New Mill Build...Can I use LinuxCNC?

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

02 May 2020 20:11 #166424

by Mayberry Customs

New Mill Build...Can I use LinuxCNC? was created by Mayberry Customs

First time posting here. I really want to use Linux CNC, but I am having a bit of hard time finding traction with the whole thing. The ease of use and setup of Mach 3 or UCCNC are very attractive, but I am very interested in Linux CNC as an alternative to those...first off I have almost completed my fixed gantry mill build, and have already built the electronics enclosure and bought the stepper motors. I’ll try to add some pictures just for context. Keep in mind the mill is only about 80% done.

Here is a list of the components I have. Let me know if I need to add any other specs.

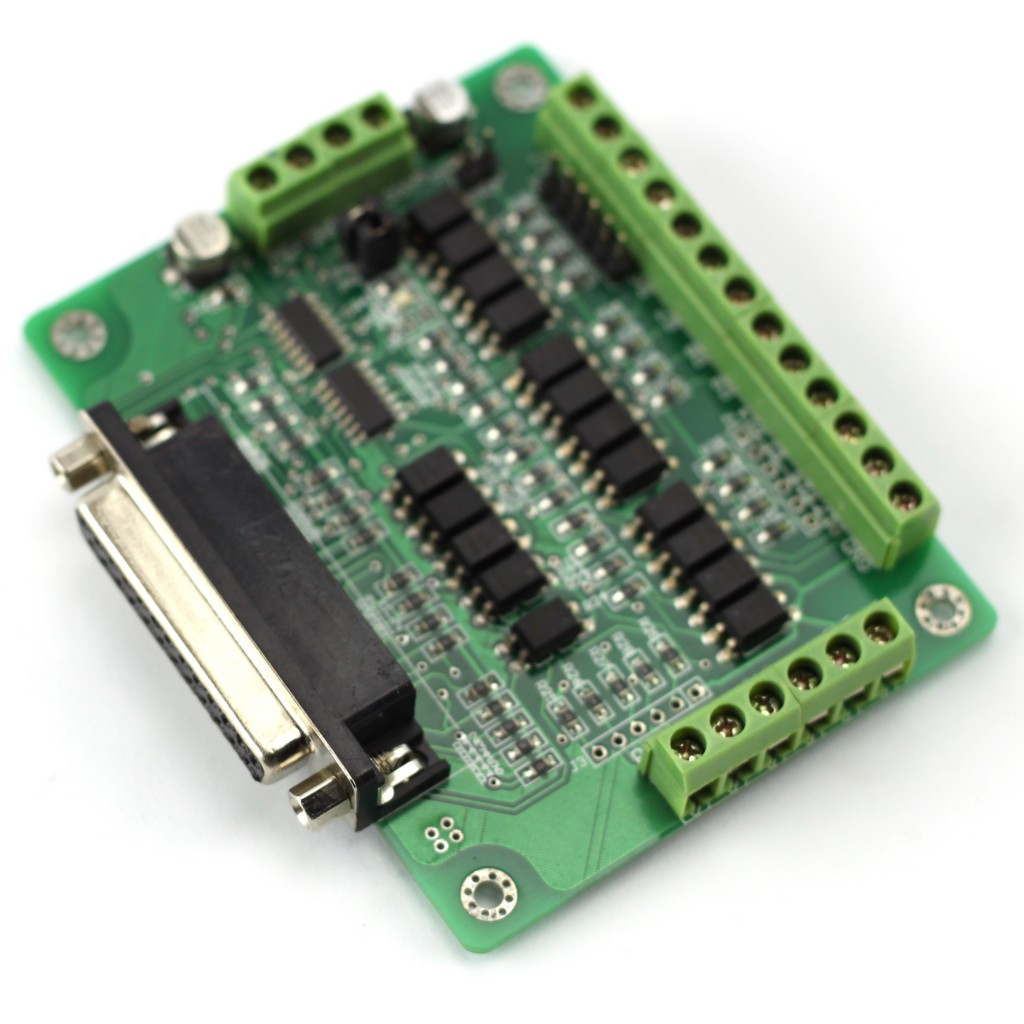

-Standard Basic DB25 Breakout Board (see picture)

-Three DM860A Longs Motor Drivers

-Three 878oz Longs NEMA 34 stepper motors

-Older Windows 7 era Acer laptop to run Linux CNC

-4kw spindle with matching VFD

The first issue that I see is finding a motion controller board that is compatible with Linux CNC. I originally planned on using the uc100 to go straight from my DB25 to USB, but I see that the uc100 is not compatible. By research the best option i see is to use a Mesa 7I92M Anything I/O board. As far as I can tell I can hook my breakout board directly to this board then I can run Ethernet to the laptop. So my first question is if these are correct assumptions and if this combination will work with LinuxCNC? Do I need a certain version of LCNC for this board or is there anything I need to be aware of that is unique about this combination?

Next question is wether or not my drivers will have any compatibility or functionality issues? Is there any specific information I need to know about these drivers before setting them up with LCNC?

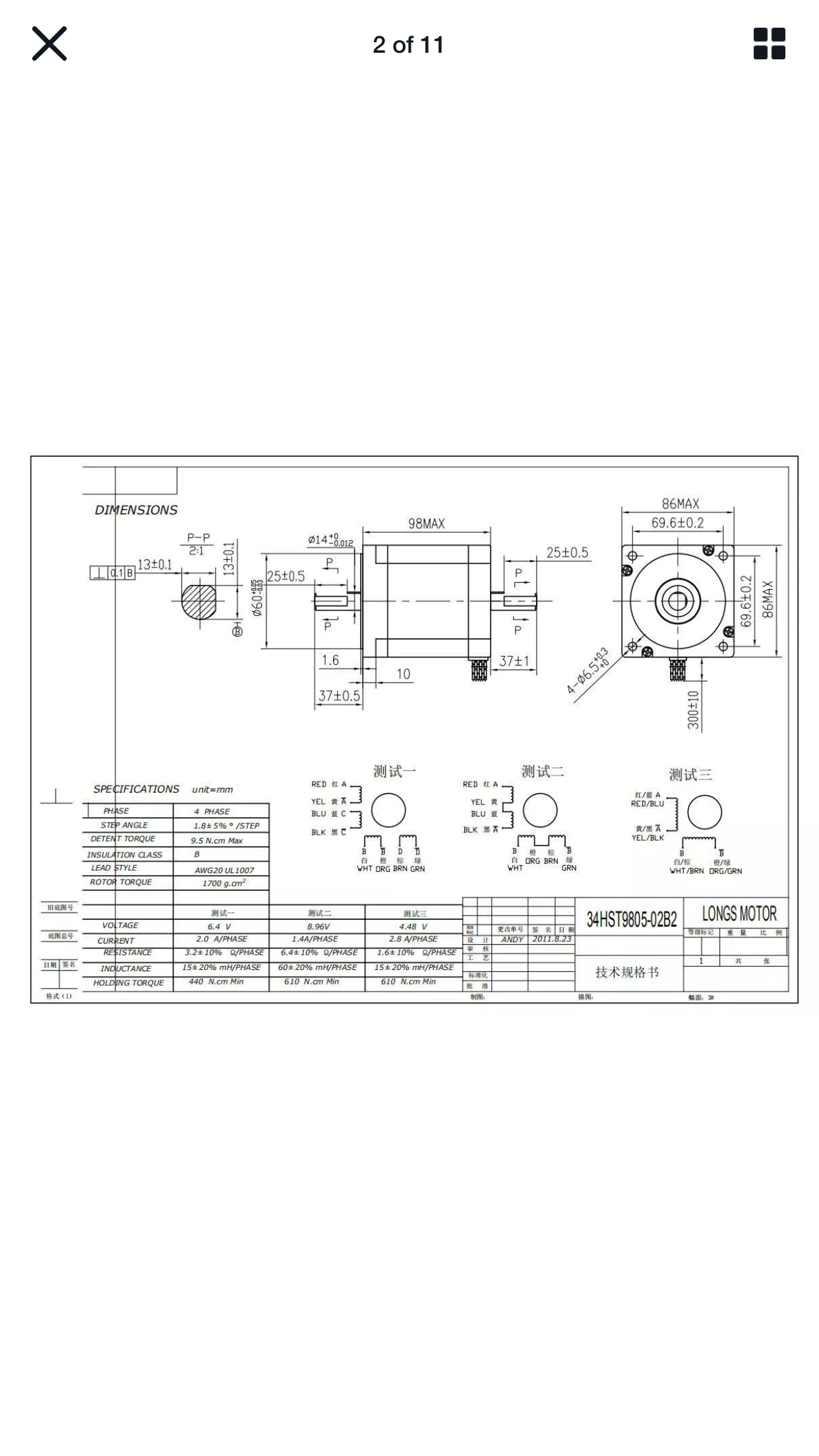

I don’t have a lot of information on the stepper motors beside the document that I have attached to the post. I recall hearing or reading somewhere that I needed a lot of specific information about the motors for setup in LCNC, maybe I’m wrong there. Is there any compatibility issues with my motors, or any information I need to know before installing?

At this point I am really trying to determine which way I want to go... It would be great to have some reassurance that LCNC will work for me before ordering the Mesa board. If it’s too difficult or expensive to make my current system work with LCNC I will just go with the UC100 with Mach or UCCNC.

As I conclude this long post I want to say upfront that I appreciate any and all advice or direction that is sent my way. I don’t post on forums often but I am always amazed at the community help that comes from them. Thanks, Andy

Here is a list of the components I have. Let me know if I need to add any other specs.

-Standard Basic DB25 Breakout Board (see picture)

-Three DM860A Longs Motor Drivers

-Three 878oz Longs NEMA 34 stepper motors

-Older Windows 7 era Acer laptop to run Linux CNC

-4kw spindle with matching VFD

The first issue that I see is finding a motion controller board that is compatible with Linux CNC. I originally planned on using the uc100 to go straight from my DB25 to USB, but I see that the uc100 is not compatible. By research the best option i see is to use a Mesa 7I92M Anything I/O board. As far as I can tell I can hook my breakout board directly to this board then I can run Ethernet to the laptop. So my first question is if these are correct assumptions and if this combination will work with LinuxCNC? Do I need a certain version of LCNC for this board or is there anything I need to be aware of that is unique about this combination?

Next question is wether or not my drivers will have any compatibility or functionality issues? Is there any specific information I need to know about these drivers before setting them up with LCNC?

I don’t have a lot of information on the stepper motors beside the document that I have attached to the post. I recall hearing or reading somewhere that I needed a lot of specific information about the motors for setup in LCNC, maybe I’m wrong there. Is there any compatibility issues with my motors, or any information I need to know before installing?

At this point I am really trying to determine which way I want to go... It would be great to have some reassurance that LCNC will work for me before ordering the Mesa board. If it’s too difficult or expensive to make my current system work with LCNC I will just go with the UC100 with Mach or UCCNC.

As I conclude this long post I want to say upfront that I appreciate any and all advice or direction that is sent my way. I don’t post on forums often but I am always amazed at the community help that comes from them. Thanks, Andy

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

02 May 2020 20:54 #166428

by tommylight

Replied by tommylight on topic New Mill Build...Can I use LinuxCNC?

Welcome to the "light" side, Andy !

You have built a nice machine there, great work, and then you went overboard with the spindle and motors, but this way you can move them to a bigger machine anytime in the future.

Since you have put that much time and effort in, it would be a real pity to have it controlled by anything but Linuxcnc, and you would have eventually come to that conclusion on your own after a bit of use and a few "spindle went through the table" issues, i have seen plenty of those.

My advice,

-if you can afford it, get a Mesa 7i76E as it has full 5 axis and spindle control with encoder feedback.

-the spindle can also be controlled through RS485 interface is the VFD supports that with a cheap USB to RS485 adapter.

-you can control the whole machine with parallel port, but with limited inputs and outputs, that should get you a fully working machine with limits but not much spindle control.

-that BOB you have has the same issues as the parallel port, but with much lower step rate or velocity as it uses very slow optocouplers.

-Mesa 7i92 will do very nicely for everything but the spindle, although some VFD can be set to use 5V for full speed instead of 10V, and that would get you full spindle speed, that is also valid for parallel and BOB.

Some more info that might be of interest, i do have an Acer laptop that can work with a Mesa 7i92 for days without a single issue, but overall laptops are not very good for machine control due to to much power saving stuff messing the timing of the step pulses.

As a start, download the Stretch version of Linuxcnc from here:

www.linuxcnc.org/downloads/

write it to a USB stick using DD in Linux or win32imagger in Windows, set the laptop to boot from USB devices in BIOS and boot from that USB, that way you can test and get used to Linuxcnc without installing it to HDD, you can do that at any time you feel confident.

If you need more reasons to avoid mach3 and the rest, let me know, i have plenty.

And no, i am not affiliated with Mesa in any way shape or form, i just use their products a lot.

You have built a nice machine there, great work, and then you went overboard with the spindle and motors, but this way you can move them to a bigger machine anytime in the future.

Since you have put that much time and effort in, it would be a real pity to have it controlled by anything but Linuxcnc, and you would have eventually come to that conclusion on your own after a bit of use and a few "spindle went through the table" issues, i have seen plenty of those.

My advice,

-if you can afford it, get a Mesa 7i76E as it has full 5 axis and spindle control with encoder feedback.

-the spindle can also be controlled through RS485 interface is the VFD supports that with a cheap USB to RS485 adapter.

-you can control the whole machine with parallel port, but with limited inputs and outputs, that should get you a fully working machine with limits but not much spindle control.

-that BOB you have has the same issues as the parallel port, but with much lower step rate or velocity as it uses very slow optocouplers.

-Mesa 7i92 will do very nicely for everything but the spindle, although some VFD can be set to use 5V for full speed instead of 10V, and that would get you full spindle speed, that is also valid for parallel and BOB.

Some more info that might be of interest, i do have an Acer laptop that can work with a Mesa 7i92 for days without a single issue, but overall laptops are not very good for machine control due to to much power saving stuff messing the timing of the step pulses.

As a start, download the Stretch version of Linuxcnc from here:

www.linuxcnc.org/downloads/

write it to a USB stick using DD in Linux or win32imagger in Windows, set the laptop to boot from USB devices in BIOS and boot from that USB, that way you can test and get used to Linuxcnc without installing it to HDD, you can do that at any time you feel confident.

If you need more reasons to avoid mach3 and the rest, let me know, i have plenty.

And no, i am not affiliated with Mesa in any way shape or form, i just use their products a lot.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

02 May 2020 21:06 #166431

by JohnnyCNC

Replied by JohnnyCNC on topic New Mill Build...Can I use LinuxCNC?

Yes, you can use LinuxCNC for your build. You don't need a motion controller board. LinuxCNC is the motion controller. You also don't need a breakout board if you were to use a Mesa 7i76E, 7i96, or 7i95 all of which have an Ethernet interface to connect to the PC and plenty of I/O ports to connect to t he machine. The may be other choices but I spotted these quickly on t he mesanet.com site. A laptop is not the best choice for the PC as the power saving feature can cause problems with controlling a machine. You don't need a high powered PC to run the machine. There are plenty of older PCs that are cheap and will give good performance. There is also plenty of excellent help available here on the forum. Looking at all the choices of Mesa cards can make your head spin but with the help you will get here you can't go wrong. The Mesa cards are top of the line.

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

02 May 2020 22:59 - 02 May 2020 23:10 #166443

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

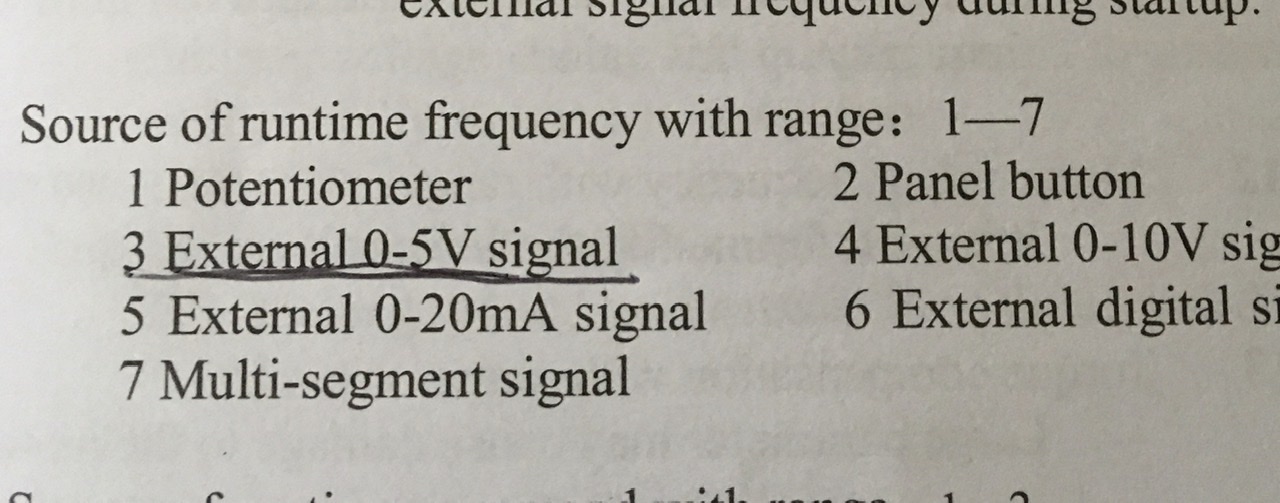

Oh, thanks. It has been a long slow build but it has turned out good so far. Ya both the stepper motors and the spindle ended up bigger than planned, but i got a great deal on both and am happy to have them. i did understand that i could control the cnc directly from a parallel port, but was also aware of the limitations and the fact that i have to have a PC with a parallel port. I see how the 7i76E is a superior board but budget is a major consideration at this point in the build. Although if i really need to go with that it would be silly not to. I would like to explore the 7I92M a little further if possible. So you mentioned that one of the downsides is the spindle speed control because of the lack of ability to send 0-10v signal. I have attached the VFD documentation and it appears that this VFD can receive 0-5v analog input signal for speed control. Check out photos to confirm. Also if i understand you correctly the 7I92 does not have a RS connection so i will have to hard wire the spindle control features. In effect making the wiring somewhat harder but the end result will be the same?

I understand that my BOB is slow by itself, but as far as i understand it using something like the 7I92 helps solve this issue. is that a correct assumption? Much like the UC100 takes on a lot of the processing load off of the computer. Is that the case with this Mesa board or is it just simply an expanded I/O board? Is my BOB still a bottleneck?

I hear you loud and clear on the laptop and i have an older desktop that will work great, so that's what i will use. I just wanted to use the laptop for the smaller footprint.

Being able to have a discussion about it makes me excited to use LCNC. Appreciate the great response so far. Thanks, Andy

I understand that my BOB is slow by itself, but as far as i understand it using something like the 7I92 helps solve this issue. is that a correct assumption? Much like the UC100 takes on a lot of the processing load off of the computer. Is that the case with this Mesa board or is it just simply an expanded I/O board? Is my BOB still a bottleneck?

I hear you loud and clear on the laptop and i have an older desktop that will work great, so that's what i will use. I just wanted to use the laptop for the smaller footprint.

Being able to have a discussion about it makes me excited to use LCNC. Appreciate the great response so far. Thanks, Andy

Attachments:

Last edit: 02 May 2020 23:10 by Mayberry Customs.

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

- Visitor

-

02 May 2020 23:16 #166446

by BeagleBrainz

Replied by BeagleBrainz on topic New Mill Build...Can I use LinuxCNC?

Seriously I'd go with the 7i76e, if I was starting over.

I was going to use the 7i92 with a parallel port BOB, but then decided I wanted the extras provided by a 7i76. I know it's a big wedge of Beer Tokens to begin with (more so when you live Down Under and postage is high, no fault of the supplier, it is was it is), but very much well worth it.

The Mesa boards,as I understand it, take on the processing of the timing of the step & direction and the high-speed serial interfaces. Linuxcnc still interprets the gcode, where as I've been lead to believe the various boards that are design for Mach interpret the gcode and do the timing.

Sorry if I sound like a "Mesa fanboy" but the products are fantastic and the support is fantastic as well.

I was going to use the 7i92 with a parallel port BOB, but then decided I wanted the extras provided by a 7i76. I know it's a big wedge of Beer Tokens to begin with (more so when you live Down Under and postage is high, no fault of the supplier, it is was it is), but very much well worth it.

The Mesa boards,as I understand it, take on the processing of the timing of the step & direction and the high-speed serial interfaces. Linuxcnc still interprets the gcode, where as I've been lead to believe the various boards that are design for Mach interpret the gcode and do the timing.

Sorry if I sound like a "Mesa fanboy" but the products are fantastic and the support is fantastic as well.

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

03 May 2020 01:59 - 03 May 2020 02:04 #166456

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

Ok I’m hearing you guys on the 7i76e.. what’s the difference between the sourcing and sinking output versions?...what power does it require, I have 5v going to my existing BOB, is it the same? It appears to be...is there any other obvious hang ups with the rest of my system components that any of you see?

Last edit: 03 May 2020 02:04 by Mayberry Customs.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

03 May 2020 02:47 #166459

by JohnnyCNC

Replied by JohnnyCNC on topic New Mill Build...Can I use LinuxCNC?

You would need 5 volts for the logic power and 8-32 volts for field power. I think 24volts is the most common for field power. It is used for relays, limits switches etc. I'm using the 6i24+7i76 combo but if I was doing it over I would use the 7i76E. Although I put the computer motherboard inside my CNC cabinet and I am using a wireless mouse and keyboard. The monitor and my pendant are the only two things with cords.

Please Log in or Create an account to join the conversation.

- Mayberry Customs

- Offline

- Senior Member

-

Less

More

- Posts: 62

- Thank you received: 8

03 May 2020 02:53 #166460

by Mayberry Customs

Replied by Mayberry Customs on topic New Mill Build...Can I use LinuxCNC?

I see...since it’s field power and not the logic power can I run it off the same 12v PS that I am using for the fans??

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

- Visitor

-

03 May 2020 03:32 #166464

by BeagleBrainz

Replied by BeagleBrainz on topic New Mill Build...Can I use LinuxCNC?

I'd use a separate 24v or 12v supply just to be on the safe side of noise.

Which would also mean if the fans took the 12v PSU out for any reason the rest of the system would be safe, throw in an alarm for the fan PSU and if it goes belly up you can take the action you think it requires, rather than loosing all your field power. But I'm kind of paranoid like that.

Which would also mean if the fans took the 12v PSU out for any reason the rest of the system would be safe, throw in an alarm for the fan PSU and if it goes belly up you can take the action you think it requires, rather than loosing all your field power. But I'm kind of paranoid like that.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11693

- Thank you received: 3945

03 May 2020 09:29 #166486

by rodw

Replied by rodw on topic New Mill Build...Can I use LinuxCNC?

I think the guys have set you on the straight and narrow. If you are going to buy a Mesa card for a mill, get the 7i76e and never look back. its just so superior to a BOB on a 7i92

Regarding the power supplies, you don't need the extra 5 volt supply. there is a switch that lets it get the 5V logic power from the field power. You only need the 5v power if you are adding daughter cards to the two 25 pin connectors (which you won't). I wasted my money on this.

Peronally I would buy a small (2 amp or so) din rail power supply from Meanwell or similar for field power. It will only cost you $40 or so. 24 volt gets you up into industrial quality system and significantly reduces the impact of any electrical noise because it needs a much greater voltage drop to trigger a false reading. I used a big 7 amp supply which was also a waste of money!

But if you have a 12 volt power supply now, you can give it a go if you are really short on cash.

The D version is used if you are retrofitting an existing machine with active low I/O. But for a new build don't buy it.

Also when you buy it, Mesa have a cool little bus bar that has two banks of 12 common connections. Get 1 or 2 of them. And also they have some nice din rail standoff mounts. You need 5 of them and the bus bars can also use them so you need to buy a few (they come in packs of 2.

I know I'm spending your money here but I'm just passing on what I've learnt by wasting my money!

Finally, check out Norberts amazing connection sheet for the 7i76e. Just read on a bit to get the bug free one.

forum.linuxcnc.org/27-driver-boards/3191...-sheet?start=0#85072

Regarding the power supplies, you don't need the extra 5 volt supply. there is a switch that lets it get the 5V logic power from the field power. You only need the 5v power if you are adding daughter cards to the two 25 pin connectors (which you won't). I wasted my money on this.

Peronally I would buy a small (2 amp or so) din rail power supply from Meanwell or similar for field power. It will only cost you $40 or so. 24 volt gets you up into industrial quality system and significantly reduces the impact of any electrical noise because it needs a much greater voltage drop to trigger a false reading. I used a big 7 amp supply which was also a waste of money!

But if you have a 12 volt power supply now, you can give it a go if you are really short on cash.

The D version is used if you are retrofitting an existing machine with active low I/O. But for a new build don't buy it.

Also when you buy it, Mesa have a cool little bus bar that has two banks of 12 common connections. Get 1 or 2 of them. And also they have some nice din rail standoff mounts. You need 5 of them and the bus bars can also use them so you need to buy a few (they come in packs of 2.

I know I'm spending your money here but I'm just passing on what I've learnt by wasting my money!

Finally, check out Norberts amazing connection sheet for the 7i76e. Just read on a bit to get the bug free one.

forum.linuxcnc.org/27-driver-boards/3191...-sheet?start=0#85072

The following user(s) said Thank You: BeagleBrainz

Please Log in or Create an account to join the conversation.

Time to create page: 0.240 seconds