Un-lobotomizing a Maho MH600T

- Finngineering

- Online

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 34

10 Jan 2024 18:21 #290389

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

Everything is available on Github:

github.com/finngineering/sincos_interpolator

In the disclaimer I wrote that the latest design (v1.3) is untested. That is no longer completely correct. I have tested it by running one axis back and forth at varying speeds for ~10 minutes, and verified that when I drive it back to the starting position (measured with dial indicator), the position feedback is also back to zero. No issues found. Not all that thorough testing, but at least something.

I use it for 11 µApp Heidenhain scales, but it should be usable also for other types of sin/cos signals. Configuration is made by component selection and jumper solders. Its explained (for 11uApp) on the Github page.

The interpolation is selected by jumper solders between 1 and 16 (not all values available). I use interpolation 5 with 20 µm grating scales, which gives me a resolution of 1 µm (because there are 4 edges per quadrature cycle).

github.com/finngineering/sincos_interpolator

In the disclaimer I wrote that the latest design (v1.3) is untested. That is no longer completely correct. I have tested it by running one axis back and forth at varying speeds for ~10 minutes, and verified that when I drive it back to the starting position (measured with dial indicator), the position feedback is also back to zero. No issues found. Not all that thorough testing, but at least something.

I use it for 11 µApp Heidenhain scales, but it should be usable also for other types of sin/cos signals. Configuration is made by component selection and jumper solders. Its explained (for 11uApp) on the Github page.

The interpolation is selected by jumper solders between 1 and 16 (not all values available). I use interpolation 5 with 20 µm grating scales, which gives me a resolution of 1 µm (because there are 4 edges per quadrature cycle).

The following user(s) said Thank You: COFHAL

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1541

- Thank you received: 572

12 Jan 2024 08:18 - 12 Jan 2024 08:28 #290479

by RotarySMP

Replied by RotarySMP on topic Un-lobotomizing a Maho MH600T

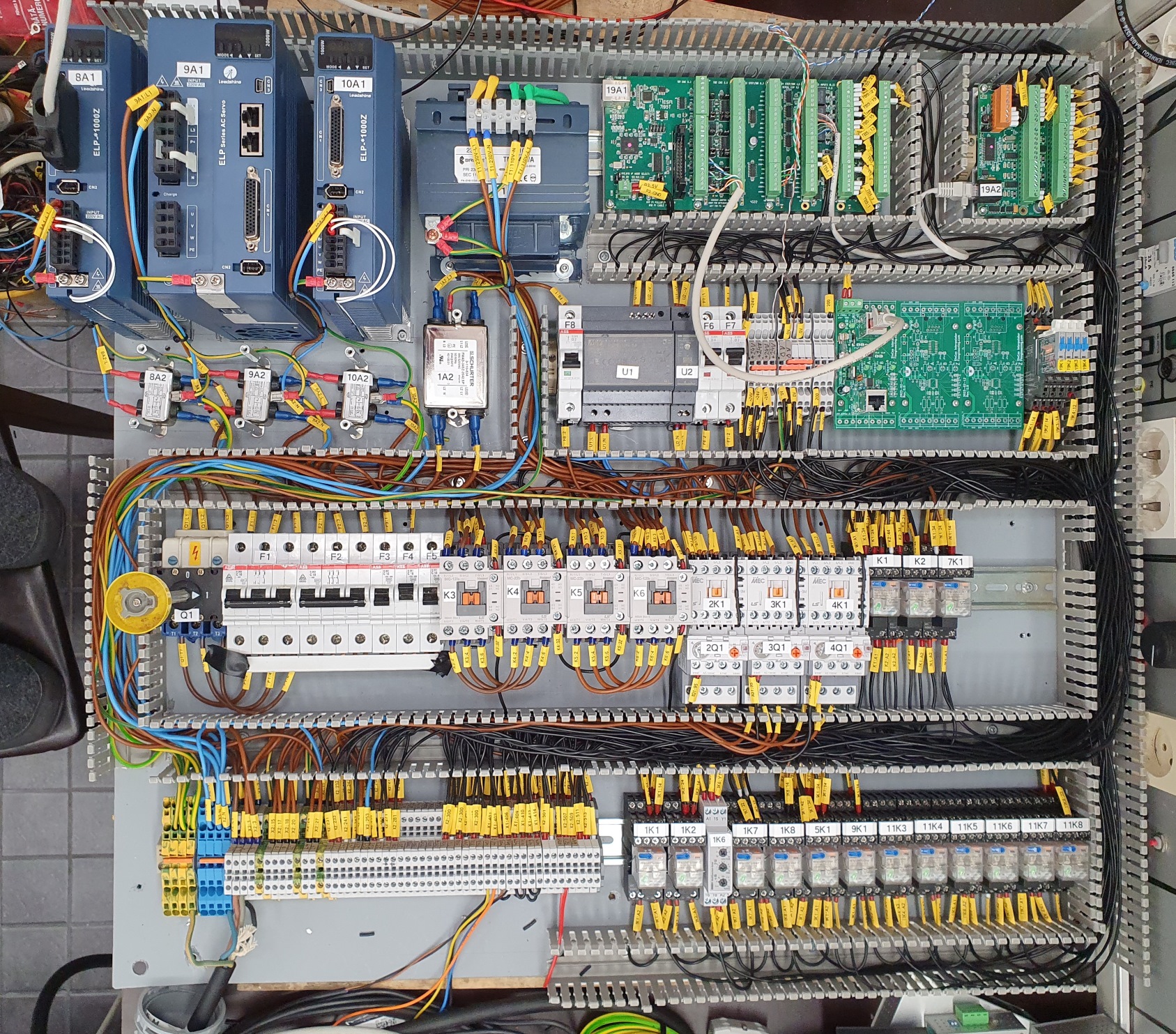

I missed your thread when you first started it. Nice work you are doing in this retrofit. I really like the way you have laid out your control cabinet. They always seem some oversized, untill you start adding wire

Did you pick up that the Maho gearbox control comp is here:

github.com/jin-eld/mh400e-linuxcnc

I recorded all I know about it in the githubwiki:

github.com/jin-eld/mh400e-linuxcnc/wiki

You wrote:

And still another question: What physical indications / push buttons would you recommend for the control panel? I know this is almost like asking how long a rope is, but nevertheless. I plan to get a decent pendant to use for "manual operations" and overrides, and didn't plan to add too much to the main control panel.

Which GUI will you design around?

Have you seen "tom's simple handwheel" from Tom and Peter (Talla83). This is a really well thought out pendant for a Mesa user.

Did you pick up that the Maho gearbox control comp is here:

github.com/jin-eld/mh400e-linuxcnc

I recorded all I know about it in the githubwiki:

github.com/jin-eld/mh400e-linuxcnc/wiki

You wrote:

And still another question: What physical indications / push buttons would you recommend for the control panel? I know this is almost like asking how long a rope is, but nevertheless. I plan to get a decent pendant to use for "manual operations" and overrides, and didn't plan to add too much to the main control panel.

Which GUI will you design around?

Have you seen "tom's simple handwheel" from Tom and Peter (Talla83). This is a really well thought out pendant for a Mesa user.

Last edit: 12 Jan 2024 08:28 by RotarySMP.

Please Log in or Create an account to join the conversation.

- Finngineering

- Online

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 34

15 Jan 2024 00:04 #290720

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

Thank you for the compliments. I will use the original cabinet, but plan to fit everything on one backplane. It's actually a little bit too little space, but with the double row terminal blocks I can make it work.

Yes, I am aware of the gearbox component you and your friend developed. It's great you have put it "out there" (as everything else), and I will likely use it in some form. I have not checked in detail how it works. But because I will use a VFD for the main spindle motor (all the original transformers were scrapped when I bought the mill), I have a feeling I can just run the motor on low speed instead of twitching back and forth.

Right now, I'm leaning towards gmoccapy for the GUI, mainly because of your videos. It does look like a good GUI. I plan on using a touchscreen, but also having a full keyboard + mouse available. And an MPG. I have seen the Talla83 pendant, and it does look good. As of now, I have not made a decision about it yet. There are some nice "ready-made" ones available as well.

Keep up the good work with you machines and videos. I always enjoy watching what you make.

Yes, I am aware of the gearbox component you and your friend developed. It's great you have put it "out there" (as everything else), and I will likely use it in some form. I have not checked in detail how it works. But because I will use a VFD for the main spindle motor (all the original transformers were scrapped when I bought the mill), I have a feeling I can just run the motor on low speed instead of twitching back and forth.

Right now, I'm leaning towards gmoccapy for the GUI, mainly because of your videos. It does look like a good GUI. I plan on using a touchscreen, but also having a full keyboard + mouse available. And an MPG. I have seen the Talla83 pendant, and it does look good. As of now, I have not made a decision about it yet. There are some nice "ready-made" ones available as well.

Keep up the good work with you machines and videos. I always enjoy watching what you make.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

20 Mar 2024 07:09 #296373

by vre

In the schematic MC3487DX PIN16 connected to GND and PIN8 to +5V

but in datasheet of MC3487DX PIN16 is VCC and PIN8 GND.

Also what value is R3? 500kohm ?

Do you have populated differential transmitter ?

If i want 16x interpolation must populate it ?

Replied by vre on topic Un-lobotomizing a Maho MH600T

Everything is available on Github:

github.com/finngineering/sincos_interpolator

In the disclaimer I wrote that the latest design (v1.3) is untested. That is no longer completely correct. I have tested it by running one axis back and forth at varying speeds for ~10 minutes, and verified that when I drive it back to the starting position (measured with dial indicator), the position feedback is also back to zero. No issues found. Not all that thorough testing, but at least something.

I use it for 11 µApp Heidenhain scales, but it should be usable also for other types of sin/cos signals. Configuration is made by component selection and jumper solders. Its explained (for 11uApp) on the Github page.

The interpolation is selected by jumper solders between 1 and 16 (not all values available). I use interpolation 5 with 20 µm grating scales, which gives me a resolution of 1 µm (because there are 4 edges per quadrature cycle).

In the schematic MC3487DX PIN16 connected to GND and PIN8 to +5V

but in datasheet of MC3487DX PIN16 is VCC and PIN8 GND.

Also what value is R3? 500kohm ?

Do you have populated differential transmitter ?

If i want 16x interpolation must populate it ?

Please Log in or Create an account to join the conversation.

- Finngineering

- Online

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 34

20 Mar 2024 14:24 #296388

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

That is a bit embarrassing. It appears I forgot to update the pdf schematic after correcting the VCC/GND pin issue. I will update this in the github repository. Please note that it's only the pdf schematic that has this issue. The Kicad project and fabrication files are correct.

R3 is the same as RCLK in the datasheet, and it's mentioned that its optional (unless you want to configure minimum transition distance). I have connected the pin to VCC by shorting solder jumper JP6 and leaving R3 empty.

I use the differential transmitter. If you have differential inputs on your interface card, I would recommend you use it.

R3 is the same as RCLK in the datasheet, and it's mentioned that its optional (unless you want to configure minimum transition distance). I have connected the pin to VCC by shorting solder jumper JP6 and leaving R3 empty.

I use the differential transmitter. If you have differential inputs on your interface card, I would recommend you use it.

The following user(s) said Thank You: tommylight, vre

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

21 Mar 2024 13:49 #296468

by vre

Replied by vre on topic Un-lobotomizing a Maho MH600T

Why you choose 5x interpolation and not 16x for sub-micron resolution ?

Please Log in or Create an account to join the conversation.

- Finngineering

- Online

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 34

22 Mar 2024 05:51 #296534

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

My scales have a 20 µm grating, which gives 1 µm resolution with 5x interpolation. That just seems quite reasonable to me, and I'm not sure if there is much benefit in going to a higher resolution. But if I want later, and/or find a reason for it, it's of course easy to change.

I do want to have "easy" increments for every pulse. The 5x interpolation gives 1 µm for each pulse. 16x interpolation would give 0.3125 µm, which is mentally harder to deal with. But for instance at 10x interpolation, the increment is 0,5 µm, which again is "easy". So that's for sure an option for me.

I do want to have "easy" increments for every pulse. The 5x interpolation gives 1 µm for each pulse. 16x interpolation would give 0.3125 µm, which is mentally harder to deal with. But for instance at 10x interpolation, the increment is 0,5 µm, which again is "easy". So that's for sure an option for me.

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

24 Mar 2024 08:49 - 24 Mar 2024 08:49 #296613

by vre

Replied by vre on topic Un-lobotomizing a Maho MH600T

for input connection 90 connects to psin

and 0 connects to pcos ?

and 0 connects to pcos ?

Last edit: 24 Mar 2024 08:49 by vre.

Please Log in or Create an account to join the conversation.

- Finngineering

- Online

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 34

25 Mar 2024 06:05 #296686

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

For most applications (maybe all CNC) it does not matter if you connect the 90° signal to PSIN and 0° signal to PCOS, or the other way around. So just whatever is more convenient.

I would say the only time it would be important is if you cannot change the direction the scale is "counting" in software. That is of course no issue with LinuxCNC.

I would say the only time it would be important is if you cannot change the direction the scale is "counting" in software. That is of course no issue with LinuxCNC.

The following user(s) said Thank You: vre

Please Log in or Create an account to join the conversation.

- Finngineering

- Online

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 34

28 Mar 2024 08:14 #296971

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

After a long time, I have been able to make some progress on the Maho the past couple of weeks.

The control cabinet starts to be close to finished. It's still missing the control wires for the gear change motors, because I do not yet have the brake resistors for those. And I need to make control cables for the servo drives, and solder up two more of my SinCos interpolators. But all in all, things are looking good, and it seems like everything will work out, even if it was a bit of a tight fit. I do still have some room for expanding with a few more terminal blocks and a couple of relays, in case I need to add something.

Hopefully I can complete the rest of the wiring over easter. The machine also start to be mechanically ready to start putting everything together.

The control cabinet starts to be close to finished. It's still missing the control wires for the gear change motors, because I do not yet have the brake resistors for those. And I need to make control cables for the servo drives, and solder up two more of my SinCos interpolators. But all in all, things are looking good, and it seems like everything will work out, even if it was a bit of a tight fit. I do still have some room for expanding with a few more terminal blocks and a couple of relays, in case I need to add something.

Hopefully I can complete the rest of the wiring over easter. The machine also start to be mechanically ready to start putting everything together.

Attachments:

The following user(s) said Thank You: RotarySMP, tommylight, besriworld, Unlogic

Please Log in or Create an account to join the conversation.

Time to create page: 0.320 seconds