Homemade, cheap, plasma CNC

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

04 Jan 2022 11:52 #230747

by RNJFAB

so no updates for a while then?

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Phillc54,

This is the error I got updating.

That looks like your internat connection may have an issue.

The Buildbut has hung for several hours so there won't be much in the way of updates in any case.

buildbot.linuxcnc.org/buildbot/waterfall

so no updates for a while then?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

04 Jan 2022 12:03 #230749

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

It looks like it is up to date now.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

06 Jan 2022 11:04 #230936

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

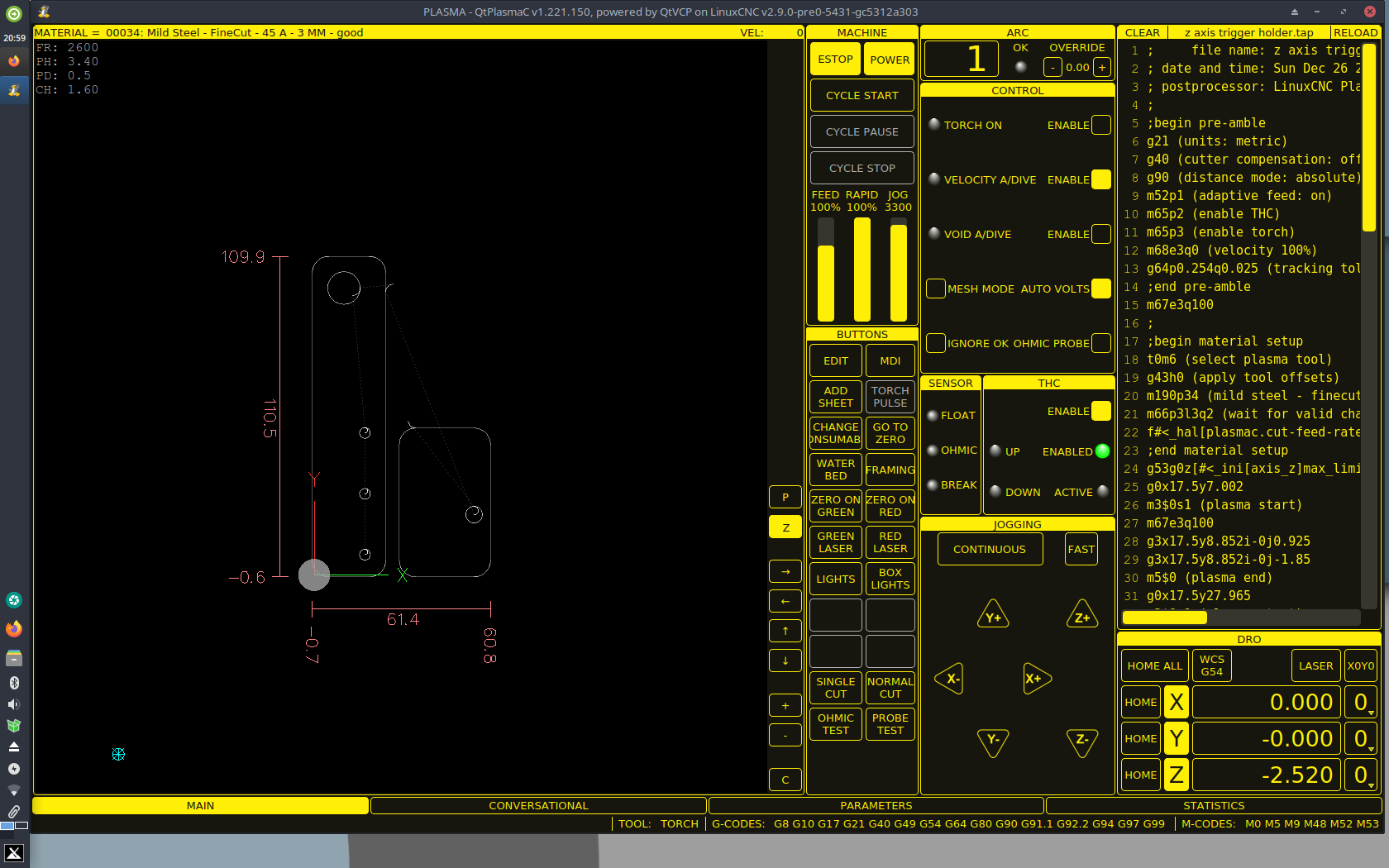

Tonight's problem, brought to you by the bloke in the shed who still has no idea.

When I first zero the machine off then open a cut file I get this.

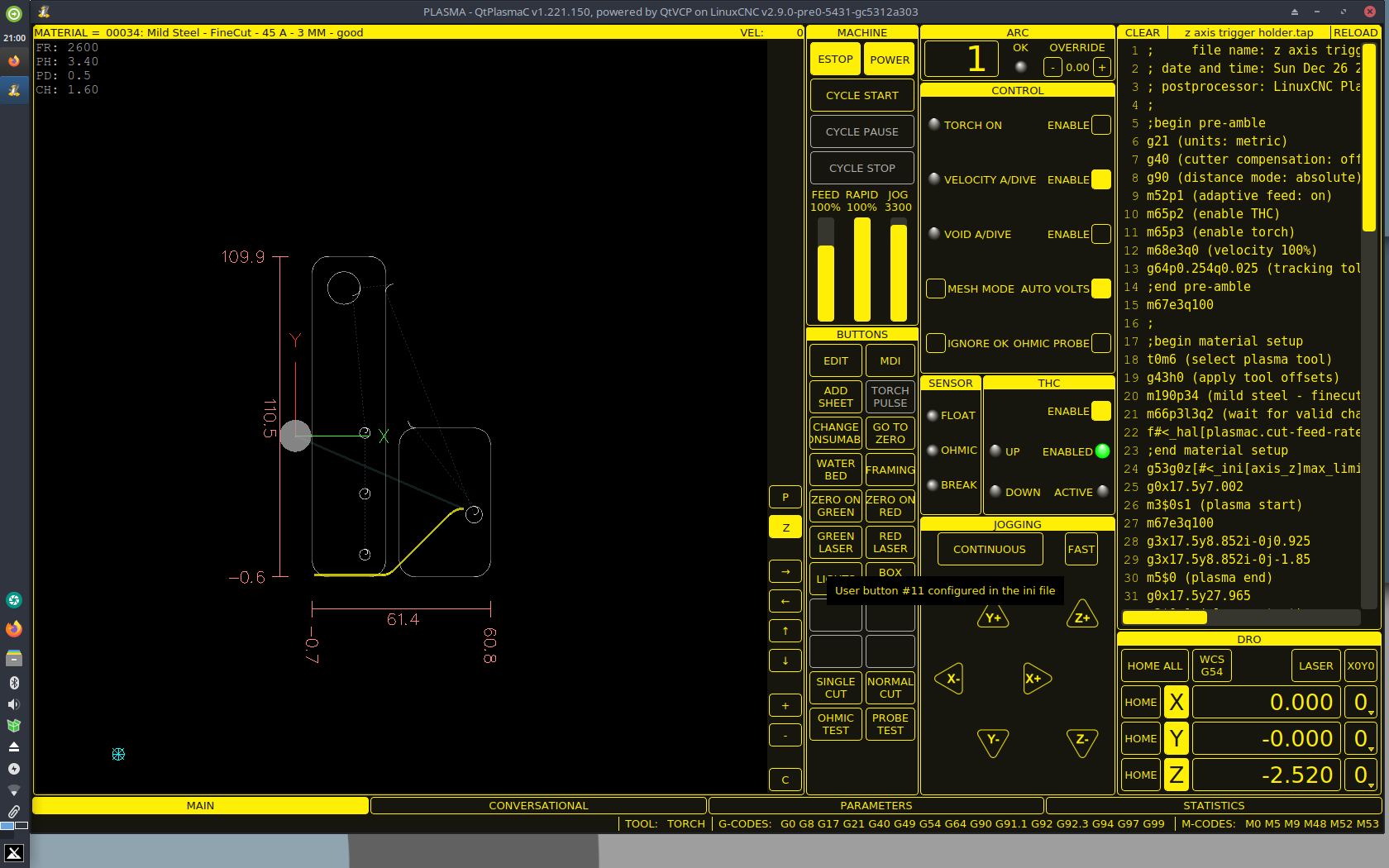

Then if I zero on the laser button (I created)

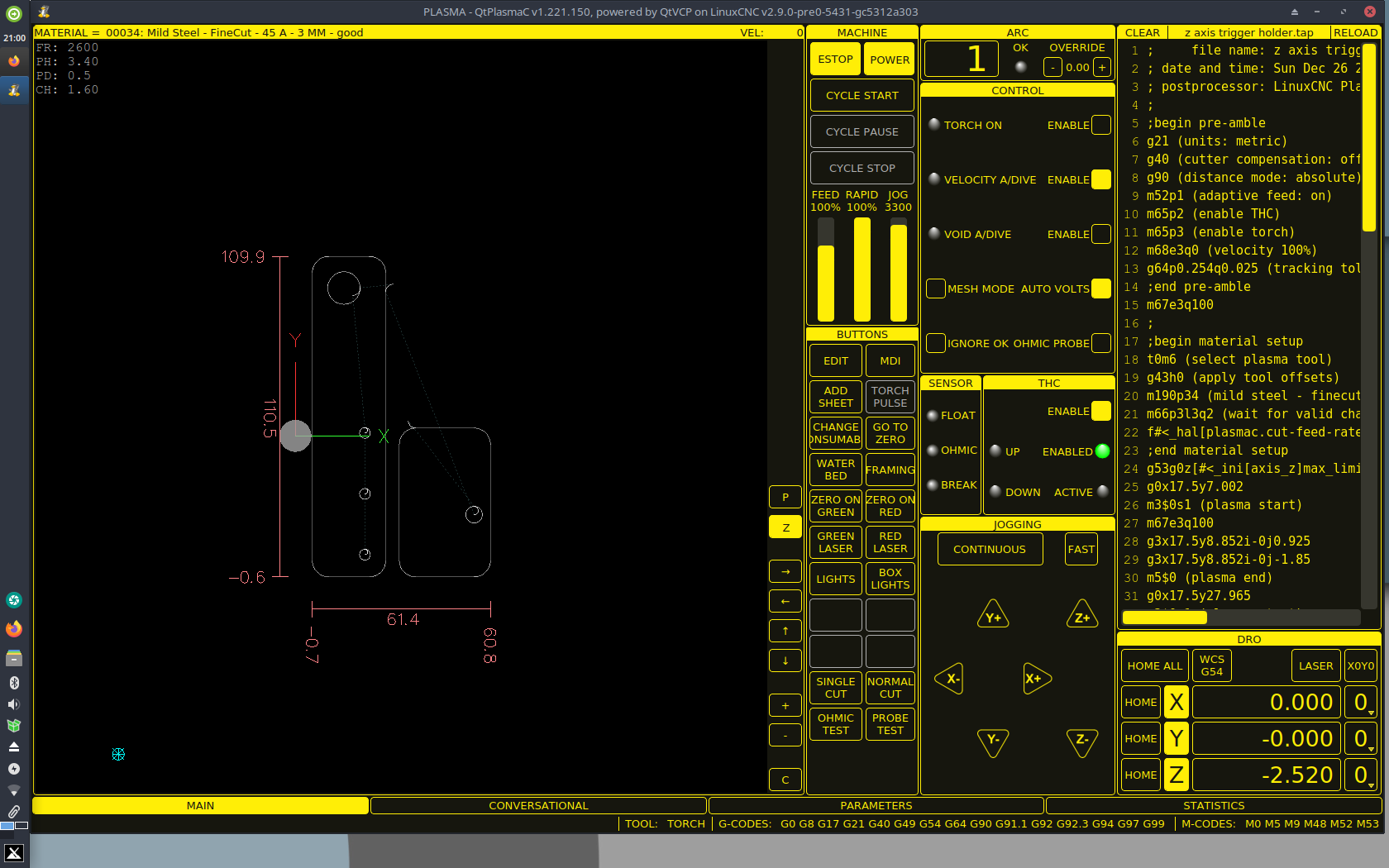

Now if i close the file and reload it (and any file after this) it will always setup like this

I have tried to re home and zero, however every time i load a file it will align like this.

What have I done????

When I first zero the machine off then open a cut file I get this.

Then if I zero on the laser button (I created)

Now if i close the file and reload it (and any file after this) it will always setup like this

I have tried to re home and zero, however every time i load a file it will align like this.

What have I done????

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jan 2022 11:11 #230937

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

What is your laser touchoff code?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11652

- Thank you received: 3921

06 Jan 2022 11:14 #230938

by rodw

Replied by rodw on topic Homemade, cheap, plasma CNC

Sometimes linuxcnc's persistent g code variables get corrupted, particularly when setting up a machine.

It has not happened to me for a long time.

You could try deleting metric_parameters.txt in your config folder.

It has not happened to me for a long time.

You could try deleting metric_parameters.txt in your config folder.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

06 Jan 2022 11:19 #230939

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

What is your laser touchoff code?

BUTTON_7_NAME = ZERO ON\GREEN

BUTTON_7_CODE = G92 X0 Y0 \ G0 X-69.533 Y9.724 F800 \ G92 X0 Y0

BUTTON_8_NAME = ZERO ON\RED

BUTTON_8_CODE = G92 X0 Y0 \ G0 X-58.064 Y25.190 F800 \ G92 X0 Y0

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

06 Jan 2022 11:33 #230942

by RNJFAB

On a different note,

Could you let me know how to generate a g code with out the material settings? I have all my tools saved into QtPlasmaC, however whatever tool i set when creating the g code in sheetcam, is the one it will always use.

Cheers

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Rod, I couldn't find this.Sometimes linuxcnc's persistent g code variables get corrupted, particularly when setting up a machine.

It has not happened to me for a long time.

You could try deleting metric_parameters.txt in your config folder.

On a different note,

Could you let me know how to generate a g code with out the material settings? I have all my tools saved into QtPlasmaC, however whatever tool i set when creating the g code in sheetcam, is the one it will always use.

Cheers

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

06 Jan 2022 22:11 #230991

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

Try this button code, it ought to do what you're after (at least it did in a sim here  ):

):

Without seeing your g-code, assuming you're using the sheetcam post, if you remove these two lines from your g-code, you should be able to run whatever material is selected in the drop down above the graphics preview window:

(note that the lines may not be exactly this, and that XXX is the material number)

That ought to do it, but be sure to report back!

BUTTON_7_NAME = ZERO ON\GREEN

BUTTON_7_CODE = G10 L20 P0 X69.533 Y-9.724 \ G0 X0 Y0

BUTTON_8_NAME = ZERO ON\RED

BUTTON_8_CODE = G10 L20 P0 X58.064 Y-25.190 \ G0 X0 Y0Without seeing your g-code, assuming you're using the sheetcam post, if you remove these two lines from your g-code, you should be able to run whatever material is selected in the drop down above the graphics preview window:

(note that the lines may not be exactly this, and that XXX is the material number)

m190pXXX

m66p3l3q2 That ought to do it, but be sure to report back!

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

06 Jan 2022 22:12 #230992

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

I meant to note that while you can run it with any speed, any kerf width compensation done in the CAM software will not be updated, and so the size of the cut material may/will vary by the size of the kerf.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jan 2022 22:47 #230993

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

That is how I run my table, I only do garden art stuff on a limited size of thicknesses so kerf width doesn't bother me at all.I meant to note that while you can run it with any speed, any kerf width compensation done in the CAM software will not be updated, and so the size of the cut material may/will vary by the size of the kerf.

Please Log in or Create an account to join the conversation.

Time to create page: 0.195 seconds