RB1-CNC Retrofit

- andypugh

-

- Offline

- Moderator

-

- Posts: 23541

- Thank you received: 5013

thread.gmane.org/gmane.linux.distributio...evel/4043/focus=4238

Alternatively you might be able to use closed-loop spindle control to work with wherever you set the variable speed.

For extra fun, a sensor could measure the variable speed head position and use a "lincurve" HAL component to get the right scaling factor.

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

Are you recommending your patch to the gearchange component or Les Newell spindle gearchange component?

How would I implement either one of these? Do I need to copy the text of the Les Newell component and compile it? Since this would be a first for me in Linux can you direct me to a guide?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 23541

- Thank you received: 5013

Are you recommending your patch to the gearchange component or Les Newell spindle gearchange component?

I am not sure. Either ought to work.

To compile / install

sudo comp --install spindle.compMore details:

www.linuxcnc.org/docs/html/hal/comp.html

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

I copied the text from Les Newell's post and it does not compile without errors. I was able to fix some of the errors due to improper quotation marks however I now have one that is stumping me at the moment. Could be that I am tired and need to go to bed.

Anyway here is the error that I am getting.

make KBUILD_EXTRA_SYMBOLS=/usr/realtime-3.4-9-rtai-686-pae/modules/linuxcnc/Module.symvers -C /usr/src/linux-headers-3.4-9-rtai-686-pae SUBDIRS=`pwd` CC=gcc V=0 modules

make[1]: Entering directory `/usr/src/linux-headers-3.4-9-rtai-686-pae'

CC [M] /tmp/tmp6BfU3g/spindle.o

/tmp/tmp6BfU3g/spindle.c:57:5: error: unknown type name ‘gear_t’

spindle.comp: In function ‘_’:

spindle.comp:166:25: warning: initialization from incompatible pointer type [enabled by default]

spindle.comp:170:18: warning: assignment from incompatible pointer type [enabled by default]

spindle.comp:174:22: warning: assignment from incompatible pointer type [enabled by default]

spindle.comp: In function ‘extra_setup’:

spindle.comp:296:9: warning: passing argument 3 of ‘add_gear’ from incompatible pointer type [enabled by default]

spindle.comp:155:5: note: expected ‘struct gear_t *’ but argument is of type ‘int *’

spindle.comp:300:19: error: request for member ‘select’ in something not a structure or union

make[4]: *** [/tmp/tmp6BfU3g/spindle.o] Error 1

make[3]: *** [_module_/tmp/tmp6BfU3g] Error 2

make[2]: *** [sub-make] Error 2

make[1]: *** [all] Error 2

make[1]: Leaving directory `/usr/src/linux-headers-3.4-9-rtai-686-pae'

make: *** [modules] Error 2I spent most of the night trying to get VNC to work so I could work on the pc for the milling machine from my living room. I had no luck there either. I did get realVNC to work but I was trying to get vnc4server to work so it would start up when the machine boots up.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 23541

- Thank you received: 5013

The problem is likely to be that you haven't downloaded the spindle.h file which is included by the lineI copied the text from Les Newell's post and it does not compile without errors.

include "components/spindle.h";I spent most of the night trying to get VNC to work so I could work on the pc for the milling machine from my living room. I had no luck there either. I did get realVNC to work but I was trying to get vnc4server to work so it would start up when the machine boots up.

I use ssh with the -Y option, is that a possibility for you?

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

There were some rough spots in the spindle taper that you could feel. I put some blue dykem on a toolholder and placed it in the spindle to find out how the fit was. It was only contacting near the small end of the taper.

What do I do now? I can replace the spindle or regrind the taper. I got in touch with Spindle Grinding Service. They will regrind the spindle taper with the spindle still in your machine. I told them that I was in no hurry and sometime that they were going to be in the area to let me know. It turned out they were in my area this week. They did the regrinding of the spindle taper and it is as good as new. The runout with an edge finder in a used ER 32 collet holder is about 0.0005" and the runout on the ID of a brand new ER 32 collet holder is close to 0.0001". I am happy and I will be making the first chips with the machine this weekend.

Below are some videos of the runout before and after the spindle grinding.

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

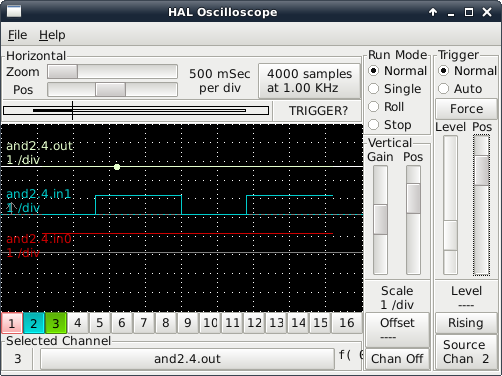

I have the connections made to the and2.4 component in my PostGUI hal file. I am attaching it below.

#RB1-CNC_PostGUI.hal

# Written by NitroCH3NO2, Jim Craig

#This HAL file will configure the controls in the custom glade panels so that the following are taken care of

#1. Spindle brake on and off

# loadrt statements preceded by ## are loaded in a previous HAL file

# connect spindle brake to I/O controller

# This will check the motion.spindle-brake and the SpindleBrakeOverride signal

# to activate the spindle brake if the spindle brake override is false

# Add an and2 components

# Add a not component

##loadrt and2 count=1

##loadrt not count=1

net SpindleBrakeOnCmd <= motion.spindle-brake

net SpindleBrakeOnCmd => and2.4.in0

net SpindleBrakeOverride <= SBOGladeCB4.TBSpindleBrakeOverride

net SpindleBrakeOverride-not <= SBOGladeCB4.TBSpindleBrakeOverride-not

net SpindleBrakeOverride-not => and2.4.in1

net SpindleBrakeOn and2.4.out => ppmc.0.dout.06.outWhat is going on here?

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

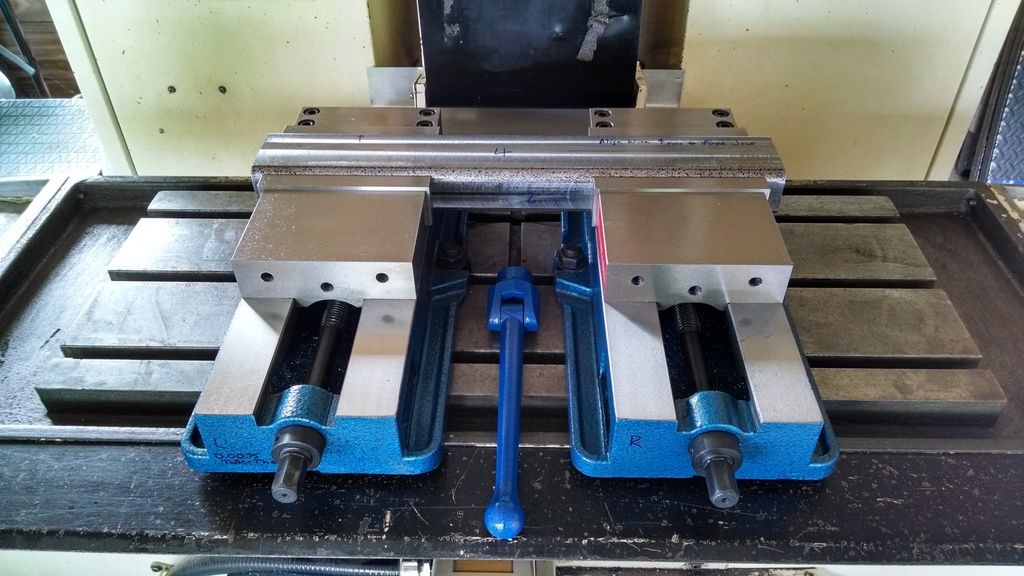

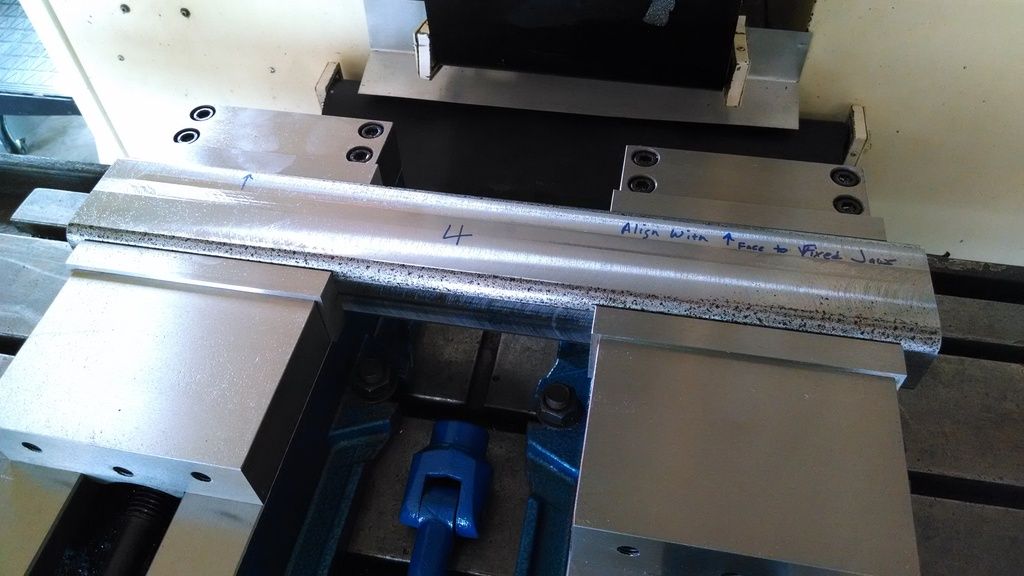

I made an alignment bar for my two 6" vises that I will have mounted on the machine most of the time. This was a piece of 2" x 3" x 3/16" rectangular tubing that I surfaced all four sides on so that I can clamp it into the two vises so that the two fixed jaws of the vise are parallel and collinear when I go to clamp them down. I still need to do a quick tram job on the alignment bar to make sure they are in line with the axis but it should speed up the setup of the two vises.

Here are a couple pics of the bar after surfacing with a 2" three insert face mill.

I want to thank everyone that has helped me through this process. Especially Jon Elson, Andy Pugh, BigJohnT, PCW, and Newbynobi.

I am not finished with the project by any means. I still have the following things I want to do. Some are trivial and some are not.

- Connect the mpg wheel on my control panel

- Add touch probe and use the probe interface that has been developed by verser

- Possibly add modbus control of my VFD's so that I can get feedback from the VFD as to the amp load on the spindle etc.

- Possibly add the XHC-HB04 wireless pendant to my control setup

- Add a spindle encoder of some sort for speed feedback and rigid tapping

- Maybe add a usb mesa card to control the original keypad that was on the fanuc control panel.

- Oh yea get a new monitor so the touch screen works.

I am going to go take a video overview of the machine and the retrofit in it's current state. I will try to post it up tonight.

Once I get my equipment moved into my new shop it will be time to start a CNC conversion on my Grizzly lathe. Now I can make all kinds of cool parts for the conversion with the mill!

Thanks again everyone.

NitroCH3NO2, Jim Craig

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 319

- Thank you received: 48

Please Log in or Create an account to join the conversation.