Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

07 Sep 2021 05:09 - 07 Sep 2021 05:40 #219814

by Grotius

Replied by Grotius on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

Hi,

For the libopencascade.so project:

You can do a "sudo make install" for the libopencascade.so "makefile". It's then installed to the system. It will then be found by the testproject.

The project has includepaths:

INCLUDEPATH += /usr/local/include/opencascade/ \

/usr/include/eigen3/ \

/usr/include/ \

/usr/local/lib/ \

*At compile time of the opencascade.pro it asks for a file ... etc. see picture from last entry.

Please sent the picture agian. I don't see it.

*Any clue how to send the feedback of the drive back to the cnc over the nml channel. This is most pressing. No step forward.

Hi no clue, but we can find out.

A more general question would be, how to send data from hal to the nml channel.

In the file nml.hh :

Once your app compiles, we can test some nml stuff.

For the libopencascade.so project:

You can do a "sudo make install" for the libopencascade.so "makefile". It's then installed to the system. It will then be found by the testproject.

The project has includepaths:

INCLUDEPATH += /usr/local/include/opencascade/ \

/usr/include/eigen3/ \

/usr/include/ \

/usr/local/lib/ \

*At compile time of the opencascade.pro it asks for a file ... etc. see picture from last entry.

Please sent the picture agian. I don't see it.

*Any clue how to send the feedback of the drive back to the cnc over the nml channel. This is most pressing. No step forward.

Hi no clue, but we can find out.

A more general question would be, how to send data from hal to the nml channel.

In the file nml.hh :

/* Read and Write Functions. */

int write(NMLmsg * nml_msg, int *serial_number = NULL);

/code]

line 1585 of nml.cc, this is interesting:

[code]

cms->set_mode(CMS_WRITE);

cms->write(nml_msg, serial_number); Once your app compiles, we can test some nml stuff.

Last edit: 07 Sep 2021 05:40 by Grotius.

Please Log in or Create an account to join the conversation.

- udoS

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 25

07 Sep 2021 07:41 #219821

by udoS

Replied by udoS on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

@Grotius

I'm talking about Page 6 @ 06 Sep 2021 13:29 #219758

the other stuff I will try out today.

I'm talking about Page 6 @ 06 Sep 2021 13:29 #219758

the other stuff I will try out today.

Please Log in or Create an account to join the conversation.

- udoS

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 25

07 Sep 2021 07:58 #219824

by udoS

Replied by udoS on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

@Grotius

That woked better then I thought. Good start into the day. LOLOL

That woked better then I thought. Good start into the day. LOLOL

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- udoS

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 25

07 Sep 2021 19:32 - 07 Sep 2021 20:51 #219871

by udoS

Replied by udoS on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

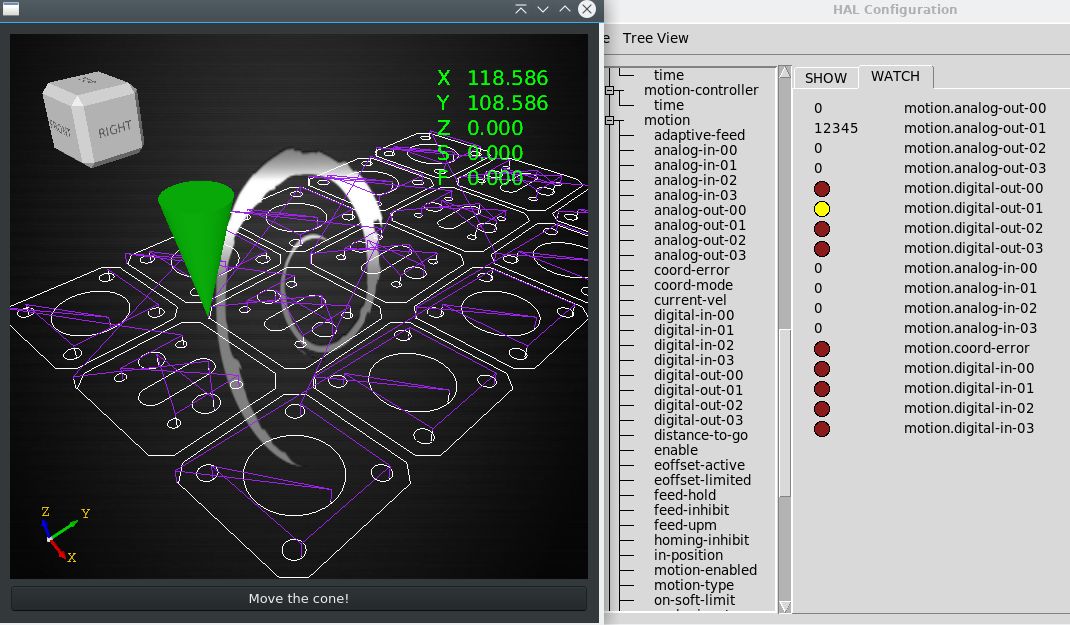

Here we go.

Last edit: 07 Sep 2021 20:51 by udoS.

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

07 Sep 2021 22:06 #219889

by Grotius

Replied by Grotius on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

Hi,

Nice work !

0.

Now you can change the background of the widget to something you like.

The background is now stretched: "Aspect_FM_STRETCH", but there are more settings available.

1.

To setup the cone z upwards, edit the file :

draw_primitives.cpp line 14 + line 21 must be : gp_Dir axis=gp::DZ();

2.

To send tool position data from nml to the opencascade you could consider a function like below.

The typedef is used to avoid confilects between qt and lcnc source files.

3.

Then to setup the cone (only once) in opencascade :

4.

And for translating the cone. Following your nml xyz positons.We pick the quaternion function.You can see i used the QVariant datatype to sent the data visa versa.

You can expand the Stringlist with extra axis values.

Ok good luck!

I hope the gcode parser can read this type of gcode.

Nice work !

0.

Now you can change the background of the widget to something you like.

The background is now stretched: "Aspect_FM_STRETCH", but there are more settings available.

1.

To setup the cone z upwards, edit the file :

draw_primitives.cpp line 14 + line 21 must be : gp_Dir axis=gp::DZ();

2.

To send tool position data from nml to the opencascade you could consider a function like below.

The typedef is used to avoid confilects between qt and lcnc source files.

typedef RCS_STAT_CHANNEL mystattype;

mystattype *status_channel;

QStringList list;

QVariant Nml_plugin::get_tcp_pos(){

EMC_STAT *emcStatus;

for(int i=0; i<1; i++){

usleep(100);

if(!status_channel->valid()) continue;

if(status_channel->peek() != EMC_STAT_TYPE) continue;

emcStatus = static_cast<EMC_STAT*>(status_channel->get_address());

list.clear();

list.push_back(QString::number(emcStatus->motion.traj.position.tran.x,'f',3));

list.push_back(QString::number(emcStatus->motion.traj.position.tran.y,'f',3));

list.push_back(QString::number(emcStatus->motion.traj.position.tran.z,'f',3));

}

QVariant data(list);

return data;

}3.

Then to setup the cone (only once) in opencascade :

void Opencascade::load_tool_cone(QVariant data){

QStringList list=data.toStringList();

double bottomdiameter = list.at(0).toDouble();

double topdiameter = list.at(1).toDouble();

double height = list.at(2).toDouble();

Ais_ToolCone = draw_primitives().draw_3d_cone({0,0,0},bottomdiameter,topdiameter,height);

Ais_ToolCone = draw_primitives().colorize(Ais_ToolCone,Quantity_NOC_GREEN,0);

m_context->Display(Ais_ToolCone,Standard_False);

}4.

And for translating the cone. Following your nml xyz positons.We pick the quaternion function.

void Opencascade::translate_tool_cone(QVariant data){

QStringList list=data.toStringList();

double x = list.at(0).toDouble();

double y = list.at(1).toDouble();

double z = list.at(2).toDouble();

Ais_ToolCone = draw_primitives().rotate_translate_3d_quaternion(Ais_ToolCone,{x,y,z},0,0,0);

m_context->Redisplay(Ais_ToolCone,Standard_False);

m_context->Display(Ais_ToolCone,Standard_False);

}You can expand the Stringlist with extra axis values.

Ok good luck!

I hope the gcode parser can read this type of gcode.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

07 Sep 2021 22:07 - 07 Sep 2021 22:10 #219890

by Grotius

Replied by Grotius on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

P.s. i uploaded a archive today on the other forum thread. It contains above code examples, this for info.

For above post, The coneshape (only once) in opencascade.h : Handle(AIS_Shape) Ais_ToolCone;

For above post, The coneshape (only once) in opencascade.h : Handle(AIS_Shape) Ais_ToolCone;

Last edit: 07 Sep 2021 22:10 by Grotius.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

08 Sep 2021 17:18 #219976

by Grotius

Replied by Grotius on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

Hi,

I looked for your question. The first solution i found is :

I looked for your question. The first solution i found is :

command_channel = new RCS_CMD_CHANNEL(emcFormat, "emcCommand", "xemc", filename.toStdString().c_str());

EMC_MOTION_SET_AOUT out;

out.now=1;

out.index=1;

out.start=12345;

out.end=54321;

command_channel->write(&out);

EMC_MOTION_SET_DOUT dout;

dout.now=1;

dout.index=1;

dout.start=1;

dout.end=0;

command_channel->write(&dout);Attachments:

Please Log in or Create an account to join the conversation.

- udoS

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 25

08 Sep 2021 19:35 #219994

by udoS

Replied by udoS on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

@Grotius AND .....

I was talking about the equivalent of the joint.n.pos.fb in the hal.

I get vel.cmd and pos.cmd from nml RCS_STATUS

How tho send my encoder position back at RCS_...... to the cnc to have the loop closed. Not hal.

Thanks for any helpful reply.

I was talking about the equivalent of the joint.n.pos.fb in the hal.

I get vel.cmd and pos.cmd from nml RCS_STATUS

How tho send my encoder position back at RCS_...... to the cnc to have the loop closed. Not hal.

Thanks for any helpful reply.

Please Log in or Create an account to join the conversation.

- udoS

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 25

10 Sep 2021 07:34 #220109

by udoS

Replied by udoS on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

@andypugh

My problem is as follows:

I have a plugin in c++ reading the joint motor cmd over the RCS_STATUS_CHANNAL nml .

Same goes for the velocity .

I feed that into my drive and get a pos-feedback. ( I could feed it into HAL but that's not what I want. If I can avoid it ) .

Now how and where to can I send that feedback. I do not want to use the hal if that is possible. But where to and how is the hal sending that feedback signal .

Or where do I have to put that Value so that is available to the cnc.

Best rgds to all

My problem is as follows:

I have a plugin in c++ reading the joint motor cmd over the RCS_STATUS_CHANNAL nml .

Same goes for the velocity .

I feed that into my drive and get a pos-feedback. ( I could feed it into HAL but that's not what I want. If I can avoid it ) .

Now how and where to can I send that feedback. I do not want to use the hal if that is possible. But where to and how is the hal sending that feedback signal .

Or where do I have to put that Value so that is available to the cnc.

Best rgds to all

Please Log in or Create an account to join the conversation.

- udoS

- Offline

- Elite Member

-

Less

More

- Posts: 216

- Thank you received: 25

19 Sep 2021 09:49 #221072

by udoS

Replied by udoS on topic Building new Full Qt c/c++ HMI (incl. nml and EtherCAT )

This is where I'm as of today. (Yesterday... )

and still going...

and still going...

Please Log in or Create an account to join the conversation.

Time to create page: 0.110 seconds