Un-lobotomizing a Maho MH600T

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 98

- Thank you received: 44

15 Jan 2025 19:16 #319046

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

Quite some time since the last update. And I have put in a bit of work on the Maho as well. And struggled a bit with the linear scales.

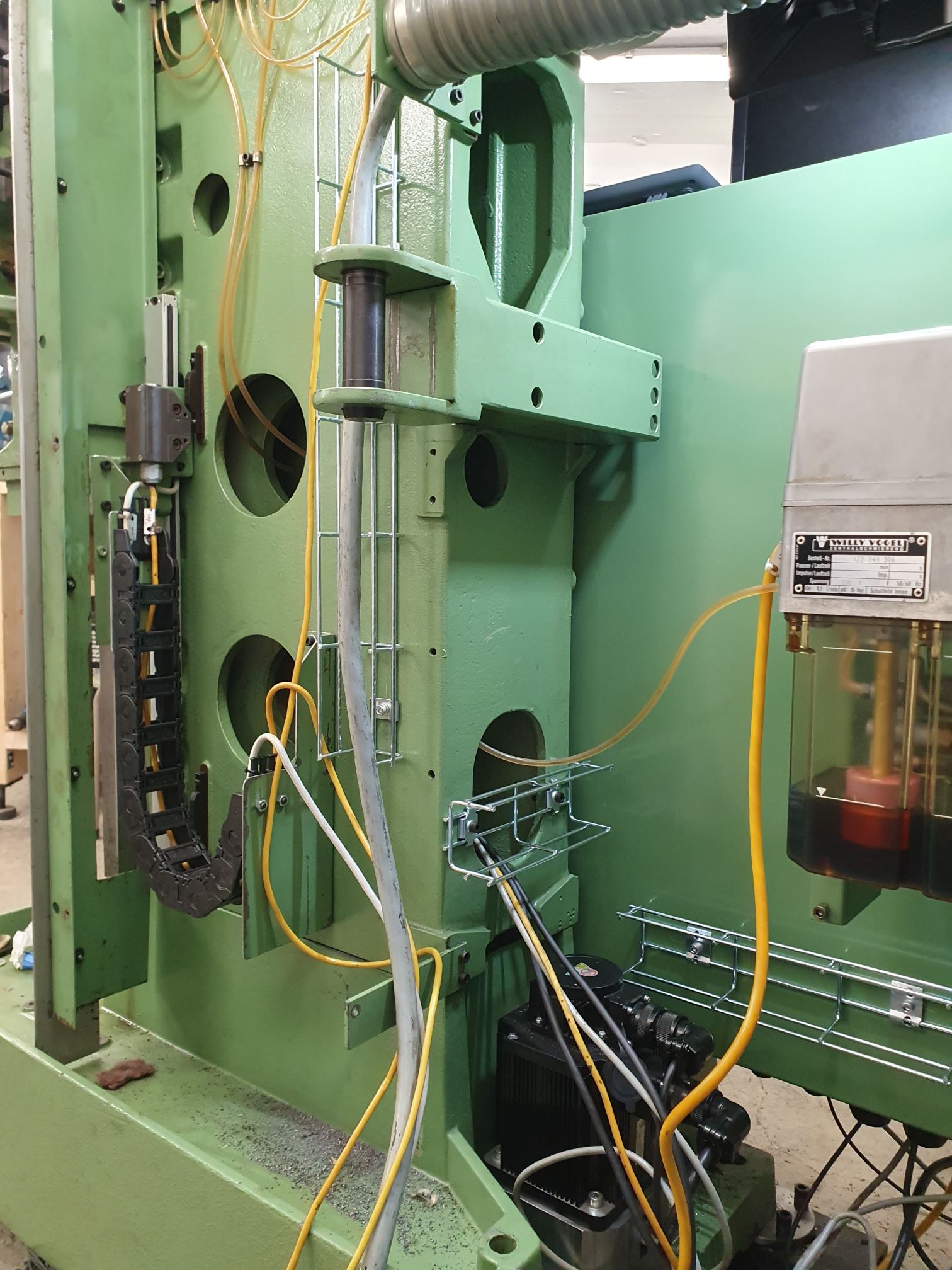

The first step was to get all axes moving under power, and that was easy enough. The following was to install all linear scales and do a bit of cable routing through new cable chains instead of through the old hoses.

I installed a VFD for the main motor on top of the ram and fixed communication to it through Modbus and Mesa PktUART. I struggled a bit with that because of what I would say is a bug in the Mesa Modbus driver. There is a separate thread with that discussion

forum.linuxcnc.org/27-driver-boards/5432...v2d-firmware?start=0

Anyway, the VFD control of the motor now works.

I wired up almost all of the rest of the electrical equipment. The gearbox, hydraulic pump with sensors and so on all work, but still need configuration to work from the GUI buttons or G-code. I haven't decided yet whether to use the gearbox component from Rotary SMP. It expects some gearbox "search direction" inputs which are not present on my Maho. There are ways around that problem, though.

The linear scales have given me all kinds of issues, including:

- approximately 0.5V voltage drop over the miniature circuit breaker, causing the scales to receive too low voltage and give too weak output signals

- bad connection for the onboard fuse on one of the boards, also giving high voltage drop

- mixed up negative/positive connections for the sin/cos/reference signals

- a lot of noise when measuring the signals with an oscilloscope

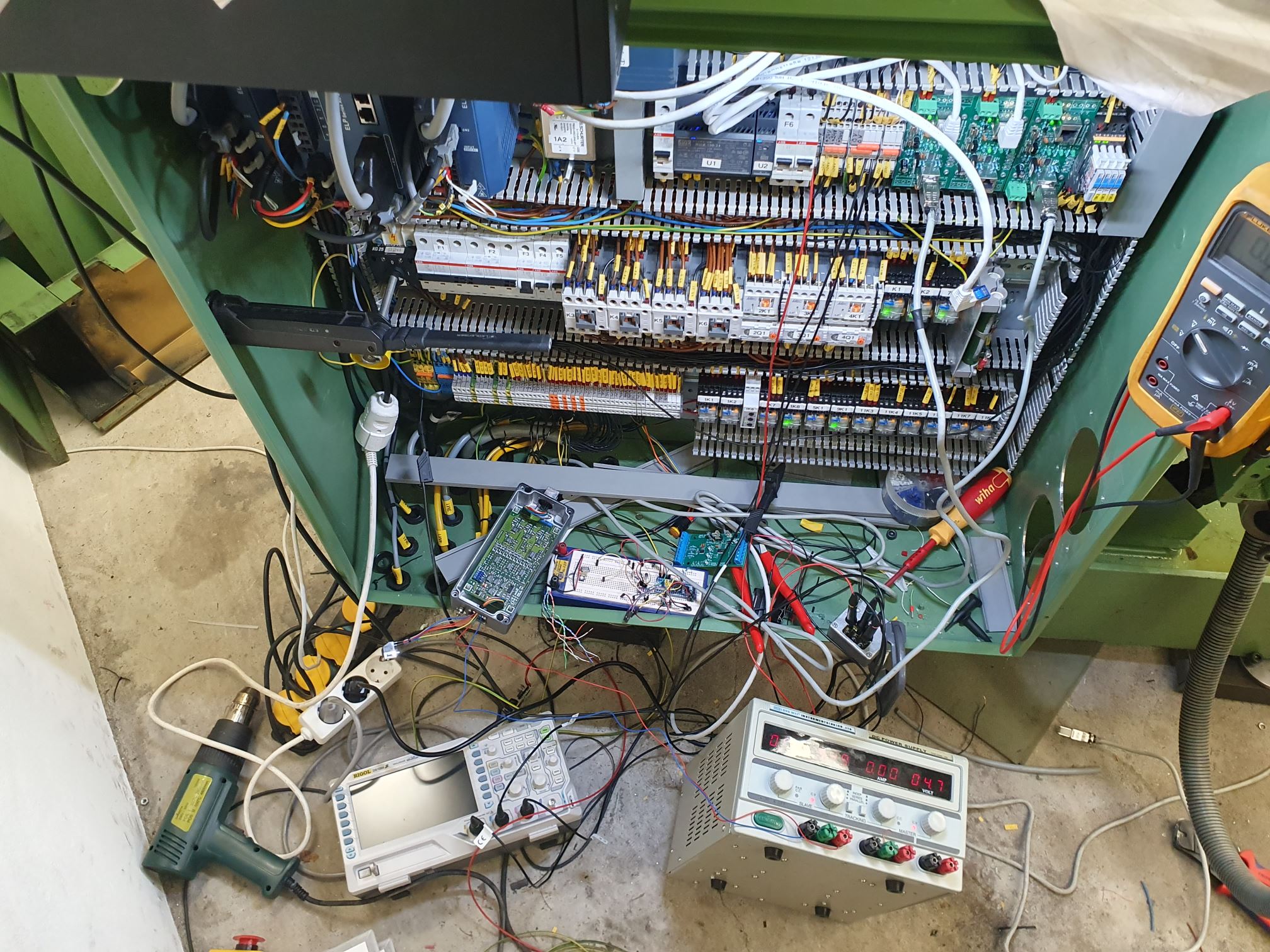

After resolving those issues, I got everything working, except for the index signal on the vertical axis. That works erratically. I decided to order an EXE 602E interpolator to test, and with that one it works. To avoid getting stuck here, I ordered two more EXE 602E for the other axes. I haven't given up on my own boards though, but they may require a redesign to work in these conditions. Below a photo from the equipment during the height of troubleshooting.

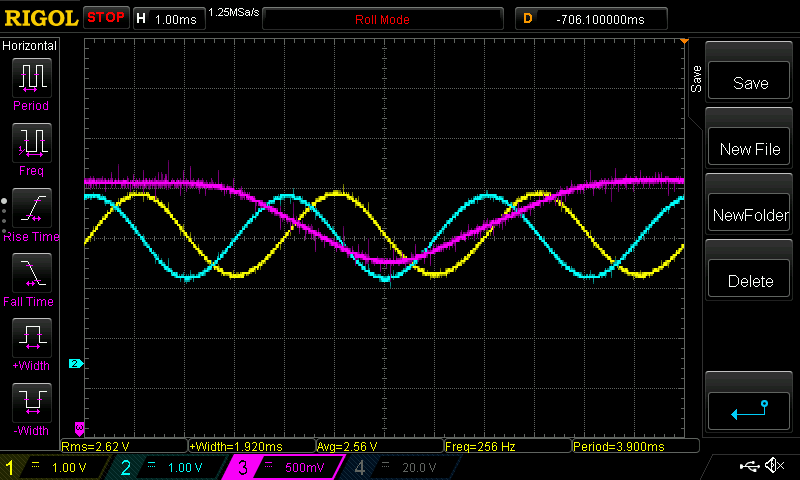

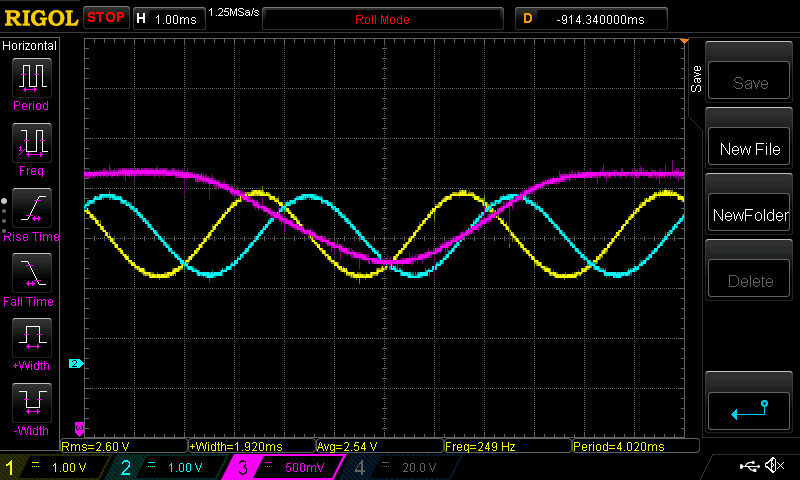

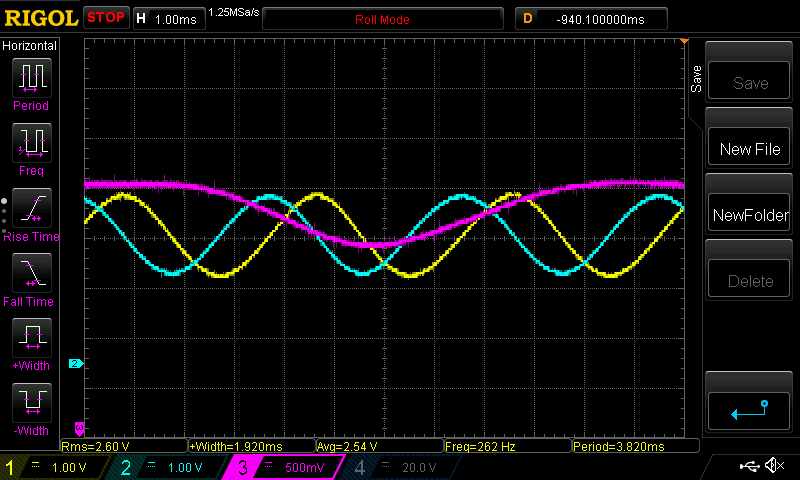

The reason for the issue with the vertical axis is that the reference signal is a bit weaker and barely passes "0V" on that axis. Below oscilloscope traces of the X, Y (ram) and Z (vertical) axis. It might provide useful for somebody.

The machine is basically usable already now if I needed to. But I will try to finish all else than the operator panel before taking it into use for real. Because of upcoming work trips, progress will likely be slow again for a couple of months.

The first step was to get all axes moving under power, and that was easy enough. The following was to install all linear scales and do a bit of cable routing through new cable chains instead of through the old hoses.

I installed a VFD for the main motor on top of the ram and fixed communication to it through Modbus and Mesa PktUART. I struggled a bit with that because of what I would say is a bug in the Mesa Modbus driver. There is a separate thread with that discussion

forum.linuxcnc.org/27-driver-boards/5432...v2d-firmware?start=0

Anyway, the VFD control of the motor now works.

I wired up almost all of the rest of the electrical equipment. The gearbox, hydraulic pump with sensors and so on all work, but still need configuration to work from the GUI buttons or G-code. I haven't decided yet whether to use the gearbox component from Rotary SMP. It expects some gearbox "search direction" inputs which are not present on my Maho. There are ways around that problem, though.

The linear scales have given me all kinds of issues, including:

- approximately 0.5V voltage drop over the miniature circuit breaker, causing the scales to receive too low voltage and give too weak output signals

- bad connection for the onboard fuse on one of the boards, also giving high voltage drop

- mixed up negative/positive connections for the sin/cos/reference signals

- a lot of noise when measuring the signals with an oscilloscope

After resolving those issues, I got everything working, except for the index signal on the vertical axis. That works erratically. I decided to order an EXE 602E interpolator to test, and with that one it works. To avoid getting stuck here, I ordered two more EXE 602E for the other axes. I haven't given up on my own boards though, but they may require a redesign to work in these conditions. Below a photo from the equipment during the height of troubleshooting.

The reason for the issue with the vertical axis is that the reference signal is a bit weaker and barely passes "0V" on that axis. Below oscilloscope traces of the X, Y (ram) and Z (vertical) axis. It might provide useful for somebody.

The machine is basically usable already now if I needed to. But I will try to finish all else than the operator panel before taking it into use for real. Because of upcoming work trips, progress will likely be slow again for a couple of months.

Attachments:

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 98

- Thank you received: 44

23 Feb 2025 19:15 #322388

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

My work trip has gotten delay a couple of times, and I have had time to get some things done on the Maho during this week.

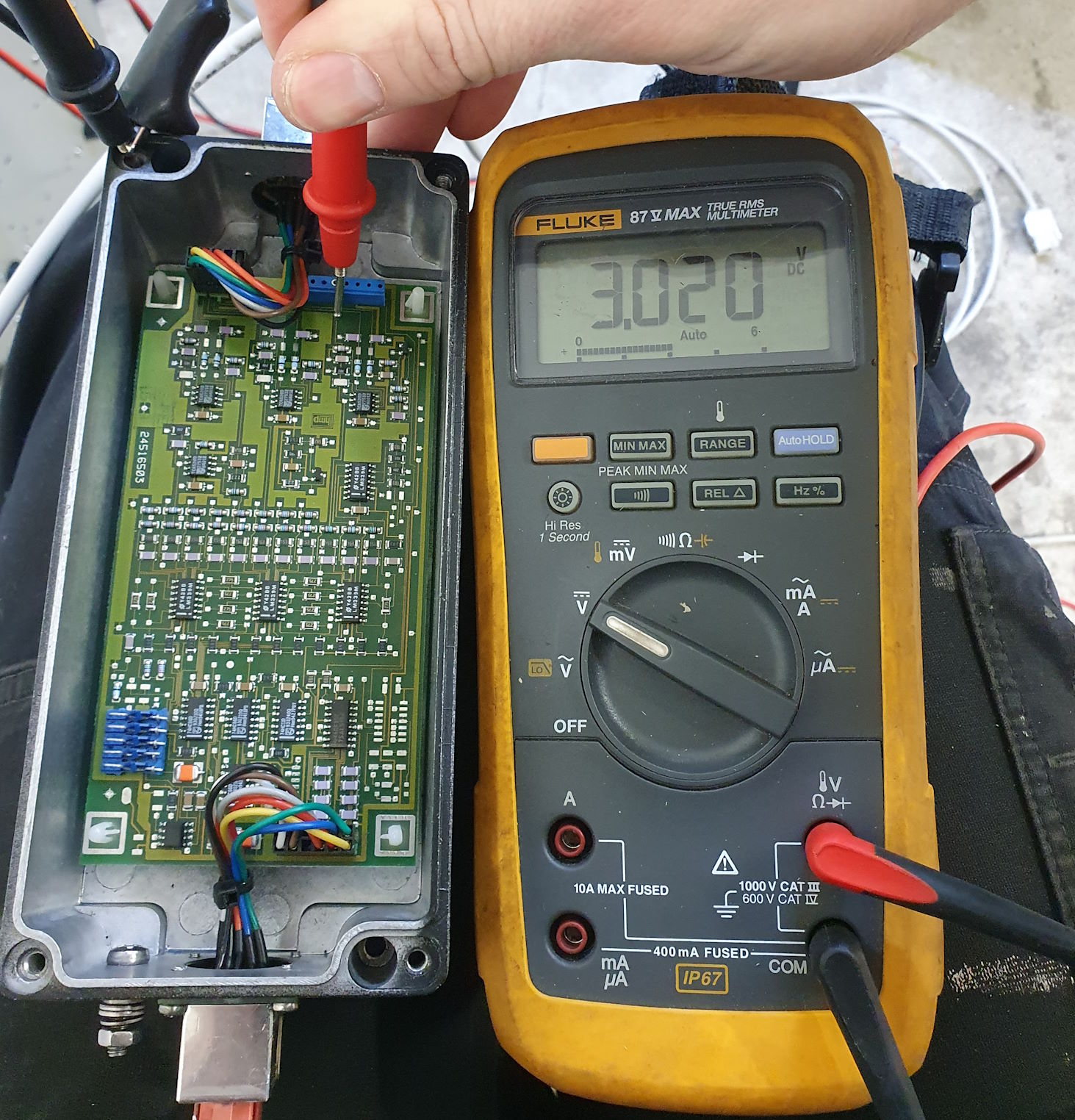

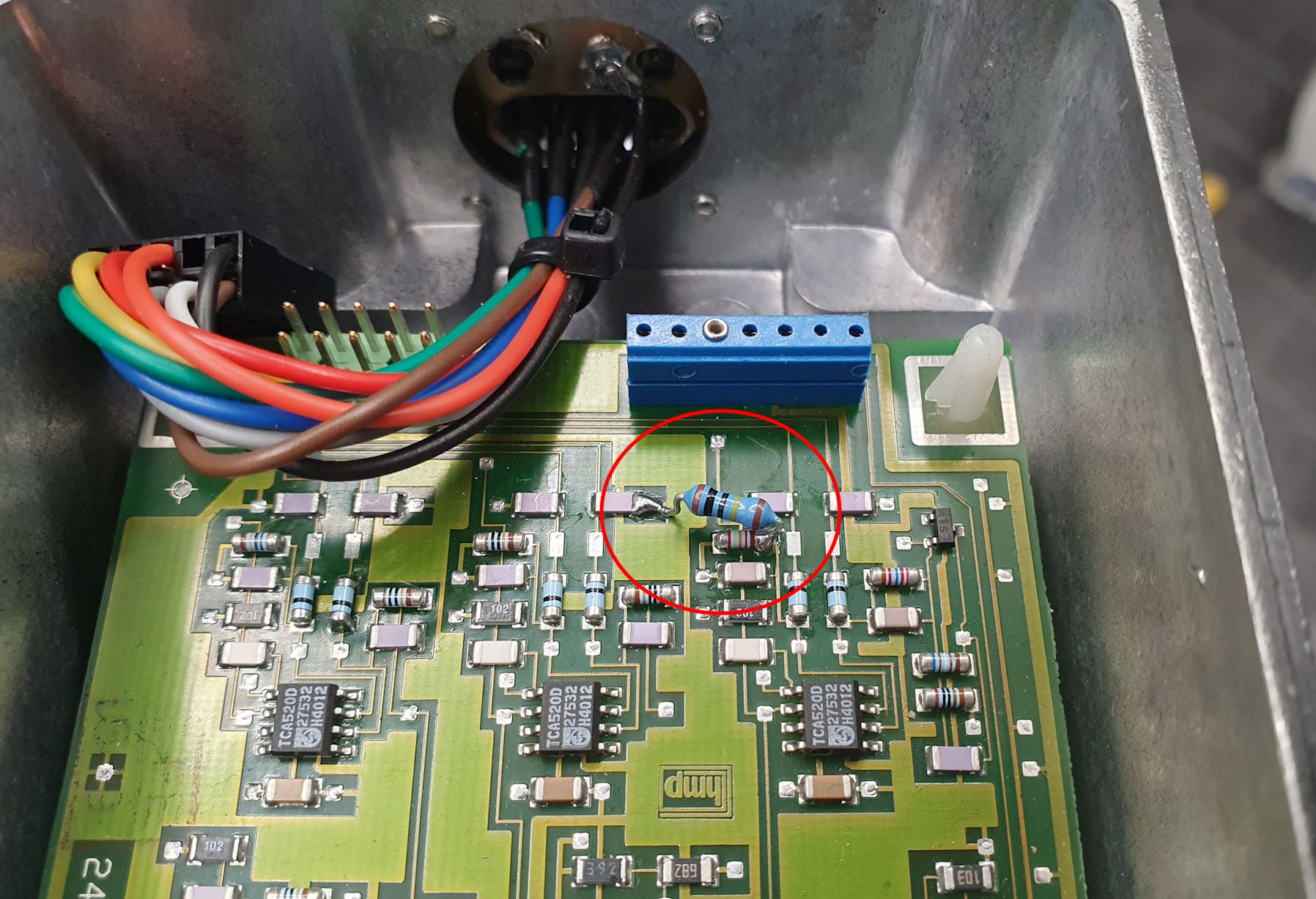

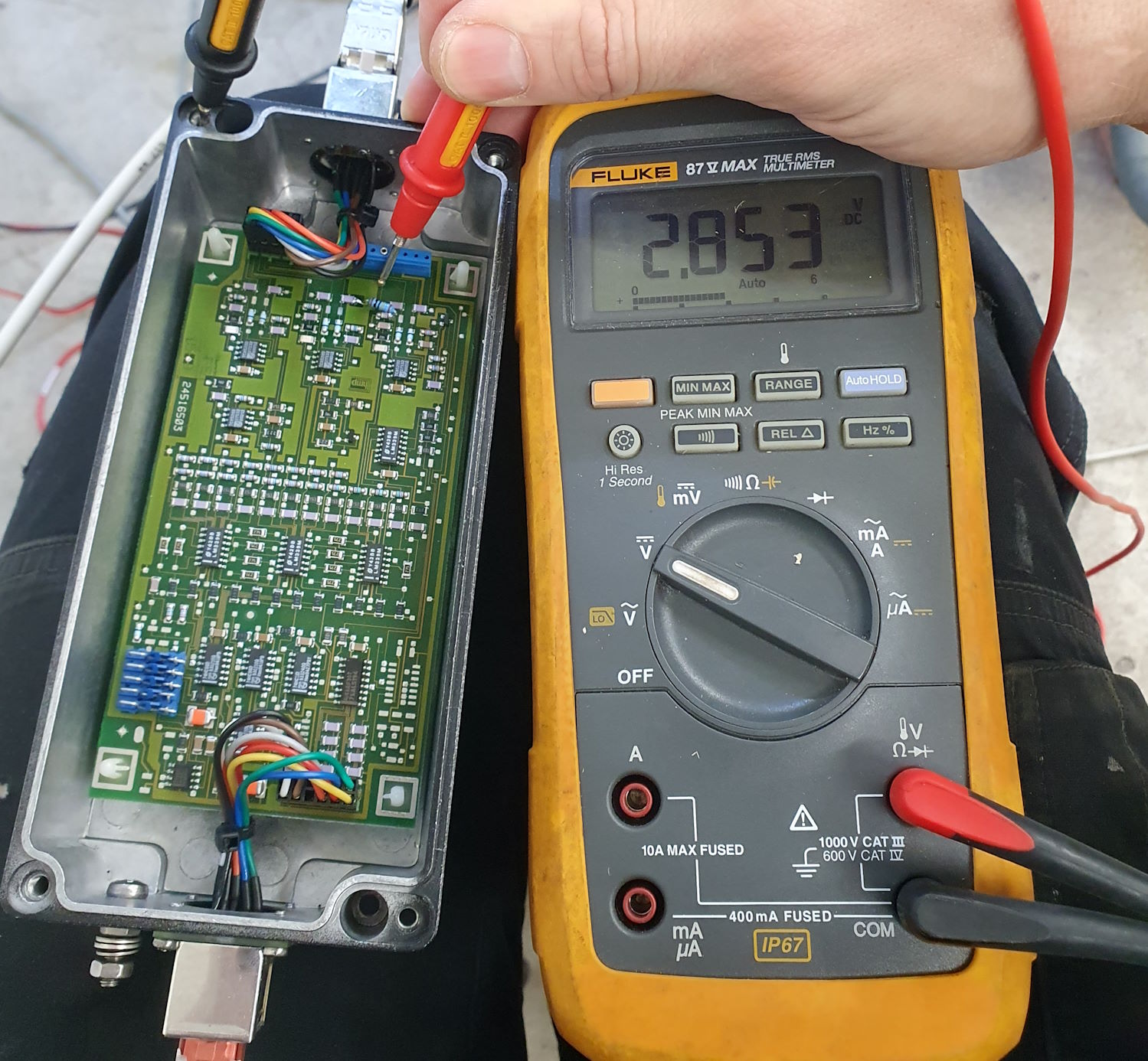

The last oscilloscope screenshot in the last post showed that the index signal for the vertical axis only barely made it past the "zero" point (which for the EXE 602 is 2.5V and vertically in the middle of the oscilloscope screen). I did have at least one missed zero on the vertical axis with the EXE 602 as well. So I hacked in a 1 Mohm resistor between the 2.5V reference to the transimpedance amplifier and ground, which pulled the index signal down by approximately 0.2V. So now it should be more in line with the signals for the other scales, and I have not missed zero since that modification. The root cause of this issue has the be inside the linear scale. Anyway, below some photos measuring the voltage on the index signal (away from the zero mark) before and after the resistor hack.

I have also done quite a few other things:

Here a photo of the air bubbles in the lubrication lines to verify that they are all working. Quite easy to see that all the bubbles are moving when the lubrication pump starts.

The last oscilloscope screenshot in the last post showed that the index signal for the vertical axis only barely made it past the "zero" point (which for the EXE 602 is 2.5V and vertically in the middle of the oscilloscope screen). I did have at least one missed zero on the vertical axis with the EXE 602 as well. So I hacked in a 1 Mohm resistor between the 2.5V reference to the transimpedance amplifier and ground, which pulled the index signal down by approximately 0.2V. So now it should be more in line with the signals for the other scales, and I have not missed zero since that modification. The root cause of this issue has the be inside the linear scale. Anyway, below some photos measuring the voltage on the index signal (away from the zero mark) before and after the resistor hack.

I have also done quite a few other things:

- Installed EXE 602:s for all axes (I hope to still revert to my own boards at some point)

- Adjusted hardwired end stops and scale position so I have travels (and overtravels) approximately according to the MH600T manual

- Created a central lubrication realtime HAL component

- Introduced some air bubbles in all lubrication lines so I could verify that oil is moving in all lines

- Took a gearbox realtime HAL component I had written into use

- Created a realtime component for spindle speed control to the VFD

- Did at least basic servo tuning for all axes. With this I stay below 0.01 mm f-error on 1000 mm/min moves with 0.5m/s² acceleration.

Here a photo of the air bubbles in the lubrication lines to verify that they are all working. Quite easy to see that all the bubbles are moving when the lubrication pump starts.

Attachments:

The following user(s) said Thank You: tommylight, Clive S, besriworld, Aciera, Unlogic

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1570

- Thank you received: 576

25 Feb 2025 13:51 #322589

by RotarySMP

Replied by RotarySMP on topic Un-lobotomizing a Maho MH600T

You are really making a great job of that retrofit.

The following user(s) said Thank You: Finngineering

Please Log in or Create an account to join the conversation.

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 98

- Thank you received: 44

25 Feb 2025 21:15 #322633

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

Thank you RotarySMP. You certainly are an inspiration!

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

28 Feb 2025 07:03 #322847

by vre

Replied by vre on topic Un-lobotomizing a Maho MH600T

Greet work..

How much ferror min_ferror rapid speed and acceleration per axis have you in config ?

How much ferror min_ferror rapid speed and acceleration per axis have you in config ?

Please Log in or Create an account to join the conversation.

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 98

- Thank you received: 44

28 Feb 2025 08:40 #322857

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

This is what the config looks like right now:Same for all axes. The machine units is mm. Except the vertical MAX_VELOCITY is 40.0, because I would need to reduce the servo pulses per revolution in case I want to go higher (currently limited by step timings).

FERROR and MIN_FERROR are just the defaults from PnCconf (I think). Based on the current tuning, I might reduce them by an order of magnitude. Provided they work how I think they do. I need to look into that at some point.

[JOINT_0]

TYPE = LINEAR

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 500.0FERROR and MIN_FERROR are just the defaults from PnCconf (I think). Based on the current tuning, I might reduce them by an order of magnitude. Provided they work how I think they do. I need to look into that at some point.

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

30 Mar 2025 03:46 #325301

by D Jensen

Replied by D Jensen on topic Un-lobotomizing a Maho MH600T

Unbelievably good job! I can say that your wiring puts Maho to shame. I'm looking at my rebuild now with shame.

It's a pity about the missing servos. They weren't great, and neither were the servo amplifiers, but they matched the machine nicely.

I'd like to make a comment about the lube system. If you go to Marks rebuild on p165 you will see my detailed comments on it.

But to make it short moving bubbles are good. A few of mine didn't move and I found them blocked at the slide. Fortunately on my CNC rotary table when I had it apart. Just sludge and lacquered old oil in the drillings.

I don't know if you have the Vogel pump.

I'd suggest opening one of the brass items on those manifolds to see what type you have. With luck it might look like this attachment. It is a metering piston so it delivers a measured dose. The photo has the brass nut the wrong way around. Older versions may not have had that which means the brass piece was a metering orifice and they were hard to balance, with different sized orifices. Another giveaway is that the metering type all have the same number on them. I presume they just used the same large orifice all over.

With the metering type the pump should run until they all cock. The the delivery pressure rises and the pump runs another 15 seconds or so on the relief valve to the reservoir then switches off. Then the bubbles should move as the metering pistons deliver.

If you open it, check the little conical rubber cup down inside isn't stuck. Some of mine were, again sticky oil from lack of use. And then they pop out onto the floor. That's always fun.

I have a copy of the Willy Vogel manual if you want me to post it

Cheers,

David

It's a pity about the missing servos. They weren't great, and neither were the servo amplifiers, but they matched the machine nicely.

I'd like to make a comment about the lube system. If you go to Marks rebuild on p165 you will see my detailed comments on it.

But to make it short moving bubbles are good. A few of mine didn't move and I found them blocked at the slide. Fortunately on my CNC rotary table when I had it apart. Just sludge and lacquered old oil in the drillings.

I don't know if you have the Vogel pump.

I'd suggest opening one of the brass items on those manifolds to see what type you have. With luck it might look like this attachment. It is a metering piston so it delivers a measured dose. The photo has the brass nut the wrong way around. Older versions may not have had that which means the brass piece was a metering orifice and they were hard to balance, with different sized orifices. Another giveaway is that the metering type all have the same number on them. I presume they just used the same large orifice all over.

With the metering type the pump should run until they all cock. The the delivery pressure rises and the pump runs another 15 seconds or so on the relief valve to the reservoir then switches off. Then the bubbles should move as the metering pistons deliver.

If you open it, check the little conical rubber cup down inside isn't stuck. Some of mine were, again sticky oil from lack of use. And then they pop out onto the floor. That's always fun.

I have a copy of the Willy Vogel manual if you want me to post it

Cheers,

David

Please Log in or Create an account to join the conversation.

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 98

- Thank you received: 44

30 Mar 2025 17:26 #325334

by Finngineering

Replied by Finngineering on topic Un-lobotomizing a Maho MH600T

Thank you for the compliments!

I have had pretty much the whole machine apart, and I had a few oil ports that were full of gunk as well. But those are all cleaned and open now. I did also open one of the metering valves in the past, and from my recollection it looked very similar to the photo you attached. And it does measure a certain amount every time the pump operates. The bubbles move a certain distance and then stop even if the pump is still running.

I made my own lubricator component, because I did not find anything else I liked. I have attached the component here, even though it is not 100% finished. It works much like you outlined. It runs the pump until the pressure switch activates, then runs the pump for 10 more seconds before it switches off. If it doesn't get the pressure feedback within 60 seconds it turns off and prints and error message. It runs the pump at first motion of the machine, and after that every time it has "accumulated" 10 min of motion.

To the best of my recollection, the bubbles move when the pump starts, and not when it turns off. But I am now travelling and unable to verify.

Thank you for the information. And if it's not too much trouble, it would be interesting to see the Vogel manual as well.

I have had pretty much the whole machine apart, and I had a few oil ports that were full of gunk as well. But those are all cleaned and open now. I did also open one of the metering valves in the past, and from my recollection it looked very similar to the photo you attached. And it does measure a certain amount every time the pump operates. The bubbles move a certain distance and then stop even if the pump is still running.

I made my own lubricator component, because I did not find anything else I liked. I have attached the component here, even though it is not 100% finished. It works much like you outlined. It runs the pump until the pressure switch activates, then runs the pump for 10 more seconds before it switches off. If it doesn't get the pressure feedback within 60 seconds it turns off and prints and error message. It runs the pump at first motion of the machine, and after that every time it has "accumulated" 10 min of motion.

To the best of my recollection, the bubbles move when the pump starts, and not when it turns off. But I am now travelling and unable to verify.

Thank you for the information. And if it's not too much trouble, it would be interesting to see the Vogel manual as well.

Attachments:

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 610

- Thank you received: 17

30 Mar 2025 22:16 #325352

by vre

Replied by vre on topic Un-lobotomizing a Maho MH600T

Why you put exe 602 and not your ic-nv boards?

Can you share your configs and hal components for gears and spindle speed?

Can you share your configs and hal components for gears and spindle speed?

Please Log in or Create an account to join the conversation.

- D Jensen

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 16

30 Mar 2025 23:50 #325354

by D Jensen

Replied by D Jensen on topic Un-lobotomizing a Maho MH600T

Sounds like you spot on with you home made lubricator.Since the mechanical logic in the Willy Vogel system is dumb there is the possibility that the relief pressure to the tank may end up at a lower pressure than the controller pressure switch. It hasn't happened on mine though.The Vogel controller is very simple on mine. It only allows you to set the time between lubrication events. And it always does a cycle on power up. During commissioning my machine it dumped and the entire tank because of that. So I put a delay on timer on it to delay the startup cycle.It also has a mode where it will lube after a certain number of pulses are sent to it. So you could put micro-switches on the drive motors to count the slide movements and oil accordingly. My Heidenhain has the ability to count slide distance traveled, but I haven't figured out how to invoke that.Plus I would need to have 4 individual solenoids to deliver to my 4 axes individually as they reach the distance.BTW: the pump on the lubricator is a a cycloidal one typical of many cars. That's so the pressure pulsations are smaller and don't confuse the pressure switches.

Please Log in or Create an account to join the conversation.

Time to create page: 0.363 seconds