RB1-CNC Retrofit

- Alloy Craft

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 1

27 Jul 2015 09:34 #60945

by Alloy Craft

Replied by Alloy Craft on topic RB1-CNC Retrofit

Nice work, now to make some cool parts on that thing. Does the head tilt like a Bridgeport on that machine? On the spindle, I don't know how I'd live without rigid tapping, It's actually pretty easy to do.

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 319

- Thank you received: 48

27 Jul 2015 09:48 #60946

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic RB1-CNC Retrofit

Alloy Craft,

Thanks for the complement. The head does not tilt.

I will be making a pulley set to put on the spindle nose and on a ABZ encoder. Then I will be able to rigid tap. Just don't have all the bells and whistles done yet. This will also allow me to do more with setting spindle speed.

I spent this afternoon cleaning out the coolant sump so that I can put new coolant in it this week. Had some help from my lovely wife. She can't help it she hears the word cleaning and she comes running. Skimmed the oil out of the sump. Bleached the sump twice. Then cleaned it all with dawn and water. That thing was a mess. Looks good as new now.

If I get time this week I will be making a NMTB 30 toolholder jig so that I can tighten my er collet holders without putting them in the spindle. This jig will hold the toolholder horizontal so that it is easier to get the tool set to the right stick out length. May not have time though as the county fair is this week.

Thanks for the complement. The head does not tilt.

I will be making a pulley set to put on the spindle nose and on a ABZ encoder. Then I will be able to rigid tap. Just don't have all the bells and whistles done yet. This will also allow me to do more with setting spindle speed.

I spent this afternoon cleaning out the coolant sump so that I can put new coolant in it this week. Had some help from my lovely wife. She can't help it she hears the word cleaning and she comes running. Skimmed the oil out of the sump. Bleached the sump twice. Then cleaned it all with dawn and water. That thing was a mess. Looks good as new now.

If I get time this week I will be making a NMTB 30 toolholder jig so that I can tighten my er collet holders without putting them in the spindle. This jig will hold the toolholder horizontal so that it is easier to get the tool set to the right stick out length. May not have time though as the county fair is this week.

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 319

- Thank you received: 48

13 Aug 2015 08:26 #61365

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic RB1-CNC Retrofit

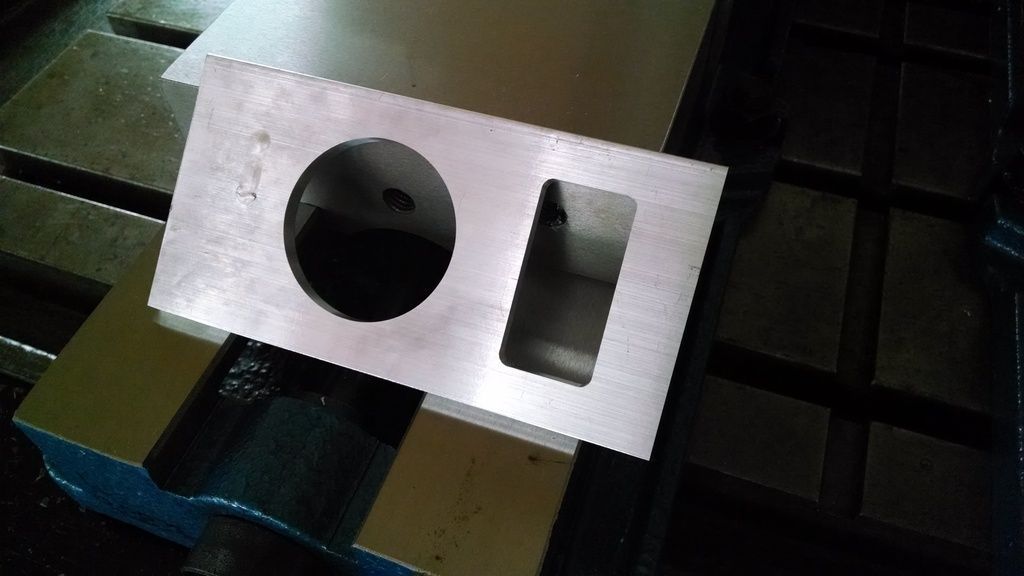

Here is a picture of the test part that I ran on the machine last weekend. Simple part with a trued edge a 2.000" diameter hole and a 2.000" x 1.000" rectangle. All of the dimensions came out to correct within 0.001" I am pretty happy with that. I roughed the openings with a 3/8" roughing end mill using HSM toolpaths. I left 0.020" for the finishing pass. I took the 0.020" off with a single pass then ran a spring pass on all cuts and had excellent results.

I need to work on the variable speed head now as it is not adjusting properly. hopefully that will be the last gremlin with this machine.

Now to make some parts that can be actually used for something.

I need to work on the variable speed head now as it is not adjusting properly. hopefully that will be the last gremlin with this machine.

Now to make some parts that can be actually used for something.

Please Log in or Create an account to join the conversation.

Time to create page: 0.082 seconds