Rigid Tapping Help

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

30 Jul 2018 15:19 #115144

by andypugh

You can do this with a scale component fed from a mux2 component switched by gear position.

Or, possibly, by using a mux2 to set the encoder.scale to two different numbers.

It might be possible to use gearchange rather than mux2 for this, I don't know if that would be advantageous.

You can't scale the index. It isn't worth trying.

Replied by andypugh on topic Rigid Tapping Help

You would need to scale the input to motion.spindle-revs. That should be all that is needed.How about scaling the encoder? Is there anything I need to be aware of in using the scale component for this application, scaling index?

You can do this with a scale component fed from a mux2 component switched by gear position.

Or, possibly, by using a mux2 to set the encoder.scale to two different numbers.

It might be possible to use gearchange rather than mux2 for this, I don't know if that would be advantageous.

You can't scale the index. It isn't worth trying.

Yes, that is correct.Andy, there isn't currently a peck tap cycle correct? You just repeat the 33.1 code with different z depths?

Not as far as I know.does G64 path blending not affect rigid tapping?

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

30 Jul 2018 17:00 - 30 Jul 2018 17:02 #115153

by Mike_Eitel

Replied by Mike_Eitel on topic Rigid Tapping Help

M5C

When U use a encoder plus a comp element and use as input your real encoder index signal than you should be able to uses encoder.index-enable as simulated/divided index puls...

The Idea ist similar to TTL using counter with Reset as a divided..

Or easier do it in a small comp.

Mike

When U use a encoder plus a comp element and use as input your real encoder index signal than you should be able to uses encoder.index-enable as simulated/divided index puls...

The Idea ist similar to TTL using counter with Reset as a divided..

Or easier do it in a small comp.

Mike

Last edit: 30 Jul 2018 17:02 by Mike_Eitel.

Please Log in or Create an account to join the conversation.

- verticalperformance

-

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 11

26 Aug 2018 11:15 #116601

by verticalperformance

Replied by verticalperformance on topic Rigid Tapping Help

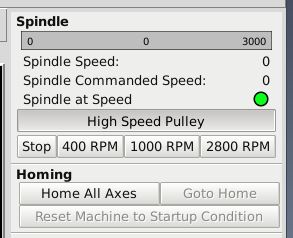

I've used the gearchange function with a sherline mill with a two speed pulley. the "gearchange" is affected manually by a glade UI button (High Speed Pulley in screen grab), but I see no reason why that would not work with a physical sensor that detects which pulley the belt is on. (or gearbox setting etc)

As the encoder is directly on the spindle shaft, all the gearchange is doing on the sherline is scaling the speed bar graph in the GUI, but it is a reasonable example of what the function does.

Few fragments of code (hopefully not missing anything important), the HAL files get their scaling parameters from the .ini file BTW and a screen grab of the relevant bit of the axis GUI

.ini file fragment

Spindle.hal

sherline-mill-gVCP.hal

And the python handler

As the encoder is directly on the spindle shaft, all the gearchange is doing on the sherline is scaling the speed bar graph in the GUI, but it is a reasonable example of what the function does.

Few fragments of code (hopefully not missing anything important), the HAL files get their scaling parameters from the .ini file BTW and a screen grab of the relevant bit of the axis GUI

.ini file fragment

###############################################################################

# Spindle Control section

###############################################################################

[SPINDLE]

# High Gear

MAX_RPM_HIGH = 3000

GEAR_RATIO = 2

# Low Gear

SCALE_LOW = 1650

OFFSET_LOW = 0.035

MAX_RPM_LOW = 1500

# Spindle at Speed tolerance (RPM)

TOLERANCE = 200

# Preset Speeds for GUI

S1 = 400

S2 = 1000

S3 = 2800

###############################################################################

# Hardware Abstraction Layer section

###############################################################################

[HAL]

# The run script first uses halcmd to execute any HALFILE

# files, and then to execute any individual HALCMD commands.

#

# list of hal config files to run through halcmd

#+ files are executed in the order in which they appear

HALFILE = stepper_xyza.hal

HALFILE = standard_pinout.hal

HALFILE = Spindle.hal

HALFILE = manualtoolchange.hal

POSTGUI_HALFILE = sherline-mill-gVCP.hal

Spindle.hal

# Spindle Control File

loadrt abs count=1

loadrt pwmgen output_type=0

# spindle speed feedback

loadrt encoder num_chan=1

loadrt lowpass count=1

loadrt mult2 count=1

loadrt near

loadrt gearchange

# base thread

addf pwmgen.make-pulses base-thread

addf encoder.update-counters base-thread

#servo thread

addf pwmgen.update servo-thread

addf abs.0 servo-thread

addf encoder.capture-position servo-thread

addf lowpass.0 servo-thread

addf near.0 servo-thread

addf mult2.0 servo-thread

addf gearchange.0 servo-thread

#Spindle Control

net spindle-enable <= motion.spindle-on => pwmgen.0.enable

net spindle-cmd <= motion.spindle-speed-out => gearchange.0.speed-in

net spindle-cmd-scaled <= gearchange.0.speed-out => pwmgen.0.value

net spindle-pwm <= pwmgen.0.pwm

#Spindle Speed Scaling

setp pwmgen.0.pwm-freq 5

setp gearchange.0.min1 0

setp gearchange.0.max1 [SPINDLE]MAX_RPM_LOW

setp gearchange.0.min2 0

setp gearchange.0.max2 [SPINDLE]MAX_RPM_HIGH

setp gearchange.0.scale2 [SPINDLE]GEAR_RATIO

setp pwmgen.0.scale [SPINDLE]SCALE_LOW #low gear

setp pwmgen.0.offset [SPINDLE]OFFSET_LOW #low gear

setp pwmgen.0.dither-pwm true

#Spindle Feedback

setp encoder.0.position-scale 6.000000

setp encoder.0.counter-mode 1

# report our revolution count to the motion controller

net spindle-position encoder.0.position => motion.spindle-revs

net spindle-velocity encoder.0.velocity => motion.spindle-speed-in

net spindle-phase-a encoder.0.phase-A

setp lowpass.0.gain 0.01

net spindle-velocity => lowpass.0.in

net spindle-fb-filtered <= lowpass.0.out

net spindle-fb-filtered mult2.0.in1

net spindle-fb-rpm mult2.0.out

setp mult2.0.in0 60

# Test for spindle at speed

net spindle-cmd near.0.in1

net spindle-fb-rpm near.0.in2

net spindle-at-speed motion.spindle-at-speed <= near.0.out

setp near.0.difference [SPINDLE]TOLERANCE #If within 100 RPM

#Connect to physical pins

setp parport.0.pin-01-out-invert 1

net spindle-pwm => parport.0.pin-01-out

setp parport.0.pin-17-out-invert 1

net spindle-enable => parport.0.pin-17-out

net spindle-phase-a <= parport.0.pin-15-in-not

sherline-mill-gVCP.hal

# create a 'estop-is-deactivated' signal

loadrt not count=3 #names=not.0,not.1

addf not.0 servo-thread

addf not.1 servo-thread

addf not.2 servo-thread

net estop halui.estop.is-activated => not.0.in

# and activate the settings box when estop is off

#net estop-inactive not.0.out => gladevcp.settings

# activate the spindle HAL table and all its children when the machine is on

net machine-on halui.machine.is-on => gladevcp.spindle => gladevcp.pulley

net machine-on => gladevcp.preset-speeds

# **** Setup of spindle speed display using glade -START ****

# **** Use ACTUAL spindle velocity from spindle encoder

# **** spindle-velocity is signed so we use absolute component to remove sign

net spindle-fb-rpm => abs.0.in

net spindle-fb-abs-rpm abs.0.out => gladevcp.spindle-rpm-hbar

net spindle-fb-abs-rpm => gladevcp.spindle-speed

net spindle-cmd => gladevcp.spindle-commanded-speed

# **** set up spindle at speed indicator ****

net spindle-at-speed => gladevcp.spindle-at-speed-led

# Link the gearchange to the pulley button

net gearchange-cmd <= gladevcp.high_speed_pulley => gearchange.0.sel

And the python handler

import os,sys

from gladevcp.persistence import IniFile,widget_defaults,set_debug,select_widgets

import hal

import hal_glib

import gtk

import glib

import linuxcnc

import time

debug = 1

c = linuxcnc.command()

s = linuxcnc.stat()

config_ini_file = linuxcnc.ini(os.getenv("INI_FILE_NAME"))

axes = int(config_ini_file.find("TRAJ", "AXES") or 0)

def all_axes_homed():

print "axes: %i" % axes

axes_home= s.homed

print axes_home

print axes_home.count(1)

if axes_home.count(1) == axes:

print ("All axes homed")

return 1

else:

print ("At least one axes is not homed")

return 0

def ok_for_mdi():

s.poll()

print ("OK for MDI Mode")

print ("estop: %i" % s.estop)

print ("enabled: %i" % s.enabled)

print ("interp_state: %i" % s.interp_state)

return not s.estop and s.enabled and all_axes_homed() and (s.interp_state == linuxcnc.INTERP_IDLE)

def ok_for_manual():

s.poll()

print ("OK for Manual Mode")

print ("estop: %i" % s.estop)

print ("enabled: %i" % s.enabled)

print ("interp_state: %i" % s.interp_state)

print ("task_mode: %i" % s.task_mode)

return not s.estop and s.enabled and (s.interp_state == linuxcnc.INTERP_IDLE) and (s.task_mode <> linuxcnc.MODE_AUTO)

class HandlerClass:

'''

class with gladevcp callback handlers

'''

S1 = 0

S2 = 0

S3 = 0

def on_pulley_toggled(self,widget,data=None):

if widget.get_active():

self.builder.get_object('spindle-rpm-hbar').max = float(self.max_speed_high_gear)

else:

self.builder.get_object('spindle-rpm-hbar').max = float(self.max_speed_low_gear)

self.builder.get_object('spindle-rpm-hbar').queue_draw()

self.spindle_rpm_hbar_max = self.builder.get_object('spindle-rpm-hbar').max

print "Toggle Pulley"

def on_stop_clicked(self,widget,data=None):

c.spindle(0)

print "Stop Clicked"

def on_s1_clicked(self,widget,data=None):

if ok_for_mdi():

c.mode(linuxcnc.MODE_MDI)

c.wait_complete() # wait until mode switch executed

c.mdi("M3 S%d" % self.S1)

print "S1: M3 S%d" % self.S1

def on_s2_clicked(self,widget,data=None):

if ok_for_mdi():

c.mode(linuxcnc.MODE_MDI)

c.wait_complete() # wait until mode switch executed

c.mdi("M3 S%d" % self.S2)

print "S2: M3 S%d" % self.S2

def on_s3_clicked(self,widget,data=None):

if ok_for_mdi():

c.mode(linuxcnc.MODE_MDI)

c.wait_complete() # wait until mode switch executed

c.mdi("M3 S%d" % self.S3)

print "S3: M3 S%d" % self.S3

def on_destroy(self,obj,data=None):

self.ini.save_state(self)

def __init__(self, halcomp,builder,useropts):

'''

Handler classes are instantiated in the following state:

- the widget tree is created, but not yet realized (no toplevel window.show() executed yet)

- the halcomp HAL component is set up and the widhget tree's HAL pins have already been added to it

- it is safe to add more hal pins because halcomp.ready() has not yet been called at this point.

after all handlers are instantiated in command line and get_handlers() order, callbacks will be

connected with connect_signals()/signal_autoconnect()

The builder may be either of libglade or GtkBuilder type depending on the glade file format.

'''

self.halcomp = halcomp

self.builder = builder

self.useropts = useropts

self.max_speed_high_gear = float(config_ini_file.find("SPINDLE", "MAX_RPM_HIGH") or 0.0)

self.max_speed_low_gear = float(config_ini_file.find("SPINDLE", "MAX_RPM_LOW") or 0.0)

self.S1 = float(config_ini_file.find("SPINDLE", "S1") or 100.0)

self.S2 = float(config_ini_file.find("SPINDLE", "S2") or 1000.0)

self.S3 = float(config_ini_file.find("SPINDLE", "S3") or 2800.0)

spindle_S1=self.builder.get_object('hal_spindle_s1')

spindle_S2=self.builder.get_object('hal_spindle_s2')

spindle_S3=self.builder.get_object('hal_spindle_s3')

spindle_S1.set_label("%d RPM" % self.S1)

spindle_S2.set_label("%d RPM" % self.S2)

spindle_S3.set_label("%d RPM" % self.S3)

print "High Gear: %d" % self.max_speed_high_gear

print "Low Gear: %d" % self.max_speed_low_gear

self.defaults = {

IniFile.vars : { 'spindle_rpm_hbar_max' : self.max_speed_high_gear},

IniFile.widgets: widget_defaults(select_widgets(self.builder.get_objects(), hal_only=True,output_only = True))

}

self.ini_filename = __name__ + ".ini"

print "Ini File Name: %s" % self.ini_filename

self.ini = IniFile(self.ini_filename,self.defaults,self.builder)

self.ini.restore_state(self)

self.builder.get_object('spindle-rpm-hbar').max= float(self.spindle_rpm_hbar_max)

self.builder.get_object('spindle-rpm-hbar').queue_draw()

def get_handlers(halcomp,builder,useropts):

'''

this function is called by gladevcp at import time (when this module is passed with '-u <modname>.py')

return a list of object instances whose methods should be connected as callback handlers

any method whose name does not begin with an underscore ('_') is a callback candidate

the 'get_handlers' name is reserved - gladevcp expects it, so do not change

'''

return [HandlerClass(halcomp,builder,useropts)]

The following user(s) said Thank You: OT-CNC

Please Log in or Create an account to join the conversation.

- gmarconi2

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 5

22 Mar 2019 20:00 #129283

by gmarconi2

Replied by gmarconi2 on topic Rigid Tapping Help

I happened by chance here, but the error is a comma instead of the point in the first post N445 line

instead of G43 Z0.6 H2 changes to G43 Z0.6 H2

Hi gmarconi2

instead of G43 Z0.6 H2 changes to G43 Z0.6 H2

Hi gmarconi2

The following user(s) said Thank You: OT-CNC

Please Log in or Create an account to join the conversation.

Time to create page: 0.191 seconds