Retrofitting a 1986 Maho MH400E

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

21 May 2019 20:18 #134526

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Hello darkness my old friend...

Milling acrylic at 4000 rpm with 400 Nm of torque and 4 kW, with a feedrate of 420.

At least it works! Before I got the HF spindle I had no idea how to set feedrates correctly in this material. If you ever need them, I use a carbide 1-flute endmill at Vc=134,378 and feed per tooth 0,105. It's a quality endmill at ca. 25€ a pop for a 3mm version. More flutes or not polished and the plastic will melt if you don't use coolant, which you shouldn't.

Thanks again Mark for your fantastic help! I owe you big. Maybe if we visit Vienna again with the wife then I can buy you some drinks, I know Poland isn't exactly a tourist magnet

Milling acrylic at 4000 rpm with 400 Nm of torque and 4 kW, with a feedrate of 420.

At least it works! Before I got the HF spindle I had no idea how to set feedrates correctly in this material. If you ever need them, I use a carbide 1-flute endmill at Vc=134,378 and feed per tooth 0,105. It's a quality endmill at ca. 25€ a pop for a 3mm version. More flutes or not polished and the plastic will melt if you don't use coolant, which you shouldn't.

Thanks again Mark for your fantastic help! I owe you big. Maybe if we visit Vienna again with the wife then I can buy you some drinks, I know Poland isn't exactly a tourist magnet

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

22 May 2019 11:43 #134570

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I am glad you are back in business. Since the MAHO is only a hobby project for me, I can't imagine what a sinking feeling you must get when you have customers waiting and the HF spindle wrecked. How long do you expect the HF spindle rebuild to take? If you come to Vienna, I'd love to show you my MAHO.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 May 2019 11:44 #134571

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Hi to all, sorry to hear for the machine crash. You had set the machine with positive z travels, so you can actually measure and verify the work offsets with a simple caliper or rule. This makes sense but is prone to accidents.

The same debate exists for positive or negative tool offsets.

www.practicalmachinist.com/vb/cnc-machin...ngth-offsets-187207/

www.cnccookbook.com/touch-off-tool-sette...ng-tools-for-length/

john

The same debate exists for positive or negative tool offsets.

www.practicalmachinist.com/vb/cnc-machin...ngth-offsets-187207/

www.cnccookbook.com/touch-off-tool-sette...ng-tools-for-length/

john

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 May 2019 13:00 - 22 May 2019 13:03 #134578

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

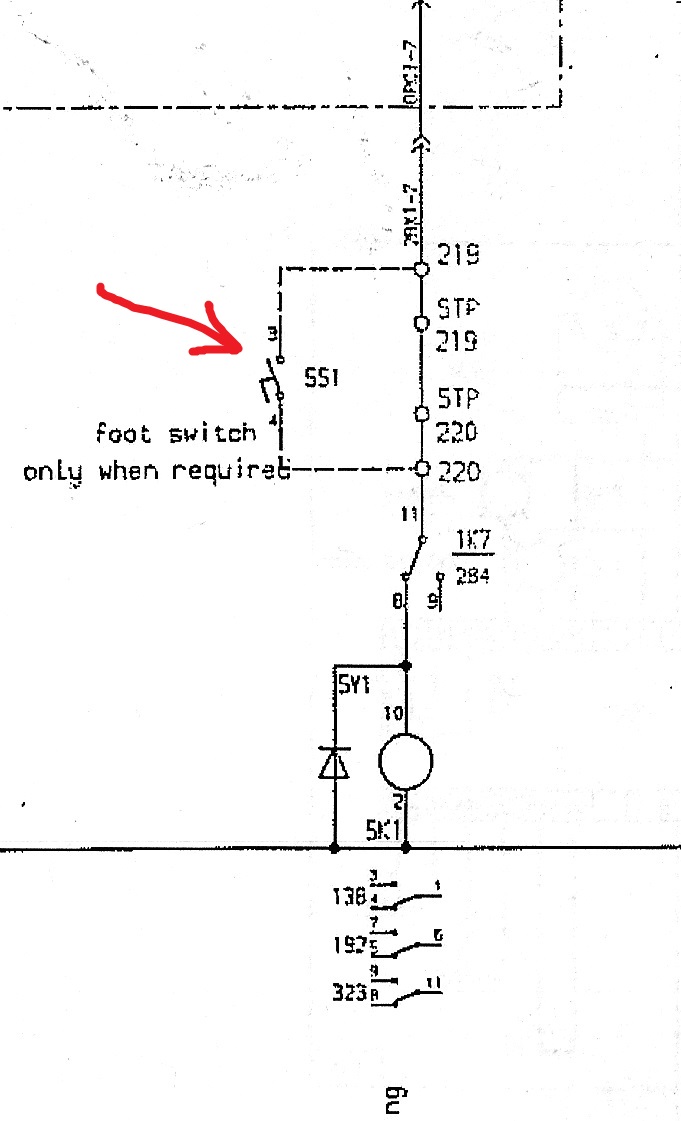

Attachments:

Last edit: 22 May 2019 13:03 by drimaropoylos.

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

22 May 2019 15:18 - 22 May 2019 15:25 #134583

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Hey John, I was actually thinking about a footswitch solution using a footswtich from my guitar amp. But after opening it I decided against the idea. I could go with a dedicated footswitch, purchased separately, because the Maho pendant I still have uses a system whereby you have to press two buttons with one hand to activate it, and simultaneaously use your other hand to press the button you want. That leaves you with precisely zero hands left for holding the released/inserted tool. I used to press the tool release button with my chin to get the system working

Since there are a lot of pins on the Mesa 7i73, I will consider adding a footswitch. I will also work on a GladeVCP panel that will interface LinuxCNC functions with the Philips control panel. But all that after I make all the outstanding parts on backorder since the beginning of May.

EDIT: when it comes to tool retracts, I just think it's a jolly assumption to make that every machine has the same coordinate system and then bake a rapid move in the Z axis twice in every program from the post processor. With no info to the end user. The learning curve for LinuxCNC is brutal, but then when you get the machine working you think you're safe. Not so! For the Maho I had user-friendly programming manuals with great illustrations and pictures of a cartoon machinist setting parameters using blueprints. They were so friendly I didn't care they were in French! Here the documentation file does have all the info you need, but it's over 700 pages and when you don't know what you don't know it's hard to navigate, despite the authors' best intentions and good work.

Since there are a lot of pins on the Mesa 7i73, I will consider adding a footswitch. I will also work on a GladeVCP panel that will interface LinuxCNC functions with the Philips control panel. But all that after I make all the outstanding parts on backorder since the beginning of May.

EDIT: when it comes to tool retracts, I just think it's a jolly assumption to make that every machine has the same coordinate system and then bake a rapid move in the Z axis twice in every program from the post processor. With no info to the end user. The learning curve for LinuxCNC is brutal, but then when you get the machine working you think you're safe. Not so! For the Maho I had user-friendly programming manuals with great illustrations and pictures of a cartoon machinist setting parameters using blueprints. They were so friendly I didn't care they were in French! Here the documentation file does have all the info you need, but it's over 700 pages and when you don't know what you don't know it's hard to navigate, despite the authors' best intentions and good work.

Last edit: 22 May 2019 15:25 by Glemigobles.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 May 2019 17:17 #134594

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

LolI used to press the tool release button with my chin to get the system working

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

22 May 2019 17:21 #134595

by andypugh

I have seen the following in a couple of places on how to rest the PRAM on a Mac:

"To reset (a process often called zapping) your PRAM/NVRAM, restart your Mac and press Command+Option+P+R (that’s four keys — good luck; it’s okay to use your nose) until your Mac restarts itself. It’s kind of like a hiccup."

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

LolI used to press the tool release button with my chin to get the system working

I have seen the following in a couple of places on how to rest the PRAM on a Mac:

"To reset (a process often called zapping) your PRAM/NVRAM, restart your Mac and press Command+Option+P+R (that’s four keys — good luck; it’s okay to use your nose) until your Mac restarts itself. It’s kind of like a hiccup."

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

22 May 2019 17:32 #134596

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

It's pretty entertaining when you realize we're both talking about systems that are otherwise very user-friendly, and yet they ended up with this kind of stuff baked in (I mean, I have no idea what PRAM/NVRAM is, but a tool change on a toolroom mill)

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 May 2019 17:36 #134598

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

22 May 2019 17:41 #134599

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Also a chin is harder than a nose but is also less precise.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.199 seconds