600 stepped drivers getting bit funny in the heat of QLD (35+ deg C in the shed with 99.997% humidity).

New z axis has been completed, tested and is working - pictures to follow shortly. New torch also added to make life easier. 160mm travel.

New laser is in and linked to a button in the GUI. Offset all worked in to zero off laser point. Offset also worked out for framing as part of QtPlasmaC.

Still haven't worked out spotting in Sheetcam, or how to se the tool from QtPlasmaC instead of Sheetcam. Must need to watch more video's.

TB6600 stepped drivers getting bit funny in the heat of QLD (35+ deg C in the shed with 99.997% humidity).

New z axis has been completed, tested and is working - pictures to follow shortly. New torch also added to make life easier. 160mm travel.

New laser is in and linked to a button in the GUI. Offset all worked in to zero off laser point. Offset also worked out for framing as part of QtPlasmaC.

Still haven't worked out spotting in Sheetcam, or how to se the tool from QtPlasmaC instead of Sheetcam. Must need to watch more video's.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

27 Dec 2021 05:19 #230042

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Attachments:

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

27 Dec 2021 05:25 - 27 Dec 2021 05:36 #230043

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

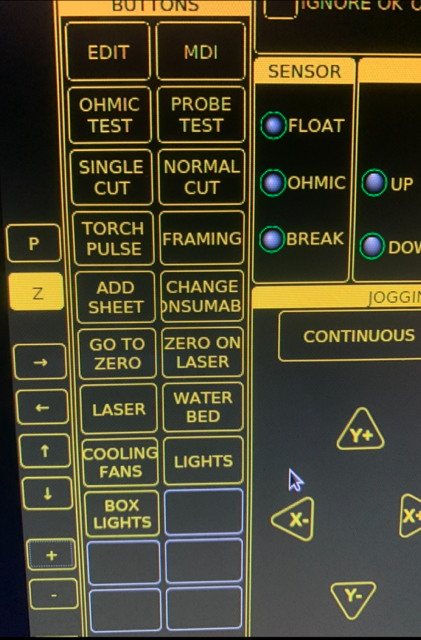

Here you can see some of the buttons that I have set. These just make my life easier in the way that I use my CNC.

Add Sheet - moves plasma to the back left to allow me to load a new sheet of material.

Change Consumable - Moves plasma to middle of bed right at the front to allow me to change consumables.

Go To Zero - Go to where the machine has been zeroed

Zero On Laser - zero on the laser pointer (still not working 100% of the time - if a job I loaded it doesn't work correctly)

Laser - Toggle the laser pointer on/off

Water Bed - timed button to fill the water table. ensuring the table doesn't overflow. and making sure I don't forget to turn the pump off.

Cooling Fans - turn the fans on in the control box.

Lights - Turn on lights around machine to help me see (not fully hooked up yet)

Box Lights - Turn on lights in control box (not fully hooked up yet)

Add Sheet - moves plasma to the back left to allow me to load a new sheet of material.

Change Consumable - Moves plasma to middle of bed right at the front to allow me to change consumables.

Go To Zero - Go to where the machine has been zeroed

Zero On Laser - zero on the laser pointer (still not working 100% of the time - if a job I loaded it doesn't work correctly)

Laser - Toggle the laser pointer on/off

Water Bed - timed button to fill the water table. ensuring the table doesn't overflow. and making sure I don't forget to turn the pump off.

Cooling Fans - turn the fans on in the control box.

Lights - Turn on lights around machine to help me see (not fully hooked up yet)

Box Lights - Turn on lights in control box (not fully hooked up yet)

Attachments:

Last edit: 27 Dec 2021 05:36 by RNJFAB.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11718

- Thank you received: 3966

27 Dec 2021 05:43 #230044

by rodw

You then did a seperate drill operation using that tool.

This required you to move the holes you wanted to spot to a new layer.

The default sheetcam post just needs a drill operation with any tool.

Thats about it.

In the gui, set the spotting threshold for 10 volts and start the delay at 0.5 seconds.

What should happen is plasmac will see the voltage threshold exceeded. Then it will wait for 0.5 seconds or whatever you set and turn the torch off before you get an ArcOK.

This should result in a finer spot than would normally be achieved.

The time delay is very machine dependent. If it does not work for you (eg torch does not turn on), try extending the time delay.

The reason why we wait until a voltage is seen is that different plasmas and relays have different lag times from the time the torch is activated so it allows for this.

Replied by rodw on topic Homemade, cheap, plasma CNC

The original plasmac post for sheetcam required a seperate tool defined called "Centre Spot"So post Christmas update 2021.

Still haven't worked out spotting in Sheetcam, or how to se the tool from QtPlasmaC instead of Sheetcam. Must need to watch more video's.

You then did a seperate drill operation using that tool.

This required you to move the holes you wanted to spot to a new layer.

The default sheetcam post just needs a drill operation with any tool.

Thats about it.

In the gui, set the spotting threshold for 10 volts and start the delay at 0.5 seconds.

What should happen is plasmac will see the voltage threshold exceeded. Then it will wait for 0.5 seconds or whatever you set and turn the torch off before you get an ArcOK.

This should result in a finer spot than would normally be achieved.

The time delay is very machine dependent. If it does not work for you (eg torch does not turn on), try extending the time delay.

The reason why we wait until a voltage is seen is that different plasmas and relays have different lag times from the time the torch is activated so it allows for this.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

Time to create page: 0.260 seconds