2 seperate MPG handwheels for each axis - CNC Lathe build

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

My feeling is that you have the problem in the start where you choose your cards..

But sorry pncconf is years ago....

But anyhow. Taking a good sleep helps. I mostely burn things up when i press myself to hard.

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

The thing is i want currently only test the MPG handwheel. I have no switches for the scale or so, so i would somehow need to have a scale selector on the Linuxcnc GUI. Also i want the encoder to be active and not as some have it with a button or so, because i currently do not have those things here, so i think my test setup should be less complicated.

Just to explain my situation shortly and why i am "just testing right now": I am still doing the mechanical stuff at my CNC lathe, and i need about 2-3 weeks to get the mechanical part done, but the MPG Handwheels part sits all the time in my head, because i have never done it and i knew it will be difficult, but not that difficult. I want to get it done, so i will have a free head to continue with the mechanical part.

@tommylight: That sounds really great, because i need fresh air. I will visit my gf and go out for a walk with the dogs to get some energy for tomorrow

Thanks in advance and have a nice evening!

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

PS: i tested the halmeter in linuxcnc, tryied all enc0 pins, but when turning the handwheel, nothing happens. When measuring on the A and B wires from the MPG then i get 4,10V when turning the wheel. Not sure why 4,10V and not 5V.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21157

- Thank you received: 7223

Learned that when i was young and stubborn as hell, now i just leave everything and go grab a coffee somewhere else, not in the shop.I mostely burn things up when i press myself to hard.

I am in Europe, or part of it, so European time should do just fine, but at some point i will have to go help a friend assemble a plasma cutter as he dismantled it to have it painted, probably under an hour or so.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17577

- Thank you received: 5141

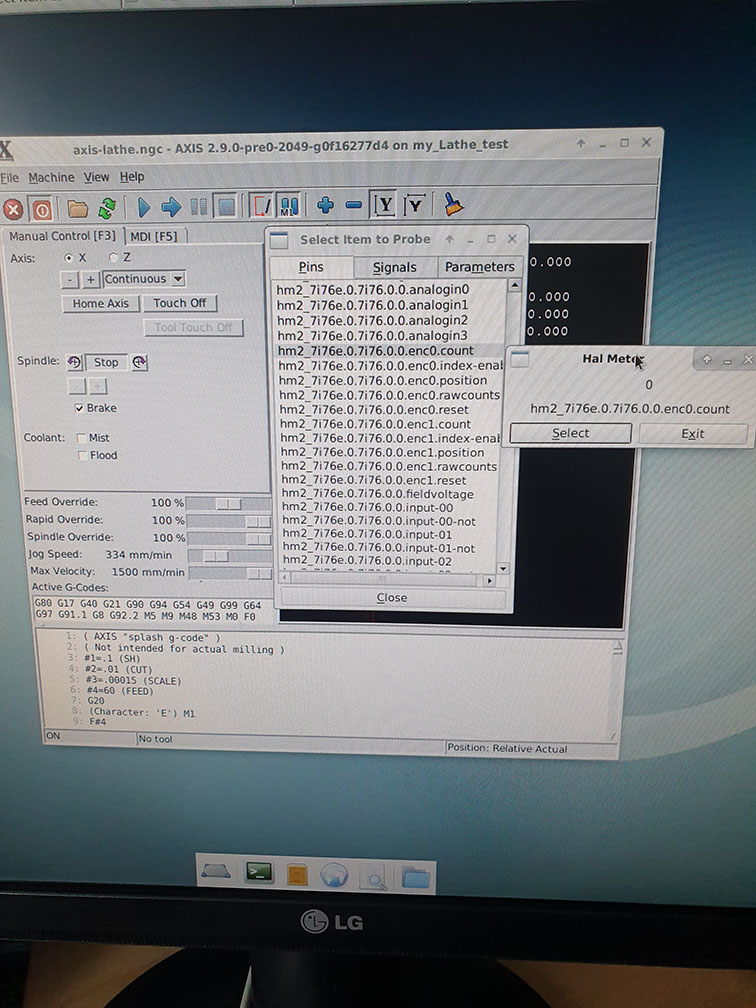

hm2_7i76e.0.7i76.0.0.enc0.count

To count, the inputs must swing below 2V and above 3V relative to field ground

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3905

Hand editing your hal and ini files is the only way to go. Then you have total control.

pncconcf did not support the 7i76e when I started so I survived without it.

I use halshow a lot to watch pins and see what is going on as you can see more than one at a time in one window.

The only thing I thought of is that if you don't have the axis select switch installed, you might have to setp the MPG scale pin to a value. If it is 0 , nothing will happen.

ANd yes, I hit the wall heaps of times. So I Would stop for a day or so have a think then go back to it. Take Tommy's advice. Coffee is good!

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

@PCW: Thanks for that! Now i do understand that the input pins 16 and 17 dont need to be somewhere in the HAL, because those pins are already linked with "hm2_7i76e.0.7i76.0.0.enc0.count". Correct?

So, 4.10V is totally fine.To count, the inputs must swing below 2V and above 3V relative to field ground

@rodw: I have read your build thread many times, really, but my problem is, i have no switches at all, so i dont know what i have to change in the HAL so that the MPG is always active just to test it.

Thats a good point. Make sense for me, but again i dont know what i have to enter/change in the HAL to set one scale which is always active, so that no switches are needed.The only thing I thought of is that if you don't have the axis select switch installed, you might have to setp the MPG scale pin to a value. If it is 0 , nothing will happen.

It seems that i would need to study all those codes for linuxcnc and the complete MESA 7i76e manual or so, but i want to be honest: I want a working machine and not be a pro in Linuxcnc setup. Some time ago i wanted to set up a test pc and learn classic ladder etc., but i do not have a lot of time anymore, so i want spent my free time with other things than something which i will not really need a lot in future. Of course i would like to understand the configuration, because later when the mechanical part on the Lathe is done, i want a panel with a switch for the scale change (ordered the same as you have, but i already wrote that i think on page 1). Also i want to have some buttons to start/stop g code, but right now i just do not want to think about it. As soon as i get the switch for the scale and some buttons i will start thinking about that.

In my next post i will precisly explain my current setup, so that it will be easier to help me out.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3905

Where I said

net x-jog-scale mux4.0.out => axis.x.jog-scalesetp axis.x.jog-scale 1Assuming a metric machine, that will give you a 1mm step. Change it to suit if you are in inches ot it will move 1 inch per click!

I might ad that I di move 1 meter per click once!

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 298

- Thank you received: 26

Debian vers. 9

Wiring of MPG to Mesa 7i76e: See picture:

*GND from TB3 Pin 9 is connected to GND of TB3 Pin 23

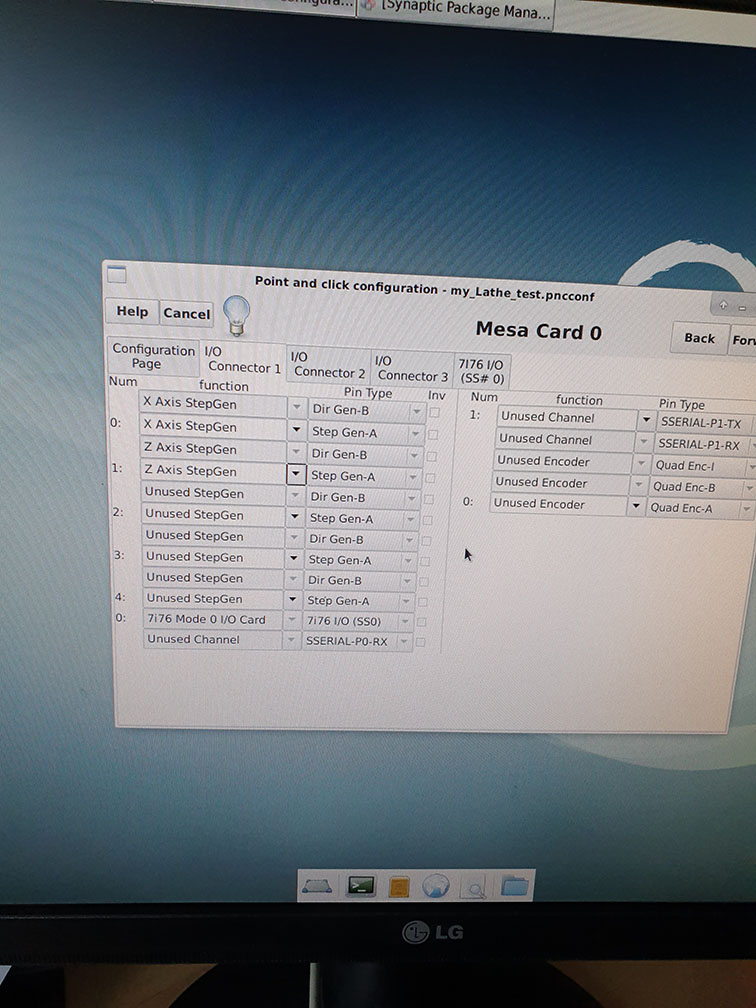

I used PCCONF to create a RAW setup. See pictures:

Everything else has been not set up and left as default.

After the set up i changed in the HAL the sserial port: sserial_port_0=2xxxx

I attached the .HAL and .INI file

I started Linuxcnc, opened the Halmeter and unfortunately nothing happens when turning the MPG handwheel, no matter which Pins enc0 pins i choose. See picture:

Do i understand it correctly, that if the wiring of the MPG is correct, then something should happen in the Halmeter when selecting the correct Pin ?

To remember: I have no switches to select the scale also no buttons to enable to MPG, so as Rodw wrote, i would need to set a standard scale. Also i would need to have the MPG active without any buttons to press.

I hope that are all informations you need to help me out.

Of course, in meantime until i get some help i will try to get it done by my self and not just wait until someone helps

Thanks in advance guys.

Please Log in or Create an account to join the conversation.