Fehlemann Picomax 100 Retrofit

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

21 Dec 2021 21:52 #229660

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

The good, the bad and the wonky.

With the right power supply all the little gismos went on…

But all the button bits are permanently high

And there are only three digits on the segment displays not sure if I need to adjust the feedback algorithm.

This needs a bit of investigation. But the key pad is not necessary to make progress. And in doubt I have enough inputs to bypass the bit encoder

With the right power supply all the little gismos went on…

But all the button bits are permanently high

And there are only three digits on the segment displays not sure if I need to adjust the feedback algorithm.

This needs a bit of investigation. But the key pad is not necessary to make progress. And in doubt I have enough inputs to bypass the bit encoder

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

29 Dec 2021 20:02 #230271

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

So....

the feedback is working since I adjusted from 4 to 3 digit segments

But the buttons are not working. All outputs are permanently high. It could be that Button 17 ist stuck or defective. But I don't know If it's connected or wich button it might be. I have more buttons than in the schematics. I tried to switch on the backlight of Button 17, but this didn't work. So my plan to skip the key panel for now.

Later I will take it apart and use the buttons individually als make six groups for backlight, this way I don't need extra outputs.

The spindle load I will reroute to the analog ins of the 7ia0. Suitable resistors are ordered.

Next I ned to "hal up" the hand wheel and PID's for the drives (the rest is done). Then make dummy buttons for oil, main and spindle contactor for testing. And then it's manually testing the end switches and relays before switching on the 400V power and see what happens.

I think end of Jan I will see first movements if the drives are OK.

the feedback is working since I adjusted from 4 to 3 digit segments

But the buttons are not working. All outputs are permanently high. It could be that Button 17 ist stuck or defective. But I don't know If it's connected or wich button it might be. I have more buttons than in the schematics. I tried to switch on the backlight of Button 17, but this didn't work. So my plan to skip the key panel for now.

Later I will take it apart and use the buttons individually als make six groups for backlight, this way I don't need extra outputs.

The spindle load I will reroute to the analog ins of the 7ia0. Suitable resistors are ordered.

Next I ned to "hal up" the hand wheel and PID's for the drives (the rest is done). Then make dummy buttons for oil, main and spindle contactor for testing. And then it's manually testing the end switches and relays before switching on the 400V power and see what happens.

I think end of Jan I will see first movements if the drives are OK.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

30 Dec 2021 20:53 #230362

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

02 Jan 2022 16:52 #230558

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

while testing I fried the old contactors it seam the documentation I found for them was wrong and they were 24v ac only.

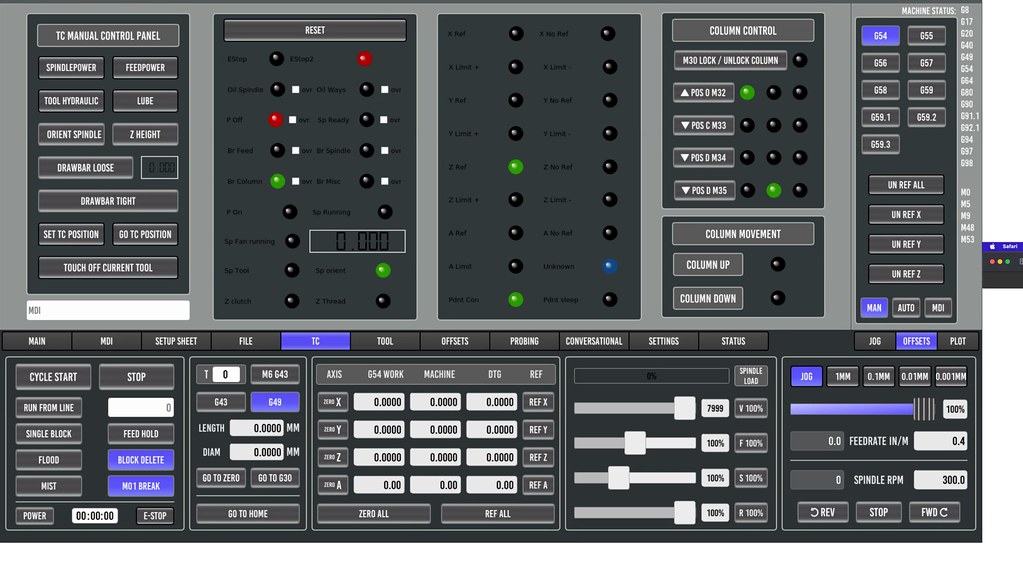

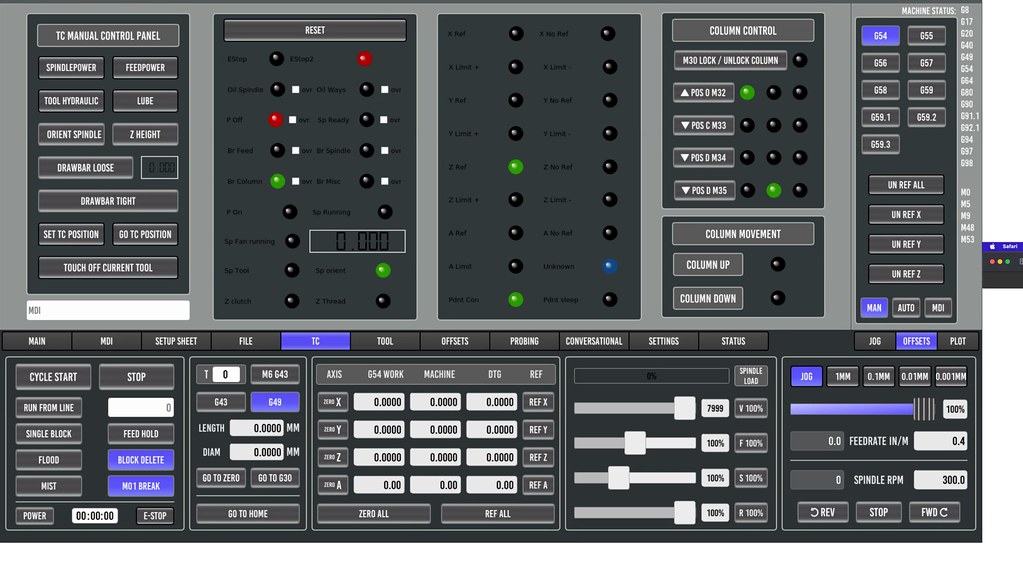

While waiting for replacement I made some changes to my vcp.

I wrote the needed M Codes for column control.

I wrote a hal component for the secondary estop mechanisms like oil and breakers. And can override them if needed or wanted.

I need to find a way to test the drives without running them full speed towards estop. With the servos I used before I you set them up without connecting them to the spindles. With glas scales this is not possible are there Andy good suggestions?

While waiting for replacement I made some changes to my vcp.

I wrote the needed M Codes for column control.

I wrote a hal component for the secondary estop mechanisms like oil and breakers. And can override them if needed or wanted.

I need to find a way to test the drives without running them full speed towards estop. With the servos I used before I you set them up without connecting them to the spindles. With glas scales this is not possible are there Andy good suggestions?

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

31 Jan 2022 09:28 #233617

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

slow progress is still progress...

The new contactors arrived:

now I have three circuits switchable by contactors: spindle, drives and accessories.

While making this I realized a couple of the IO's were not wired according to the documentation. So there will be some checking to do.

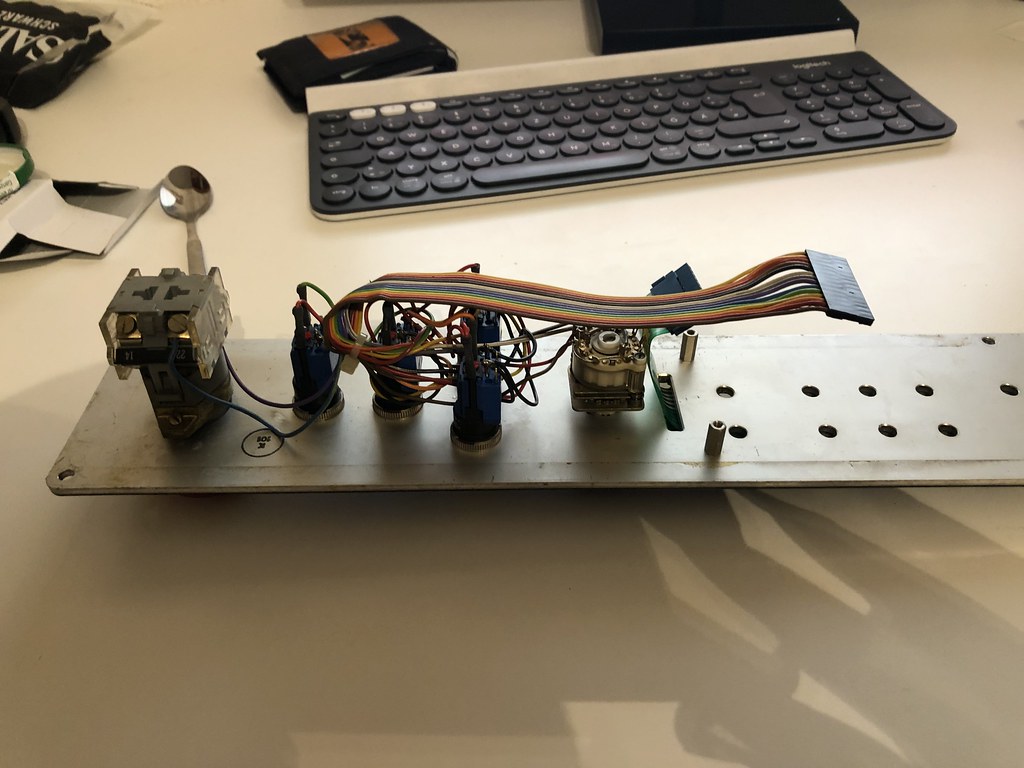

Then I installed the reworked button panel:

Next setback ist that the glas scales are not working. I guess the color code I found for the Heidenhain's where not correct, So I need to do some checking there.

Still need to figure out how to get an encoder to the spindle.

To make it short I don't see the machine running soon, wich is quite a bummer.

The new contactors arrived:

now I have three circuits switchable by contactors: spindle, drives and accessories.

While making this I realized a couple of the IO's were not wired according to the documentation. So there will be some checking to do.

Then I installed the reworked button panel:

Next setback ist that the glas scales are not working. I guess the color code I found for the Heidenhain's where not correct, So I need to do some checking there.

Still need to figure out how to get an encoder to the spindle.

To make it short I don't see the machine running soon, wich is quite a bummer.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1479

- Thank you received: 543

31 Jan 2022 09:39 #233619

by RotarySMP

Replied by RotarySMP on topic Fehlemann Picomax 100 Retrofit

Attachments:

The following user(s) said Thank You: anfänger

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

31 Jan 2022 12:47 #233626

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

Wow many thanks I'll give it a try.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

05 Feb 2022 19:40 #234043

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

06 Feb 2022 12:50 #234099

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

I tried to tackle the encoders today and found something odd, even with the corrected color code i can't get a signal.

then I tires to mesure with a multimeter. and all the signal were high even with no wiring present. is this normal?

thanks Patrick

then I tires to mesure with a multimeter. and all the signal were high even with no wiring present. is this normal?

thanks Patrick

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 626

- Thank you received: 255

06 Feb 2022 16:25 #234122

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

Still no solution for the encoders, H hipe it's just s Iron jumper and no damage in the Mesa board.

But I added a mount for the hand wheel.

and the panel is painted and wired up. After some testing in halshow I can edit the hal files now

Ohne Titel

by

Patrick Laible

, auf Flickr

Ohne Titel

by

Patrick Laible

, auf Flickr

But I added a mount for the hand wheel.

and the panel is painted and wired up. After some testing in halshow I can edit the hal files now

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.126 seconds