2 seperate MPG handwheels for each axis - CNC Lathe build

- rodw

-

- Away

- Platinum Member

-

- Posts: 11729

- Thank you received: 3973

I appreciate that this stuff take us way outside our comfort zone. But by using a digital switch that can count to 4 in binary saves pins. eg. We get 4 states out of 4 pins.... That was my big discovery, Re read my tutorial

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11729

- Thank you received: 3973

I never used any resistors.

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

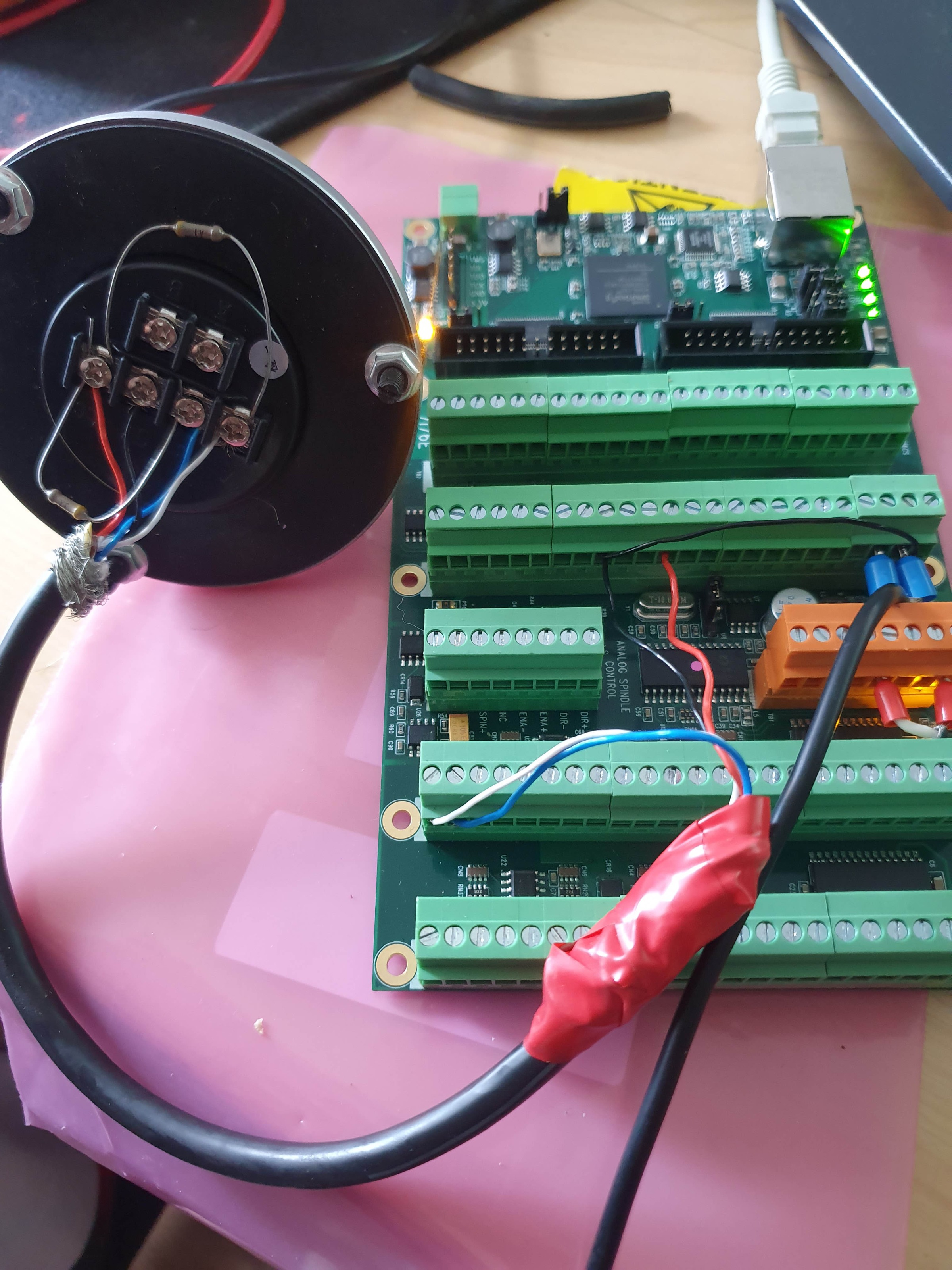

Current situation: The wiring is done as shown on this manual (page: Connection of MPG's): wiki.eusurplus.com/downloads/7i76E.pdf

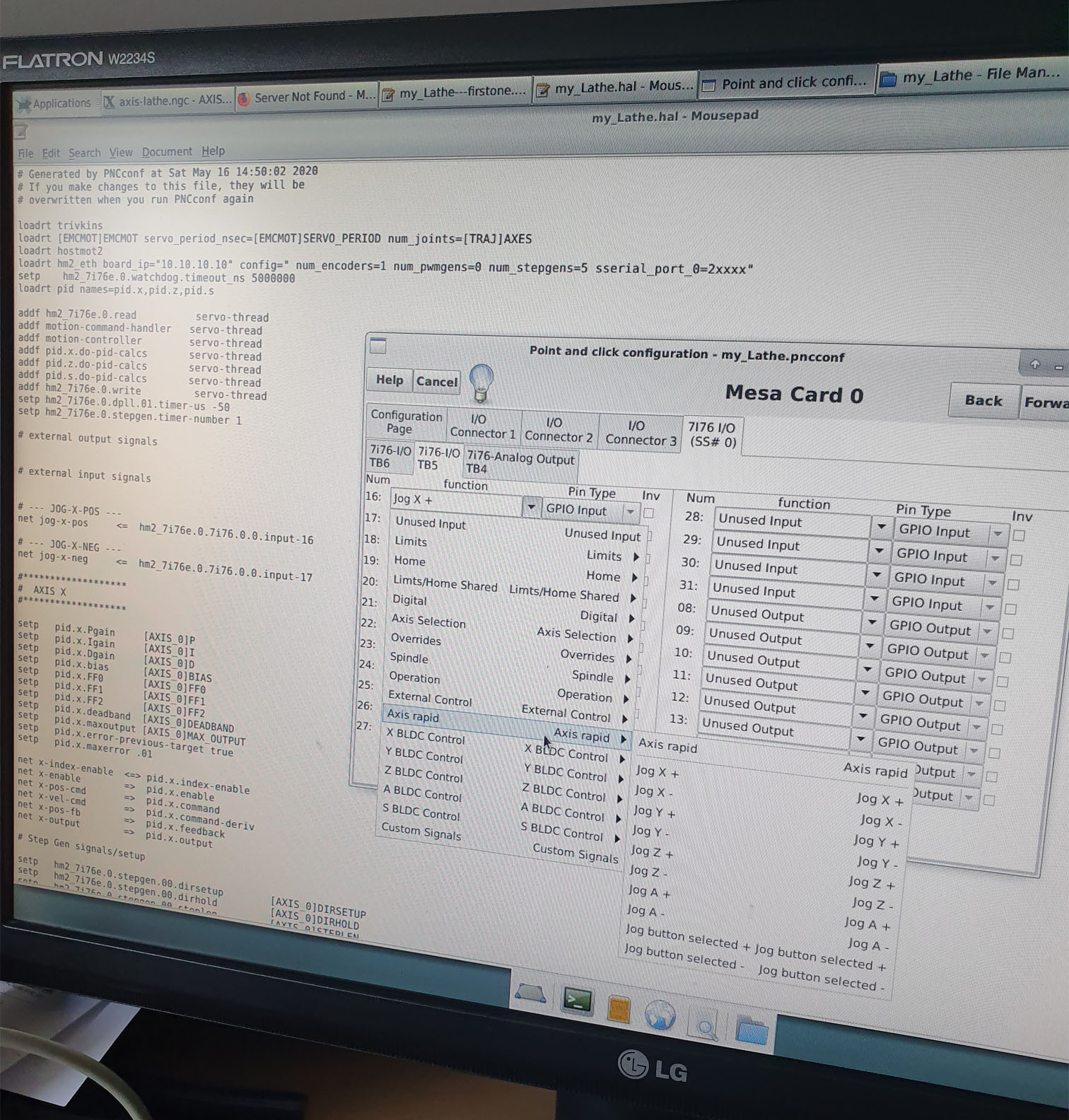

Now i would like to make the setup for the MPG with the PCCONF tool: I am on the configuration page on the main Tab "7i76 I/O (SS 0)" and the daughter tab "7i76-I/O TB5". There os jabe to chose the function. I choosed "Jog X +" for Input 16 and "Jog X -" for Input 17, which is for sure wrong, because nothing happend on the AXIS GUI DRO, but the MPG gives 5v when turning the handwheel.

Attachments:

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

It is based on gmoccapy

In that there are a lot of hals. If i remember right one is called mpg...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21348

- Thank you received: 7285

@Danhen, you are not using two power supplies , so you are good and the wiring should be ok if those are +5V and gnd from the Mesa with the red and black wire.

@Rod, those are pull up resistor as the encoder has open collector outputs, so it can pull the signal to ground but not to +5V.

@Danhen, in pncconf, there is the option of using MPG, but i think it is for the spindle encoder, so you can set that and later edit the hal to point them to the actual encoders.

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

Sorry for my lathe reply, but unfortunately (as always with Linux) i had and still have problems with my wifi on the test pc. Its disconnecting from time to time when using a brower. But it does not matter right now.

To Mikel_Eitel: I cant find that post: #130396. Could you send me the link?

To tommylight: thanks, but its impossible to get it done for me, because i just dont know what i am doing or what i have to do. Its so complicated for me and i really dont know why. The CNC router with the cheap BOB was so easy to set up, but i really dont know how to do that with the mpg handwheels.

I try to check some settings from others, but the first thing which i just dont understand is, why in no lines in the HAL are the input pines pointed out.

Like for example i found this answer from Andypugh on that topic Mesa 5i25 and 7176 getting started :

Then connect the mpg to each axis:

net x-jog hm2_5i25.0.7i76.0.0.enc0.count => axis.0.jog-counts

net z-jog hm2_5i25.0.7i76.0.0.enc1.count => axis.2.jog-counts

Are there no input pins missing? I just dont get it. No even a bit. I would really wish someone would make a tutorial or something and not just give 10% info. At least i think that its impossible to know what to do for a "mesa beginner" as i am.

Here one more example of a HAL file to explain you what i dont understand (it was for a 3 axis mpg pendant i think) from this topic: 5i25 7i76 mpg help please

# Generated by PNCconf at Sun Apr 3 20:58:52 2011

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=200xxxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt mux16 names=jogincr

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf jogincr servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# --- MACHINE-IS-ENABLED ---

net machine-is-enabled hm2_5i25.0.7i76.0.0.output-07

# external input signals

# --- HOME-X ---

net home-x <= hm2_5i25.0.7i76.0.0.input-00

# --- HOME-Y ---

net home-y <= hm2_5i25.0.7i76.0.0.input-01

# --- HOME-Z ---

net home-z <= hm2_5i25.0.7i76.0.0.input-02

# --- JOINT-SELECT-A ---

net joint-select-a <= hm2_5i25.0.7i76.0.0.input-20

# --- JOINT-SELECT-B ---

net joint-select-b <= hm2_5i25.0.7i76.0.0.input-21

# --- JOINT-SELECT-C ---

net joint-select-c <= hm2_5i25.0.7i76.0.0.input-22

# --- JOG-INCR-A ---

net jog-incr-a <= hm2_5i25.0.7i76.0.0.input-24

# --- JOG-INCR-B ---

net jog-incr-b <= hm2_5i25.0.7i76.0.0.input-25

# --- JOG-INCR-C ---

net jog-incr-c <= hm2_5i25.0.7i76.0.0.input-26

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.00.dirsetup [AXIS_0]DIRSETUP

setp hm2_5i25.0.stepgen.00.dirhold [AXIS_0]DIRHOLD

setp hm2_5i25.0.stepgen.00.steplen [AXIS_0]STEPLEN

setp hm2_5i25.0.stepgen.00.stepspace [AXIS_0]STEPSPACE

setp hm2_5i25.0.stepgen.00.position-scale [AXIS_0]STEP_SCALE

setp hm2_5i25.0.stepgen.00.step_type 0

setp hm2_5i25.0.stepgen.00.control-type 1

setp hm2_5i25.0.stepgen.00.maxaccel [AXIS_0]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.00.maxvel [AXIS_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= axis.0.motor-pos-cmd

net x-vel-cmd <= axis.0.joint-vel-cmd

net x-output => hm2_5i25.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_5i25.0.stepgen.00.position-fb

net x-pos-fb => axis.0.motor-pos-fb

net x-enable <= axis.0.amp-enable-out

net x-enable => hm2_5i25.0.stepgen.00.enable

# ---setup home / limit switch signals---

net home-x => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [AXIS_1]P

setp pid.y.Igain [AXIS_1]I

setp pid.y.Dgain [AXIS_1]D

setp pid.y.bias [AXIS_1]BIAS

setp pid.y.FF0 [AXIS_1]FF0

setp pid.y.FF1 [AXIS_1]FF1

setp pid.y.FF2 [AXIS_1]FF2

setp pid.y.deadband [AXIS_1]DEADBAND

setp pid.y.maxoutput [AXIS_1]MAX_OUTPUT

setp pid.y.error-previous-target true

setp pid.y.maxerror .0005

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.01.dirsetup [AXIS_1]DIRSETUP

setp hm2_5i25.0.stepgen.01.dirhold [AXIS_1]DIRHOLD

setp hm2_5i25.0.stepgen.01.steplen [AXIS_1]STEPLEN

setp hm2_5i25.0.stepgen.01.stepspace [AXIS_1]STEPSPACE

setp hm2_5i25.0.stepgen.01.position-scale [AXIS_1]STEP_SCALE

setp hm2_5i25.0.stepgen.01.step_type 0

setp hm2_5i25.0.stepgen.01.control-type 1

setp hm2_5i25.0.stepgen.01.maxaccel [AXIS_1]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.01.maxvel [AXIS_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= axis.1.motor-pos-cmd

net y-vel-cmd <= axis.1.joint-vel-cmd

net y-output => hm2_5i25.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net y-pos-fb => axis.1.motor-pos-fb

net y-enable <= axis.1.amp-enable-out

net y-enable => hm2_5i25.0.stepgen.01.enable

# ---setup home / limit switch signals---

net home-y => axis.1.home-sw-in

net y-neg-limit => axis.1.neg-lim-sw-in

net y-pos-limit => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror .0005

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.02.dirsetup [AXIS_2]DIRSETUP

setp hm2_5i25.0.stepgen.02.dirhold [AXIS_2]DIRHOLD

setp hm2_5i25.0.stepgen.02.steplen [AXIS_2]STEPLEN

setp hm2_5i25.0.stepgen.02.stepspace [AXIS_2]STEPSPACE

setp hm2_5i25.0.stepgen.02.position-scale [AXIS_2]STEP_SCALE

setp hm2_5i25.0.stepgen.02.step_type 0

setp hm2_5i25.0.stepgen.02.control-type 1

setp hm2_5i25.0.stepgen.02.maxaccel [AXIS_2]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.02.maxvel [AXIS_2]STEPGEN_MAXVEL

setp hm2_5i25.0.gpio.004.invert_output true

# ---closedloop stepper signals---

net z-pos-cmd <= axis.2.motor-pos-cmd

net z-vel-cmd <= axis.2.joint-vel-cmd

net z-output => hm2_5i25.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_5i25.0.stepgen.02.position-fb

net z-pos-fb => axis.2.motor-pos-fb

net z-enable <= axis.2.amp-enable-out

net z-enable => hm2_5i25.0.stepgen.02.enable

# ---setup home / limit switch signals---

net home-z => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-output <= pid.s.output

# ---digital potentionmeter output signals/setup---

setp hm2_5i25.0.7i76.0.0.spinout-minlim [SPINDLE_9]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i76.0.0.spinout-maxlim [SPINDLE_9]OUTPUT_MAX_LIMIT

setp hm2_5i25.0.7i76.0.0.spinout-scalemax [SPINDLE_9]OUTPUT_SCALE

net spindle-output => hm2_5i25.0.7i76.0.0.spinout

net spindle-enable => hm2_5i25.0.7i76.0.0.spinena

net spindle-ccw => hm2_5i25.0.7i76.0.0.spindir

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---jogwheel signals to mesa encoder - shared MPG---

net joint-selected-count <= hm2_5i25.0.encoder.00.count

# ---mpg signals---

# for axis x MPG

setp axis.0.jog-vel-mode 0

net selected-jog-incr => axis.0.jog-scale

net joint-select-a => axis.0.jog-enable

net joint-selected-count => axis.0.jog-counts

# for axis y MPG

setp axis.1.jog-vel-mode 0

net selected-jog-incr => axis.1.jog-scale

net joint-select-b => axis.1.jog-enable

net joint-selected-count => axis.1.jog-counts

# for axis z MPG

setp axis.2.jog-vel-mode 0

net selected-jog-incr => axis.2.jog-scale

net joint-select-c => axis.2.jog-enable

net joint-selected-count => axis.2.jog-counts

# connect selectable mpg jog increments

net jog-incr-a => jogincr.sel0

net jog-incr-b => jogincr.sel1

net jog-incr-c => jogincr.sel2

net jog-incr-d => jogincr.sel3

net selected-jog-incr <= jogincr.out-f

setp jogincr.debounce-time 0.200000

setp jogincr.use-graycode False

setp jogincr.suppress-no-input False

setp jogincr.in00 0.000000

setp jogincr.in01 0.001000

setp jogincr.in02 0.010000

setp jogincr.in03 0.100000

setp jogincr.in04 0.005000

setp jogincr.in05 0.010000

setp jogincr.in06 0.050000

setp jogincr.in07 0.100000

setp jogincr.in08 0.125000

setp jogincr.in09 0.125000

setp jogincr.in10 0.125000

setp jogincr.in11 0.125000

setp jogincr.in12 0.125000

setp jogincr.in13 0.125000

setp jogincr.in14 0.125000

setp jogincr.in15 0.125000

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-preparedHe did connect the MPG to TB5 Pin 1 and Pin 2, as i did also for one MPG handwheel. But no where in the HAL i can find something like "input 16" and "input 17".

Guys, i dont wanna cry, but i dont get it done by my self. No chance. I know that this is not your problem and you are helping here for free, but since i have got the Mesa 7i76e i have spend about 24 hours to get things done and from the 24h a spend at least 10 hours, just to get the Handwheels connected and setup, but with no positive result. I am currently really thinking to give up and sell the 7i76e, forget about the mpg handwheels and just use a cheap BOB which i know that i will be able to setup.

Another option is that someone does the work for me and i pay for that. There are nicer things to do then trying something without any clue about it.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

code inserts

########################################

# 7i73 hal connections for the MPG #

# (c) Norbert Schechner #

# modified by Mike Eitel #

########################################

### DECLARATION OF USED COMPONENTS ###

loadrt ilowpass names=lowpass-x,lowpass-y,lowpass-z,lowpass-a

loadrt mux4 names=jog-scale-xy,jog-scale-z,jog-scale-a

### STARTING OF USED COMPONENTS ###

addf lowpass-x servo-thread

addf lowpass-y servo-thread

addf lowpass-z servo-thread

addf lowpass-a servo-thread

addf jog-scale-xy servo-thread

addf jog-scale-z servo-thread

addf jog-scale-a servo-thread

### DEFINITION OF CONSTANTS ###

# For velocity mode, set to 1

# In velocity mode the axis stops when the dial is stopped even if that means

# the commanded motion is not completed. For position mode (the default), set to 0

# In position mode the axis will move exactly jog-scale

# units for each count, regardless of how long that might take,

setp axis.x.jog-vel-mode 0

setp axis.y.jog-vel-mode 0

setp axis.z.jog-vel-mode 0

setp axis.a.jog-vel-mode 0

setp joint.0.jog-vel-mode 0

setp joint.1.jog-vel-mode 0

setp joint.2.jog-vel-mode 0

setp joint.3.jog-vel-mode 0

# Make the movements smother by avoiding big jumps

setp lowpass-x.scale 1

setp lowpass-x.gain 0.01

setp lowpass-y.scale 1

setp lowpass-y.gain 0.0075

setp lowpass-z.scale 1

setp lowpass-z.gain 0.0050

setp lowpass-a.scale 1

setp lowpass-a.gain 0.0025

# This sets the scale that will be used based on the input to the mux4

# The scale used here has to be multiplied by the ilowpass scale

# X an Y are using the same scale factors

setp jog-scale-xy.in0 1.000

setp jog-scale-xy.in1 0.100

setp jog-scale-xy.in2 0.010

setp jog-scale-xy.in3 0.001

#Z ist normal spindel axis

setp jog-scale-z.in0 1.000

setp jog-scale-z.in1 0.100

setp jog-scale-z.in2 0.010

setp jog-scale-z.in3 0.001

#A is a rotating axis !

setp jog-scale-a.in0 15.0

setp jog-scale-a.in1 3.6

setp jog-scale-a.in2 1.0

setp jog-scale-a.in3 0.1

### IMPLEMENTATION OF HAL CONNECTIONS ###

# X an Y are using the same scale factors

# The selector inputs of the mux4 component are connected with the hw switches

net scale-xy1 jog-scale-xy.sel0 <= hm2_7i76e.0.7i73.0.1.input-18-not

net scale-xy2 jog-scale-xy.sel1 <= hm2_7i76e.0.7i73.0.1.input-19-not

net scale-z1 jog-scale-z.sel0 <= hm2_7i76e.0.7i73.0.1.input-20-not

net scale-z2 jog-scale-z.sel1 <= hm2_7i76e.0.7i73.0.1.input-21-not

net scale-a1 jog-scale-a.sel0 <= hm2_7i76e.0.7i73.0.1.input-22-not

net scale-a2 jog-scale-a.sel1 <= hm2_7i76e.0.7i73.0.1.input-23-not

# This sets the scale that will be used based on the input of the mux4

# The output from the mux4 is sent to each axis jog scale

net mpg-scale-xy jog-scale-xy.out => axis.x.jog-scale => joint.0.jog-scale

net mpg-scale-xy => axis.y.jog-scale => joint.1.jog-scale

net mpg-scale-z jog-scale-z.out => axis.z.jog-scale => joint.2.jog-scale

net mpg-scale-a jog-scale-a.out => axis.a.jog-scale => joint.3.jog-scale

# Connecting of encoder hw outputs to hal

# The output from encoder counts is sent to ilowpass

net jog-wheel-counts-x lowpass-x.in <= hm2_7i76e.0.7i73.0.1.enc0.count

net jog-wheel-counts-y lowpass-y.in <= hm2_7i76e.0.7i73.0.1.enc1.count

net jog-wheel-counts-z lowpass-z.in <= hm2_7i76e.0.7i73.0.1.enc2.count

net jog-wheel-counts-a lowpass-a.in <= hm2_7i76e.0.7i73.0.1.enc3.count

net jog-wheel-counts-x => joint.0.jog-counts => axis.x.jog-counts

net jog-wheel-counts-y => joint.1.jog-counts => axis.y.jog-counts

net jog-wheel-counts-z => joint.2.jog-counts => axis.z.jog-counts

net jog-wheel-counts-a => joint.3.jog-counts => axis.a.jog-counts

# already connected cont_joging on jog vel mode selection

# net jog_cont gmoccapy.jog.jog-inc-0 <= hm2_7i76e.0.7i73.0.1.input-07

#net jog_1000 gmoccapy.jog.jog-inc-1 <= hm2_7i76e.0.7i73.0.1.input-06

#net jog_0100 gmoccapy.jog.jog-inc-2 <= hm2_7i76e.0.7i73.0.1.input-05

#net jog_0010 gmoccapy.jog.jog-inc-3 <= hm2_7i76e.0.7i73.0.1.input-04

#net jog_0001 gmoccapy.jog.jog-inc-4 <= hm2_7i76e.0.7i73.0.1.input-03

# loaded at estop_and_enable.hal

#loadrt and2 names=and_x,and_y,and_z

#addf and_x servo-thread

#addf and_y servo-thread

#addf and_z servo-thread

#addf and_a servo-thread

net jog-enable <= halui.machine.is-on

net jog-enable => joint.0.jog-enable => axis.x.jog-enable

net jog-enable => joint.1.jog-enable => axis.y.jog-enable

net jog-enable => joint.2.jog-enable => axis.z.jog-enable

net jog-enable => joint.3.jog-enable => axis.a.jog-enable

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21348

- Thank you received: 7285

Tomorrow is Sunday, so grab a coffee and a smoke and a chair, we'll give it a go at a slower pace.

Please Log in or Create an account to join the conversation.