Biesse Rover 18 CNC router

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

29 Jan 2018 00:42 #105136

by Peterdeleu

Replied by Peterdeleu on topic Biesse Rover 18 CNC router

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

29 Jan 2018 00:44 #105137

by Peterdeleu

Replied by Peterdeleu on topic Biesse Rover 18 CNC router

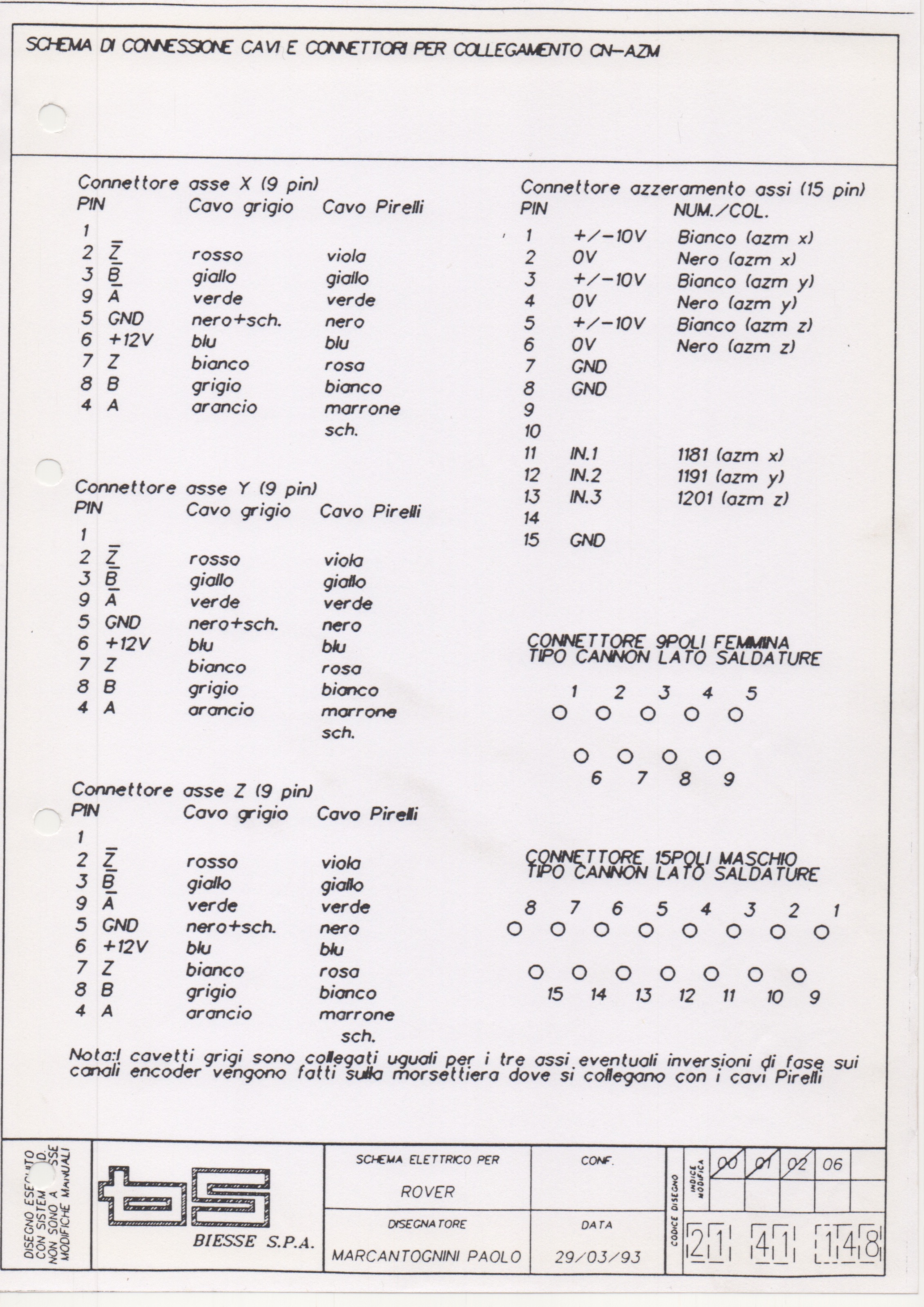

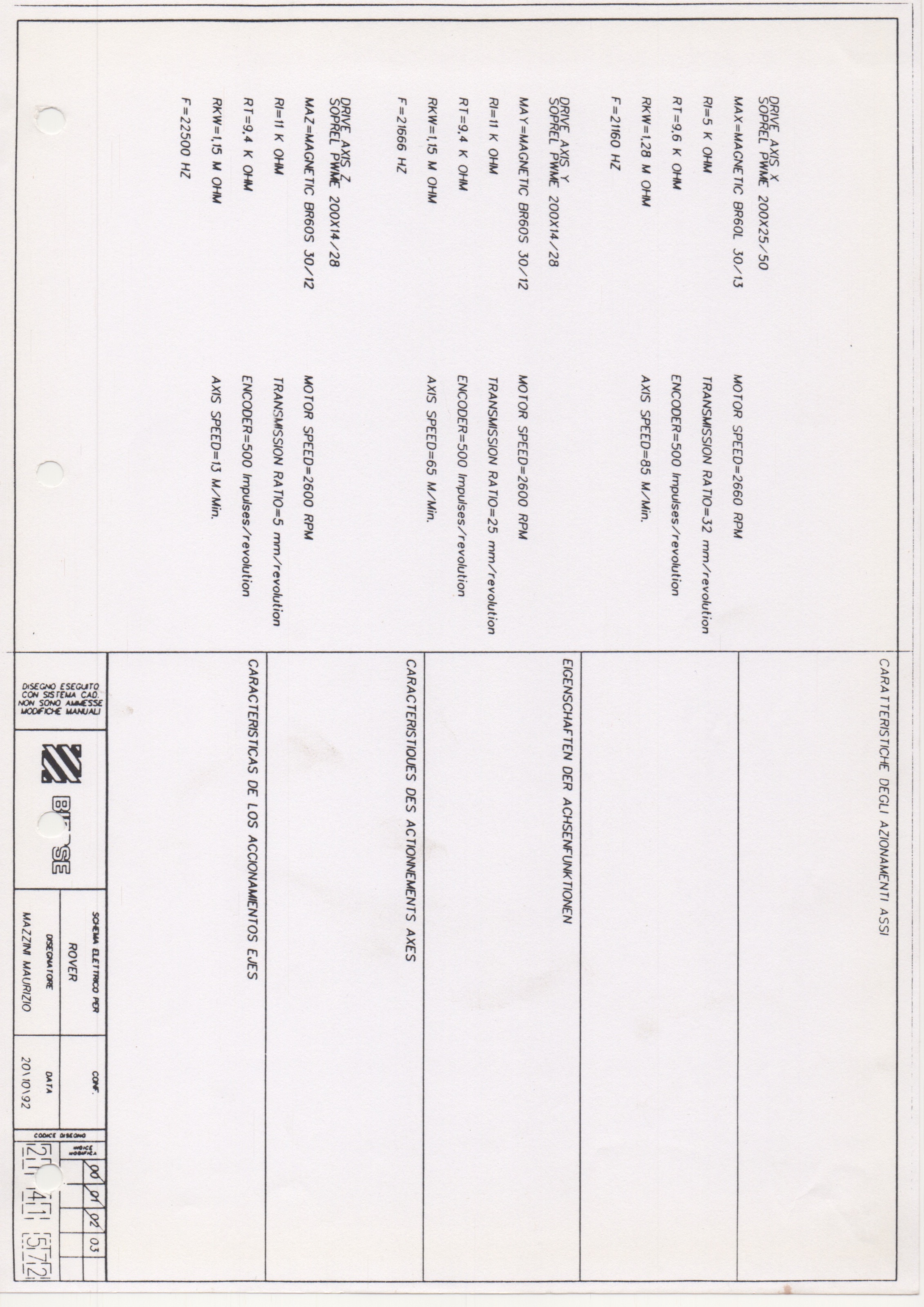

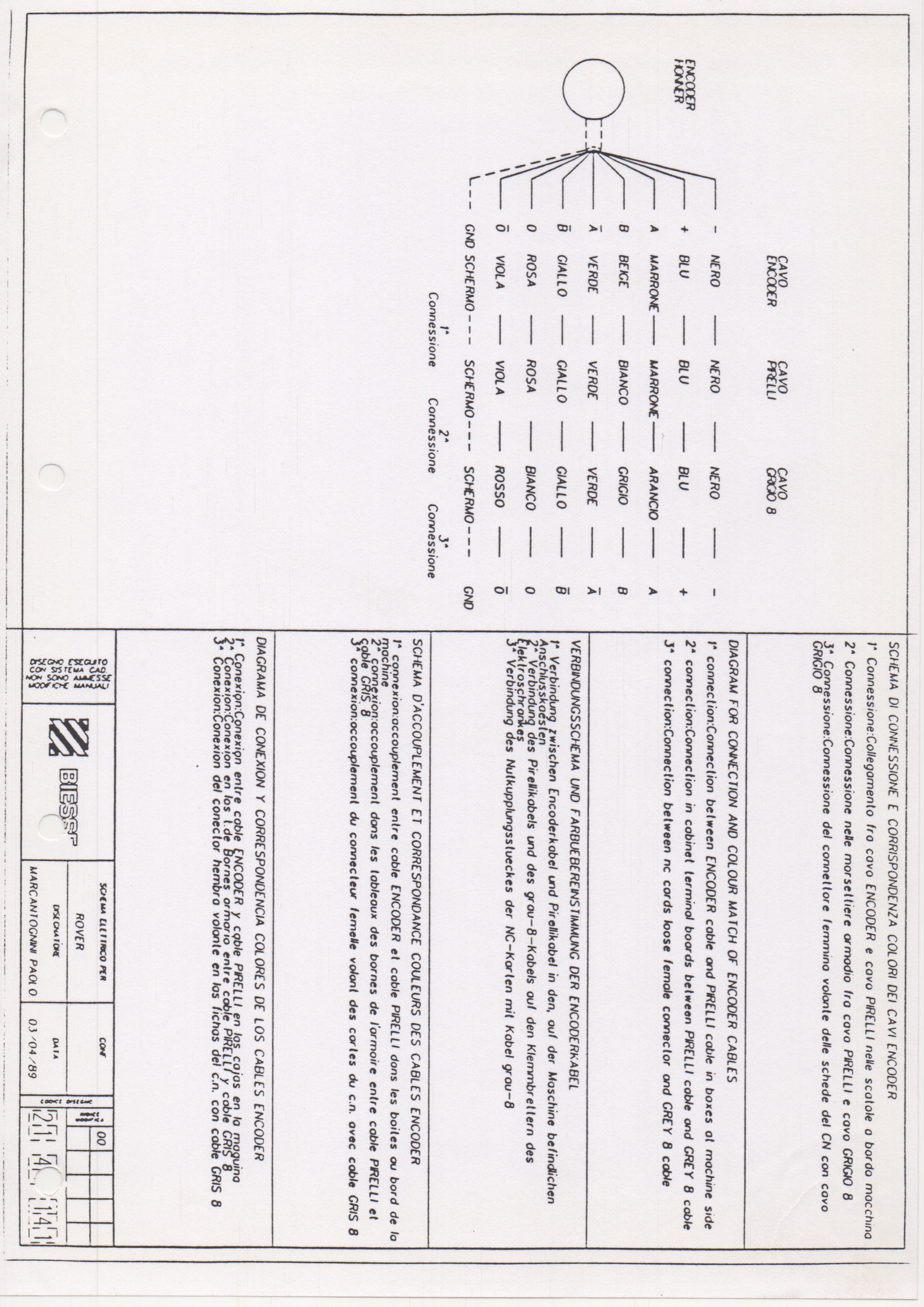

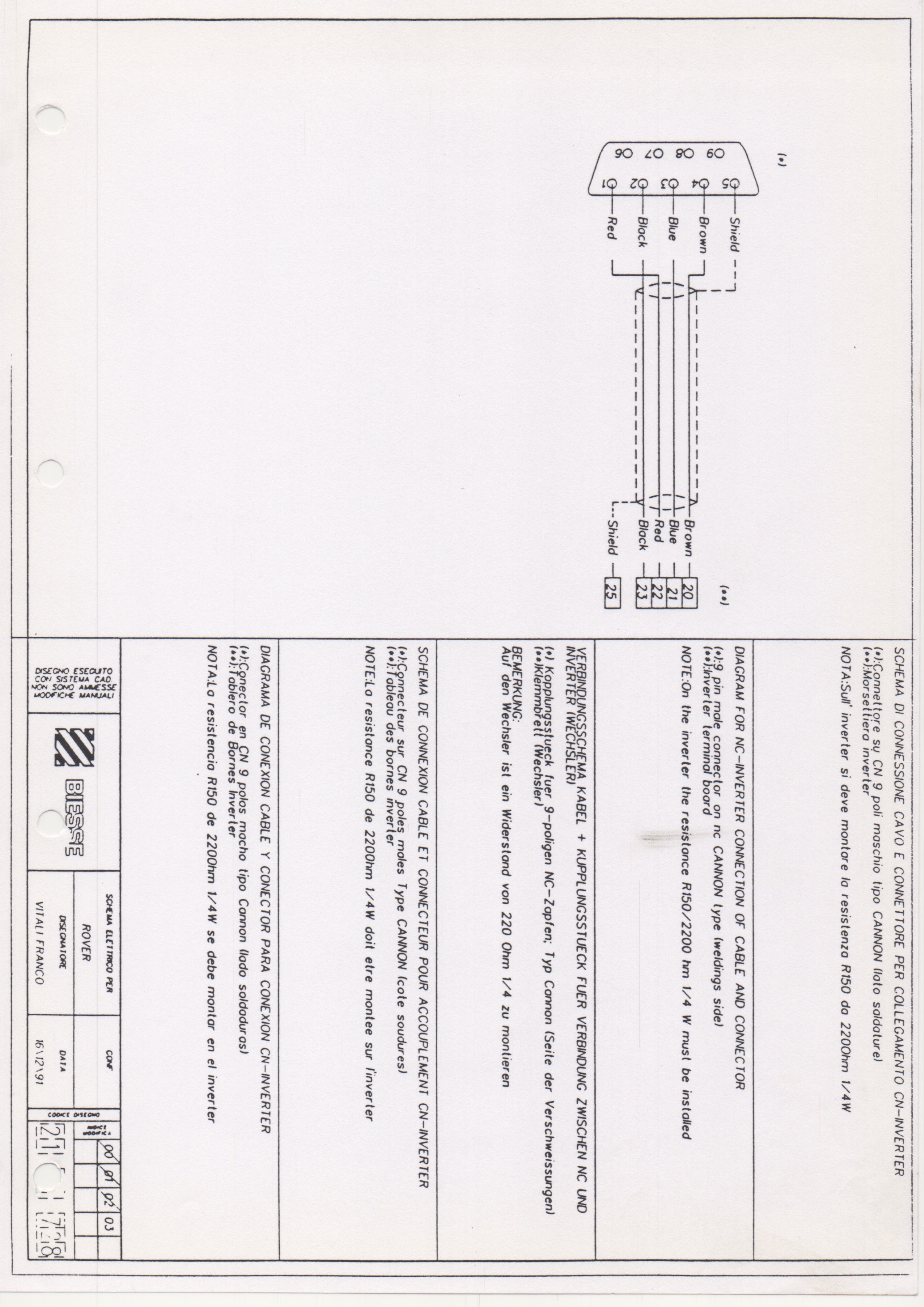

I've found some information in the manual.

In attach you can find the wiring diagrams

In attach you can find the wiring diagrams

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

29 Jan 2018 03:46 #105140

by Todd Zuercher

Replied by Todd Zuercher on topic Biesse Rover 18 CNC router

It looks like it would be a relatively straight forward servo conversion. A Mesa 7i77 + one of Mesa's DB25 FPGA cards woiuld be able to send analog velocity commands to the drives and read the encoder feedbacks.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21177

- Thank you received: 7235

29 Jan 2018 10:36 #105148

by tommylight

Replied by tommylight on topic Biesse Rover 18 CNC router

That looks all good and as far as i can see there is only the encoder voltage that has to be lowered to 5V level through voltage dividers. Your encoders are 12Volts, 7i77 has 5V envoder inputs.

That requires adding some resistors to encoder outputs before wiring them to 7i77 encoder inputs.

Can be done, it looks that you can keep the existing drives and motors.

That requires adding some resistors to encoder outputs before wiring them to 7i77 encoder inputs.

Can be done, it looks that you can keep the existing drives and motors.

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

29 Jan 2018 11:10 #105151

by Peterdeleu

Replied by Peterdeleu on topic Biesse Rover 18 CNC router

Ok, Great

I've just looked at the website of messa.

There are a lot of cards available.

Is it possible to give me a specific 7i77 card and a DB25 FPGA card?

Then I'm sure that I have a good starting point

tx !!

I've just looked at the website of messa.

There are a lot of cards available.

Is it possible to give me a specific 7i77 card and a DB25 FPGA card?

Then I'm sure that I have a good starting point

tx !!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

29 Jan 2018 14:38 #105154

by Todd Zuercher

Replied by Todd Zuercher on topic Biesse Rover 18 CNC router

It depends on how you want to connect the FPGA card to your computer, PCI 5i25, PCIe 6i25, Ethernet 7i92.

Just because your encoders ran off of 12v before, does not mean they can not work with a 5v system. Some encoders can work with a range of voltages. You should try looking up the specifications for your specific encoder model. They may in fact be perfectly happy running off of a more common 5v supply or output 5v signals. If the encoders do in fact require and output 12v signals, contact Mesa for specific instructions how you should connect them (the encoder inputs on the 7i77 might be 12v tolerant anyway.)

PS Peter (PCW) is the owner of Mesa, and is very active and helpful on the forums.

Just because your encoders ran off of 12v before, does not mean they can not work with a 5v system. Some encoders can work with a range of voltages. You should try looking up the specifications for your specific encoder model. They may in fact be perfectly happy running off of a more common 5v supply or output 5v signals. If the encoders do in fact require and output 12v signals, contact Mesa for specific instructions how you should connect them (the encoder inputs on the 7i77 might be 12v tolerant anyway.)

PS Peter (PCW) is the owner of Mesa, and is very active and helpful on the forums.

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

29 Jan 2018 15:28 #105159

by Peterdeleu

Replied by Peterdeleu on topic Biesse Rover 18 CNC router

Perfect!!

First of all I want to explain what I like to do

I was looking to build my own CNC. But building a strong CNC is not a easy task.

There's a lot involved and the cost of decent linear rails, ball screws, the frame, servo's or steppers, .. can be high.

Last week I found a Biesse Rover 18 for 1200 euro. The machine is still working fine and has been weekly used the last years. For my opinion, this is a good base to start with.

The only disadvantage is the controller. It is a NC481 and as far as I know it is only capable of running 400 lines.

This is sufficient to drill some holes, but insufficient to do more complex milling.

I was trying to find a CAD/CAM solution (Fusion 360 and and FDD replacement to USB), but even then I still have the limitations of the NC481 controller.

Therefore I started thinking about replacing the controller by a modern controller. (Mach3, LinuxCNC, .... )

With the information I got from this forum, I am sure that this is the best option.

The Rover 18 is equipped with 12 vertical boring and 4 horizontal boring spindels. There is also a 125 mm saw, and a main router.

In the first fase I would like to start with the main router only. This will give me the same possibilities as a own build router.

Later on I can try to find out how I could use the vertical and horizontal boring spindels.

So, for now I'm looking how to control the X,Y and Z-axis, the router speed, the homing sensors, the vacuum pump and the pneumatic things to position my workpiece (I don't know the name if this )

)

I'm pretty sure that this will not be a difficult task. Especially if I can keep my servo's, encoders and drivers.

Regards

Peter

First of all I want to explain what I like to do

I was looking to build my own CNC. But building a strong CNC is not a easy task.

There's a lot involved and the cost of decent linear rails, ball screws, the frame, servo's or steppers, .. can be high.

Last week I found a Biesse Rover 18 for 1200 euro. The machine is still working fine and has been weekly used the last years. For my opinion, this is a good base to start with.

The only disadvantage is the controller. It is a NC481 and as far as I know it is only capable of running 400 lines.

This is sufficient to drill some holes, but insufficient to do more complex milling.

I was trying to find a CAD/CAM solution (Fusion 360 and and FDD replacement to USB), but even then I still have the limitations of the NC481 controller.

Therefore I started thinking about replacing the controller by a modern controller. (Mach3, LinuxCNC, .... )

With the information I got from this forum, I am sure that this is the best option.

The Rover 18 is equipped with 12 vertical boring and 4 horizontal boring spindels. There is also a 125 mm saw, and a main router.

In the first fase I would like to start with the main router only. This will give me the same possibilities as a own build router.

Later on I can try to find out how I could use the vertical and horizontal boring spindels.

So, for now I'm looking how to control the X,Y and Z-axis, the router speed, the homing sensors, the vacuum pump and the pneumatic things to position my workpiece (I don't know the name if this

I'm pretty sure that this will not be a difficult task. Especially if I can keep my servo's, encoders and drivers.

Regards

Peter

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4694

- Thank you received: 1439

29 Jan 2018 16:31 #105161

by Todd Zuercher

Replied by Todd Zuercher on topic Biesse Rover 18 CNC router

That machine is a large industrial machine with a lot of digital io that you will need to control. It will also have some complex PLC logic you will need to recreate. It will be a large but very rewarding project once finished. Don't take shortcuts, do it right. You will likely need more digital io than the 7i77 can provide by it's self. Adding one or two of Mesa's remote serial daughter cards (Smart Serial) is a good option to add very large numbers of digital io. For example you will need 16 digital outputs just for the drilling head.

Just remember this isn't going to be a quick weekend project. It will take a few weeks of planning and work, if you know what you are doing. Longer if you are learning as you go.

Just remember this isn't going to be a quick weekend project. It will take a few weeks of planning and work, if you know what you are doing. Longer if you are learning as you go.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21177

- Thank you received: 7235

29 Jan 2018 17:42 #105167

by tommylight

Replied by tommylight on topic Biesse Rover 18 CNC router

Do not overthink this, just order mesa cards from masanet.com or mesaus.com or eusurplus.com since you are in Europe, and start the retrofit.

In the meantime study the machine indetail, make notes of things of interest like : the machine has several spindles but only one VFD to control them, check the relays and what and how they control things like solenoids (air valves), check the limit switches and other sensors etc etc. Get to know what you are dealing with as it will come handy later on.

The best thing about linuxcnc is that it is open source, it can be modified and programmed for almost any machine and it has the best techical support of very competent users on this forum.

I could not get a Rover 346 even at 9000 euro and with mesed up computer, since i have seen Bevins ( a user on this forum ) do a retrofit to the same machine i have been looking to find one as i really like the hardware on them.

Then again, to many projects and not enough time.

In the meantime study the machine indetail, make notes of things of interest like : the machine has several spindles but only one VFD to control them, check the relays and what and how they control things like solenoids (air valves), check the limit switches and other sensors etc etc. Get to know what you are dealing with as it will come handy later on.

The best thing about linuxcnc is that it is open source, it can be modified and programmed for almost any machine and it has the best techical support of very competent users on this forum.

I could not get a Rover 346 even at 9000 euro and with mesed up computer, since i have seen Bevins ( a user on this forum ) do a retrofit to the same machine i have been looking to find one as i really like the hardware on them.

Then again, to many projects and not enough time.

Please Log in or Create an account to join the conversation.

- Peterdeleu

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 0

29 Jan 2018 17:44 #105168

by Peterdeleu

Replied by Peterdeleu on topic Biesse Rover 18 CNC router

Todd, I don't underestimate the time needed to update the machine.

I don't need the machine, it's purely a bobby project.

The only thing is, I'm new in LinuxCNC and it looks complex at first sight.

I'll try to install a Linux machine with the LinuxCNC in the next couple of days to find out how it works.

There is probably less complicate software on the market, but I don't know if they can handle a machine with analog drivers... We'll see

And is the PLC logic programmable within LinuxCNC? Or do I need another controller to handle this jobs?

I don't need the machine, it's purely a bobby project.

The only thing is, I'm new in LinuxCNC and it looks complex at first sight.

I'll try to install a Linux machine with the LinuxCNC in the next couple of days to find out how it works.

There is probably less complicate software on the market, but I don't know if they can handle a machine with analog drivers... We'll see

And is the PLC logic programmable within LinuxCNC? Or do I need another controller to handle this jobs?

Please Log in or Create an account to join the conversation.

Time to create page: 0.231 seconds