Anybody using a thermal dynamics CM 52?

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21054

- Thank you received: 7181

30 Sep 2019 08:44 #146693

by tommylight

Replied by tommylight on topic Anybody using a thermal dynamics CM 52?

Can the hys go lover, i can not recall ?

Are you using the ARCOK signal from the proma and does it work properly ? Setting the HU to something like 150 to 160 would be better for some plasma cutters, but if it working, leave it as is.

Also check if the torch is at 90 degrees on all sides, tapered edges are always caused by that or bad nozzles.

You should do some testing with various feed rates while cutting, that changes the cut quality a lot.

Find a welding helmet and see if the torch is roughly 1 to 2mm above the metal while cutting.

Are you using the ARCOK signal from the proma and does it work properly ? Setting the HU to something like 150 to 160 would be better for some plasma cutters, but if it working, leave it as is.

Also check if the torch is at 90 degrees on all sides, tapered edges are always caused by that or bad nozzles.

You should do some testing with various feed rates while cutting, that changes the cut quality a lot.

Find a welding helmet and see if the torch is roughly 1 to 2mm above the metal while cutting.

The following user(s) said Thank You: TexasCNC

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11557

- Thank you received: 3878

30 Sep 2019 10:57 #146705

by rodw

Replied by rodw on topic Anybody using a thermal dynamics CM 52?

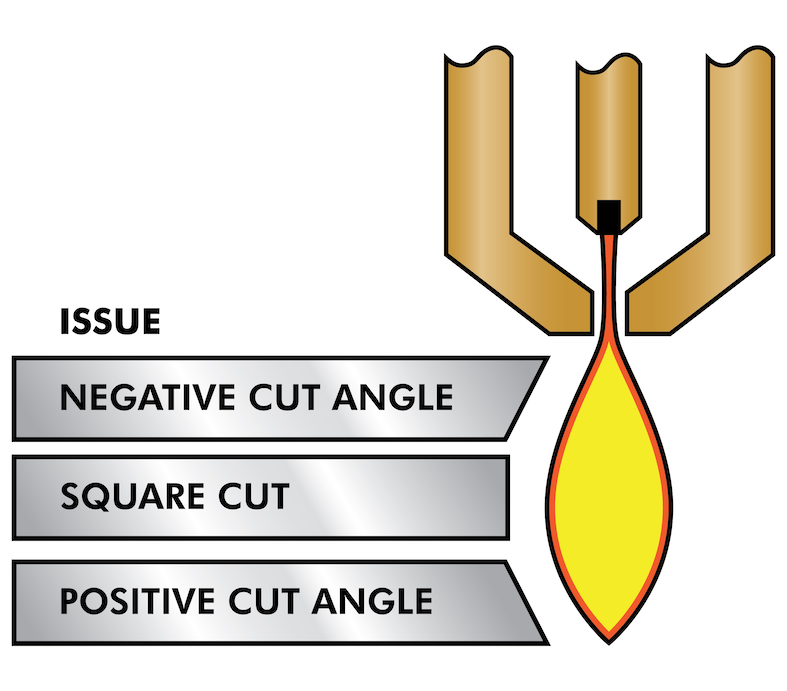

The plasma primer has a diagram showing what causes bevel cuts (releated to cut height)

But you don't say how thick the material is you are cutting. I cut a fair bit at 40 amps with my TD A120 but mostly 2mm

Also check your manual and make sure you are cutting in the right direction. If the swirl is going the wrong way, it can cause a bevel.

But you don't say how thick the material is you are cutting. I cut a fair bit at 40 amps with my TD A120 but mostly 2mm

Also check your manual and make sure you are cutting in the right direction. If the swirl is going the wrong way, it can cause a bevel.

The following user(s) said Thank You: TexasCNC

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

01 Oct 2019 03:46 #146779

by TexasCNC

Replied by TexasCNC on topic Anybody using a thermal dynamics CM 52?

Arc ok was fine I think what I was worry about was that the threshold of the plus and minus on the voltage when I was cutting and had the voltage set at 94v it would be fluctuating plus and minus 6-8v

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

01 Oct 2019 03:49 #146780

by TexasCNC

Replied by TexasCNC on topic Anybody using a thermal dynamics CM 52?

I saw on another thread that the cut direction was important also and I didn’t know that and I went to check sheetcam and it was cutting counter clockwise on outside cuts and clock wise on inside cuts. I changed my direction but didnt have time to test some cuts. I will check to see my squareness on my torch I am using the hand torch so it will be a task to check but I will see if I can. I am getting bevel cuts on any material I put on it from 1/4 10g 14g

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

02 Oct 2019 04:16 #146851

by TexasCNC

Replied by TexasCNC on topic Anybody using a thermal dynamics CM 52?

I got it figure out the cut direction was the fix I had it backwards and I raised the voltage on the thc man what a difference it made thanks a lot for the pointers on this.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

02 Oct 2019 04:21 #146852

by phillc54

Replied by phillc54 on topic Anybody using a thermal dynamics CM 52?

I'm glad you got it sorted, good work.

The following user(s) said Thank You: TexasCNC

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11557

- Thank you received: 3878

02 Oct 2019 04:23 #146853

by rodw

Replied by rodw on topic Anybody using a thermal dynamics CM 52?

Great work. We've all been through a learning curve ... I got caught the same way.

The following user(s) said Thank You: TexasCNC

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

04 Oct 2019 01:15 #147058

by TexasCNC

Replied by TexasCNC on topic Anybody using a thermal dynamics CM 52?

Is there a way to move the part or drawing that gets imported on linuxcnc to move to 0/0? The drawings are setting 2 inches X and 2 inches Y. so when I am cutting a part out it runs out of material but I should theoretically have enough but linuxcnc doesn’t put part on 0/0. Any ideas or a setting I can change?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

04 Oct 2019 01:19 #147059

by phillc54

Replied by phillc54 on topic Anybody using a thermal dynamics CM 52?

Your CAM program should be setting up the coordinates. Can you post the start of a typical GCode file up until the first M3.

Please Log in or Create an account to join the conversation.

- TexasCNC

- Offline

- Platinum Member

-

Less

More

- Posts: 373

- Thank you received: 10

04 Oct 2019 02:08 #147072

by TexasCNC

Replied by TexasCNC on topic Anybody using a thermal dynamics CM 52?

Here is a pic

Please Log in or Create an account to join the conversation.

Time to create page: 0.073 seconds