ROS LinuxCNC Link

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2070

Nice, thanks!Here is a tiny present for you :

Looks like a rainy day tomorrow, so I'll give it a go and report back.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

Wich linux version are you running?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2070

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2070

Is there actually a branch for me to build and test there?

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

If you clone it and build it without git checkout, i think it will be up to date.

[edit]

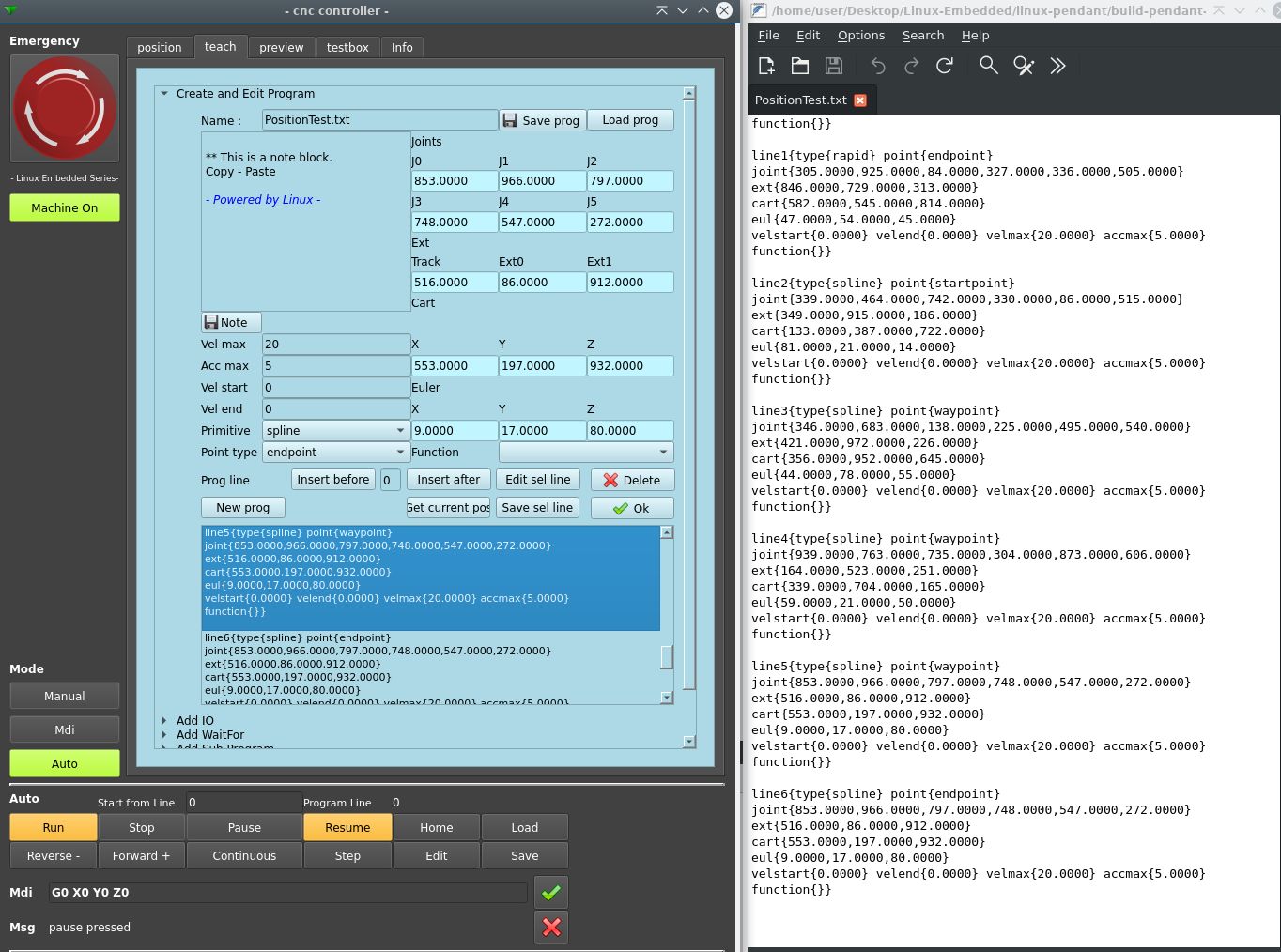

I did some work for the teach-in function.

It can now teach all points. It can insert points before and after a certain programline. It can edit and save a program line.

It can delete a random selected programline.

When edit's, insertions or deletions are done, the programlines are automatic renumbered.

Saving is tested ok. I have to code the file loading sequence now.

For file extension i used the simple .txt extension.

For coding the treewidget i used a different methode, using stackedwidgets.

Coding the treewidget by texteditor is not a nice way. So i code a treewidget structure and then i add a stackedwidget page

at the right place. This stackedwidget holds all the button's etc.

I think when you look at the file output, everyone can understand what is going on.

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2070

git clone git://github.com/grotius-cnc/linuxcnc.git linuxcnc-robotapp-dev

cd linuxcnc-robotapp-dev/src

./autogen.sh

./configure --with-realtime=uspace

make && sudo make setuid

cd ..

source ./scripts/rip-environmentBut all I see is linuxcnc-master. Even all the nyx stuff is missing.

[edit]

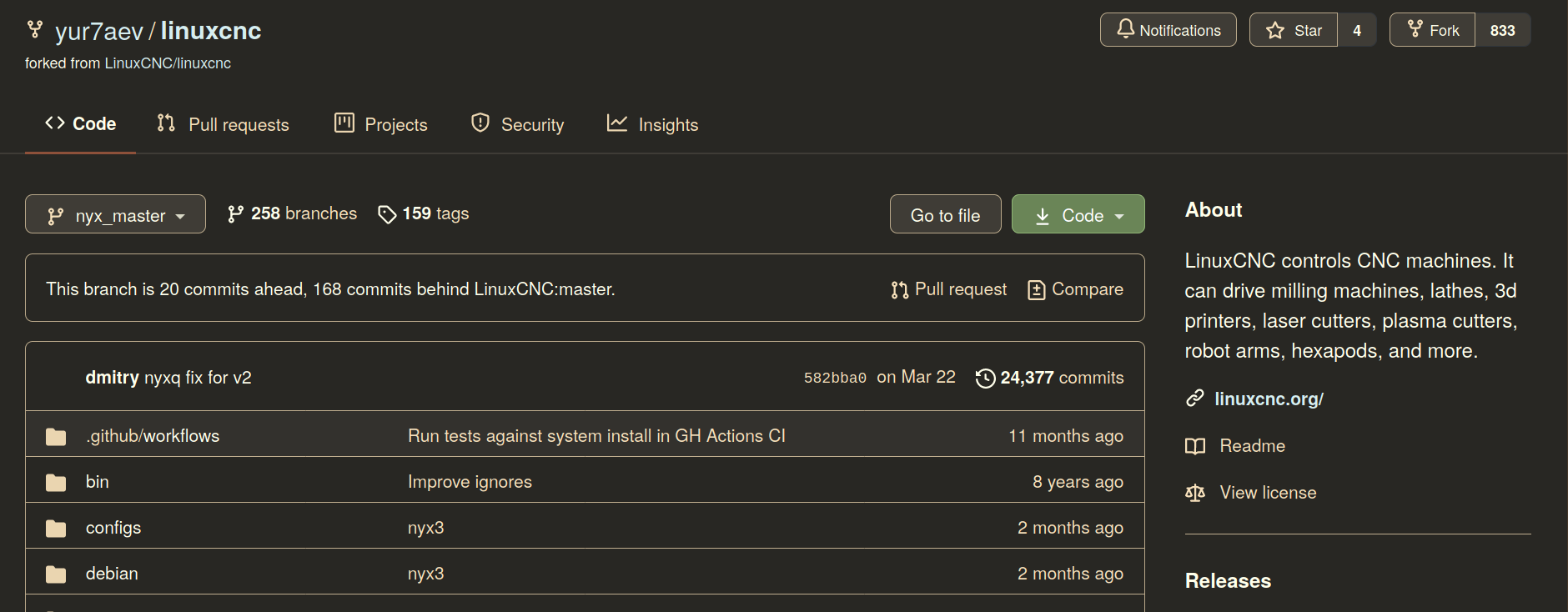

Are you sure you forked the correct branch? github.com/yur7aev/linuxcnc/tree/nyx_master

Attachments:

Please Log in or Create an account to join the conversation.

- Roiki

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 19

@Roiki

Actually I'm not aware that there is support for industry style robot programming even in ROS. Last time I had a look at it one had to use c++ or python script to send the commands. But maybe this has changed.

There isn't because no one has built one yet. The tools are all there. And imo it would make more sense to contribute to an already existing framework that others can use than to roll your own solution.

quote="Bari" post=208492]

You would want to use ros for this. It already has a support for real sense cameras and more so all you need is to figure out what you want to use it with.

The problem I have with ROS and with most robots is the lack of real time support for things that have to be synchronized in well under 1mS. I need to synchronize motion to mechanisms e.g., printheads, lasers, etc. that operate at a hundred times faster and I can't use interpolation. Try and ask for encoder outputs from inside a robot so that you can keep track of position in real time. I need realer time!

I'm not a fan of Intel and the depth measurement accuracy of their cameras is only 2%. In my circuit board fiducial application XY is of most interest since the PCB's are pretty consistent in thickness. A few microns of variance in Z will cover the worst of applications. I don't need stereo vision for this.[/quote]

That's quite an exotic usecase. And for that precision I'd think you need some fpga hardware or custom realtime modules. Most of those camera systems aren't really designed for that anyway so I think you're looking for something more specialized than real sense.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

I will look and report back.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2070

And imo it would make more sense to contribute to an already existing framework that others can use than to roll your own solution.

I hear you but we've discussed this before. At the end of the day it comes down to the fact that somebody actually has to sit down and do the work. And that somebody clearly can't just be anybody given the skill, time and motivation required just to dig through all the old undocumented code, let alone find the most elegant way to get the job done and please everybody who will be eager to voice an opinion. Even if money was offered you'd be hard pressed to find that person.

And then just because somebody actually finds a working solution does not mean it will be accepted to be merged into the source code.

So sometimes we just need to be grateful for what may look as a suboptimal solution in order to advance at all.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21240

- Thank you received: 7250

+1So sometimes we just need to be grateful for what may look as a suboptimal solution in order to advance at all.

I used LinuxCNC as a hobby just to ditch Mach3 and it's ugly/disgusting/vomit inducing GUI and instability and basically if i sneezed from across the shop it would stumble and fall. Once i opened an Inch gcode, i could never get it to turn back to mm, even reinstalling did not work.

Looking at Axis GUI and seeing the machine actually working was a revelation, both mentally and spiritually, and then i saw HAL and nearly had a heart attack! Soooo simple and sooo usable and easy to shape to whatever i may need.

Fast forward and it has become a part of my life, with all it's imperfections it still works 24/7/365/ for over 12 years now. >>> note to self = getting old !

I needed something that was not there, so i edited/wrote whatever was required and made it work with a THC, there are plenty of machines using it still all over the world as it never fails so nobody bothers to look for something else although now we have a much more advanced version and a new GUI and .... i still have a dozen machines using the old version, no one wants to change it no matter how much i tell them the new version is better.

This was all to prove a point, there was something missing, it got added, then came an even better version, who knows that might also be replaced ...

Open source pretty much means everybody does what he/she/it needs/wants/ however he/she/it needs/wants.

Also i've noticed here we hate money, as Andy so eloquently put it: we do not want to bother thinking what to do with it!

Please Log in or Create an account to join the conversation.