Gildemeister NEF 480 Retrofit

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

06 Jan 2021 19:59 #194274

by tommylight

Replied by tommylight on topic Gildemeister NEF 480 Retrofit

I have a solution i use for that, i start screaming at myself for being lazy ! In my head, not out loud, that would promptly win me the title of "insane"....... and I am running out of excuses not to start assembling

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

09 Jan 2021 21:07 #194648

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

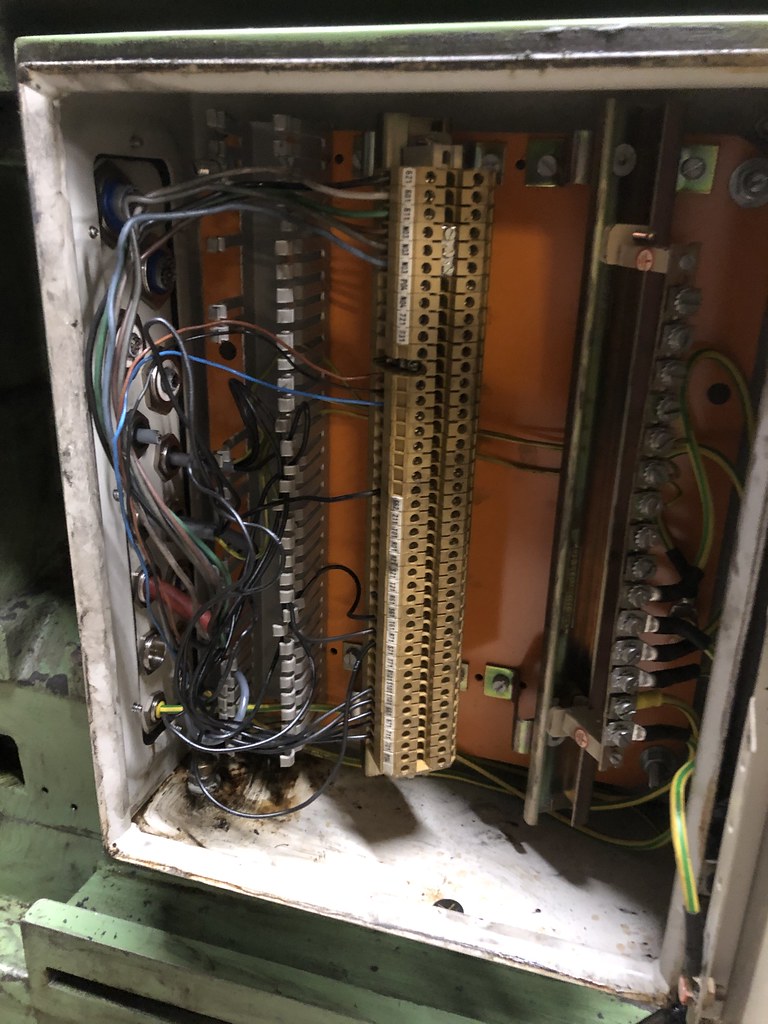

So did more cleaning before Monday hopefully the last parts for the cabinet will arrive.

The cabinet is free of dust and chips now:

also the console is cleaned out

Then the were the cable guides still uncleaned while removing most of the old cables I also cleaned them an d the rest of the machine:

The cabinet is free of dust and chips now:

also the console is cleaned out

Then the were the cable guides still uncleaned while removing most of the old cables I also cleaned them an d the rest of the machine:

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

09 Jan 2021 21:07 #194649

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

17 Jan 2021 21:35 - 17 Jan 2021 21:39 #195708

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

This week some more parts arrived:

So now just a few parts are missing.

I opens the spindle to check is everything is OK there:

It looks good, but there was a surprise the electric clutch turned out to by hydraulic and drives by the oil pump driven my the main shaft. This can turn in to a problem when using the vfd. But this is something to take care of when it causes troubles.

After this I removed more unused cables. now it's quite empty there:

Just the spindle clamp, coolant and the additional spindle index.

Also removed the unused connectors from the back:

quite a pile of old cables it habs become

Then I salvaged and cleaned the connectors and also cleaned the spindle encoder hoping to get a clue how many increments if has and if it has an index signal. The additional one gives to signal per turn. I think Linuxcnc likes on per rev.

so reassembly comes in sight and less excuses to postpone it again are there

So now just a few parts are missing.

I opens the spindle to check is everything is OK there:

It looks good, but there was a surprise the electric clutch turned out to by hydraulic and drives by the oil pump driven my the main shaft. This can turn in to a problem when using the vfd. But this is something to take care of when it causes troubles.

After this I removed more unused cables. now it's quite empty there:

Just the spindle clamp, coolant and the additional spindle index.

Also removed the unused connectors from the back:

quite a pile of old cables it habs become

Then I salvaged and cleaned the connectors and also cleaned the spindle encoder hoping to get a clue how many increments if has and if it has an index signal. The additional one gives to signal per turn. I think Linuxcnc likes on per rev.

so reassembly comes in sight and less excuses to postpone it again are there

Last edit: 17 Jan 2021 21:39 by anfänger.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

20 Jan 2021 07:30 #195972

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

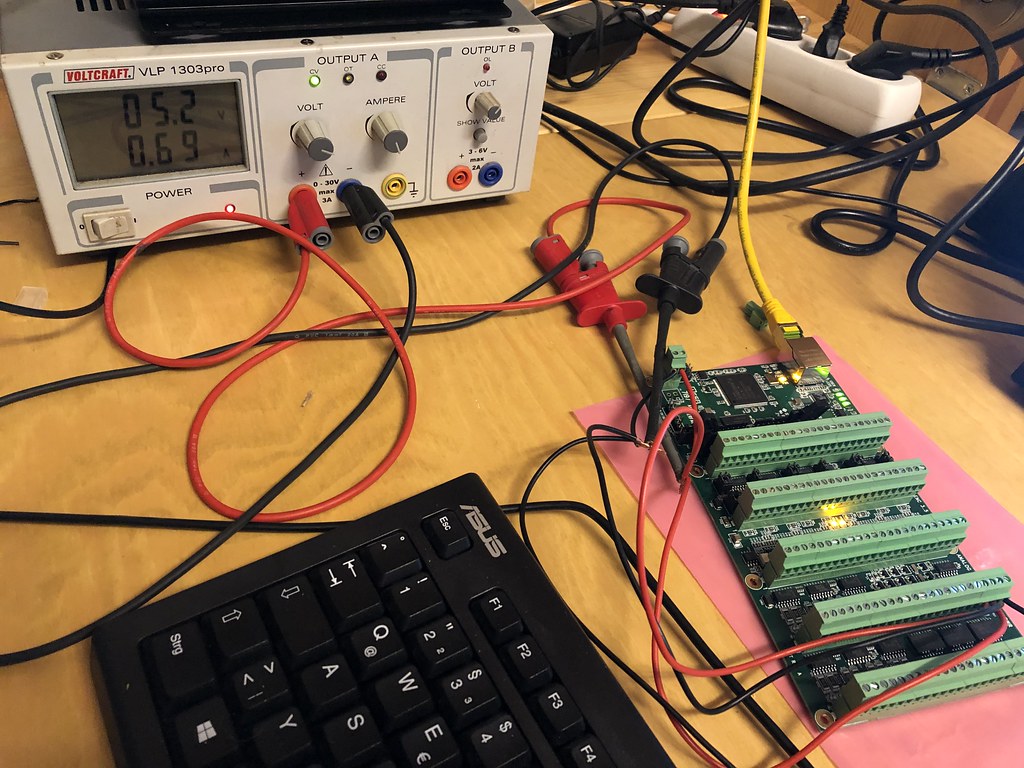

So did the first board test yesterday:

[/url]

Ok the first after playing pin pong. Let’s call it first contact from LinuxCNC to the mesa card.

And tested my hand wheels. And it works... Next step is to see if I get the spindle encoder running but I have no Pinout is there a kind of standard with color coding in the cable or the plugs? Otherwise I screwed and need to find a new encoder that fits.

[/url]

Ok the first after playing pin pong. Let’s call it first contact from LinuxCNC to the mesa card.

And tested my hand wheels. And it works... Next step is to see if I get the spindle encoder running but I have no Pinout is there a kind of standard with color coding in the cable or the plugs? Otherwise I screwed and need to find a new encoder that fits.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4655

- Thank you received: 2078

20 Jan 2021 13:45 #195991

by Aciera

Do you have any information about the encoder at all?

Replied by Aciera on topic Gildemeister NEF 480 Retrofit

is there a kind of standard with color coding in the cable or the plugs?

Do you have any information about the encoder at all?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17721

- Thank you received: 5185

20 Jan 2021 16:19 #196003

by PCW

Replied by PCW on topic Gildemeister NEF 480 Retrofit

Even with no information on an encoder, you can possibly

determine the power supply connections by continuity

testing from known IC ground and power pins to cable

connections. Once you have figured out the power

connections, you can power the encoder and then

determine the other signals with a voltmeter

determine the power supply connections by continuity

testing from known IC ground and power pins to cable

connections. Once you have figured out the power

connections, you can power the encoder and then

determine the other signals with a voltmeter

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

20 Jan 2021 18:35 #196012

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

this is more ore less the way I want to try it

Type TSI508 then its not readable.

Power supply 5v cd number of increments is all not readable, but easy for figure out

A86L-0024-0001

There is also an engraving C4063 but I think this is for the interface

maybe the color code for my Siemens encoders will work.. otherwise it a session with the multimeter.

Type TSI508 then its not readable.

Power supply 5v cd number of increments is all not readable, but easy for figure out

A86L-0024-0001

There is also an engraving C4063 but I think this is for the interface

maybe the color code for my Siemens encoders will work.. otherwise it a session with the multimeter.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

20 Jan 2021 20:44 #196018

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

I figured out the outputs. But it looks like it has some problem.

I opend it and found some of the degreaser in it not much but maybe it did some harm. I wonder if I can do something.

It could be also have issues before. I don’t know

I opend it and found some of the degreaser in it not much but maybe it did some harm. I wonder if I can do something.

It could be also have issues before. I don’t know

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

20 Jan 2021 20:57 #196023

by Todd Zuercher

Replied by Todd Zuercher on topic Gildemeister NEF 480 Retrofit

Why do you think it has issues? The watch screen in Halshow is not a reliable way to watch for quadrature error. The update frequency is much much too slow and in user-space. Infact watching the A and B signal pins in Halscope probably isn't even good enough since that is only sampled in the servo thread. I'd say as long as the count seems reasonable and it isn't setting quadrature error alarms, it's probably ok.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.118 seconds