Fryer MB-11 Bed Mill Retrofit

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

10 May 2018 16:01 #110524

by andypugh

Replied by andypugh on topic Fryer MB-11 Bed Mill Retrofit

I quite like three-position rotary switches for things with an Off-Auto-On behaviour.

Please Log in or Create an account to join the conversation.

- DeckelHead

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 2

10 May 2018 17:34 #110526

by DeckelHead

Replied by DeckelHead on topic Fryer MB-11 Bed Mill Retrofit

Thanks, Andy... I'll give that some thought. Obviously there is a concrete assignment of an intent with a physical switch which I should consider. I opted for the ephemeral approach of using pushbuttons because it allows the control to reset to a consistent state when it powers on, and I can make judicious use of lighted buttons. This is how the Hurco was setup and I liked that. However, I have to be honest... I really didn't consider using a 3 position switch, and I can see the use. If I go that route, I'll likely add an LED above/near the switch to indicate 'AUTO' though.

Thanks for the suggestion/feedback.

Alan

Thanks for the suggestion/feedback.

Alan

Please Log in or Create an account to join the conversation.

- adamj12b

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 5

10 May 2018 17:34 #110527

by adamj12b

Replied by adamj12b on topic Fryer MB-11 Bed Mill Retrofit

Alan,

I like the copy/paste of the rotary switchs

Feedhold and M1 op stop are basically pauses. linuxcnc.org/docs/html/gcode/m-code.html#mcode:m0-m1

I wanted a button to turn M1 on/off.

I like the touchscreen much better then a house. Im currently using a wireless keyboard with trackpad and hate it...

For the jog increment, My machine has 0.0001 = 0.010" per rev, 0.001 = 0.100" per rev and 0.010 = 1.000" per rev, as these are directly related to the numbers on the MPG.

What screen GUI are you planing on using?

I like the copy/paste of the rotary switchs

Feedhold and M1 op stop are basically pauses. linuxcnc.org/docs/html/gcode/m-code.html#mcode:m0-m1

I wanted a button to turn M1 on/off.

I like the touchscreen much better then a house. Im currently using a wireless keyboard with trackpad and hate it...

For the jog increment, My machine has 0.0001 = 0.010" per rev, 0.001 = 0.100" per rev and 0.010 = 1.000" per rev, as these are directly related to the numbers on the MPG.

What screen GUI are you planing on using?

Please Log in or Create an account to join the conversation.

- DeckelHead

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 2

10 May 2018 17:50 #110530

by DeckelHead

Replied by DeckelHead on topic Fryer MB-11 Bed Mill Retrofit

LOL... Yeah, I unabashedly admit that I have both hijacked your thread and your switch drawings.

I'll visit the M1 op stop, feed, pause issue. Thanks for the link.

I understand the jog increment thing. Units of 10 definitely make a lot more sense; to that end, 0.0001, 0.001, 0.010, 0.1 are pretty much what I would want. Unfortunately, I don't have a 4 position switch, so I expanded to the x5 units too. That is, frankly, probably pretty stupid. What is wagging what? I'm letting the lack of a readily available 4P switch push the design consideration of a console? Duh! What am I thinking! I'll fix that.

I'll fix that.

I'm not sure what UI I'll be using on it right now. I was thinking I wanted basic mouse movement to be through the touch panel. But that leaves key input as a problem and I don't have a solution there. I've considered putting a numeric keypad in the console but I'm torn with whether or not that will be sufficient. It would probably be the "safe" thing to do though.... But I can't see a way around a supplemental BT keyboard and mouse for more complex things. Glad you brought up the keyboard thing though... I think that warrants a longer conversation....

I'll visit the M1 op stop, feed, pause issue. Thanks for the link.

I understand the jog increment thing. Units of 10 definitely make a lot more sense; to that end, 0.0001, 0.001, 0.010, 0.1 are pretty much what I would want. Unfortunately, I don't have a 4 position switch, so I expanded to the x5 units too. That is, frankly, probably pretty stupid. What is wagging what? I'm letting the lack of a readily available 4P switch push the design consideration of a console? Duh! What am I thinking!

I'm not sure what UI I'll be using on it right now. I was thinking I wanted basic mouse movement to be through the touch panel. But that leaves key input as a problem and I don't have a solution there. I've considered putting a numeric keypad in the console but I'm torn with whether or not that will be sufficient. It would probably be the "safe" thing to do though.... But I can't see a way around a supplemental BT keyboard and mouse for more complex things. Glad you brought up the keyboard thing though... I think that warrants a longer conversation....

Please Log in or Create an account to join the conversation.

- adamj12b

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 45

- Thank you received: 5

10 May 2018 18:08 #110531

by adamj12b

Replied by adamj12b on topic Fryer MB-11 Bed Mill Retrofit

Maybe Andy can shed light on if this is the correct approach or not, but what I did was look at HALUI and find signals that are already created. Here is a list that is handy. linuxcnc.org/docs/html/gui/halui.html

Most of the stuff needed already exists, just needs to be connected to.

Most of the stuff needed already exists, just needs to be connected to.

Please Log in or Create an account to join the conversation.

- DeckelHead

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 2

10 May 2018 21:48 #110545

by DeckelHead

Replied by DeckelHead on topic Fryer MB-11 Bed Mill Retrofit

AndyJ... Where did you purchase your rotary switch caps? I'm surprised I didn't see those on eBay. I like yours more than the ones I have now.

I'm going to integrate a keypad into this design and repost...

I'm going to integrate a keypad into this design and repost...

Please Log in or Create an account to join the conversation.

- DeckelHead

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 2

11 May 2018 03:36 #110564

by DeckelHead

Replied by DeckelHead on topic Fryer MB-11 Bed Mill Retrofit

Disclaimer... I'm not a G-code person because the Hurco was conversational...

I don't quite understand the difference between the M0 and M1 pauses. The latter only pauses if the stop switch is enabled. But, it seems like a stop switch should, well, STOP execution! And, by extension, when I press a pause then wouldn't I want the machine to pause and not have that operation conditional on another setting? I don't get the actual use cases here.

I don't quite understand the difference between the M0 and M1 pauses. The latter only pauses if the stop switch is enabled. But, it seems like a stop switch should, well, STOP execution! And, by extension, when I press a pause then wouldn't I want the machine to pause and not have that operation conditional on another setting? I don't get the actual use cases here.

Please Log in or Create an account to join the conversation.

- DeckelHead

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 2

11 May 2018 04:04 - 11 May 2018 04:12 #110566

by DeckelHead

Replied by DeckelHead on topic Fryer MB-11 Bed Mill Retrofit

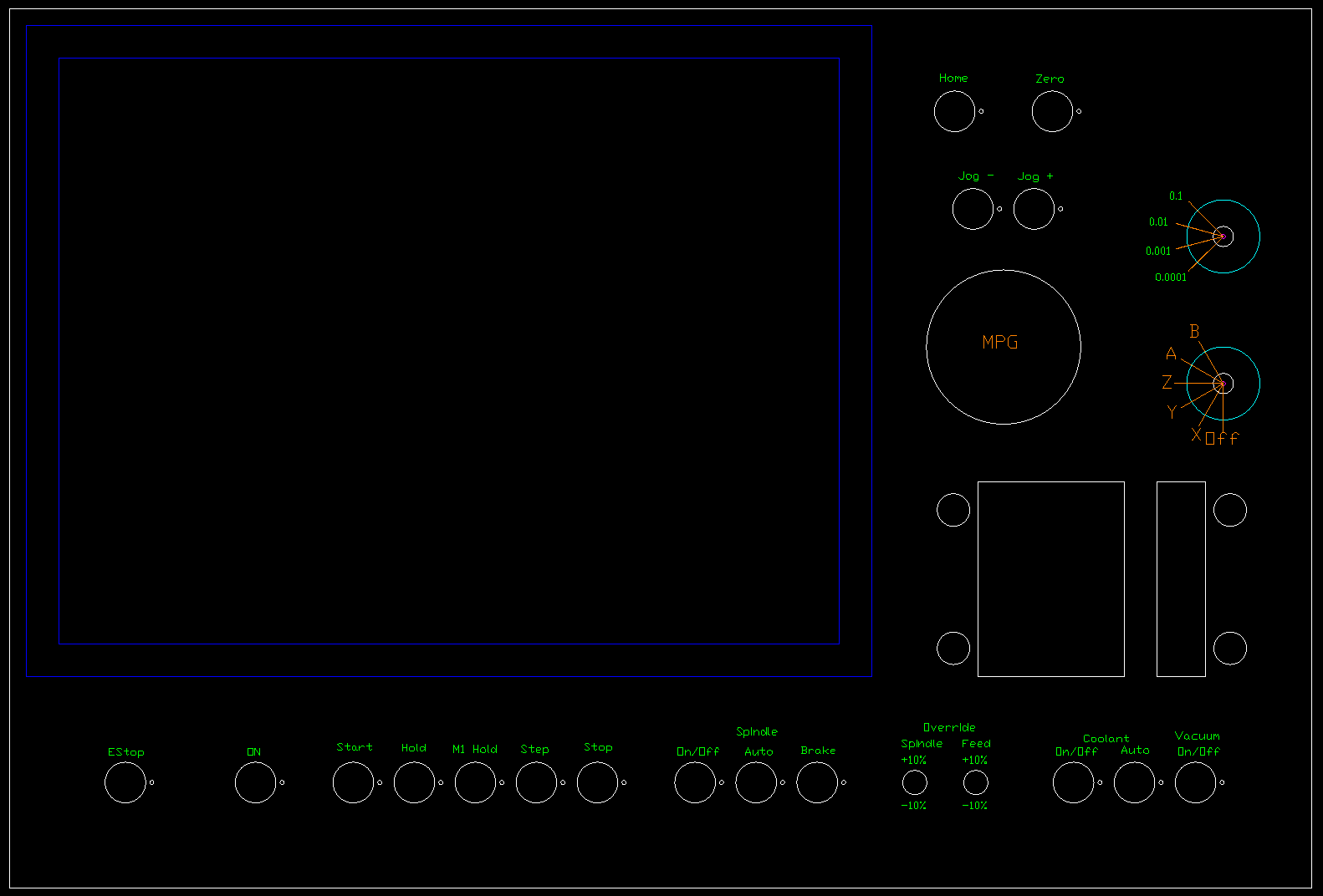

Here is another stab at the console. In this one, I have:

My four function keys (not really the right term) would be:

I'm not too sure how feasible this keypad is, however. It is a leftover from the Hurco and is *not* USB; it is a matrix keypad. That means I'll have to (somehow) have LinuxCNC scan the matrix and detect/process the switch closures. Does LinuxCNC have a facility to do this or do you have to write some funky logic ladder type of thing? That would seem a bit strange. Or, can I have the inputs go directly into the Mesa and have Linux construct meaningful keypresses from there? It is the numeric side of the world that I'm not sure about here (0-9). The only other alternative would be to put an Arduino in there so I can get into USB land, but then I'd have to write some driver (?) for LinuxCNC to read the data coming from the USB.

One use case would be: Tool -> 12 -> ENT -> CAL to calibrate tool #12

(edit: MATRIX_KB is a HAL component that will do the keypad scan)

- changed the feed switch to 4-position, all units modules of 10.

- removed the tool INC/DEC switch and Calibrate buttons

- added a cutout for a 0-9, -, (decimal point) keypad and four function keys (ignore the round mounting holes

My four function keys (not really the right term) would be:

- Tool

- CAL

- (unknown)

- ENTER

I'm not too sure how feasible this keypad is, however. It is a leftover from the Hurco and is *not* USB; it is a matrix keypad. That means I'll have to (somehow) have LinuxCNC scan the matrix and detect/process the switch closures. Does LinuxCNC have a facility to do this or do you have to write some funky logic ladder type of thing? That would seem a bit strange. Or, can I have the inputs go directly into the Mesa and have Linux construct meaningful keypresses from there? It is the numeric side of the world that I'm not sure about here (0-9). The only other alternative would be to put an Arduino in there so I can get into USB land, but then I'd have to write some driver (?) for LinuxCNC to read the data coming from the USB.

One use case would be: Tool -> 12 -> ENT -> CAL to calibrate tool #12

(edit: MATRIX_KB is a HAL component that will do the keypad scan)

Last edit: 11 May 2018 04:12 by DeckelHead.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

11 May 2018 12:32 #110574

by andypugh

Nor do I. But it's part of all G-code specifications so LinuxCNC needs to support it.

Possibly in production you would use it to pause the first job to test a dimension then disable it for the rest of the batch?

Replied by andypugh on topic Fryer MB-11 Bed Mill Retrofit

I don't quite understand the difference between the M0 and M1 pauses.

...

I don't get the actual use cases here.

Nor do I. But it's part of all G-code specifications so LinuxCNC needs to support it.

Possibly in production you would use it to pause the first job to test a dimension then disable it for the rest of the batch?

Please Log in or Create an account to join the conversation.

- DeckelHead

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 2

11 May 2018 14:41 - 11 May 2018 16:20 #110580

by DeckelHead

Replied by DeckelHead on topic Fryer MB-11 Bed Mill Retrofit

Wow. I'm proud of myself. I finally stumped you, Andy.  You seem to have had an answer for everything I've ever lobbed over the fence so far, which has been wonderful.

You seem to have had an answer for everything I've ever lobbed over the fence so far, which has been wonderful.

OK, I'm curious to see if the other Andy has some input on the different pauses as he intentionally added buttons for both to his console at the beginning of this thread. If there isn't a good reason, I'll probably nix the button for my design.

Hmmm, I recall buttons with little LCD screens on the front for 'soft' usage. I'm typically not to big on the idea of soft buttons, but I kind of wonder if something like that might not be useful. My gut is a pretty resounding 'NO' but I may do a quick look see.

[edit: surprisingly inexpensive... $36USD. Here is the result of a quick search: www.lcd-keys.com/english/FunGizmos.htm. Update: looks like FunGizmos is out of business. Further, I'm not sure how much work it would be to integrate a dynamic key into LinuxCNC. That, in addition to the concern over whether or not a changing 'function' key is even a very good idea, makes me think this is course that is probably not even worth pursuing....]

OK, I'm curious to see if the other Andy has some input on the different pauses as he intentionally added buttons for both to his console at the beginning of this thread. If there isn't a good reason, I'll probably nix the button for my design.

Hmmm, I recall buttons with little LCD screens on the front for 'soft' usage. I'm typically not to big on the idea of soft buttons, but I kind of wonder if something like that might not be useful. My gut is a pretty resounding 'NO' but I may do a quick look see.

[edit: surprisingly inexpensive... $36USD. Here is the result of a quick search: www.lcd-keys.com/english/FunGizmos.htm. Update: looks like FunGizmos is out of business. Further, I'm not sure how much work it would be to integrate a dynamic key into LinuxCNC. That, in addition to the concern over whether or not a changing 'function' key is even a very good idea, makes me think this is course that is probably not even worth pursuing....]

Last edit: 11 May 2018 16:20 by DeckelHead.

Please Log in or Create an account to join the conversation.

Time to create page: 0.346 seconds