Homemade, cheap, plasma CNC

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

06 Jan 2022 22:58 #230994

by snowgoer540

Agreed, for most stuff it's easy to just set the kerf width to 0 and let er eat, then you can pick any material to cut it out of you please.

It is air plasma after all

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

That is how I run my table, I only do garden art stuff on a limited size of thicknesses so kerf width doesn't bother me at all.

Agreed, for most stuff it's easy to just set the kerf width to 0 and let er eat, then you can pick any material to cut it out of you please.

It is air plasma after all

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jan 2022 23:06 #230995

by phillc54

Replied by phillc54 on topic Homemade, cheap, plasma CNC

I did a cut with a finecut tip and then a cut with a general purpose tip on a mid range thickness material and averaged the kerf width and that is my SheetCAM tool zero kerfwidth. Tool zero is the only tool I need in SheetCAM then.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

06 Jan 2022 23:07 #230996

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

That's a much better idea than just setting the KW to 0.00. I like it.I did a cut with a finecut tip and then a cut with a general purpose tip on a mid range thickness material and averaged the kerf width and that is my SheetCAM tool zero kerfwidth. Tool zero is the only tool I need in SheetCAM then.

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

07 Jan 2022 01:57 - 07 Jan 2022 02:29 #231005

by RNJFAB

Thanks Snow.

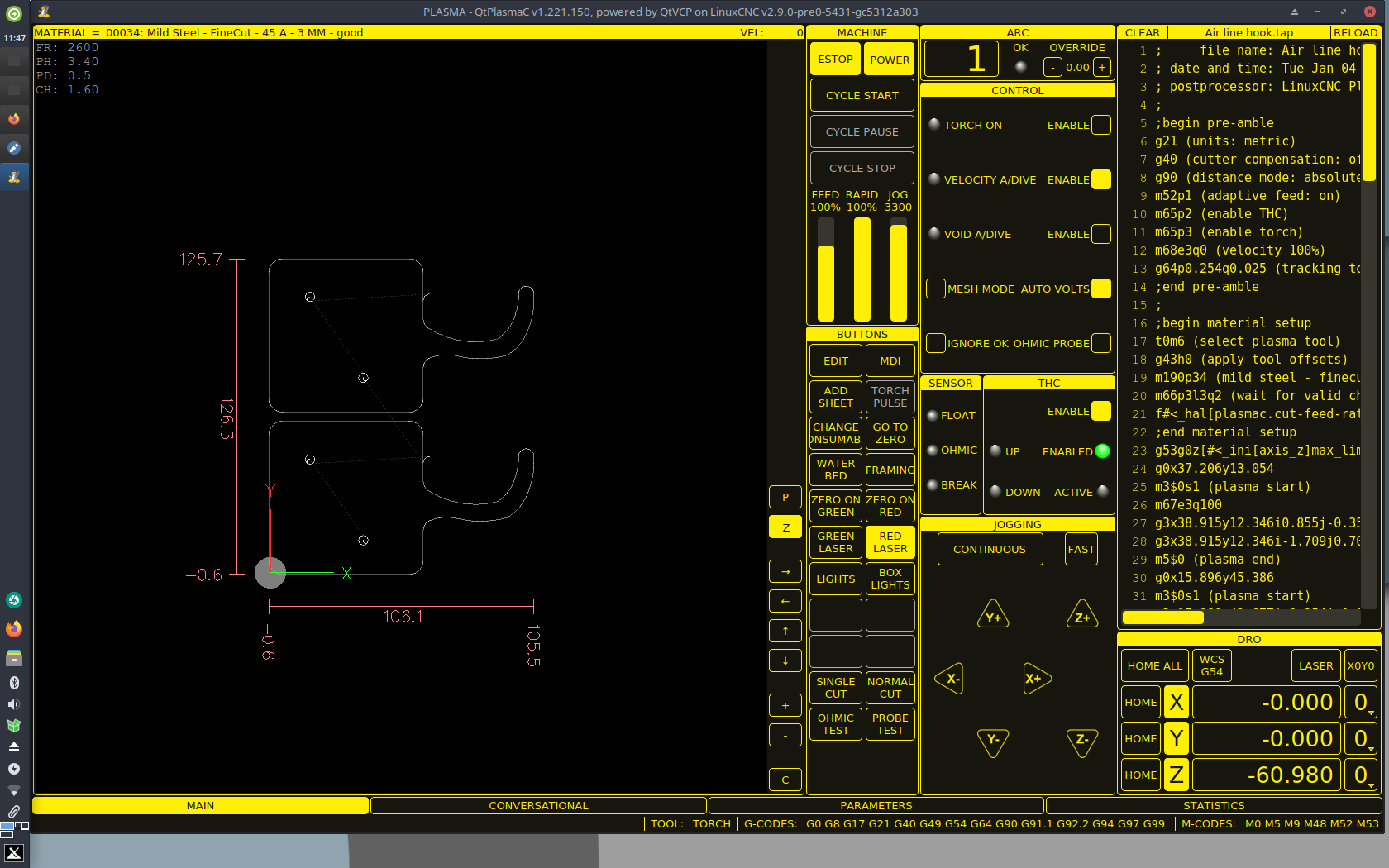

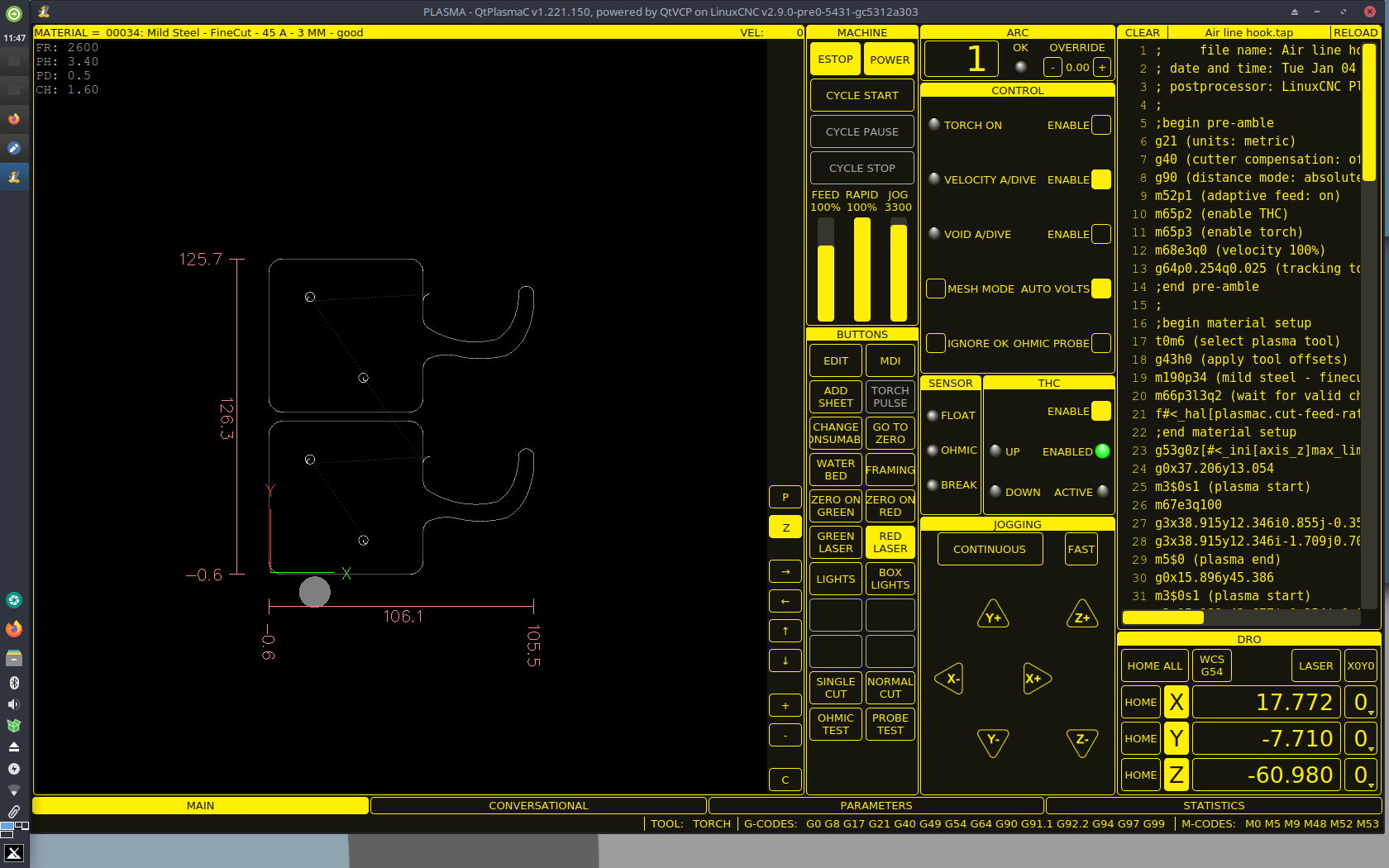

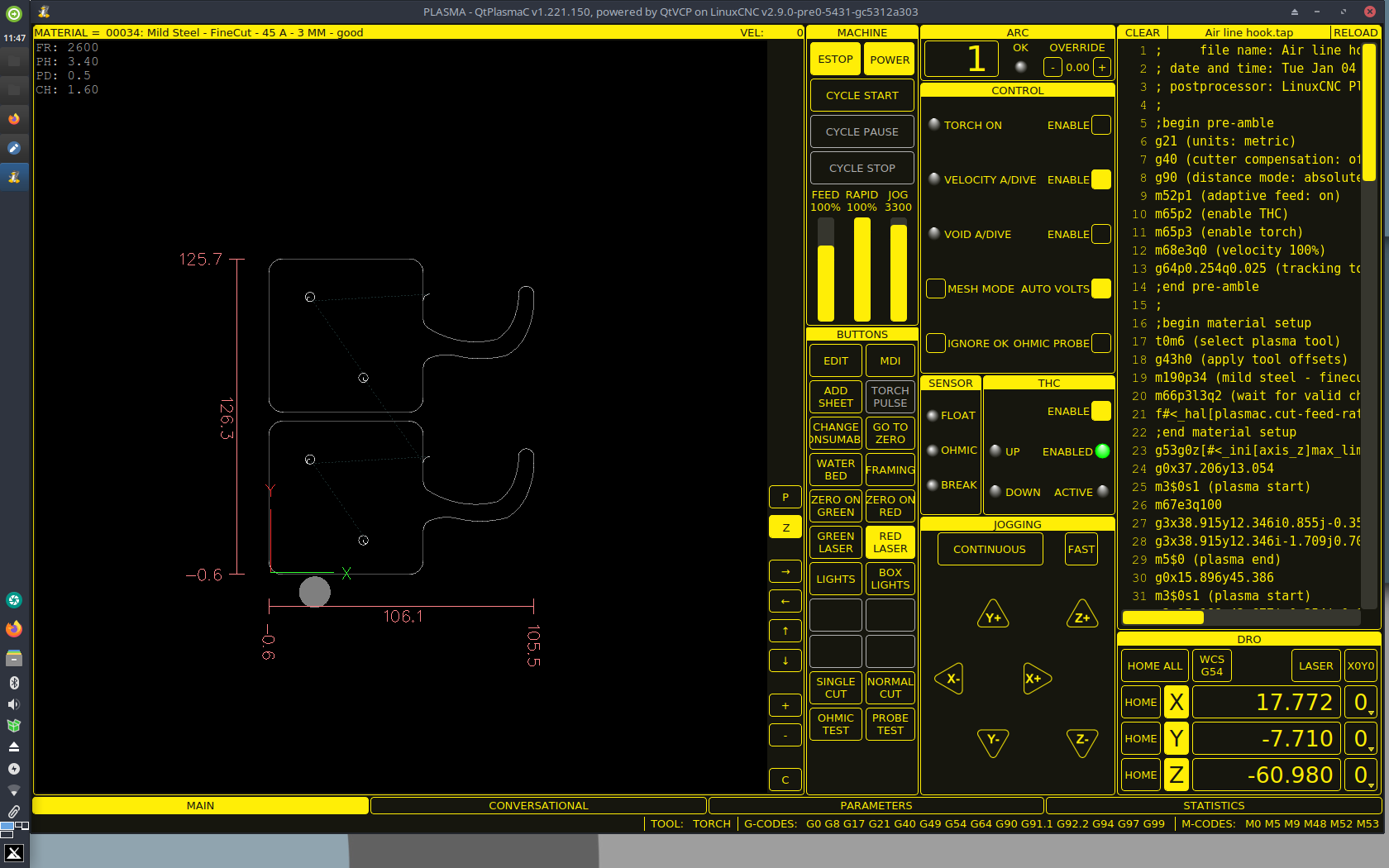

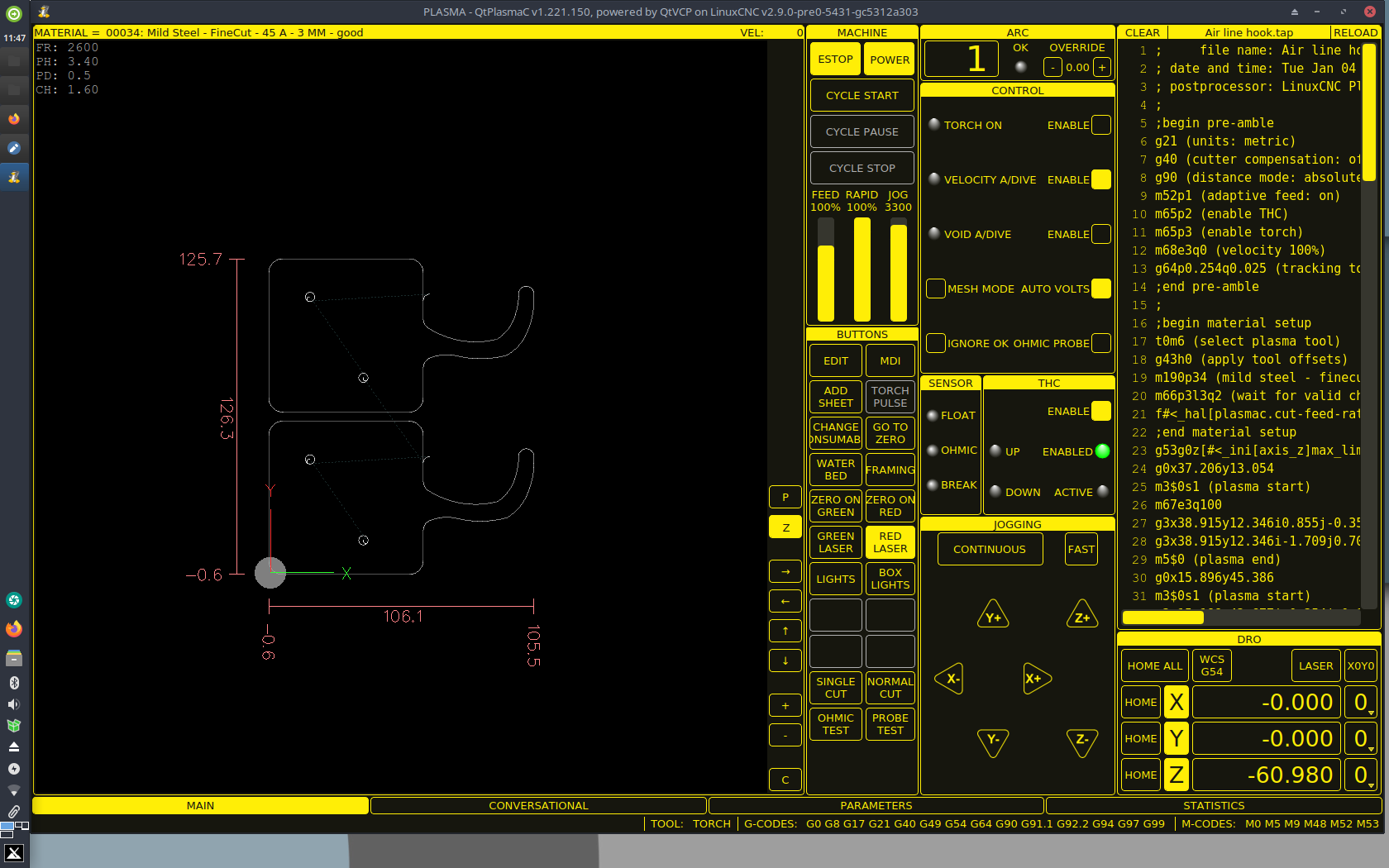

[attachment=42735"]zeroonlasersometimes.png[/attachment]

Feedback = works great.... most of the time. Initially it worked, then i loaded another file and re-zeroed and this happened.

Note the torch didn't go all the way to zero.

However, I was able to push my 'GO TO ZERO' button and it moved to the correct spot.

Yes, using sheetcam. I didn't realise that you were editing each code after setting it up. I have done this and it works a treat. Ovbiously it wont work for everthing, however it will be handy for some parts I just cut from scrap, now i can use whatever material I have. Cheers

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Try this button code, it ought to do what you're after (at least it did in a sim here

):

BUTTON_7_NAME = ZERO ON\GREEN BUTTON_7_CODE = G10 L20 P0 X69.533 Y-9.724 \ G0 X0 Y0 BUTTON_8_NAME = ZERO ON\RED BUTTON_8_CODE = G10 L20 P0 X58.064 Y-25.190 \ G0 X0 Y0

Without seeing your g-code, assuming you're using the sheetcam post, if you remove these two lines from your g-code, you should be able to run whatever material is selected in the drop down above the graphics preview window:

(note that the lines may not be exactly this, and that XXX is the material number)

m190pXXX m66p3l3q2

That ought to do it, but be sure to report back!

Thanks Snow.

[attachment=42735"]zeroonlasersometimes.png[/attachment]

Feedback = works great.... most of the time. Initially it worked, then i loaded another file and re-zeroed and this happened.

Note the torch didn't go all the way to zero.

However, I was able to push my 'GO TO ZERO' button and it moved to the correct spot.

Yes, using sheetcam. I didn't realise that you were editing each code after setting it up. I have done this and it works a treat. Ovbiously it wont work for everthing, however it will be handy for some parts I just cut from scrap, now i can use whatever material I have. Cheers

Attachments:

Last edit: 07 Jan 2022 02:29 by tommylight. Reason: Trying to fix the post

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

07 Jan 2022 02:02 #231006

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

The editor is abhorrent here. But The pics

did work at one point so I saw what you mean.

may be an issue in our end, I/we will get back to you.

I don’t know what you mean that you didn’t know I was editing each code after setting it up?

but you could edit the post processor to not include the two lines if you’d like.

my work flow is different, but there are many ways to skin the proverbial cat

did work at one point so I saw what you mean.

may be an issue in our end, I/we will get back to you.

I don’t know what you mean that you didn’t know I was editing each code after setting it up?

but you could edit the post processor to not include the two lines if you’d like.

my work flow is different, but there are many ways to skin the proverbial cat

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

07 Jan 2022 02:15 #231007

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Attachments:

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

07 Jan 2022 02:24 #231009

by RNJFAB

I think the editing was me. sorry.

With the G Code, I thought you may have had it set in the PP. However I didn't realise about the kerf compensation that would be affected. It's all good, by editing the G Codes I need to in QtPlasmac I can now cut the same bits from a range of materials.

I am still tweeking settings as I go so there will still be a lot of adjusting for my materials in sheetcam. Currently working through hole cutting, for 5mm - I draw a 13mm hole, but cut a 12.4mm hole. For 3mm - I draw a 11mm hole, but cut a 10.4mm hole. So still a little bit of work to do with my kerf with and probably cut height. Or about 1/32 out at the moment.

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thank You.The editor is abhorrent here. But The pics

did work at one point so I saw what you mean.

may be an issue in our end, I/we will get back to you.

I don’t know what you mean that you didn’t know I was editing each code after setting it up?

but you could edit the post processor to not include the two lines if you’d like.

my work flow is different, but there are many ways to skin the proverbial cat

I think the editing was me. sorry.

With the G Code, I thought you may have had it set in the PP. However I didn't realise about the kerf compensation that would be affected. It's all good, by editing the G Codes I need to in QtPlasmac I can now cut the same bits from a range of materials.

I am still tweeking settings as I go so there will still be a lot of adjusting for my materials in sheetcam. Currently working through hole cutting, for 5mm - I draw a 13mm hole, but cut a 12.4mm hole. For 3mm - I draw a 11mm hole, but cut a 10.4mm hole. So still a little bit of work to do with my kerf with and probably cut height. Or about 1/32 out at the moment.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21212

- Thank you received: 7245

07 Jan 2022 02:25 - 07 Jan 2022 02:31 #231010

by tommylight

Replied by tommylight on topic Homemade, cheap, plasma CNC

i think i fixed the above post by RNJFAB, still one picture does not show.

Last edit: 07 Jan 2022 02:31 by tommylight. Reason: Trying to fix the post by RNJFAB

The following user(s) said Thank You: snowgoer540, RNJFAB

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

07 Jan 2022 14:38 #231029

by snowgoer540

Replied by snowgoer540 on topic Homemade, cheap, plasma CNC

I do see in the code what causes your G0 X0 Y0 to not finish its move, a fix will be upcoming. I'll try to remember to drop a line here to let you know when to update.

The following user(s) said Thank You: RNJFAB

Please Log in or Create an account to join the conversation.

- RNJFAB

- Offline

- Elite Member

-

Less

More

- Posts: 244

- Thank you received: 54

07 Jan 2022 20:52 #231058

by RNJFAB

Replied by RNJFAB on topic Homemade, cheap, plasma CNC

Thanks Snow,

I kinda feel like the problem child at the moment. Everything I do seams to break linux, like I’m not using it right.

you guys have done an amazing job to create such an incredible program! I only wish I had have found it sooner.

I kinda feel like the problem child at the moment. Everything I do seams to break linux, like I’m not using it right.

you guys have done an amazing job to create such an incredible program! I only wish I had have found it sooner.

I do see in the code what causes your G0 X0 Y0 to not finish its move, a fix will be upcoming. I'll try to remember to drop a line here to let you know when to update.

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

Time to create page: 0.184 seconds