THC config that works.

- beauxnez

- Offline

- Premium Member

-

Less

More

- Posts: 149

- Thank you received: 10

08 May 2017 08:57 #92808

by beauxnez

Replied by beauxnez on topic THC config that works.

With my plasma, I have to initiate in contact with the tole and then to rise of about 2mm.

With this config I have to modify something in the gcode or in this config?

With this config I have to modify something in the gcode or in this config?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21235

- Thank you received: 7249

08 May 2017 23:52 #92886

by tommylight

Replied by tommylight on topic THC config that works.

Please Log in or Create an account to join the conversation.

- kpj10

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 1

05 Jul 2017 19:21 #95411

by kpj10

Replied by kpj10 on topic THC config that works.

Dear Tom,

This may be quite out of context of the topic, hope you will help. In your configuration, you suggested that user can start from where the machine stopped maybe due to a power failure. I'm using LinuxCNC for driving a wireEDM and I want to equip my system with that same feature. As I'm Indian here in India we do have power cuts without being notified, also wireEDM'ing is a bit slow process often we need to halt the job work for any of reason so this will save our time a lot. Can you mention how can I do so to achieve same in my system?

Thank You.

Kunal.

This may be quite out of context of the topic, hope you will help. In your configuration, you suggested that user can start from where the machine stopped maybe due to a power failure. I'm using LinuxCNC for driving a wireEDM and I want to equip my system with that same feature. As I'm Indian here in India we do have power cuts without being notified, also wireEDM'ing is a bit slow process often we need to halt the job work for any of reason so this will save our time a lot. Can you mention how can I do so to achieve same in my system?

Thank You.

Kunal.

Please Log in or Create an account to join the conversation.

- jeroenl

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

07 Jul 2017 10:11 #95469

by jeroenl

Replied by jeroenl on topic THC config that works.

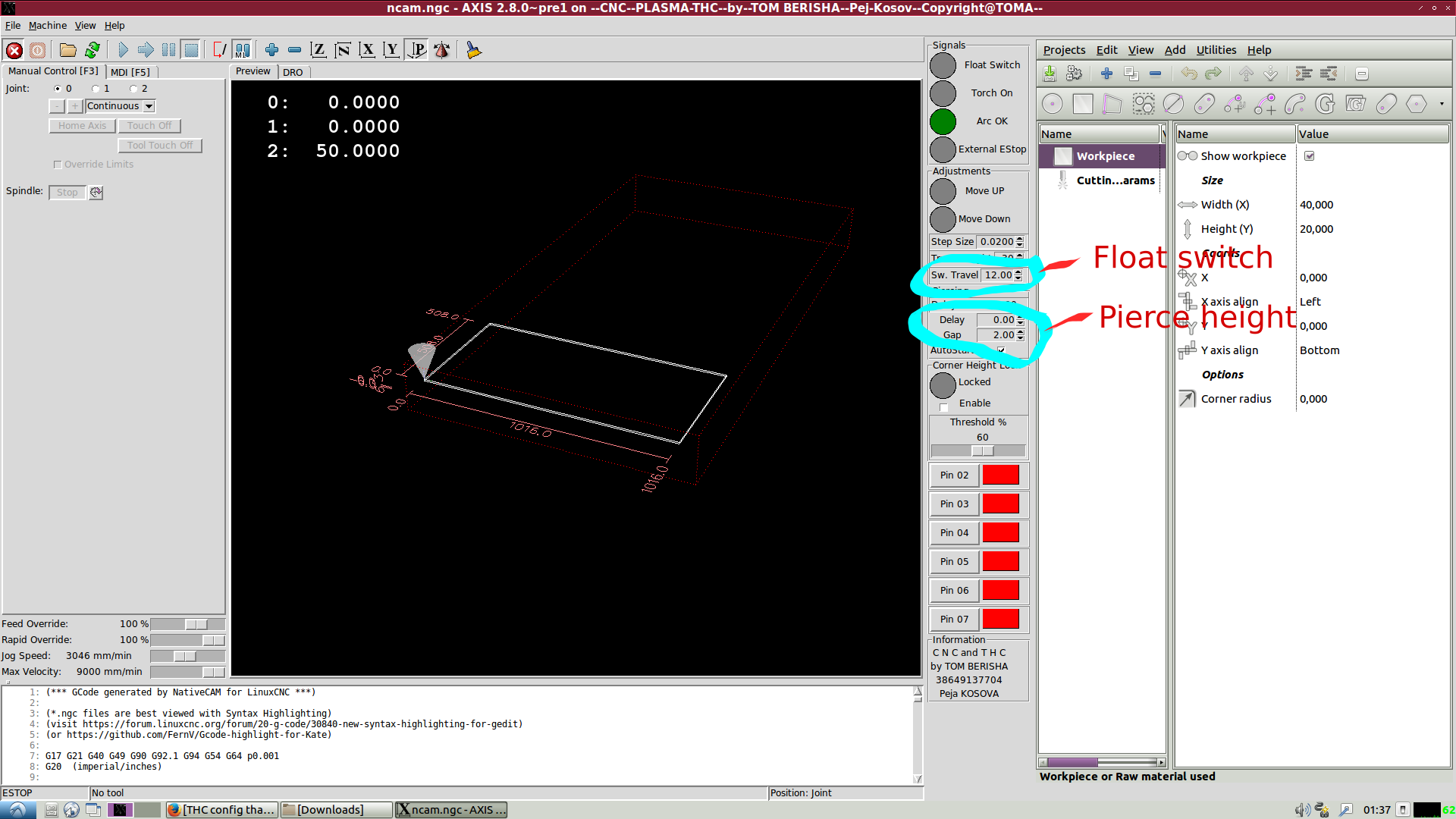

Hi Tommy, what is that interface thing on the right? Looks like something i need

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21235

- Thank you received: 7249

08 Jul 2017 07:31 #95495

by tommylight

You need to create an empty file with the name last_position.txt and add an entry to the ini file pointing to that file. That is it. It is mentioned in this thread so just have a look.

Replied by tommylight on topic THC config that works.

Dear Tom,

This may be quite out of context of the topic, hope you will help. In your configuration, you suggested that user can start from where the machine stopped maybe due to a power failure. I'm using LinuxCNC for driving a wireEDM and I want to equip my system with that same feature. As I'm Indian here in India we do have power cuts without being notified, also wireEDM'ing is a bit slow process often we need to halt the job work for any of reason so this will save our time a lot. Can you mention how can I do so to achieve same in my system?

Thank You.

Kunal.

You need to create an empty file with the name last_position.txt and add an entry to the ini file pointing to that file. That is it. It is mentioned in this thread so just have a look.

The following user(s) said Thank You: kpj10

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21235

- Thank you received: 7249

08 Jul 2017 07:33 #95496

by tommylight

That is NativeCam or NCam for plasma. It is very usefull for a lot of work done on plasma machines as you can instantly make a part, see it on screen and just run it to make that part. There are 2 threads about it on this forum.

Replied by tommylight on topic THC config that works.

Hi Tommy, what is that interface thing on the right? Looks like something i need

That is NativeCam or NCam for plasma. It is very usefull for a lot of work done on plasma machines as you can instantly make a part, see it on screen and just run it to make that part. There are 2 threads about it on this forum.

The following user(s) said Thank You: jeroenl

Please Log in or Create an account to join the conversation.

- kpj10

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 1

08 Jul 2017 18:47 #95510

by kpj10

Replied by kpj10 on topic THC config that works.

Dear Tom,

Correct me if I'm wrong.

Let's say there are ten lines of G code required to be interpreted for completing my cutting task, but a shutdown occurred when the Linuxcnc was at line 5.

So, after power resumes, I restart the machine take the data from "last_postion.txt" file, recreate the G-code again using a cam program, and again start the cut?

Or in your configuration, the g-code interpreter starts from line 5 position itself.

Regards,

Kunal

Correct me if I'm wrong.

Let's say there are ten lines of G code required to be interpreted for completing my cutting task, but a shutdown occurred when the Linuxcnc was at line 5.

So, after power resumes, I restart the machine take the data from "last_postion.txt" file, recreate the G-code again using a cam program, and again start the cut?

Or in your configuration, the g-code interpreter starts from line 5 position itself.

Regards,

Kunal

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21235

- Thank you received: 7249

10 Jul 2017 11:04 #95586

by tommylight

Replied by tommylight on topic THC config that works.

After power loss turn on the machine, note where it has stoped, jog to X0 Y0, home, select the line it was stoped at, rigt click on that line and choose "run from here".

Side note: "run from here" will not work on arcs so scroll up to a line with no arcs ( no I and/or J values ).

Side note: "run from here" will not work on arcs so scroll up to a line with no arcs ( no I and/or J values ).

Please Log in or Create an account to join the conversation.

- ebartel

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

15 Jul 2017 15:44 #95819

by ebartel

Replied by ebartel on topic THC config that works.

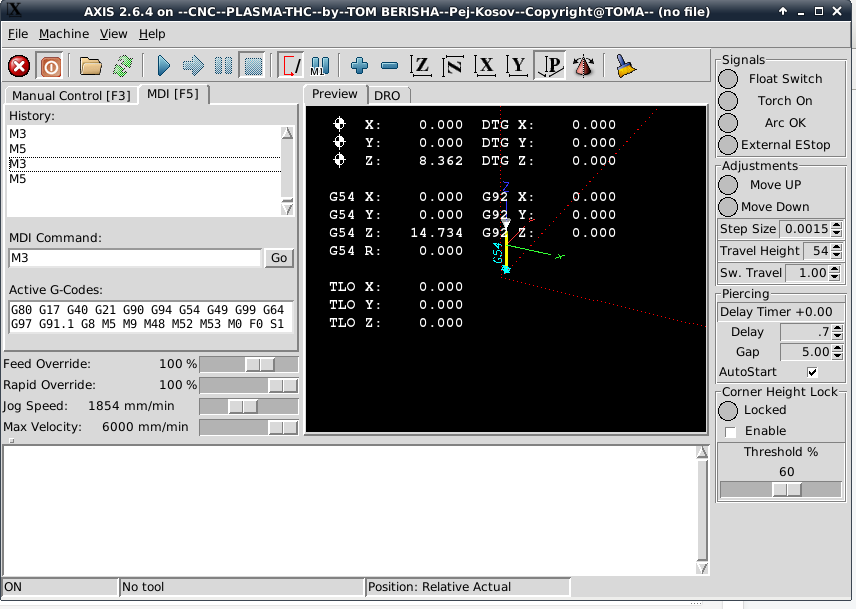

I've just finished my float switch setup and I'm trying to get the initial pierce sequence to work. My switch has 1mm of travel before activate (ie blue float switch indicator comes on). I'm cutting 3/8 mild steel so I've set the initial cut to 5mm and a delay of .7 sec. The z axis will go down, touch off, go to ~8.3 mm, and fire. This is of course to high so it just repeats.

Is there another setting I'm missing? Why does it go to 8.3mm instead of 5mm? Do I have to set something with the touch off button?

I'm a little confused as well on what the sequence is to initiall home the z axis. It seems if it is not high enough it will go down and hit the limit switch which cause a joint 2 error.

Thanks for advance for any help you can provide.

Is there another setting I'm missing? Why does it go to 8.3mm instead of 5mm? Do I have to set something with the touch off button?

I'm a little confused as well on what the sequence is to initiall home the z axis. It seems if it is not high enough it will go down and hit the limit switch which cause a joint 2 error.

Thanks for advance for any help you can provide.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21235

- Thank you received: 7249

21 Jul 2017 06:02 #96208

by tommylight

Replied by tommylight on topic THC config that works.

In the screenshot you have active offsets, so cancel them. Also make sure you have the correct scale for Z axis as that will mess up the height.

Please Log in or Create an account to join the conversation.

Time to create page: 0.211 seconds