servo dac offset

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 113

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

- Posts: 17464

- Thank you received: 5101

DRIVE-ENA --> 7I77-ENA+

DRIVE-GND --> 7I77-ENA-

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 113

Obviusly You are in right.

regards

Giorgio

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 113

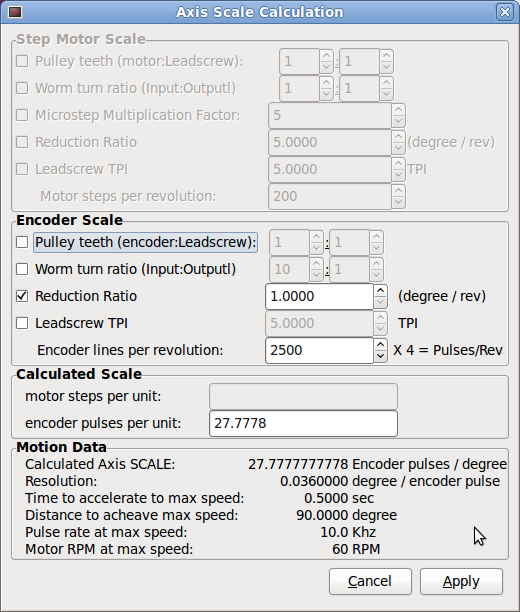

and result ini file (NOTE OLY AXIS 3=a IS CONFIGURATED... I'M IN TRIAL TEST)

At 10V reference motor make 60rpm as described in pnconfig ..... but when start axis and try to move (in jog) A axis I receive follow error axis ..... someone has suggest??

Regards

Giorgio

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

- Posts: 17464

- Thank you received: 5101

with a .05 degree following error limit you cannot tell if the system runs away (backwards feedback)

or you just dont have tuning good enough

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 113

Openloop test in pncconf the only thing it does is send out the analog signal set .... I guess it's true ?

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

- Posts: 17464

- Thank you received: 5101

Do you get any motion with LinuxCNC?

Are the drives enabled when Linuxcnc is running? (out of ESTOP and in machine-on state)

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 113

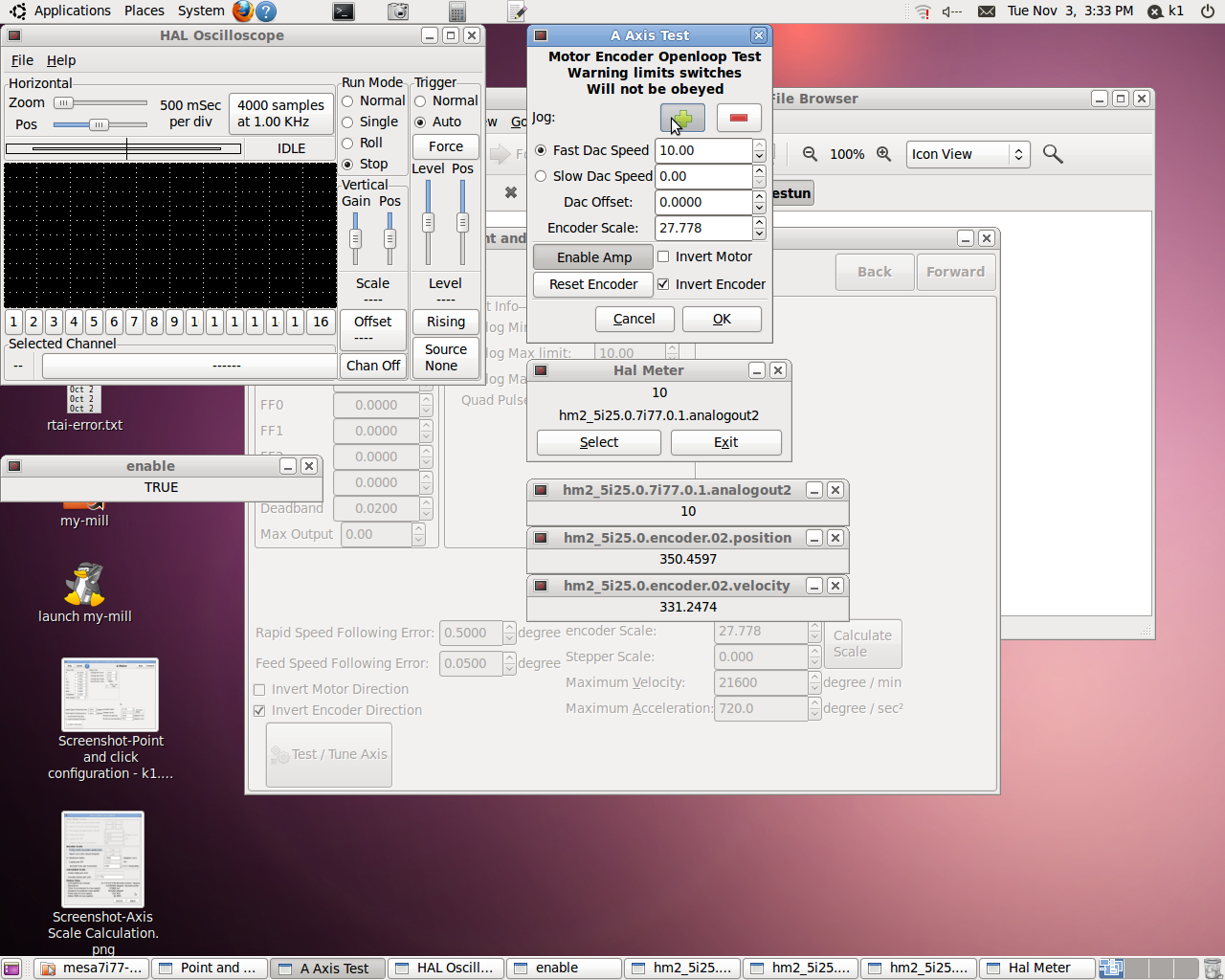

hm2_encoder.02.velocity It must correspond to the motor speed ? Because in these case when motor at 10V go to 50rpm these param hm2_encoder.02.velocity go to 299/300 .... is normal these?

Regards

Giorgio

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

- Posts: 17464

- Thank you received: 5101

Yes, when run drive go enable .... and with a wrong config the follow error come out after a little step of motor ....

This is why you need to set the following errors wider so you can see whats going on

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 113

hm2_encoder.02.velocity It must correspond to the motor speed ? Because in these case when motor at 10V go to 50rpm these param hm2_encoder.02.velocity go to 299/300 .... is normal these?

Yes is normal ...... from www.linuxcnc.org/docs/html/man/man9/hostmot2.9.html ...... " (float out) velocity Estimated encoder velocity in position units per second." ...... 50rpm = 0.83333 spsec = 300°/sec (degree is my unity) .....

Please Log in or Create an account to join the conversation.