Configuration 7i92m_7i76x1D

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

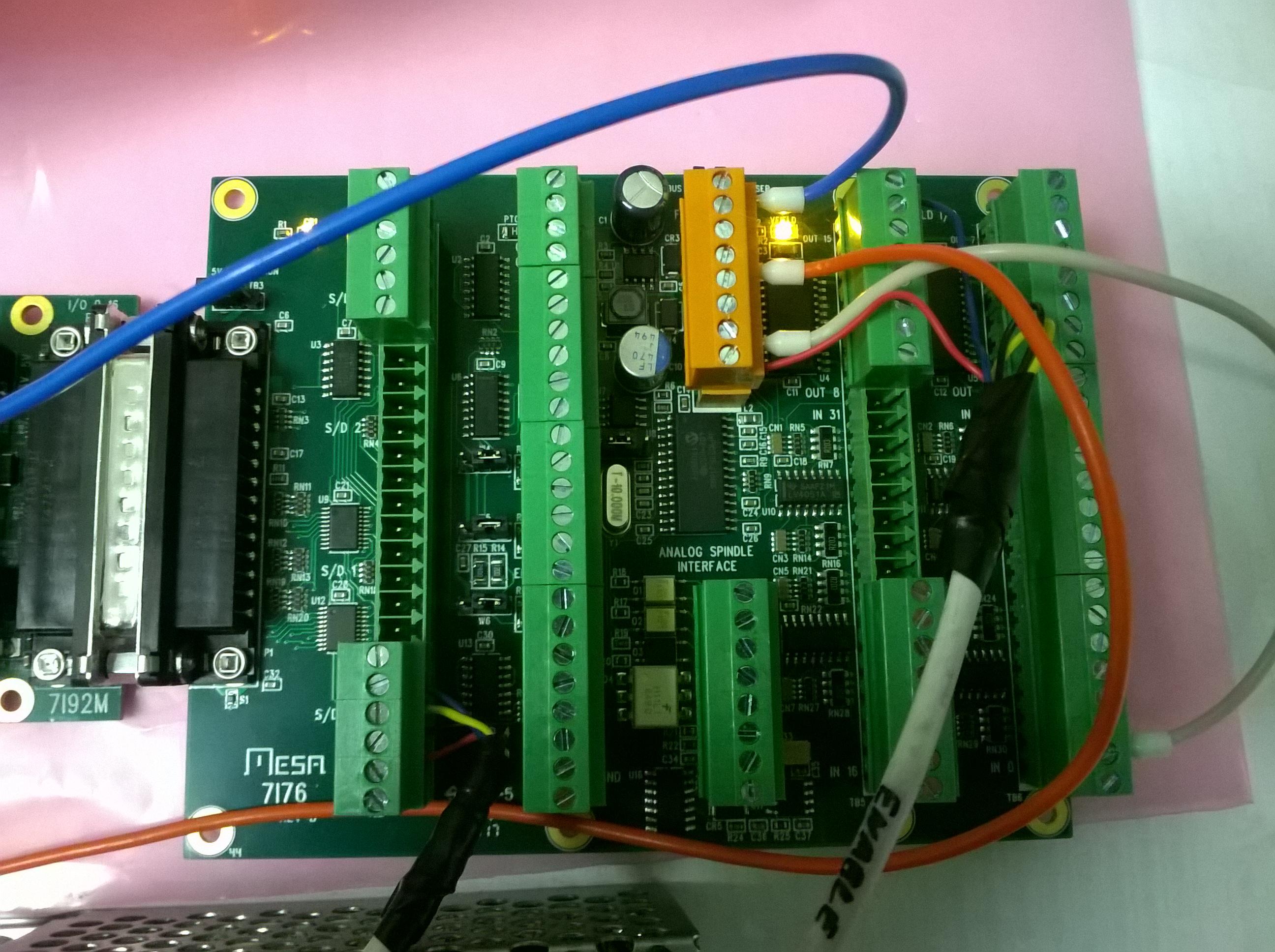

I've finaly got MESA 7i92M and 7i76 boards. It's my first experiance of configuring MESA.

I used to configure 5i25 configuration. And leave all at default settings to see what I really need in the future.

1. I loaded Mesaflash data to EEPROM of board.

2. Cnanged hm2_pci to hm2_eth

3. Changed 5i25 to 7i92.

Try to run linuxcnc but it terminates with error. What is wrong and why it's heppening? Simple stepconf configuration easyly runs but not that.

I attach config file and errors. Please help me to run my cnc.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19797

- Thank you received: 4607

./MachineCNC.hal:8: Can't find module 'hm2_eth' in /usr/realtime-3.4-9-rtai-686-pae/modules/linuxcnc

Seems to indicate that you are usint RTAI (I would assume a default ISO install).

Make a copy of your config files somewhere safe (off the PC) and then install the PREEMPT-RT version of LinuxCNC mentioned here: forum.linuxcnc.org/38-general-linuxcnc-q...69-7i76e-quick-setup

(This is instructions for the 7i76E, but there is some commonality)

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

To use the Ethernet Mesa cards you can not use the RTAI kernel.

./MachineCNC.hal:8: Can't find module 'hm2_eth' in /usr/realtime-3.4-9-rtai-686-pae/modules/linuxcnc

Seems to indicate that you are usint RTAI (I would assume a default ISO install).

Make a copy of your config files somewhere safe (off the PC) and then install the PREEMPT-RT version of LinuxCNC mentioned here: forum.linuxcnc.org/38-general-linuxcnc-q...69-7i76e-quick-setup

(This is instructions for the 7i76E, but there is some commonality)

Thanks for that AndyPugh. I run linuxcnc now.

Now I get new configuration errors. As I said, I use default configurations and changed them a little unconsciously.

I have two errors:

1) joint # following error. May be my configuration need to have encoder inputs as feedback. But I don't have encoder inputs. I need to cotrol servos with sted/dir signals only and PID regulation live to servodrive.

2) hm2/hm2_7i92.0: stepgen.00.maxvel is too big for current step & position-scale, clipping to max possible - it's for X axis. How to define this maxvel parameter for ethernet? As I worked with stepconf withard it was very simple - there was only latencytest.

My servodrive has 10000 impulses per/rev but I can change it to 1000 for example.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17698

- Thank you received: 5175

1. The following errors are due to some pncconf bugs with metric configurations.

To fix, delete these lines in the hal file:

setp pid.x.maxerror .0005

setp pid.y.maxerror .0005

setp pid.z.maxerror .0005

Then in the INI file, X axis section, change:

P = 50.0

to

P = 1000

The reason you get the maxvel error is that you have specified a X velocity of 3000 mm/second (!)

but you cannot reach that velocity with your 10000 ns steplength 10000 ns stepspace timings.

In fact, with your 10000/10000 timings, and a scale of 10000 steps per mm you can only reach 5 mm/second.

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

But I have another problems now))) Axes are not moving. I wonder, how to know if output board generates pulses at connected outputs if I don't have osciloscope? It could be problem with servodrive, but it's hard possible - they are was in work and everything was fine.

My servo drive (Maxsine EP1C) has monitoring parameter tat defines number of input pulses ( it's instead of osciloscope) but there is 0 and nothing change. Feed voltage is 5V.

It can't be low step/dir timing because step time is 1400ns in datasheet.

May be my outputs are not connected to needed inputs in hal.

As for "Enable input" - the driver see it fine.

My jumpers are in such positions:

7i92: w1 - up, w3: down , w4: up

7i76: w1 -left, w2 - left, w3 - left, w4-w6 - right.

Does somebody know what it should be?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17698

- Thank you received: 5175

to see the LED light up (the dir pin is easy to check with a LED though)

Note that a LED across the step pins will light up brightly in one direction (use the other direction)

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

I used them and saw that that pulses are present, but my servomotor doesn't see them.(((

I used steplen even 10000ns and stepspace 20000 but it's still blind.

I suspect that something bedwith that port on servomotor. May be I mixed up Step+ and step- in the past and broke some input.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17698

- Thank you received: 5175

( many servo drives have a couple choices of motion command input )

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

Today I tried to connect enother servomotor. And got the same situation - encoder doesn't see step/dir signals. But must see, because this one is surely workable.

Mesa has some suspision habit. There is Step+ and step- singnals -. When there is no ethernet connection with linuxcnc, then voltage on this pins is 5V. But when I run linuxcnc, after initiating connection voltage inverts and at step+ pin there is 0V and at step- pin there is 5V - vise versa.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17698

- Thank you received: 5175

Mesa has some suspision habit. There is Step+ and step- singnals -. When there is no ethernet connection with linuxcnc, then voltage on this pins is 5V. But when I run linuxcnc, after initiating connection voltage inverts and at step+ pin there is 0V and at step- pin there is 5V - vise versa.

This is normal and happens because the idle state of the FPGA pins is high. so before startup and after shutdown (or watchdog bite)

the pins at the FPGA will be at a high state so the + pin will idle high and go low when LinuxCNC starts. This should have no effect on your drives but you can change this behaviour if desired by inverting the step outputs in the hal file.

If your drives do not respond to a step input, it suggests a setup or wiring error of some kind

Please Log in or Create an account to join the conversation.