THC problem

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

30 May 2024 21:53 - 30 May 2024 21:54 #301893

by acourtjester

THC problem was created by acourtjester

Attachments:

Last edit: 30 May 2024 21:54 by acourtjester.

Please Log in or Create an account to join the conversation.

- jimmyrig

- Offline

- Premium Member

-

Less

More

- Posts: 135

- Thank you received: 42

30 May 2024 22:11 - 30 May 2024 22:32 #301894

by jimmyrig

Replied by jimmyrig on topic THC problem

I assume you mean qtplasmac?

Go to parameters and increase your (can't remember exact term) void anti dive. This should help but if not try decreasing (or increasing) your p term in your pid.

My guess is it's a pid issue (or you are cutting too slow)

Takes a bit to get it tuned perfect but when it is.....it's sweet. I can cut for hours on a 8x4ft sheet and never touch the torch to the table

Go to parameters and increase your (can't remember exact term) void anti dive. This should help but if not try decreasing (or increasing) your p term in your pid.

My guess is it's a pid issue (or you are cutting too slow)

Takes a bit to get it tuned perfect but when it is.....it's sweet. I can cut for hours on a 8x4ft sheet and never touch the torch to the table

Last edit: 30 May 2024 22:32 by jimmyrig.

The following user(s) said Thank You: acourtjester

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

30 May 2024 23:43 #301899

by tommylight

Replied by tommylight on topic THC problem

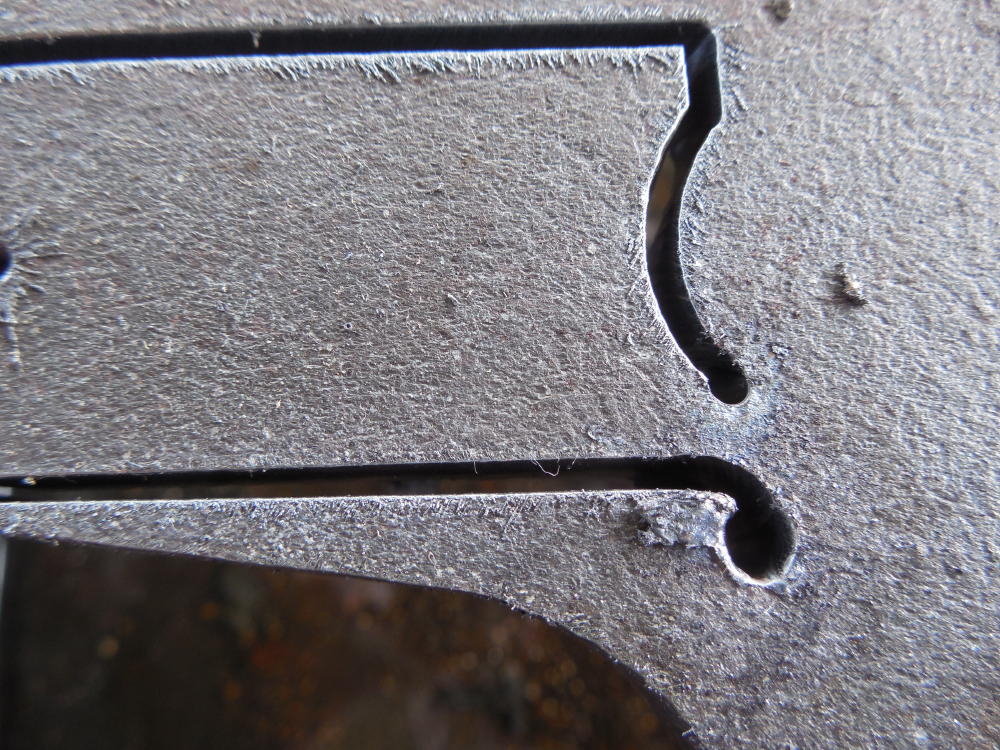

Are those cuts supposed to end like that?

I do not think so, so :

-check the THCAD division jumper is seated properly and does not move

-try to catch the screen when that happens, does the voltage rise a lot?

-tighten the screw terminals on both sides of THCAD cable, just in case

-check the high voltage cables from plasma to THCAD

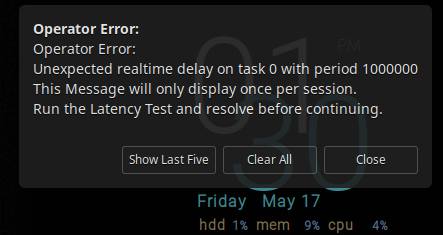

And, do you get latency warnings when running LinuxCNC?

I do not think so, so :

-check the THCAD division jumper is seated properly and does not move

-try to catch the screen when that happens, does the voltage rise a lot?

-tighten the screw terminals on both sides of THCAD cable, just in case

-check the high voltage cables from plasma to THCAD

And, do you get latency warnings when running LinuxCNC?

The following user(s) said Thank You: acourtjester

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

31 May 2024 19:49 - 31 May 2024 19:53 #301992

by acourtjester

Replied by acourtjester on topic THC problem

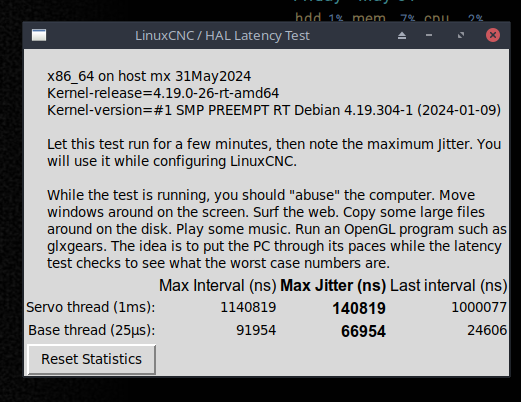

Here is what I have done, changed the speed PID from 10 to 5, PID-I form 0 to 3 and PID-D from 0 to 3. No real change it cuts some part and fails on others. Jumper on the board is on 32 and unipolar.

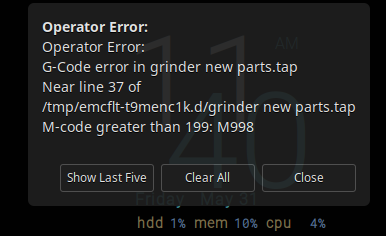

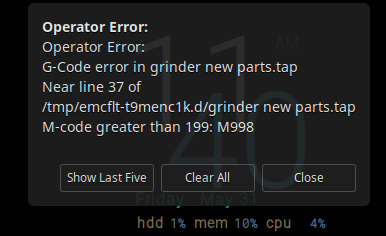

Tried to use a Cut Rule in SheetCam to drop the THC about 0.250" before end but QTPlasmaC did not like the G-code see attached. I do get a latency error but not when doing any operations, I get it when editing the G-code in QTPlasmaC randomly. Attached a screenshot of running the Latency check test. the voltage does not seem to bounce around that much, the Z axis seems to move maybe0.030" up and down until it crashes.

Tried to use a Cut Rule in SheetCam to drop the THC about 0.250" before end but QTPlasmaC did not like the G-code see attached. I do get a latency error but not when doing any operations, I get it when editing the G-code in QTPlasmaC randomly. Attached a screenshot of running the Latency check test. the voltage does not seem to bounce around that much, the Z axis seems to move maybe0.030" up and down until it crashes.

Attachments:

Last edit: 31 May 2024 19:53 by acourtjester. Reason: added info

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

31 May 2024 20:08 #301998

by PCW

Replied by PCW on topic THC problem

A dive towards the work would indicate that the voltage was read as high

It it possible that you have lost the arc and it is not signaled to LinuxCNC?

A halscope plot of the voltage, arc-ok, and velocity when you have the issue would help a lot

It it possible that you have lost the arc and it is not signaled to LinuxCNC?

A halscope plot of the voltage, arc-ok, and velocity when you have the issue would help a lot

The following user(s) said Thank You: acourtjester

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

31 May 2024 20:15 #302000

by acourtjester

Replied by acourtjester on topic THC problem

I will see what I can do. Not a real expert on LinuxCNC

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

01 Jun 2024 00:24 #302022

by phillc54

This is telling you that in line 37 of the G-code (or nearby) there is a M998 command but LinuxCNC will only accept M codes up to M199.

Replied by phillc54 on topic THC problem

Tried to use a Cut Rule in SheetCam to drop the THC about 0.250" before end but QTPlasmaC did not like the G-code see attached.

This is telling you that in line 37 of the G-code (or nearby) there is a M998 command but LinuxCNC will only accept M codes up to M199.

Attachments:

The following user(s) said Thank You: acourtjester

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

01 Jun 2024 01:52 #302025

by acourtjester

Replied by acourtjester on topic THC problem

I sent an email to Les at SheetCam about that. He has modified the PlasmaC post processor so I could use a delay (M01 code snippet) in it. So I hope he will modify it again for the Cut Rule that LinuxCNC will work with. Not sure if that will help with the problem I am having, but it was suggested by a member at Plasma Spider.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

01 Jun 2024 02:00 #302028

by phillc54

linuxcnc.org/docs/devel/html/gcode/m-code.html#mcode:m0-m1

Replied by phillc54 on topic THC problem

M01 would be a pause.I sent an email to Les at SheetCam about that. He has modified the PlasmaC post processor so I could use a delay (M01 code snippet) in it.

linuxcnc.org/docs/devel/html/gcode/m-code.html#mcode:m0-m1

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

01 Jun 2024 02:07 - 01 Jun 2024 02:09 #302029

by acourtjester

Replied by acourtjester on topic THC problem

Yes I know that I was using it between a center punch routine and normal cutting so I could change the amps on the plasma unit. I have since found it is not needed as with the tool I use in SheetCam it fires the torch so short it just makes a dimple in the surface. It is much easier to locate the drill hole in the DXF file then measuring after the part is cut.

Attachments:

Last edit: 01 Jun 2024 02:09 by acourtjester.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Time to create page: 0.213 seconds