Gildemeister NEF 480 Retrofit

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

22 Feb 2021 08:51 #199687

by RotarySMP

Replied by RotarySMP on topic Gildemeister NEF 480 Retrofit

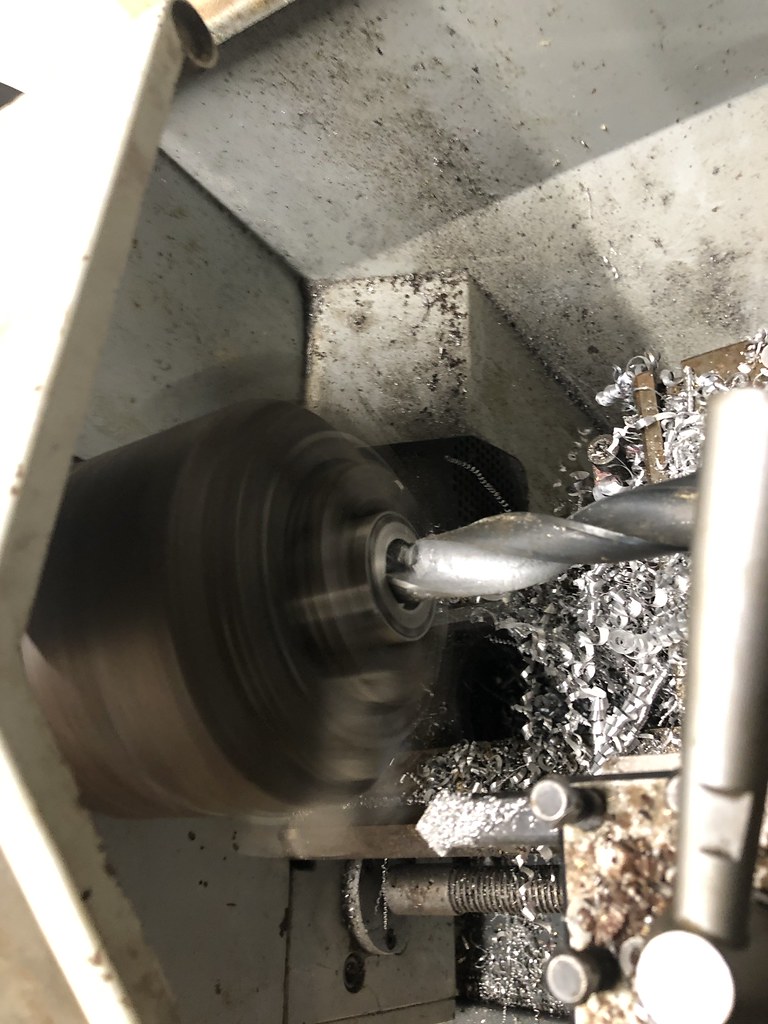

Good on you for getting those out. Novel use of a tool holder:)

Mark

Mark

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

24 Feb 2021 21:04 #200027

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Thanks for the tip with the sliding hammer. First try with m6 failed, but then I cut a m8 thread and got those little guys out and the cross slide off die cleaning.

Now I wonder if I should try to get the carriage also off. But I am not sure if I can manage this. I wonder if pumping degreaser through the system would be enough.

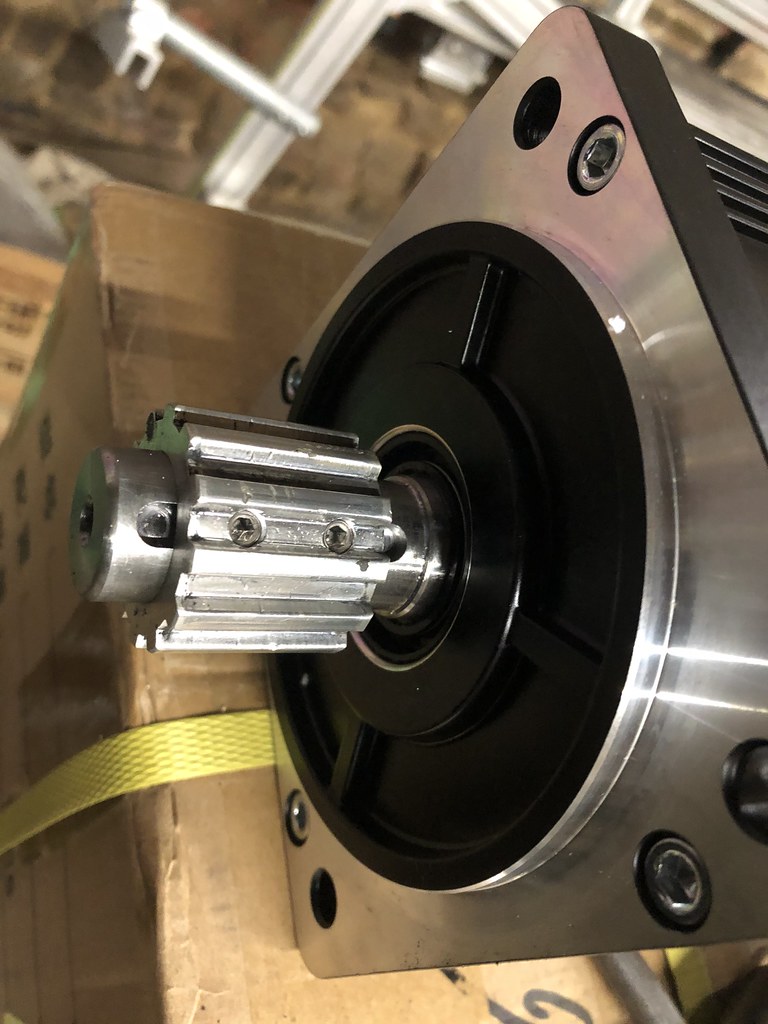

To save some time and money I will reuse the old belts and pulleys before I get new ones with a slower ratio. So I fitted them to the new servos

And the new plate for the control arrived

Today was a satisfying everything in the shop.

Thanks for listening

Patrick

Now I wonder if I should try to get the carriage also off. But I am not sure if I can manage this. I wonder if pumping degreaser through the system would be enough.

To save some time and money I will reuse the old belts and pulleys before I get new ones with a slower ratio. So I fitted them to the new servos

And the new plate for the control arrived

Today was a satisfying everything in the shop.

Thanks for listening

Patrick

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21291

- Thank you received: 7267

24 Feb 2021 21:25 #200033

by tommylight

Replied by tommylight on topic Gildemeister NEF 480 Retrofit

Glad someone is having fun in the shop, i have not been in my shop for the last 3 days, waiting and waiting and ... never mind.Today was a satisfying everything in the shop.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

25 Feb 2021 07:38 - 25 Feb 2021 07:47 #200065

by RotarySMP

Replied by RotarySMP on topic Gildemeister NEF 480 Retrofit

Last edit: 25 Feb 2021 07:47 by RotarySMP.

The following user(s) said Thank You: anfänger

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Feb 2021 07:44 - 25 Feb 2021 07:48 #200067

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

I am really glad auswelle! It‘s not always easy after a day at work to get my up. But it‘s a nice contrast to my daily work, which is mostly sitting in front of a computer. And as much as I enjoy seeing something real done with my own hands / code ist quite satisfying. But I‘m a self taught machinist and so there is a lot of room for error and frustration. Like last week wehere I spend a whole evening trying to remove the cross slide. But when I make progress then it’s incredibly satisfying.

Last edit: 25 Feb 2021 07:48 by anfänger.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

25 Feb 2021 07:49 #200068

by RotarySMP

Replied by RotarySMP on topic Gildemeister NEF 480 Retrofit

It is the same for me. Especially with home office, sitting at my laptop in my bedroom for hours, I appreciate the time working on the machines as a contrast.

Mark

You know that the one blocked line, which will cause the galled way, is the one which degreaser wont clear.But I am not sure if I can manage this. I wonder if pumping degreaser through the system would be enough.

Mark

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Feb 2021 08:36 #200072

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

I was so afraid someone would say that...

Any suggestions how?

I thought a lot about it while remaking the pulleys.

I can’t remove the the carriage with the ballsrew.

So i was thinking of detaching the ball nut from the carriage (hoping the to mange to get the oil line reattached later). And then removing the rear support of the ballsrew and some how pulling and lifting the carriage of in the end. Not really looking forward to this. And I think I will crap my pants more than once doing it.

Any suggestions how?

I thought a lot about it while remaking the pulleys.

I can’t remove the the carriage with the ballsrew.

So i was thinking of detaching the ball nut from the carriage (hoping the to mange to get the oil line reattached later). And then removing the rear support of the ballsrew and some how pulling and lifting the carriage of in the end. Not really looking forward to this. And I think I will crap my pants more than once doing it.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

25 Feb 2021 09:20 #200074

by RotarySMP

Replied by RotarySMP on topic Gildemeister NEF 480 Retrofit

I cant really picture what the build up of the carriage is. Normally CNC machines are much simpler than manual machines in that area. Is it an access problem?

Mark

Mark

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

25 Feb 2021 09:43 #200076

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

This is more or less a normal lathe. With a very professional CNC conversion. The main spindle part looks more or less like the one on a normal lathe. I haven’t figured out how to remove the „lead srew“ so I need to remove the carriage with the lead screw attached to the spindle stock. But I think I will give it a try this evening. It’s German engineering so there should be a was to remove the leadscrew without disassembling the main spindle.

Please Log in or Create an account to join the conversation.

- sivaraj

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 23

25 Feb 2021 10:58 - 25 Feb 2021 11:24 #200080

by sivaraj

Replied by sivaraj on topic Gildemeister NEF 480 Retrofit

Just checking the carriage gibs and lubrication lines are enough .

Lubrication is important for these type of carriages.

There will be either turcite or SKC coating on 'V' groove - nothing to clean there .

Unless you see guide ways gibs are loose and not holding to the ground surface not necessary to remove the carriage .

Just apply oil to the guide-ways surfaces which is sufficient to start moving smooth ..

Also on ball-screw side motor end bearing are important to look.

Either it can be lifetime greased angular contact bearings or thrust bearing which normally not required to service this unless abnormal load on ball-screw rotation - check after unscrewing the ball-nut from carriage .Tail end bearing is just to support ball-screw .Not necessary to remove and clean.

Lubrication is important for these type of carriages.

There will be either turcite or SKC coating on 'V' groove - nothing to clean there .

Unless you see guide ways gibs are loose and not holding to the ground surface not necessary to remove the carriage .

Just apply oil to the guide-ways surfaces which is sufficient to start moving smooth ..

Also on ball-screw side motor end bearing are important to look.

Either it can be lifetime greased angular contact bearings or thrust bearing which normally not required to service this unless abnormal load on ball-screw rotation - check after unscrewing the ball-nut from carriage .Tail end bearing is just to support ball-screw .Not necessary to remove and clean.

Last edit: 25 Feb 2021 11:24 by sivaraj.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.158 seconds