- Configuring LinuxCNC

- Advanced Configuration

- Servo Wiring and Tuning detailed How To example Mesa 7i77.

Servo Wiring and Tuning detailed How To example Mesa 7i77.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

01 Sep 2019 22:05 #143814

by Type_Zero_Design

Replied by Type_Zero_Design on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

01 Sep 2019 22:43 #143817

by andypugh

Replied by andypugh on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

I have no idea who I am talking to, or about what any more.

Please Log in or Create an account to join the conversation.

- Type_Zero_Design

- Offline

- Premium Member

-

Less

More

- Posts: 133

- Thank you received: 7

02 Sep 2019 03:26 #143853

by Type_Zero_Design

Replied by Type_Zero_Design on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Andy,

Sorry for the confusion, for clarity and not to muddy the waters anymore I have made my own post to continue my tuning endevor.

forum.linuxcnc.org/10-advanced-configura...ther-tc-225-retrofit

Sorry for the confusion, for clarity and not to muddy the waters anymore I have made my own post to continue my tuning endevor.

forum.linuxcnc.org/10-advanced-configura...ther-tc-225-retrofit

Please Log in or Create an account to join the conversation.

- HueyHQ

-

- Offline

- Premium Member

-

Less

More

- Posts: 90

- Thank you received: 24

09 Oct 2019 19:50 #147592

by HueyHQ

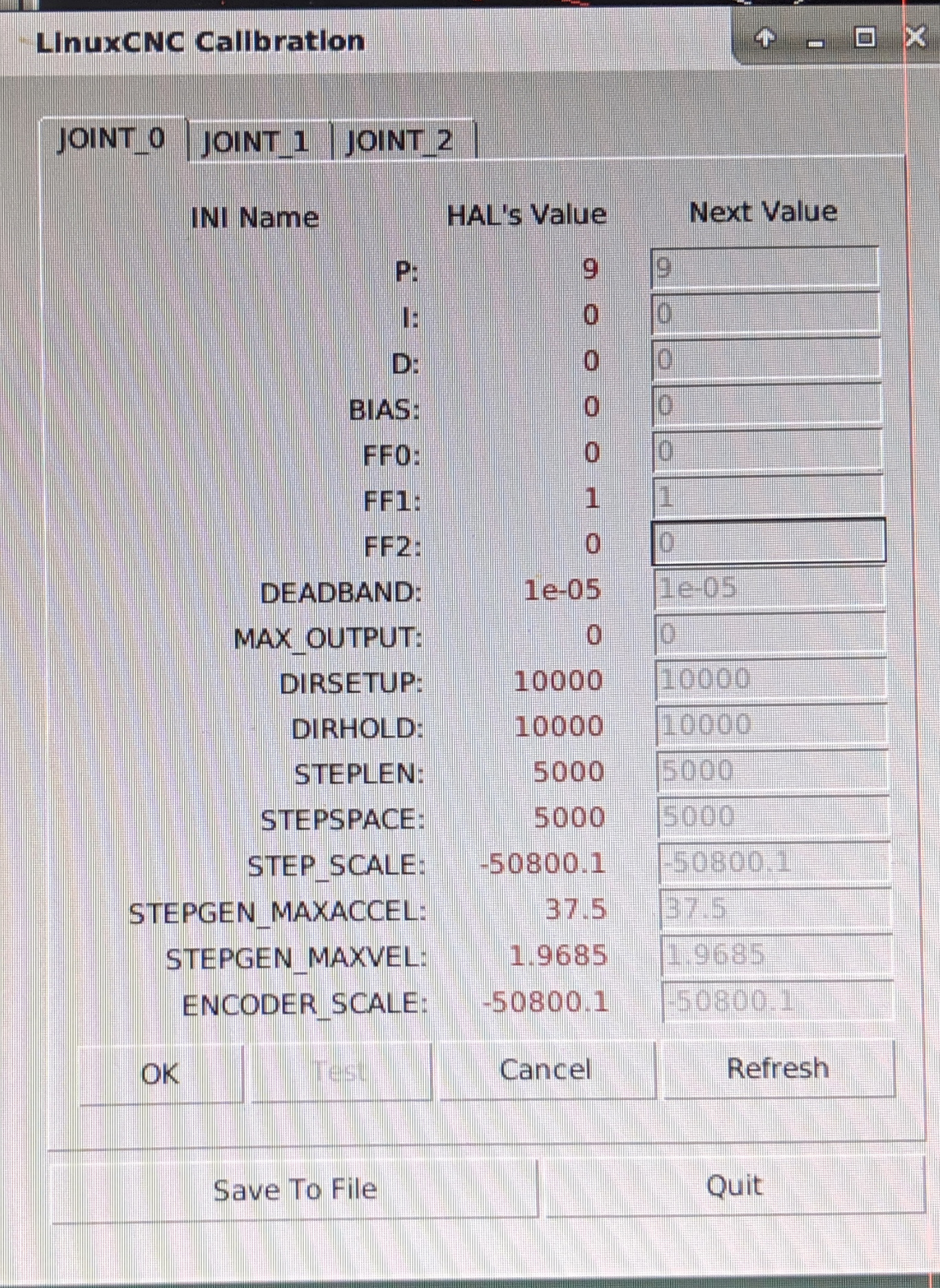

I was never really satisfied with the tuning, so I re-visited it yesterday.

What I found is, if I reduce to P = 0.1, the movements are now as smooth as silk, leading me to believe that the PID is possibly done in the servo amps? To those who know more about this than I do, does this sound right? (I have attached the driver manual in case that sheds any light, for anyone who is THAT interested!)

Setting P = 0 causes a following error, so what would be the lowest I should set it to, or is 0.1 OK?

I've also tuned FF1 = 0.00727 and FF2 = 0.00001 to get a reasonably flat (albeit very noisy) halscope'd f-error.

Replied by HueyHQ on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Recently, I found my X-axis was oscillating really badly when routing out complex shapes. Straight X and Y cuts were fine but diagonal was the worst, unless I really slowed down the feed.On my retrofit, I had a lot of trouble tuning following all the advice I had found because I had entered an arbitrary value for the acceleration parameter (way too high). It wasn't until I bumped it down to something more in line with what I had seen in others config files, that I could even start to tune my servos. My machine works fine now, but doesn't move as fast as it did before the retrofit, so I could go back and refine the tuning with higher accel params.!

I was never really satisfied with the tuning, so I re-visited it yesterday.

What I found is, if I reduce to P = 0.1, the movements are now as smooth as silk, leading me to believe that the PID is possibly done in the servo amps? To those who know more about this than I do, does this sound right? (I have attached the driver manual in case that sheds any light, for anyone who is THAT interested!)

Setting P = 0 causes a following error, so what would be the lowest I should set it to, or is 0.1 OK?

I've also tuned FF1 = 0.00727 and FF2 = 0.00001 to get a reasonably flat (albeit very noisy) halscope'd f-error.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7246

09 Oct 2019 20:21 #147594

by tommylight

Replied by tommylight on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

If it works at 0.1, leave it at that.

The following user(s) said Thank You: HueyHQ

Please Log in or Create an account to join the conversation.

- viesturs.lacis

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 3

14 Nov 2020 09:38 #189308

by viesturs.lacis

Replied by viesturs.lacis on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

I am trying to tune servo loop based on this tutorial. What I see during the process is that as I jog the motor and release the arrow button, motor should decelerate and stop. At the moment of key release there is a sudden drop in velocity, which then resumes and after that the motor stops, see attached picture. Is that related to PID tuning or is that a lag in GUI or something similar?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7246

14 Nov 2020 10:11 #189314

by tommylight

Replied by tommylight on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Are you tuning the old Yaskawa drives with encoder feedback from the drives to 7i77? Those should be very easy to tune, just set the P value till the motors start to vibrate then lower it a bit so there is no or very litle vibration, then add FF1 a bit. Leave everything else at 0 excpet the deadband.

That should be it, it literarly took 5 minutes to tune all 3 axis last time i used them.

Make sure you have the drive enable wired to LinuxCNC and working correctly before everything else.

That should be it, it literarly took 5 minutes to tune all 3 axis last time i used them.

Make sure you have the drive enable wired to LinuxCNC and working correctly before everything else.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

14 Nov 2020 11:57 #189320

by bevins

I feel like that all the time.....Time to retire I think.

Replied by bevins on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

I have no idea who I am talking to, or about what any more.

I feel like that all the time.....Time to retire I think.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- viesturs.lacis

- Offline

- Premium Member

-

Less

More

- Posts: 104

- Thank you received: 3

14 Nov 2020 13:26 #189330

by viesturs.lacis

I have 7i48 for servo control, but other than that - yes, it was pretty easy to tune motor for X axis. The table is too short to safely jog it at 45m/min, while looking at PC screen... Now I have to sort out missing encoder signal from Y motor.

BTW can you share some suggestions for controlling the VFD? At least some hints about wiring and pinout on VFD control signal terminal?

Replied by viesturs.lacis on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Are you tuning the old Yaskawa drives with encoder feedback from the drives to 7i77? Those should be very easy to tune, just set the P value till the motors start to vibrate then lower it a bit so there is no or very litle vibration, then add FF1 a bit. Leave everything else at 0 excpet the deadband.

That should be it, it literarly took 5 minutes to tune all 3 axis last time i used them.

Make sure you have the drive enable wired to LinuxCNC and working correctly before everything else.

I have 7i48 for servo control, but other than that - yes, it was pretty easy to tune motor for X axis. The table is too short to safely jog it at 45m/min, while looking at PC screen... Now I have to sort out missing encoder signal from Y motor.

BTW can you share some suggestions for controlling the VFD? At least some hints about wiring and pinout on VFD control signal terminal?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21213

- Thank you received: 7246

14 Nov 2020 18:23 #189358

by tommylight

Replied by tommylight on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Vhat VFD? Any schematics ?BTW can you share some suggestions for controlling the VFD? At least some hints about wiring and pinout on VFD control signal terminal?

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- Servo Wiring and Tuning detailed How To example Mesa 7i77.

Time to create page: 0.138 seconds