Emcoturn 120 lathe retrofit

- Muzzer

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 38

06 Jun 2016 15:22 - 06 Jun 2016 15:25 #75558

by Muzzer

Replied by Muzzer on topic Emcoturn 120 lathe retrofit

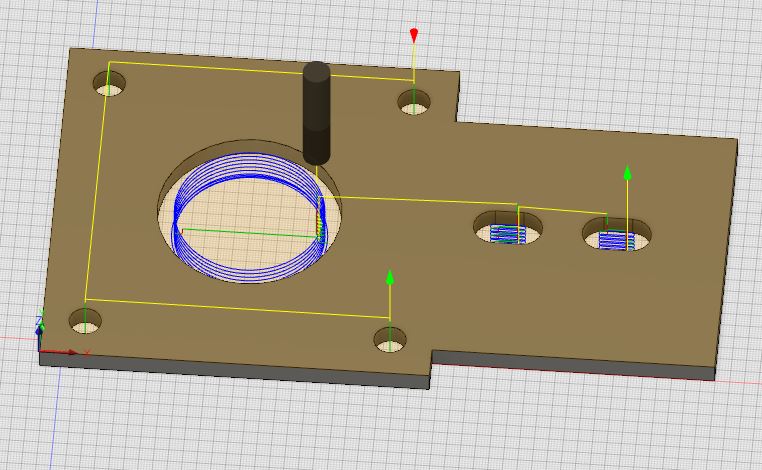

Fusion 360 is a new application being developed by Autodesk. As they bought HSMWorks not so long ago, they have included full 3D CAM inside (free!) Fusion, not just the 2.5D that you can plug in to Solidworks. I read yesterday that

PocketCNC

has got 5 axis CAM support in Fusion 360, so it sounds as if that is already implemented.

Despite being developed by Autodesk, it's reasonably easy to use, nothing like Autocad. Perhaps more like Onshape than Inventor or Solidworks. New features are being added but so far they have 3D CAD, simulation (FEA, vibration, thermal), surfacing, CAM and drawings. Not bad for free!! The Fusion 360 support forum is active and supportive.

Check out the Fusion 360 Youtube channel .

Despite being developed by Autodesk, it's reasonably easy to use, nothing like Autocad. Perhaps more like Onshape than Inventor or Solidworks. New features are being added but so far they have 3D CAD, simulation (FEA, vibration, thermal), surfacing, CAM and drawings. Not bad for free!! The Fusion 360 support forum is active and supportive.

Check out the Fusion 360 Youtube channel .

Last edit: 06 Jun 2016 15:25 by Muzzer. Reason: Add F360 YT link

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

06 Jun 2016 16:56 #75561

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

As a solidworks, pro/e Creo long time user I can see it has the typical issues with the low cost offerings. It isnt bad for small stuff but I see long term feature modification and some of the dissassociation of features as somewhat labor intensive in comparison. I will say at least that is much easier to manipulate then most of the free offerings I have tried. you can redimension a sketch and it modifies the model, but when I patterned a feature the pattern copies lost association and there was not a good way to copy feature that I found, but I have used it for about an hour so take this with that in mind. Also its not really fair to compare a free CAD package to two 5-7K offereings so on the flip side its really nice for a free offering and I was able to do a pretty easy job of making my plate, then making a copy and modifying it rather easy to the new shape. definitely better than a lot of packages out there, and the price is right. Its a keeper for me right now. I was also able to output DXF for the CAM program, looks like it outputs step, igs and others as well. Not too shabby.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

06 Jun 2016 17:14 #75563

by andypugh

Replied by andypugh on topic Emcoturn 120 lathe retrofit

The CAM is really very good. Fancy toolpaths and rapids at feed level.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

06 Jun 2016 17:23 #75565

by LutzTD

are you talking about the CAM in Fusion 360? I didnt see that.

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

The CAM is really very good. Fancy toolpaths and rapids at feed level.

are you talking about the CAM in Fusion 360? I didnt see that.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

06 Jun 2016 17:40 #75567

by andypugh

If you look in the "Linking" tab of an operation you can select the amount of stay-down and how far it is allowed to move at feed height.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

are you talking about the CAM in Fusion 360? I didnt see that.The CAM is really very good. Fancy toolpaths and rapids at feed level.

If you look in the "Linking" tab of an operation you can select the amount of stay-down and how far it is allowed to move at feed height.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

06 Jun 2016 18:18 - 06 Jun 2016 18:19 #75571

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

Last edit: 06 Jun 2016 18:19 by LutzTD.

Please Log in or Create an account to join the conversation.

- Muzzer

- Offline

- Elite Member

-

Less

More

- Posts: 260

- Thank you received: 38

06 Jun 2016 18:21 #75572

by Muzzer

I'd be surprised if your copy issue was real although I'm not certain what the problem was. If you posted on the F360 forum you'd get an answer back within hours.

I'm much more used to SW, SE and Inventor at the moment but given the features, support, cost and current investment, F360 has so much more going for it. SW etc is fine when you have access to a seat at work but when that goes you simply can't afford to buy it for home use - and then what happens?

Replied by Muzzer on topic Emcoturn 120 lathe retrofit

I suspect that when they have implemented most of the planned features (check out the features roadmap), you may be surprised. Also, they are aiming squarely at the professional mid range products like Solidworks, Solid Edge, ProE etc, rather than some shareware / hobby market. This is a well funded, fully resourced outfit with something like 200 full time s/w engineers and funding to date of over $150M. It will be paid for in the main by professional subscriptions, otherwise the investors will be looking for some serious scalps....its not really fair to compare a free CAD package to two 5-7K offereings so on the flip side its really nice for a free offering and I was able to do a pretty easy job of making my plate, then making a copy and modifying it rather easy to the new shape. definitely better than a lot of packages out there, and the price is right. Its a keeper for me right now.

I'd be surprised if your copy issue was real although I'm not certain what the problem was. If you posted on the F360 forum you'd get an answer back within hours.

I'm much more used to SW, SE and Inventor at the moment but given the features, support, cost and current investment, F360 has so much more going for it. SW etc is fine when you have access to a seat at work but when that goes you simply can't afford to buy it for home use - and then what happens?

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

07 Jun 2016 13:17 - 07 Jun 2016 13:34 #75639

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

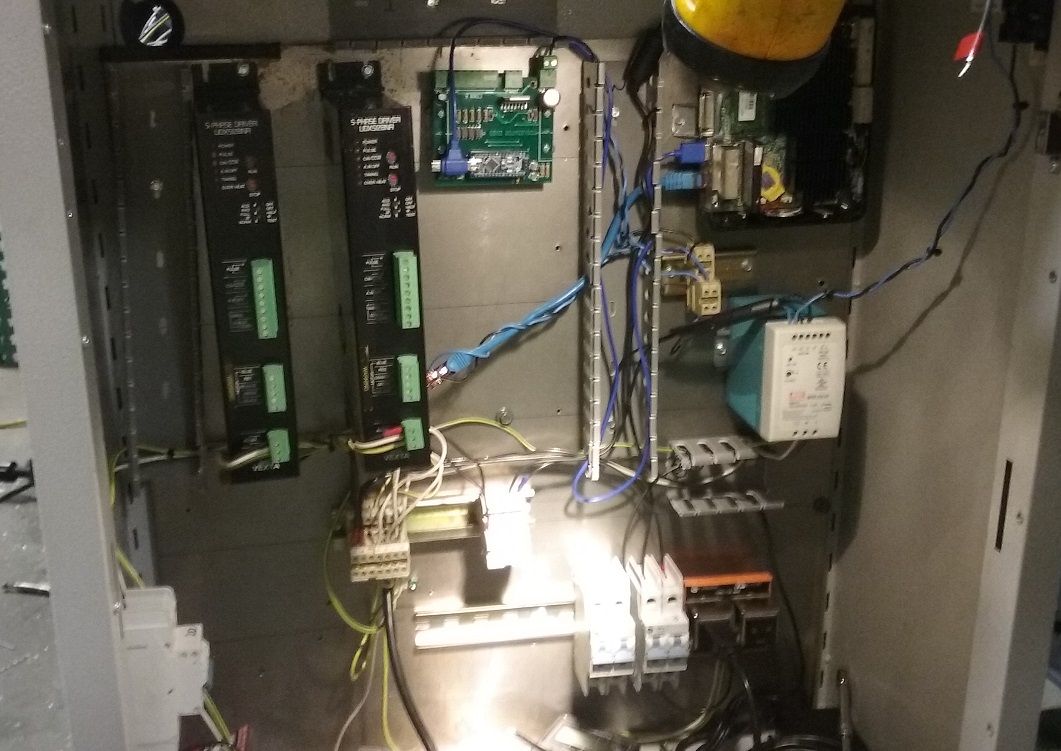

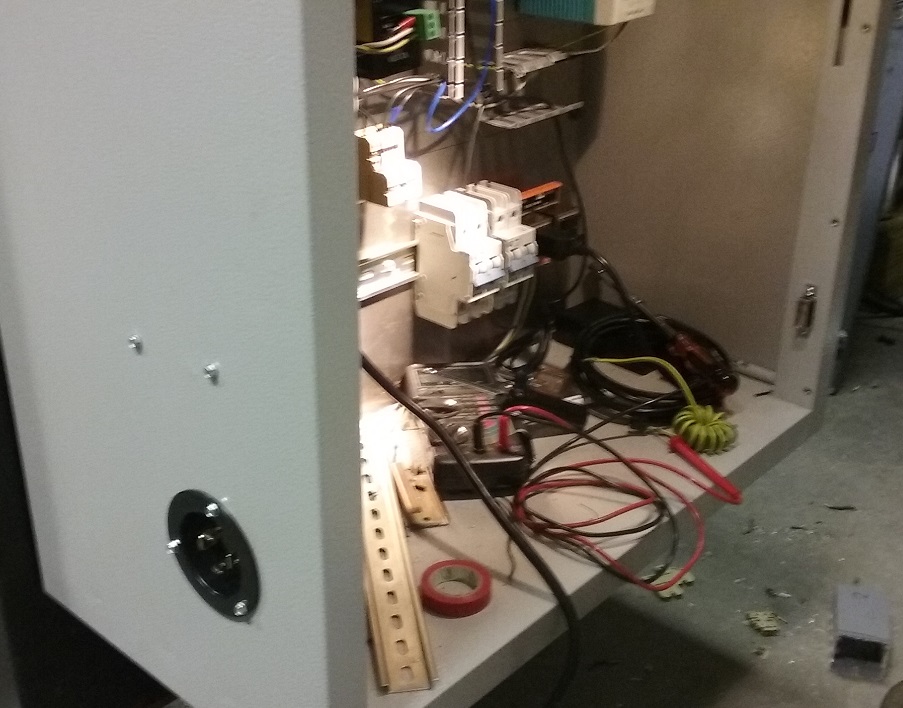

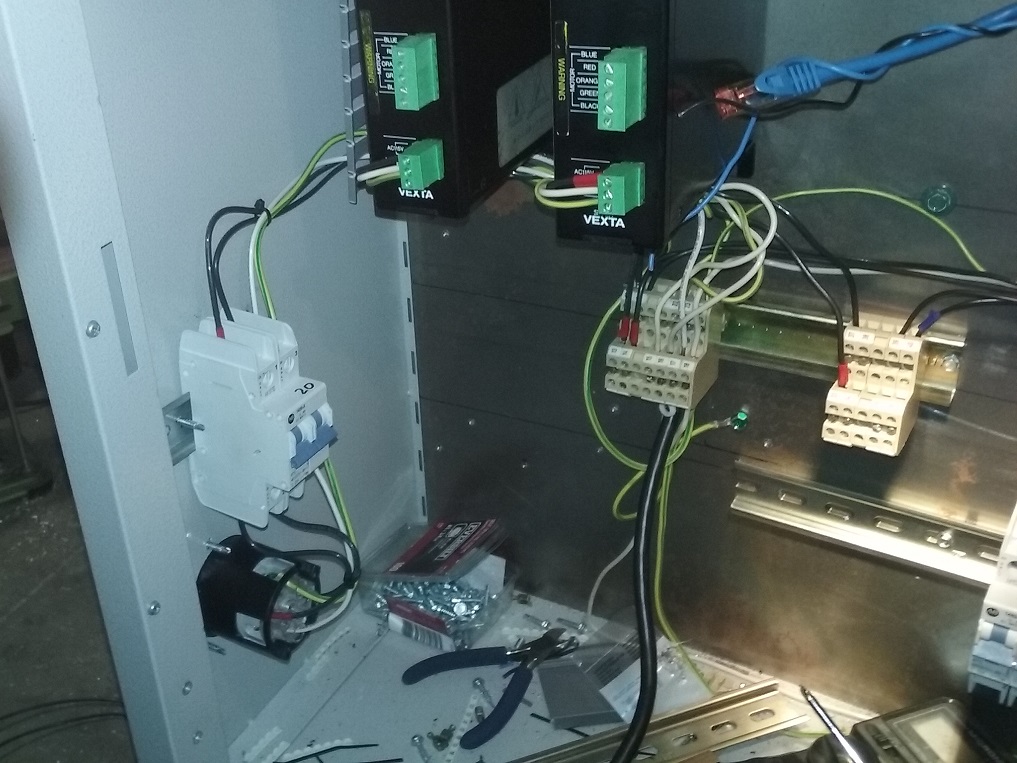

got a little more done last night. I got 5 packages of parts so I was able to do more on the power wiring. I added the inlet plug and the main breaker as well as mounting the new longer din rail for the 3A breaker and the 110vac power outlet. The tangle of commons and grounds at the power block will get re-cut in the future once everything is placed in its final spot. I also have wrap for most of the runs courtesy of the emco I will be adding at the end

Last edit: 07 Jun 2016 13:34 by LutzTD.

Please Log in or Create an account to join the conversation.

- LutzTD

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 1

09 Jun 2016 00:02 #75703

by LutzTD

Replied by LutzTD on topic Emcoturn 120 lathe retrofit

I won an Allen Bradley contactor from ebay, It was supposed to be a 24vdc coil version (A26-30-10-81) but much to my surprise the 24vdc on the label was crossed out and hand written 110VAC was on the box label. Its there in the picture now that I look, but all descriptions say its the r81 coil so I didnt look hard enough to see the hand written change on the label. Sure enough it is a 110VAC coil. A26-30-10-84) So, I rewired the stop switch to pull a 120V from the B leg and through the 3A circuit breaker and this works. It pulls .18A according to my meter so no biggy on power consumption, but the relay buzzes. If I do it one time its quiet, but if I actuate it a couple times in quick succession the buzz gets louder each time then sometime goes off. I dont know if this matters, but the buzz worries me that it will introduce noise in the line and emmitted. Is this normal for a contactor? Should I ask the seller to refund and send it back and get a 24VDC coil as I originally intended? I figured DC would be quieter, but this is just a guess.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

09 Jun 2016 12:19 #75718

by andypugh

I would be tempted to in your situation. the -81 suffix stated in the description and the title definitely means 24V DC, so what arrived isn't what was stated in the auction.

But, perhaps the 110V coil is useful, as it can operate without needing the 24V PSU to be working.

Replied by andypugh on topic Emcoturn 120 lathe retrofit

Should I ask the seller to refund and send it back and get a 24VDC coil as I originally intended?

I would be tempted to in your situation. the -81 suffix stated in the description and the title definitely means 24V DC, so what arrived isn't what was stated in the auction.

But, perhaps the 110V coil is useful, as it can operate without needing the 24V PSU to be working.

Please Log in or Create an account to join the conversation.

Time to create page: 0.161 seconds