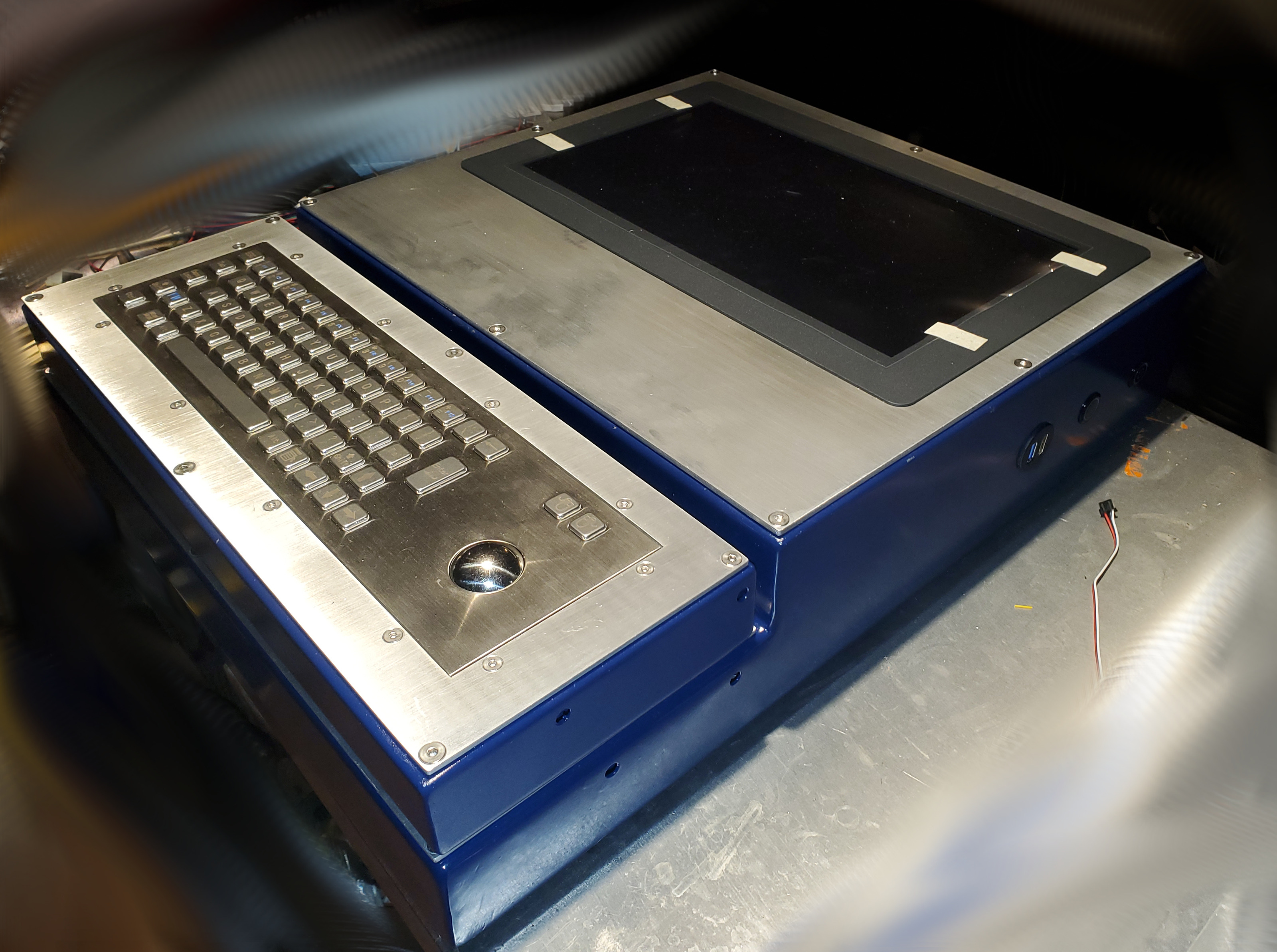

Control panel hardware buttons

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

I plan to stick a PCB in there, that's not really a good look when the keyboard is open. Even still why wouldn't I just use the rotating hinge I have now? If I wanted to do that I'd just make the overall shape more circular, like a hook to take up less space.......

Attachments:

Please Log in or Create an account to join the conversation.

- RDA

- Offline

- Premium Member

-

- Posts: 157

- Thank you received: 43

So of it can be hidden, I would do a simple hinge in the bottom and then put a couple magnets on the top to ”lock” it closed.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 808

Does the keyboard need to be visible when ”closed”? I mean I assume its quite akward to use in the closed position.

So of it can be hidden, I would do a simple hinge in the bottom and then put a couple magnets on the top to ”lock” it closed.

I'm pretty sure that was one of the primary design intents. Keyboard will be primarily used in the vertical position, and is tiltable for those infrequent longer typing sessions.

Yes, keyboards are awkward to use when they're vertical, but when operating a CNC machine you generally arent typing a bunch.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 808

What about the big gaping hole? Just wall it off and lose whatever space is behind it?

I plan to stick a PCB in there, that's not really a good look when the keyboard is open. Even still why wouldn't I just use the rotating hinge I have now? If I wanted to do that I'd just make the overall shape more circular, like a hook to take up less space.......

I didn't notice that you were planning to use the space behind the keyboard; I thought all the components were up in the 'main' section and the keyboard area was essentially dead space.

And no, it's not a great idea to have a PCB open to the elements. You'd ned to build an internal bulkhead... defeating my 'less work' argument.

As far as the hinge goes, Rotating the keyboard up (top hinges) may put it at a somewhat uncomfortable distance (i.e. too close) to the monitor. The hinges I suggested, while admittedly fiddly, drop the keyboard down a bit when open.

Have you made a cardboard yet mockup to see if you like the geometry & layout?

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

.....But you also want to be able to push some keys without having to open or adjust anything. LinuxCNC requires a bit more interaction than any commercial machine so I was originally set on the hard 20deg angle. The tilt thing got mentioned a couple of times so I warmed up to it a bit but I'm not looking to compromise on it too much. An industrial keyboard isn't a very enjoyable thing to use no matter what so I don't wanna get too far out into the weeds.

Attachments:

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 808

I seriously considered that exact model when I started my current build. If I hadn't stumbled across a handful of the iKey rubber ones at a good price I'd probably have gone your route.

I can't stand touchpads for some reason. I'd rather deal with cleaning a snotty trackball than use a trackpad...

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

I probably can fit everything in the top but having that access panel behind the keyboard makes it easier to get at the Arduino/Mesa whatever without removing the upper panel so it's a good place for it. It's not a large enclosure so it's good to be able to use all the space available.

I didn't notice that you were planning to use the space behind the keyboard; I thought all the components were up in the 'main' section and the keyboard area was essentially dead space.

And no, it's not a great idea to have a PCB open to the elements. You'd ned to build an internal bulkhead... defeating my 'less work' argument.

Looks pretty good even at full extension. Peg on the jog wheel might be a bit close to the number keys at the top of the keyboard if it's at 6 o'clock but ya can't win em all.spumco post=291111 userid=28776

As far as the hinge goes, Rotating the keyboard up (top hinges) may put it at a somewhat uncomfortable distance (i.e. too close) to the monitor. The hinges I suggested, while admittedly fiddly, drop the keyboard down a bit when open.

The layout of the upper panel might change so I'll probably just have you plasma the outline and touchscreen hole. I can run all the lower cutouts on my CNC mill. It's not for ergonomics, as long as I can push the buttons I'm happy. It's more for things you can't really replicate with a piece of cardboard......spumco post=291111 userid=28776

Have you made a cardboard yet mockup to see if you like the geometry & layout?

If you look at the Haas controller, it's mounted on the left and can pivot towards the opening of the machines enclosure. That's how I use the touchscreen on my mill now. I don't like messing with pendants so I just swing the touchscreen towards the opening. If you have to smack the Estop the way I have it, you'll wind up pushing the control out of the way. Makes a bit more sense to move that stuff to the left for that type of mounting, it's easier to reach anyway.

So yeah, I might just mill the control portion of the lower panel "on demand" so I can change it as necessary and only deal with upper panels. There's nothing else I really can or want to change, I'm happy with the package as a whole.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

I actually changed to that keyboard at the last minute. That one is an undermount the original was a top mount. Besides being $30 cheaper, after I modeled it it wound up fitting in the exact same size cutout. You actually just reminded me I forgot to put the screw holes in the mounting panel lol.Nice keyboard. Makes more sense now why you need a frame of some sort to mount that keyboard in.

I seriously considered that exact model when I started my current build. If I hadn't stumbled across a handful of the iKey rubber ones at a good price I'd probably have gone your route.

I can't stand touchpads for some reason. I'd rather deal with cleaning a snotty trackball than use a trackpad...

I don't think the trackball will be a problem. I used to work with machines that had an operator "kiosk", it used a trackball. Not sure if you've ever been in a factory environment but operators have all sorts of Cheeto and Dorito dust on their hands when they touch anything. Never once had to open up the trackball in like 5 years.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

- Posts: 1974

- Thank you received: 808

Not sure if you've ever been in a factory environment but operators have all sorts of Cheeto and Dorito dust on their hands when they touch anything.

My professional universe could be summed up as "Industrial filth & destruction." We'll swap war stories when you get here.

BTW, we're GTG. I'll send my number this evening and we can sort out details over the phone.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

Attachments:

Please Log in or Create an account to join the conversation.