Retrofitting a 1986 Maho 400E

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

22 Nov 2019 12:37 #150904

by db1981

Replied by db1981 on topic Retrofitting a 1986 Maho MH400E

Hello Chris, Brad,

i watched the video from the TNC Boot.

Has this been filmed only with power to the TNC and the screen connected ?

If not disconnect everything except power and watch the behaviour.

You have got "Stromunterbrechung" on the screen and Numbers in the DROs, so i dont think that there is an bug with the processor or the analog board.

There must be an problem with the internal power supply.

Are you able to monitor the different voltags with an oscilloscop between startup?

i watched the video from the TNC Boot.

Has this been filmed only with power to the TNC and the screen connected ?

If not disconnect everything except power and watch the behaviour.

You have got "Stromunterbrechung" on the screen and Numbers in the DROs, so i dont think that there is an bug with the processor or the analog board.

There must be an problem with the internal power supply.

Are you able to monitor the different voltags with an oscilloscop between startup?

The following user(s) said Thank You: chris mcm

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 562

22 Nov 2019 16:40 #150946

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Anders,

Thanks for joining in the conversation. Your thread on PR.Mach was one of the big confidence builder which help me take the plunge and buy 1.2 ton of non-functional machine (every one I knew thought I was nuts.).

I'm looking forward to seeing your progress on the machine. Remember in a complicate project, the key is put you hands on it every day. Even if just for a few minutes sitting looking at it and thinking about the next step.

Mark

Thanks for joining in the conversation. Your thread on PR.Mach was one of the big confidence builder which help me take the plunge and buy 1.2 ton of non-functional machine (every one I knew thought I was nuts.).

I'm looking forward to seeing your progress on the machine. Remember in a complicate project, the key is put you hands on it every day. Even if just for a few minutes sitting looking at it and thinking about the next step.

Mark

The following user(s) said Thank You: chris mcm

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

22 Nov 2019 17:08 #150950

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

I'd like to chime in and also cheer Anders on. As Mark said, you do need consistency because difficult things tend to make us all abandon them if they're optional. I copmleted my retrofit under pressure so that took care of the motivation, but it was certainly no fun. However, I'm pretty sure that even if the programming for the ATC is complex, you can still build up the module using small steps. There will be no ready-made configs that will take care of everything, but once you understand how a sample module works, it's going to be much easier to copy and modify parts of it and string your own program together. There's no "stack overflow" way around it in LinuxCNC - you will have to understand what the code is and does to make your machine work the way you want it to. OTOH, it's also not necessary to learn everything from scratch, you can jump to sections in the documentation that are relevant to your needs. At least that's how it worked for me. Good luck!

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

01 Dec 2019 00:06 #151620

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

For those ho need motivation to finish their mahos, just watch how is working with his maho.

The following user(s) said Thank You: RotarySMP, tommylight, chris mcm

Please Log in or Create an account to join the conversation.

- chris mcm

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 1

08 Dec 2019 08:11 #152318

by chris mcm

Replied by chris mcm on topic Retrofitting a 1986 Maho MH400E

Hello all

I have not written for a while. Greg has taken away the Indramat to replace the old capacitors. He also has taken the T.N.C unit and the screen away for a bench check to try and find the intermittent fault. I have purchased 3 Heidenhain EXE 602 D/5-4.to keep the retrofit going.

The machine can perform all its mechanical functions. I would like to have the DRO working with an independent system (hopefully) using 3 Heidenhain EXE 602 D/5-4. with the existing scales. I will report progress as it happens. It may take time as it is summer in NZ and holiday time. Greg will be busy so who knows. Cheers Chris

I have not written for a while. Greg has taken away the Indramat to replace the old capacitors. He also has taken the T.N.C unit and the screen away for a bench check to try and find the intermittent fault. I have purchased 3 Heidenhain EXE 602 D/5-4.to keep the retrofit going.

The machine can perform all its mechanical functions. I would like to have the DRO working with an independent system (hopefully) using 3 Heidenhain EXE 602 D/5-4. with the existing scales. I will report progress as it happens. It may take time as it is summer in NZ and holiday time. Greg will be busy so who knows. Cheers Chris

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

09 Dec 2019 12:02 #152356

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Hey Mark,

Is this the type of EXE box you bought as a replacement for one of your axes?

www.ebay.de/itm/Heidenhain-EXE-602-D-5-F...8:g:p58AAOSwFINd3RpV

Can I plug this (or something like it) into my Mesa board and wire the Z/Y axis scale through it, while leaving the X and Y on the original 3-axis board?

I'm wondering if replacing the EXE on the Z axis would fix my problem of the signal getting lost sometimes and this looks like a cheap-ish potential fix (I posted a link to the most expensive box listed atm because it looks like new old stock).

I've already tried cleaning the scale and replacing the reader head and the same problem of unreliable operation in the Z axis persisted. Maybe the old EXE board is failing, or generating a weak signal which somtimes isn't picked up by the controller. I used to have an issue where the signal wouldn't be read at startup occassionally, but it eventually worsened to the point that sometimes it's lost while the machine is working. Which is why I haven't worked on it in auto for a long time, using it sparingly to drill holes or perform simple manual operations. I'm afraid of the signal going out and crashing the spindle into something before a following error triggers the E-Stop.

Marcin

Is this the type of EXE box you bought as a replacement for one of your axes?

www.ebay.de/itm/Heidenhain-EXE-602-D-5-F...8:g:p58AAOSwFINd3RpV

Can I plug this (or something like it) into my Mesa board and wire the Z/Y axis scale through it, while leaving the X and Y on the original 3-axis board?

I'm wondering if replacing the EXE on the Z axis would fix my problem of the signal getting lost sometimes and this looks like a cheap-ish potential fix (I posted a link to the most expensive box listed atm because it looks like new old stock).

I've already tried cleaning the scale and replacing the reader head and the same problem of unreliable operation in the Z axis persisted. Maybe the old EXE board is failing, or generating a weak signal which somtimes isn't picked up by the controller. I used to have an issue where the signal wouldn't be read at startup occassionally, but it eventually worsened to the point that sometimes it's lost while the machine is working. Which is why I haven't worked on it in auto for a long time, using it sparingly to drill holes or perform simple manual operations. I'm afraid of the signal going out and crashing the spindle into something before a following error triggers the E-Stop.

Marcin

Please Log in or Create an account to join the conversation.

- akb1212

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 12

09 Dec 2019 13:11 #152357

by akb1212

Replied by akb1212 on topic Retrofitting a 1986 Maho MH400E

Hi Marcin,

Splitting encoder signals is possible. But needs to be done propperly (after it has been converted to quadrature!). And splitting the signals from the scales is NOT possible without doing propper perparation, as is therefore not recommended. The signals comming out of them are very low current signals (22uA), and needs to be terminated correctly in to ONE reader, and can not be splitt by simle means.

It's is a lot easier to split the quadrature signals coming out of the EXE-boxes. But I recommend using an active splitter, like the one Mesa is offering. Although it wold probably work without as well, for testing anyway..... balanced wiring will make this more reliable.

An easy way to confirm if the error is in the converter you are using now is to switch converters between channels (switsh inputs AND outputs!). Then verify if the error moves with the converter og stays at the same axis. If it moves with the converter you can assume it's faulty and needs to be replaced, and a new EXE-box will fix your problem.

If not you need to do something with the read head or similar, and getting a new EXE-box wil not fix your problem.

The boxes you are linking to is similar to the ones I have, and should work.

Anders

Splitting encoder signals is possible. But needs to be done propperly (after it has been converted to quadrature!). And splitting the signals from the scales is NOT possible without doing propper perparation, as is therefore not recommended. The signals comming out of them are very low current signals (22uA), and needs to be terminated correctly in to ONE reader, and can not be splitt by simle means.

It's is a lot easier to split the quadrature signals coming out of the EXE-boxes. But I recommend using an active splitter, like the one Mesa is offering. Although it wold probably work without as well, for testing anyway..... balanced wiring will make this more reliable.

An easy way to confirm if the error is in the converter you are using now is to switch converters between channels (switsh inputs AND outputs!). Then verify if the error moves with the converter og stays at the same axis. If it moves with the converter you can assume it's faulty and needs to be replaced, and a new EXE-box will fix your problem.

If not you need to do something with the read head or similar, and getting a new EXE-box wil not fix your problem.

The boxes you are linking to is similar to the ones I have, and should work.

Anders

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

09 Dec 2019 14:32 #152361

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Thanks for the quick reply Anders!

I'm going to try swapping the inputs and outputs this week to see if I can replicate the signal loss on a different axis.

I guess before buying an EXE box it'd be a good idea to go through the Heidenhain docs on their website and see if the components will be compatible with each other.

There are also original 3-axis EXE boards available on ebay.de but they're somehow more expensive per module than buying three separate boxes for each axis. That's a shame because that would be a very easy replacement.

I'm going to try swapping the inputs and outputs this week to see if I can replicate the signal loss on a different axis.

I guess before buying an EXE box it'd be a good idea to go through the Heidenhain docs on their website and see if the components will be compatible with each other.

There are also original 3-axis EXE boards available on ebay.de but they're somehow more expensive per module than buying three separate boxes for each axis. That's a shame because that would be a very easy replacement.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 562

09 Dec 2019 15:20 - 09 Dec 2019 15:26 #152364

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

The single channel EXE's offer a number of advantages.

- They are built like brick outhouses. The housing must be indestructible.

- They only need 5V. Whereas the 3 EXE board needs both 5v and 12vdc supplies.

- 602 EXE's (at lest the two I have) have the differential signals wired in the output cable, so you should have better noise resistance. The three EXE only brings out the single end signals.

- They are cheap and easy to replace.

-They all seem to have the M23 connector for the signal input. You see a variety of output cables from Heidenhain. Heidenhain wiring is fantastic. Double shielded with very robust conduits.

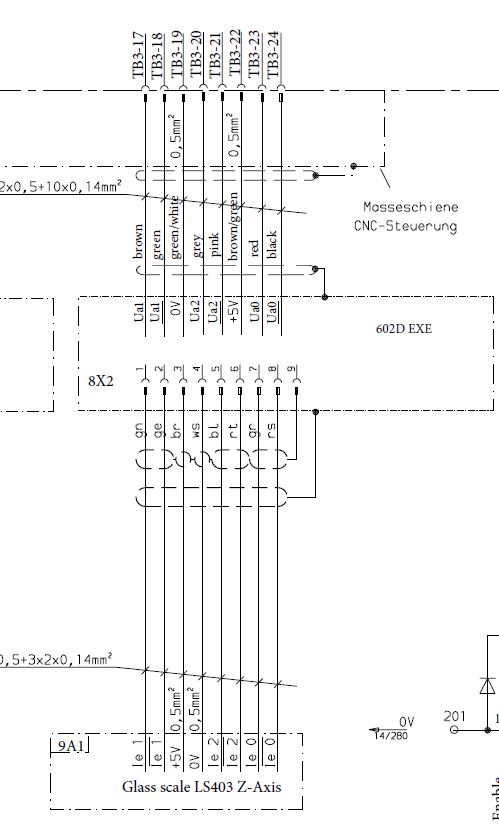

- Heidenhain seems to use consistent wiring colors across the decades and products. Here is my wiring on my 602D/1-5

Heidenhain seems to offer versions with either 5µm resolution, or with 1µm resolution. I ended up with one of each. Doesn't really matter for my level of machining. I can snap off a carbide end mill on the vise just as easily with either system. You just need to edit the INI forinstead of 1000 for that axis.

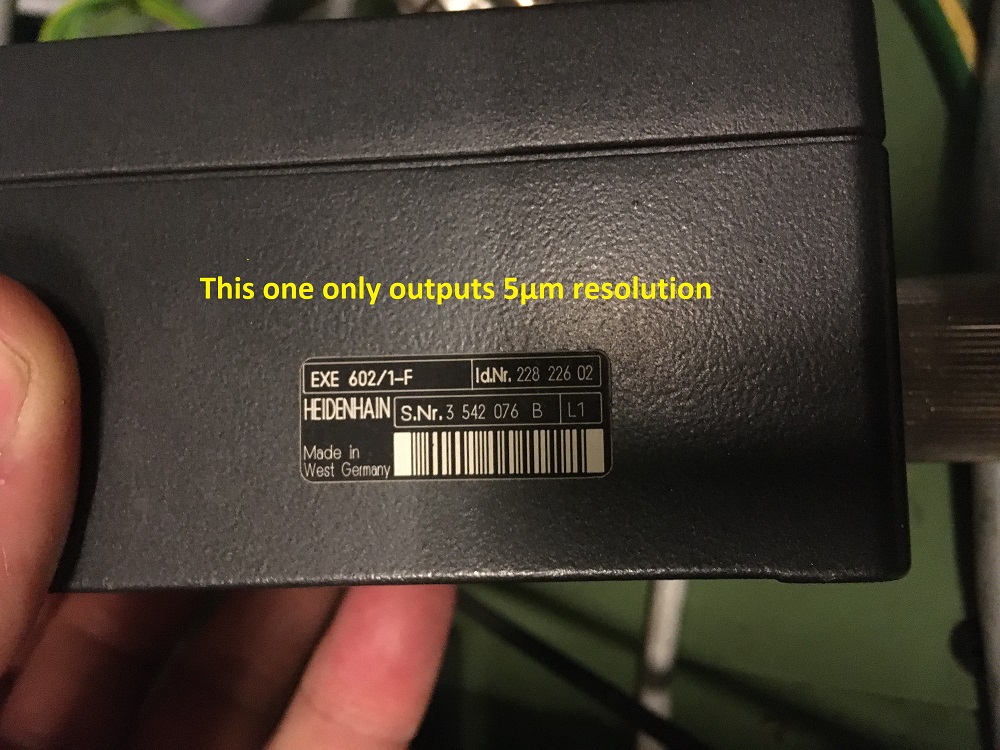

The 602/1-F has only 5µm resolution

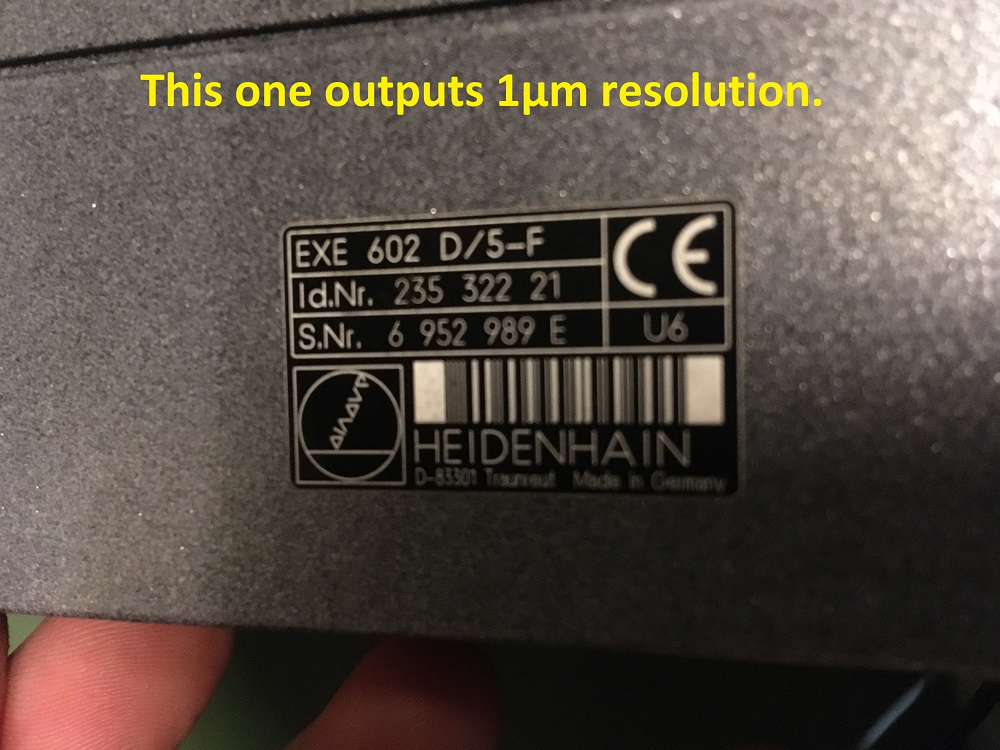

whereas the 602D/5-F ouputs 1µm resolution. I wonder whether the D means it has the extra interpolation?

I only paid about €50 for each. Both work perfectly. Some have ouput connectors and some have cables. I went for ones with output cables and hacked whatever connectors were on the ends and wired them straight in the MESA 7i77. I understand the appeal of finding three with the same output terminal connectors and making a break out connector for the 7i77 so they can be plugged in

Mark

- They are built like brick outhouses. The housing must be indestructible.

- They only need 5V. Whereas the 3 EXE board needs both 5v and 12vdc supplies.

- 602 EXE's (at lest the two I have) have the differential signals wired in the output cable, so you should have better noise resistance. The three EXE only brings out the single end signals.

- They are cheap and easy to replace.

-They all seem to have the M23 connector for the signal input. You see a variety of output cables from Heidenhain. Heidenhain wiring is fantastic. Double shielded with very robust conduits.

- Heidenhain seems to use consistent wiring colors across the decades and products. Here is my wiring on my 602D/1-5

Heidenhain seems to offer versions with either 5µm resolution, or with 1µm resolution. I ended up with one of each. Doesn't really matter for my level of machining. I can snap off a carbide end mill on the vise just as easily with either system. You just need to edit the INI for

ENCODER_SCALE = -200The 602/1-F has only 5µm resolution

whereas the 602D/5-F ouputs 1µm resolution. I wonder whether the D means it has the extra interpolation?

I only paid about €50 for each. Both work perfectly. Some have ouput connectors and some have cables. I went for ones with output cables and hacked whatever connectors were on the ends and wired them straight in the MESA 7i77. I understand the appeal of finding three with the same output terminal connectors and making a break out connector for the 7i77 so they can be plugged in

Mark

Attachments:

Last edit: 09 Dec 2019 15:26 by RotarySMP.

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 562

09 Dec 2019 15:33 #152365

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi Anders, I didn't see Marcin wanting to split encoders signals to two users, but just to replace a single channel of the 3 axis EXE board. The 3 Axis board has three electrically independant EXE's. There is nothing shared between the three channels other than the PCB fiberglass.

I agree he should switch input and output cables for two axis, and run the machine to isolate the fault between encoder and EXE though first.

Mark

I agree he should switch input and output cables for two axis, and run the machine to isolate the fault between encoder and EXE though first.

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.331 seconds