Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1538

- Thank you received: 571

Thanks for the prompt response. Are you also in a somewhat boring seminar like me?

Is there an advantage to having a manual speed change button, rather than just using the MDI and inputting an S command? If I leave the manual change HAL pin unconnected, will it still work?

Mark

Please Log in or Create an account to join the conversation.

- Fermaq

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 1

........................

Just a question but why change the servo motors and servo-drives ?

........................

Maybe cgroth can help with how to establish a connection between PC and Maho effectively.

The controller that I intend to put in has no way to communicate with the existing servodrives, it has no analog output. It has analog output only for spindle control. That is why I have to replace everything.

What I have in view is not very sophisticated. The investment I intend to make is related to the machine and its dimensions.

Of all the times I tried to communicate with the pc the best I could was to copy a program that had a total of 18 lines. I know it has nothing to do with the capacity of the machine memory because at that time the memory was empty.

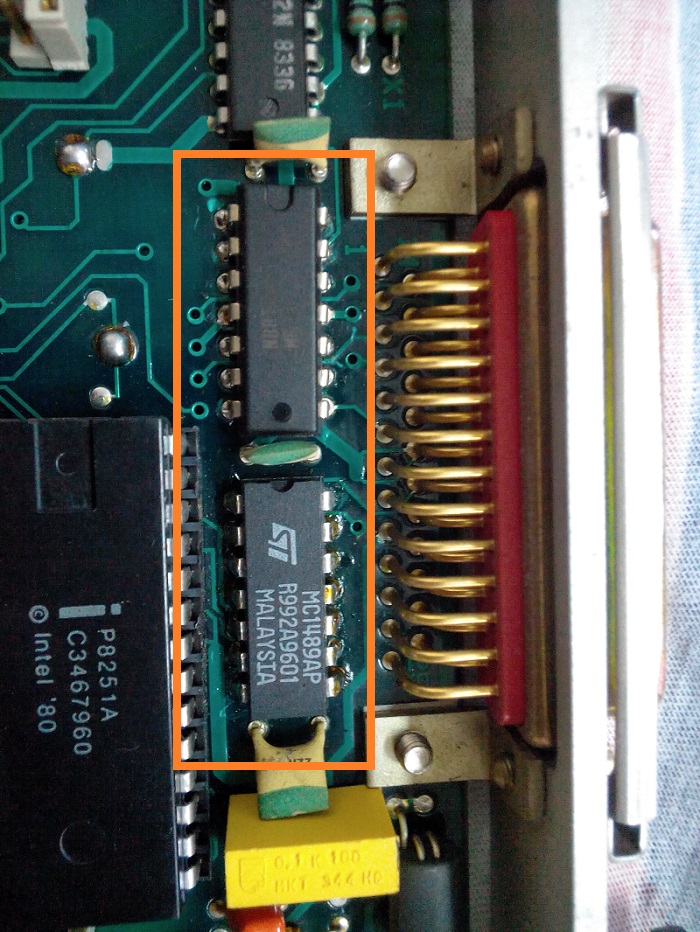

A technician advised me to replace the integrated circuits I send in this photo, possibly some of them would not be good. I replace the two circuits but the problem remained. In a diagnosis to the V24 appeared information saying "DTR / DSR Must be 1"

I tried the constants but nothing, I think there was something out of my reach there.

These integrated circuits had previously been replaced perhaps by the same problem.

pt.aliexpress.com/item/Newkye-Venda-Quen...s.8937460.0.0.VBI0vW

I will probably put this controller, or another similar one.

What is your opinion?

RotarySMPT I agree, but I'm new here, I do not know how to do it. If there is moderation here I would ask if they could do this from a post of mine, for example. I did not want to disturb your sharing or your work with myself ...

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1538

- Thank you received: 571

The controller that I intend to put in has no way to communicate with the existing servodrives, it has no analog output. It has analog output only for spindle control. That is why I have to replace everything.

If you haven't bought it yet, then dont use that controller. It is a big job and a huge waste of time and money to rip out the driver and motors if they are working fine and were designed to match the inertia of the MAHO's axis. Just get a MESA 7i77 and you have the analog outputs needed. This is a LinuxCNC format, so the expectation is that you are planning a LinuxCNC retrofit. If not, then you would be better off starting a thread in the Newkye support forum.

RotarySMPT I agree, but I'm new here, I do not know how to do it. If there is moderation here I would ask if they could do this from a post of mine, for example. I did not want to disturb your sharing or your work with myself ...

I like all things MAHO, but when I went searching the internet for info on my ones problems, I found it frustrating to have to search for relavant information buried in threads about other machines. John's 600E seems very similar to my 400E from the control prespective, but I am sure there are other people with MAHO MH300C's confronted with similar problems to you, who would appreciate the good suggestions you received here, but who won't find it here as it is no buried so deep in this thread.

There is a button to start a "New Topic"...

Mark

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

- Posts: 790

- Thank you received: 276

no seminar, break at the initial operation from an production line....

You can left the manual part disconnect, the MH700 had this buttons on the control Panel.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1538

- Thank you received: 571

How come these lines were commented out?

//pin in unsigned POSITION_COUNT;

//variable transm_pos pos[POSITION_COUNT];

//#define SWITCH_LEFT 0

//#define SWITCH_RIGHT 1

//#define SWITCH_CENTER 2

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1538

- Thank you received: 571

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

Nice work on the panel Mark, are you going to use 7i73 for the matrix on the panel?

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17568

- Thank you received: 5140

Mesa states for the 7i84 that it can handle relays, but it doesn’t state the same for the contacts on the 7i77. They have the same current and voltage capability but it is not clear that 7i77 will handle the overvoltage during the switch of on the coils. Can the diodes on the Maho relay board protect the 7i77? Or the 7i84 (or some buffer solid state relay board) is the only way?

Nice work on the panel Mark, are you going to use 7i73 for the matrix on the panel?

The 7I77 Field I/O is the same as the 7I84. The 7I77 and 7I84 outputs can drive small relays directly

without flyback diodes though in general flyback diodes are suggested since they will reduce switching EMI

and power dissipation in the output chips.

When no flyback diode is used, the energy stored in the relays magnetic field is

dissipated in the output driver chips MOSFET at turnoff. When a flyback diode is used,

most of the stored energy is dissipated in the relay coil at turnoff.

There is a slight disadvantage of using flyback diodes for high speed operation since it will slow

the relay de-energise time slightly.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

Please Log in or Create an account to join the conversation.