Mini wannabe datron build

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

05 Apr 2023 20:46 #268351

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Aaaand we're back.

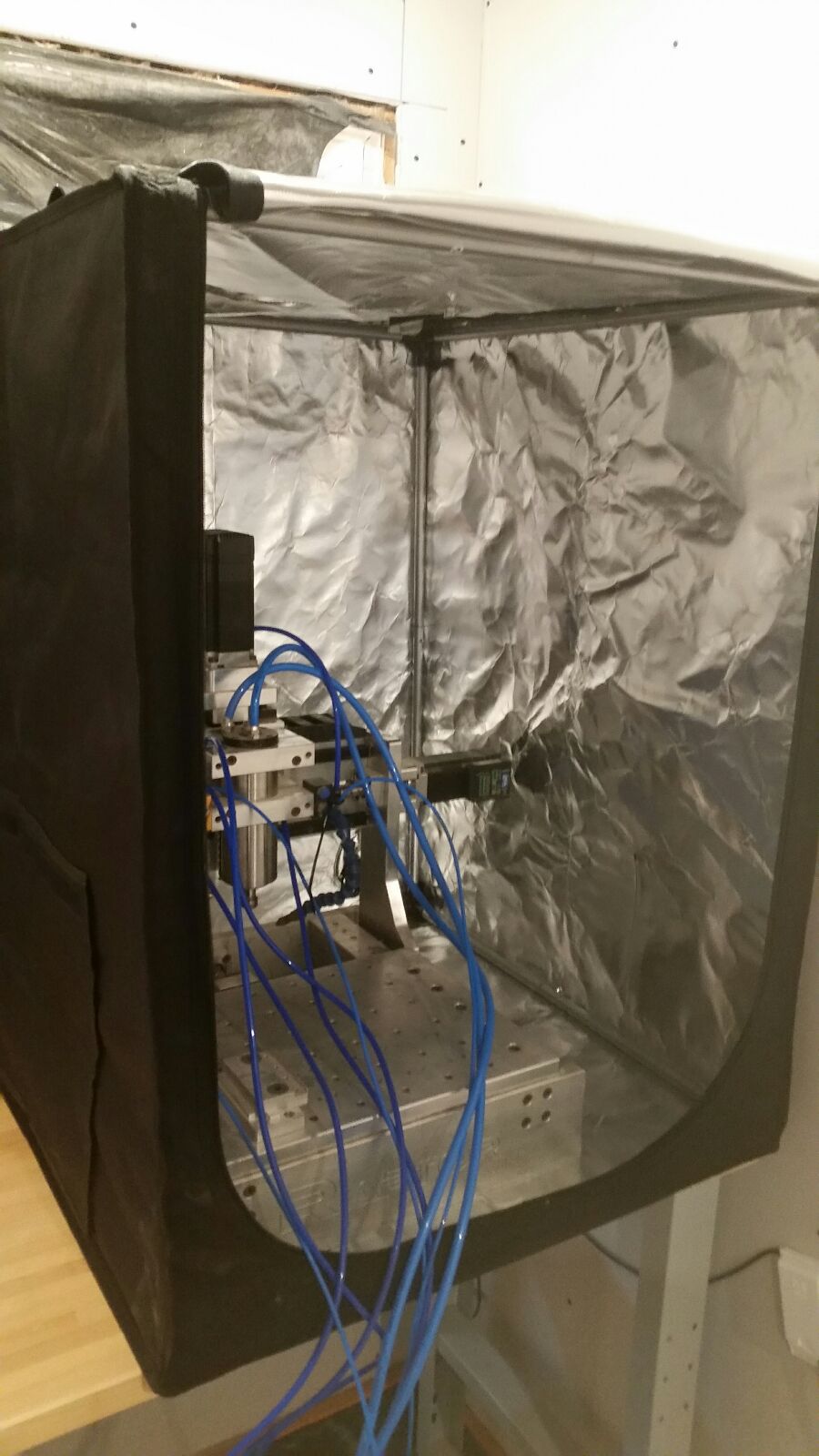

Got a new bench, and an enclosure.

Enclosure it pretty slick, it is a 3d printer enclosure from creality, but in reality it is a common grow op tent. Pretty neat. its water and dust proof, and has little velcro pass throughs for wiring, and even a round one that could be for a dust collector.

Got a new bench, and an enclosure.

Enclosure it pretty slick, it is a 3d printer enclosure from creality, but in reality it is a common grow op tent. Pretty neat. its water and dust proof, and has little velcro pass throughs for wiring, and even a round one that could be for a dust collector.

Attachments:

The following user(s) said Thank You: tommylight, spumco

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

07 Apr 2023 02:40 #268481

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Ok, mesa card installed. Gotta finish up some wiring and it should be able to move.

Been a while since I poked at linuxcnc. I noticed people on youtube using 2.9 with a fancier new UI. is that a new axis, or something else entirely?

Been a while since I poked at linuxcnc. I noticed people on youtube using 2.9 with a fancier new UI. is that a new axis, or something else entirely?

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

07 Apr 2023 04:36 #268485

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Ok, new problem. motor wired up to Y. motor is on, working properly. Linuxcnc is commanding it on stepgen1, but I get no motion.

Hmmm.

The scope is showing nothing under test an tune either, so I expect if botched up some setting, but i don't see where.

Hmmm.

The scope is showing nothing under test an tune either, so I expect if botched up some setting, but i don't see where.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

07 Apr 2023 05:12 #268488

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Fixed, it was the step timing. All good now.

18000mm/m and 5.5m/s2.

That's as fast as i dare before bolting the thing down - desk wanted to go for a walk.

On the DDCSv3.1 control I restricted it down to 12000mm/m and 3m/s2 because it did not have very smooth motion. Linux is behaving much better so I think ill be able to put the rapids up to 20m/m (2000rpm) and put acceleration at the same 3m/s2. These servos are not high performance for tuning, although still miles ahead of what I got on the brother servos, haha.

18000mm/m and 5.5m/s2.

That's as fast as i dare before bolting the thing down - desk wanted to go for a walk.

On the DDCSv3.1 control I restricted it down to 12000mm/m and 3m/s2 because it did not have very smooth motion. Linux is behaving much better so I think ill be able to put the rapids up to 20m/m (2000rpm) and put acceleration at the same 3m/s2. These servos are not high performance for tuning, although still miles ahead of what I got on the brother servos, haha.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

08 Apr 2023 07:38 #268590

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

OK, Last thing to do is spindle control.

I am reading that spindle control with the 7i96s under 2.8 is a bit weird? Would it just be easier to wipe out the machine and put 2.9 on?

Thoughts?

I am reading that spindle control with the 7i96s under 2.8 is a bit weird? Would it just be easier to wipe out the machine and put 2.9 on?

Thoughts?

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

08 Apr 2023 08:01 #268591

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Hmm, seems 2.8.4 is supposed to be fine, What I read was out of date.

Ok, then, time to wire up and see what happens.

Ok, then, time to wire up and see what happens.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

08 Apr 2023 09:48 #268596

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Woo, spindle runs. 36000rpm of goodness. haha. Some weirdness on the low speed end. I had locked out speeds below 6000rpm but the spindle will still turn on at 6000rpm. Linux is commanding the correct frequency, so i assume i need to adjust something in the vfd params. I may just remove the limited cause under cnc command ill never enter 5rpm. Also need a brake resistor, it takes like 10-15 secs to come to a stop from 36000rpm. So I will need to put in some healthy spindle dwell.

I am getting some weird messages that my maxvel is set too high, despite everything actually being set right and working right.

Anyhow, minor things to iron out. it is ready to run some air cutting programs though as soon as i bolt it to the wall tomorrow. yay.

I am getting some weird messages that my maxvel is set too high, despite everything actually being set right and working right.

Anyhow, minor things to iron out. it is ready to run some air cutting programs though as soon as i bolt it to the wall tomorrow. yay.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

09 Apr 2023 01:25 #268636

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

Vroom

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 923

- Thank you received: 275

09 Apr 2023 02:25 #268638

by cakeslob

Replied by cakeslob on topic Mini wannabe datron build

its already drilled, put the support block on that badboy. if end isnt stepped, just change the bearing. you are gonna get screw whip. really nice unit though. I recommend getting it anodized before you get to far ahead, makes such a difference.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 970

- Thank you received: 258

09 Apr 2023 02:34 #268639

by ihavenofish

Replied by ihavenofish on topic Mini wannabe datron build

"its already drilled, put the support block on that badboy"

wrong pattern for the vises on the side.

"if end isnt stepped, just change the bearing. you are gonna get screw whip. "

Nah. this is within spec of the screw. They can run up to 5000rpm like this.

"I recommend getting it anodized before you get to far ahead, makes such a differenc"

Meh, no point. if you look earlier in this thread, it is going to get some heavy modifications soon. i'll anodise it when its actually done

wrong pattern for the vises on the side.

"if end isnt stepped, just change the bearing. you are gonna get screw whip. "

Nah. this is within spec of the screw. They can run up to 5000rpm like this.

"I recommend getting it anodized before you get to far ahead, makes such a differenc"

Meh, no point. if you look earlier in this thread, it is going to get some heavy modifications soon. i'll anodise it when its actually done

Please Log in or Create an account to join the conversation.

Time to create page: 0.153 seconds