Control panel hardware buttons

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

05 Jan 2024 08:36 #289837

by rodw

Replied by rodw on topic Control panel hardware buttons

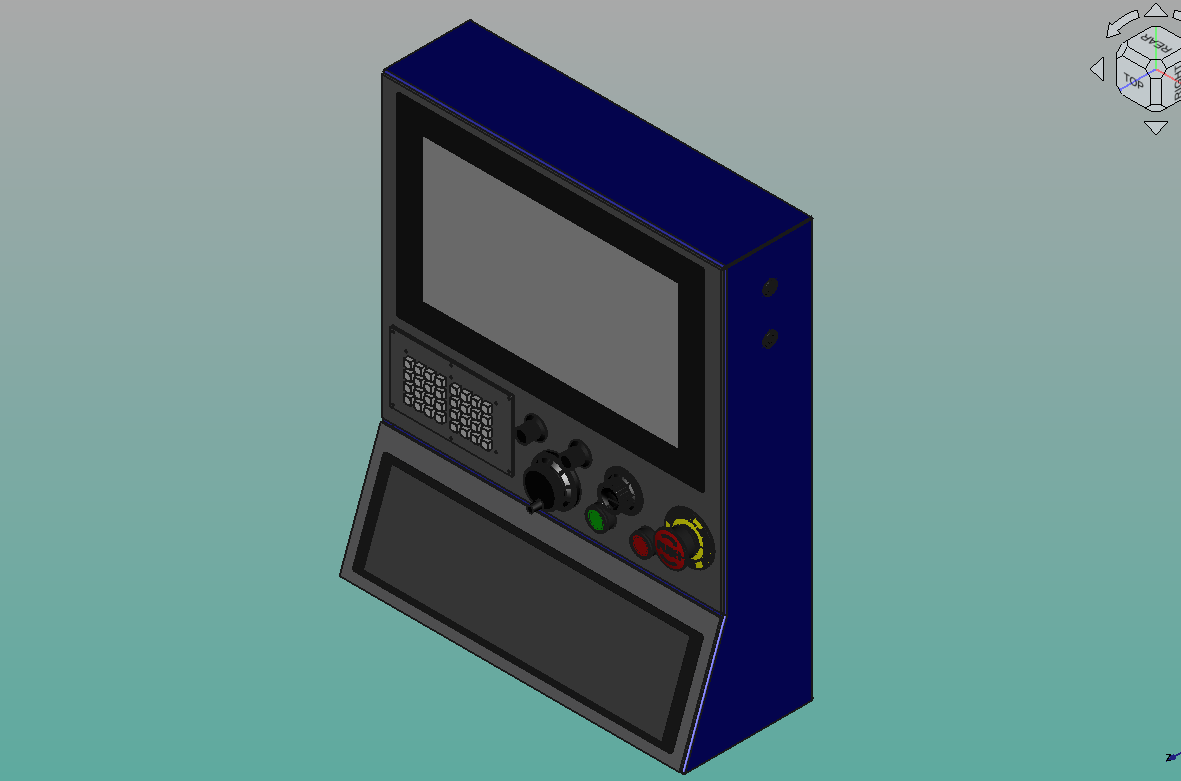

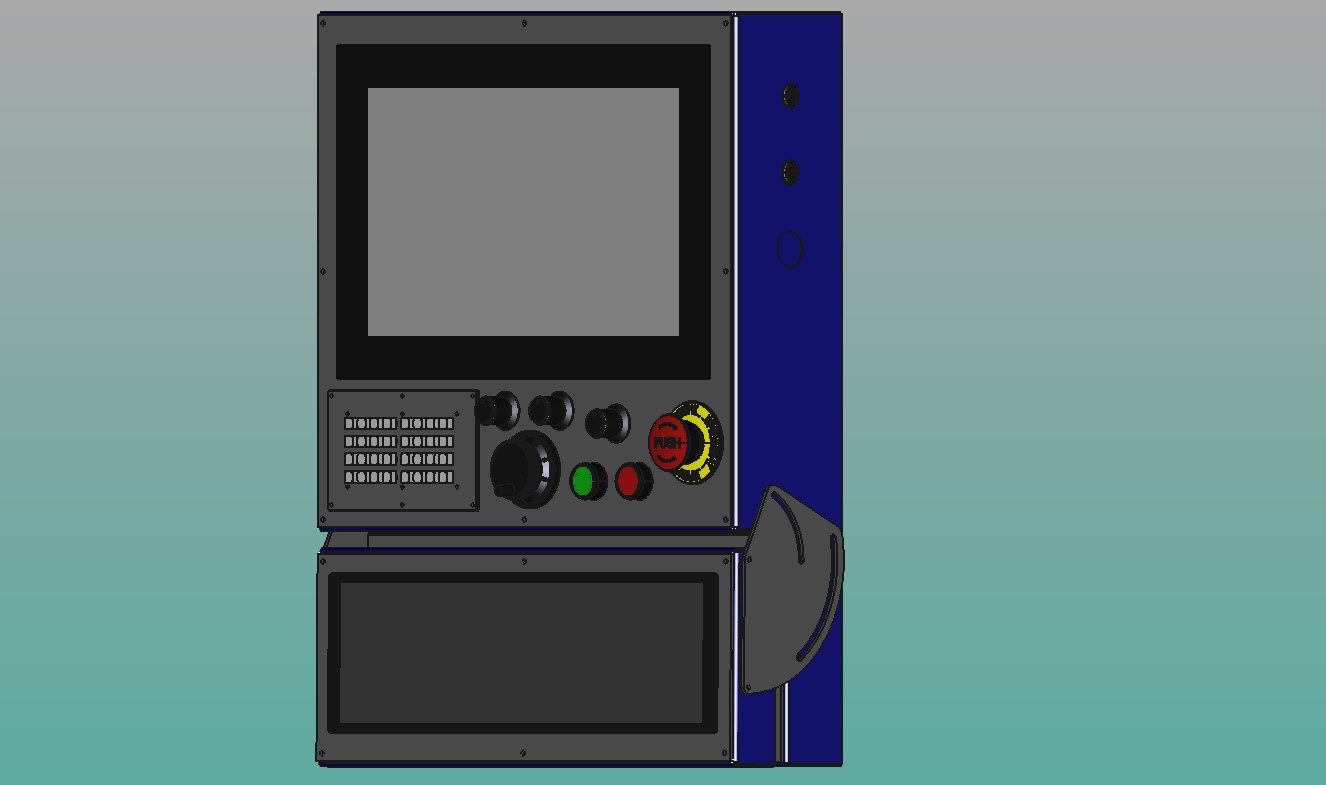

MAybe Something like this.

I have an Odroid H2+ PC inside.

Be sure you get a 1080p monitor so you can use Probe_basic or qtdragon_hd

I had to shoehorn a different monitor in because my earlier 15.6 inch screen was not 1080p. Monitoe is from greentouch and I found them very reaonably priced with hepas of options but this was the only one I could make work (with an angle grinder).

There is an estop reset button on the side of the case to keep the front clutter free.

I have an Odroid H2+ PC inside.

Be sure you get a 1080p monitor so you can use Probe_basic or qtdragon_hd

I had to shoehorn a different monitor in because my earlier 15.6 inch screen was not 1080p. Monitoe is from greentouch and I found them very reaonably priced with hepas of options but this was the only one I could make work (with an angle grinder).

There is an estop reset button on the side of the case to keep the front clutter free.

Attachments:

The following user(s) said Thank You: Mr Moo

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

05 Jan 2024 16:15 #289879

by blazini36

Replied by blazini36 on topic Control panel hardware buttons

Attachments:

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

06 Jan 2024 04:58 #289923

by rodw

Replied by rodw on topic Control panel hardware buttons

BE sure to install the r8168-dkms driver ofr the H2/H3

Also there are some settings now that let NIC's go to sleep. I cant remember what disales it, but I suspect it may be an issue with the H3

I thought about industrial keyboards but ended up using a cheap wireless keyboard you can put away somewhere until you need it.

Also there are some settings now that let NIC's go to sleep. I cant remember what disales it, but I suspect it may be an issue with the H3

I thought about industrial keyboards but ended up using a cheap wireless keyboard you can put away somewhere until you need it.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

06 Jan 2024 10:08 #289942

by blazini36

Replied by blazini36 on topic Control panel hardware buttons

Only problem Ive run into on an H3 is the bios it ships with, I didn't think to update it on one and had a bunch of latency issues until I did.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

06 Jan 2024 12:15 #289954

by RotarySMP

Replied by RotarySMP on topic Control panel hardware buttons

I prefer a keyboard closer to level, so you can rest your wrists on it when typing. Not like we will type a novel on a CNC, but you do need the key board a fair bit, especially during the config phase.

I also like buttons grouped into functional blocks.

Coolant/Off/Mist.

CW/OFF/CCW near spindle override

Stop/line feed/pause near feedoverride

Jog rate/ manual mode near jog override setting.

That is at least the logic and thought which went into my latest control.

I also like buttons grouped into functional blocks.

Coolant/Off/Mist.

CW/OFF/CCW near spindle override

Stop/line feed/pause near feedoverride

Jog rate/ manual mode near jog override setting.

That is at least the logic and thought which went into my latest control.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

06 Jan 2024 13:29 #289960

by blazini36

Replied by blazini36 on topic Control panel hardware buttons

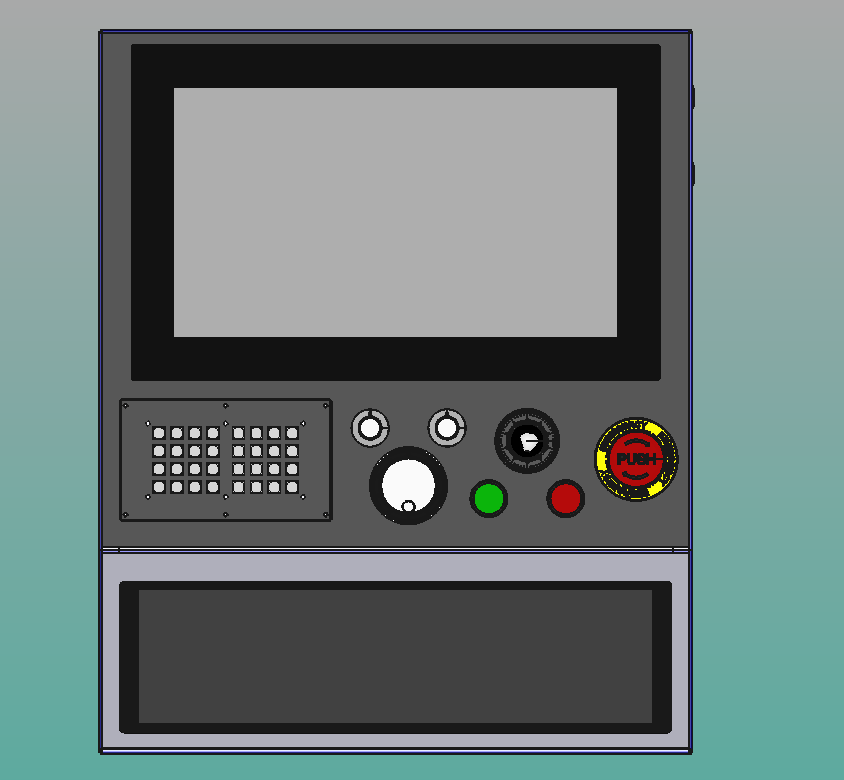

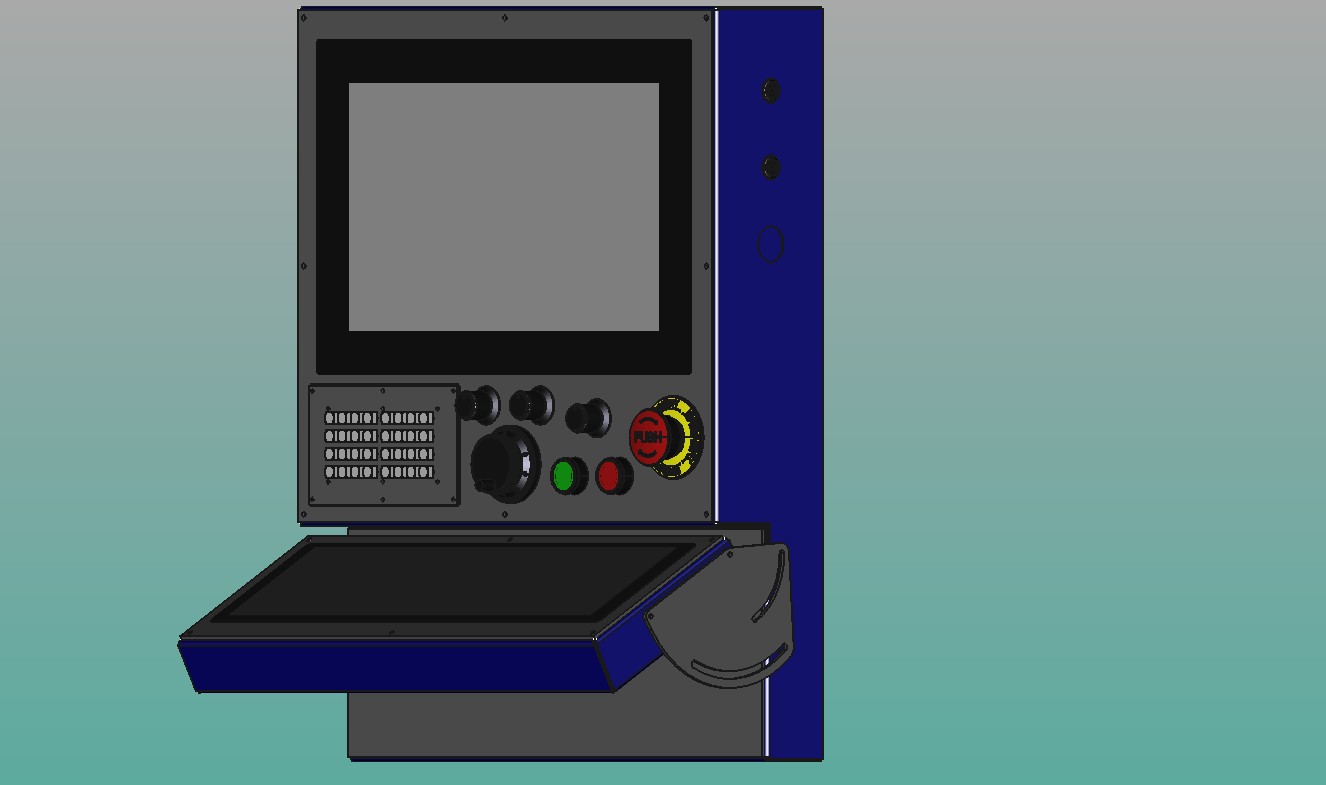

Did you settle on this as your control panels mounting position?

No offense but that looks horribly uncomfortable to use, the flatter keyboard angle makes it worse being that it's so high up.

I've used LinuxCNC on machines for years and the one thing I've never done is initial configuration at the machine itself. I write all the files ahead of time, then I either remote desktop into the machine or at the very least pull up a chair and plug in a keyboard and mouse and sit at a table near the machine. Whatever seems required but absolutely not standing at the control panel for hours especially not with a membrane keyboard. The control panel is meant for convenience while using the machine. Minor config changes and editing gcode files should not be a chore, any more than that and you're asking too much of the control panel. If you think in terms of what comes on a commercial VMC, a full keyboard (metal chicklet keys) at a 20 degree angle with a trackball is a huge convenience. Purpose built things always have concessions for convenience. I'm focused on operating convenience which means it can't be in the way and it needs to fit in reasonable places. A $150 industrial keyboard sucks to type on compared to a $20 consumer keyboard but they both have their places.

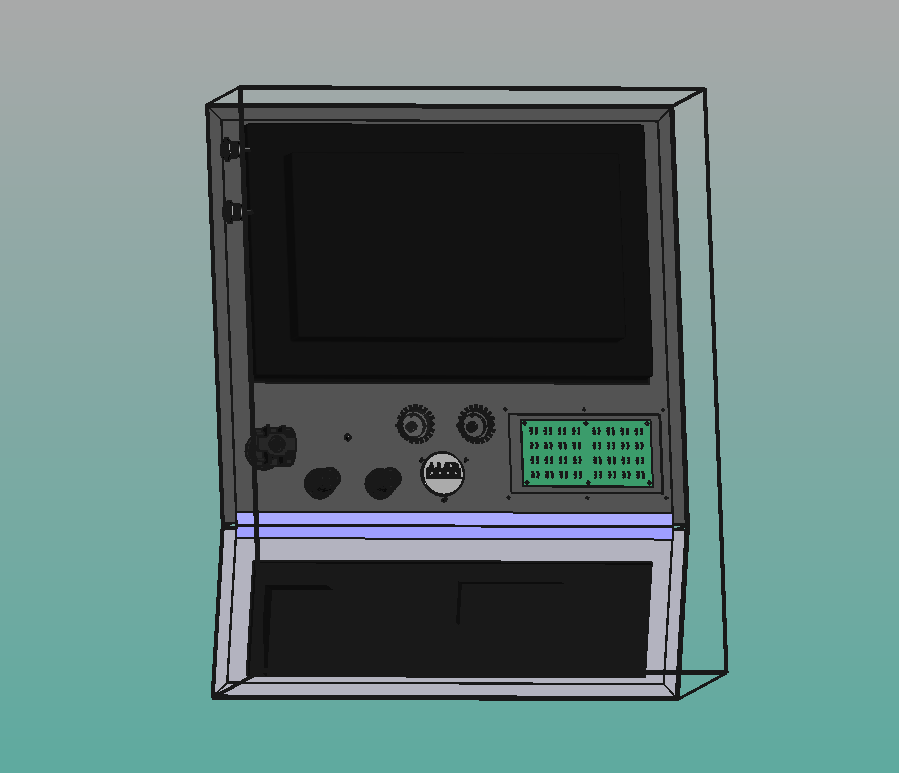

As for the function keys, you're right but your example is a control panel you built specifically for a Shaublin lathe. Meaning you already know exactly what it has and you may add in the future. If you look at my CAD setup, all of the buttons/selectors hard mounted to the panel are universal. The 2 matrix arrays on the removeable panel are a good solution for a "universal" design IMO because there's probably more buttons than necessary and they can all be labeled under removeable caps. I specifically used those buttons because they have clear outer caps and LEDs. Since that panel is removeable, it can easily be replaced with something customized or even a custom membrane like mechanix suggested. I might wind up having 3 or 4 of these things laying around and I'd like it to take minimal effort to just grab one and get it going on whatever else I decide to put it on.

No offense but that looks horribly uncomfortable to use, the flatter keyboard angle makes it worse being that it's so high up.

I've used LinuxCNC on machines for years and the one thing I've never done is initial configuration at the machine itself. I write all the files ahead of time, then I either remote desktop into the machine or at the very least pull up a chair and plug in a keyboard and mouse and sit at a table near the machine. Whatever seems required but absolutely not standing at the control panel for hours especially not with a membrane keyboard. The control panel is meant for convenience while using the machine. Minor config changes and editing gcode files should not be a chore, any more than that and you're asking too much of the control panel. If you think in terms of what comes on a commercial VMC, a full keyboard (metal chicklet keys) at a 20 degree angle with a trackball is a huge convenience. Purpose built things always have concessions for convenience. I'm focused on operating convenience which means it can't be in the way and it needs to fit in reasonable places. A $150 industrial keyboard sucks to type on compared to a $20 consumer keyboard but they both have their places.

As for the function keys, you're right but your example is a control panel you built specifically for a Shaublin lathe. Meaning you already know exactly what it has and you may add in the future. If you look at my CAD setup, all of the buttons/selectors hard mounted to the panel are universal. The 2 matrix arrays on the removeable panel are a good solution for a "universal" design IMO because there's probably more buttons than necessary and they can all be labeled under removeable caps. I specifically used those buttons because they have clear outer caps and LEDs. Since that panel is removeable, it can easily be replaced with something customized or even a custom membrane like mechanix suggested. I might wind up having 3 or 4 of these things laying around and I'd like it to take minimal effort to just grab one and get it going on whatever else I decide to put it on.

Attachments:

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

06 Jan 2024 14:14 #289965

by RotarySMP

Replied by RotarySMP on topic Control panel hardware buttons

You are right. I plug in a wireless Logitech keyboard with mouse pad during set up .

The height is not ideal, with the Schaublin blocked up off the floor to get the pallet truck under it easily, when I need to move it around for now. The a few sessions with the screen that height should cure my hunch back

Will your feed override be close to the pause button?

I also settled on the two piece transparent keycaps. Pretty handy solution.

I wonder how much take up you will have with a generic control module. My experience with hobbiest is they all sing Sinatra.

(I'll do it my way )

The height is not ideal, with the Schaublin blocked up off the floor to get the pallet truck under it easily, when I need to move it around for now. The a few sessions with the screen that height should cure my hunch back

Will your feed override be close to the pause button?

I also settled on the two piece transparent keycaps. Pretty handy solution.

I wonder how much take up you will have with a generic control module. My experience with hobbiest is they all sing Sinatra.

(I'll do it my way )

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

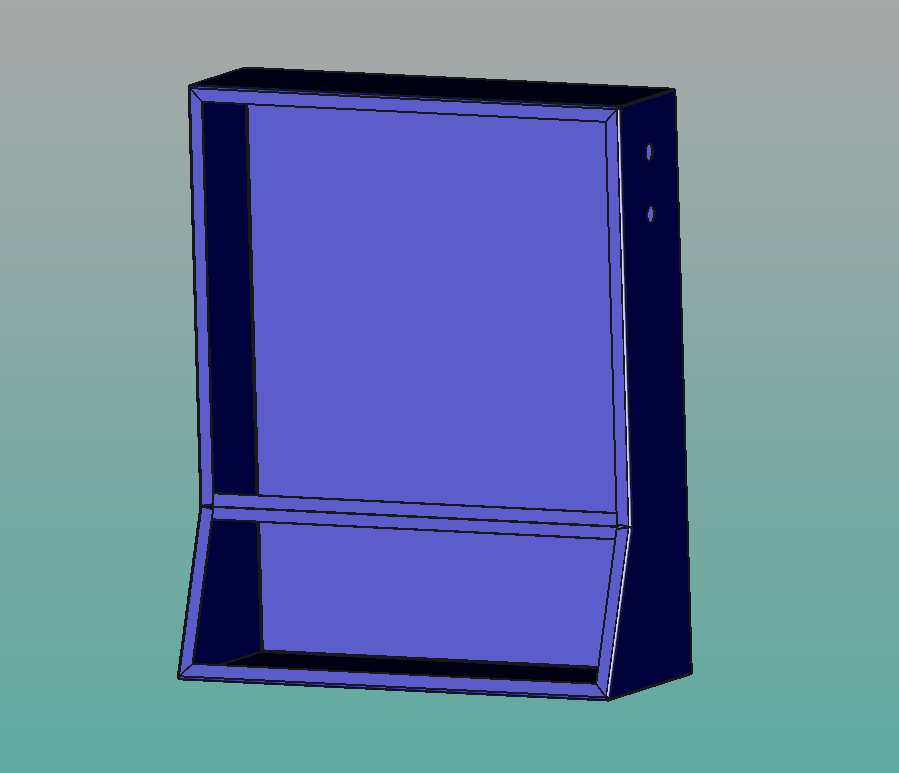

06 Jan 2024 14:45 #289972

by blazini36

As for "take up", I'm not terribly concerned but that's part of the reason I'm using Arduino based IO rather than something like a Mesa 7i73. I know somebody that does retrofits with Mach. I usually come up with stuff like this because I just wanted to buy it myself and nobody makes it. Was hoping to find something on AliExpress or something. Maybe I'm getting old but at a certain point you just don't want to DIY/one off everything and have it look like you DIY'd it.....which is why I intend to get it plasma cut and bent professionally or by someone else, I'll weld it and everything else. Like anything else, it's all in the design so while a DIY panel would generally have a ton of wires, this will have a couple of custom circuit boards and ribbon cables. Depending on what the enclosure costs me I wouldn't mind having a few of them just sitting around waiting for the next project, powdercoated and ready to go.

I posted about this in the user exchange if anyone with a CNC plasma/laser and bender wants a gig.

Replied by blazini36 on topic Control panel hardware buttons

Feed override is the encoder to the left of the Estop. Cycle start/stop are the 2 buttons under it. I'm hoping the start can also be used as pause in hal so I only need those 2 buttons but I haven't explored that yet.You are right. I plug in a wireless Logitech keyboard with mouse pad during set up .

The height is not ideal, with the Schaublin blocked up off the floor to get the pallet truck under it easily, when I need to move it around for now. The a few sessions with the screen that height should cure my hunch back

Will your feed override be close to the pause button?

I also settled on the two piece transparent keycaps. Pretty handy solution.

I wonder how much take up you will have with a generic control module. My experience with hobbiest is they all sing Sinatra.

(I'll do it my way )

As for "take up", I'm not terribly concerned but that's part of the reason I'm using Arduino based IO rather than something like a Mesa 7i73. I know somebody that does retrofits with Mach. I usually come up with stuff like this because I just wanted to buy it myself and nobody makes it. Was hoping to find something on AliExpress or something. Maybe I'm getting old but at a certain point you just don't want to DIY/one off everything and have it look like you DIY'd it.....which is why I intend to get it plasma cut and bent professionally or by someone else, I'll weld it and everything else. Like anything else, it's all in the design so while a DIY panel would generally have a ton of wires, this will have a couple of custom circuit boards and ribbon cables. Depending on what the enclosure costs me I wouldn't mind having a few of them just sitting around waiting for the next project, powdercoated and ready to go.

I posted about this in the user exchange if anyone with a CNC plasma/laser and bender wants a gig.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

07 Jan 2024 03:03 #290039

by rodw

Replied by rodw on topic Control panel hardware buttons

when I need to sit in front of mine, i just grab an office chair and a mobile trolley as a desk and move the wireless keyboard to my makeshift table.You are right. I plug in a wireless Logitech keyboard with mouse pad during set up .

The height is not ideal, with the Schaublin blocked up off the floor to get the pallet truck under it easily, when I need to move it around for now.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

16 Jan 2024 00:59 #290812

by blazini36

Replied by blazini36 on topic Control panel hardware buttons

Attachments:

The following user(s) said Thank You: Mr Moo

Please Log in or Create an account to join the conversation.

Time to create page: 0.333 seconds