servo dac offset

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17406

- Thank you received: 5070

05 Nov 2015 03:58 - 05 Nov 2015 04:00 #64768

by PCW

Replied by PCW on topic servo dac offset

Its called PWM in pncconf but that's just a leftover from previous hardware setups

Its not important

What is important:

Drives are set to velocity mode

Drives have any input filtering turned off

FF1 is tuned first (with low P term so the effect of FF1 changes are obvious)

( as mentioned before, if the analog output scaling is set right, FF1 will be 1.0)

P is tuned next

Finally FF2 is tuned to reduce errors during acceleration

The hal/ini files are good to look at in case there's some obvious parameter setting issue

Its not important

What is important:

Drives are set to velocity mode

Drives have any input filtering turned off

FF1 is tuned first (with low P term so the effect of FF1 changes are obvious)

( as mentioned before, if the analog output scaling is set right, FF1 will be 1.0)

P is tuned next

Finally FF2 is tuned to reduce errors during acceleration

The hal/ini files are good to look at in case there's some obvious parameter setting issue

Last edit: 05 Nov 2015 04:00 by PCW.

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1110

- Thank you received: 113

05 Nov 2015 04:11 #64772

by bkt

Replied by bkt on topic servo dac offset

mmmm .... my start tuning is modify P ..... tomorrow try to a little P an modify FF1 first .... and control all filter input on drive ... but I think is set to 0.

Regards

giorgio

Regards

giorgio

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1110

- Thank you received: 113

05 Nov 2015 19:40 - 05 Nov 2015 22:10 #64815

by bkt

Replied by bkt on topic servo dac offset

some filter in drive are active ... and I disable it ...ok.

I put P at 5 first and increase FF1 ..... At the end of operation P in Lcnc and in drive are equal ... FF1 in drive is at 1/4 of scale value but in Lcnc are much highter .. see below

in hal file all seems ok ...

But the result are not very good .... my gcode test put the axis to 90° make a pause of 0.1sec and put axis to -90° ... for 10 time ... after go to 50° and stop (all with G61).... the motor and reducer (at the motor I applied a reducer ratio 1/10) correctly turn on and turn of from 180° (I apply a hand to control the crowds results ... I can see 180° but not see the exact start and end point ... ) but in axis never see an exat stop to 90° or -90° bu for example 20 to -160 ... or 30 to -150 with random value .... the acceleration is hight .... but at the and When go to 50° the acceleration is 50% and in axis I see an stop at 70° and in 3 sec the end of program the value turn on 50°. During this positioning the program stop.

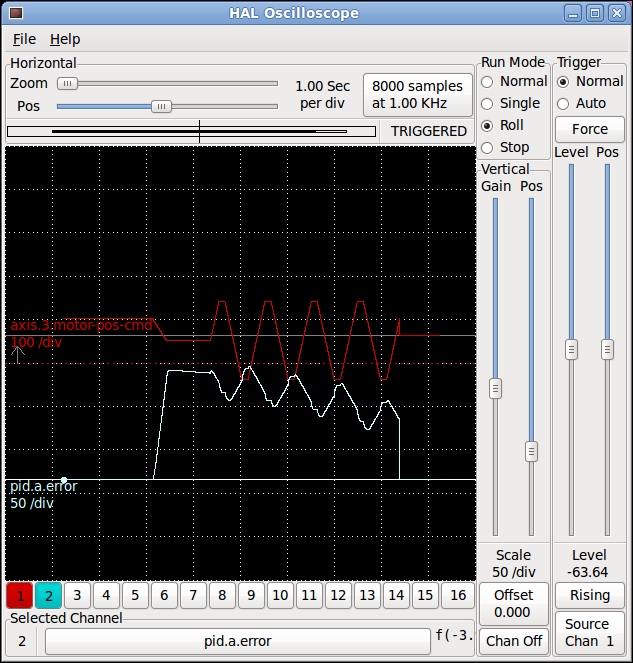

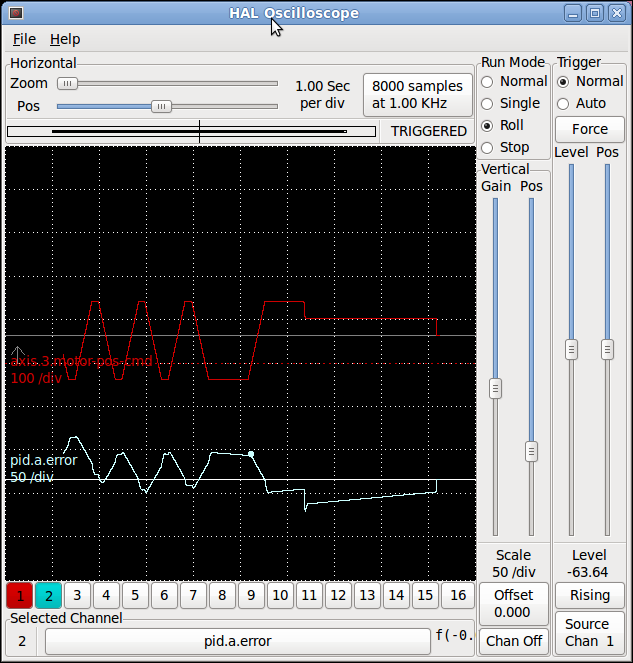

Hal scope Image of program run and during program stop ...

I put P at 5 first and increase FF1 ..... At the end of operation P in Lcnc and in drive are equal ... FF1 in drive is at 1/4 of scale value but in Lcnc are much highter .. see below

Warning: Spoiler!

[AXIS_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 100000.0

MIN_FERROR = 100000.0

MAX_VELOCITY = 36000.0

MAX_ACCELERATION = 240000.0

P = 20

I = 0.0

D = 0.000

FF0 = 0.0

FF1 =60000.0

FF2 = 50.00

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -27.7778

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -999999.0

MAX_LIMIT = 999999.0

HOME_OFFSET = 0.0in hal file all seems ok ...

#*******************

# AXIS A

#*******************

setp pid.a.Pgain [AXIS_3]P

setp pid.a.Igain [AXIS_3]I

setp pid.a.Dgain [AXIS_3]D

setp pid.a.bias [AXIS_3]BIAS

setp pid.a.FF0 [AXIS_3]FF0

setp pid.a.FF1 [AXIS_3]FF1

setp pid.a.FF2 [AXIS_3]FF2

setp pid.a.deadband [AXIS_3]DEADBAND

setp pid.a.maxoutput [AXIS_3]MAX_OUTPUT

setp pid.a.error-previous-target true

setp pid.a.maxerror .0005

net a-index-enable <=> pid.a.index-enable

net a-enable => pid.a.enable

net a-pos-cmd => pid.a.command

net a-vel-cmd => pid.a.command-deriv

net a-pos-fb => pid.a.feedback

net a-output => pid.a.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [AXIS_3]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [AXIS_3]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [AXIS_3]OUTPUT_MAX_LIMIT

net a-output => hm2_5i25.0.7i77.0.1.analogout2

net a-pos-cmd axis.3.motor-pos-cmd

net a-enable axis.3.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [AXIS_3]ENCODER_SCALE

net a-pos-fb <= hm2_5i25.0.encoder.02.position

net a-vel-fb <= hm2_5i25.0.encoder.02.velocity

net a-pos-fb => axis.3.motor-pos-fb

net a-index-enable axis.3.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net a-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net a-home-sw => axis.3.home-sw-in

net a-neg-limit => axis.3.neg-lim-sw-in

net a-pos-limit => axis.3.pos-lim-sw-inBut the result are not very good .... my gcode test put the axis to 90° make a pause of 0.1sec and put axis to -90° ... for 10 time ... after go to 50° and stop (all with G61).... the motor and reducer (at the motor I applied a reducer ratio 1/10) correctly turn on and turn of from 180° (I apply a hand to control the crowds results ... I can see 180° but not see the exact start and end point ... ) but in axis never see an exat stop to 90° or -90° bu for example 20 to -160 ... or 30 to -150 with random value .... the acceleration is hight .... but at the and When go to 50° the acceleration is 50% and in axis I see an stop at 70° and in 3 sec the end of program the value turn on 50°. During this positioning the program stop.

Hal scope Image of program run and during program stop ...

Last edit: 05 Nov 2015 22:10 by bkt.

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1110

- Thank you received: 113

05 Nov 2015 20:00 #64816

by bkt

Replied by bkt on topic servo dac offset

Now I try to reduce the velocity in G code to 0.1% .... in first test I set F8000 now I set F8 ...... the drive go to the maximum velocity at 10V refer and turn for 30000° +/- instead of 90° ...... ?????

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17406

- Thank you received: 5070

06 Nov 2015 00:03 #64835

by PCW

Replied by PCW on topic servo dac offset

Looks like at the minimum the FF1 is still completely wrong

I would set a P of say 1 and then adjust FF1 for as straight a line as you can get in the jogs

(dont worry about the offset error just try for a )

Also hard to see at that slow rate but it looks like the accel is very high I would lower this until

you get the tuning dialed in

I would set a P of say 1 and then adjust FF1 for as straight a line as you can get in the jogs

(dont worry about the offset error just try for a )

Also hard to see at that slow rate but it looks like the accel is very high I would lower this until

you get the tuning dialed in

The following user(s) said Thank You: bkt

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1110

- Thank you received: 113

06 Nov 2015 00:24 #64837

by bkt

Replied by bkt on topic servo dac offset

yes I see, I try a new conf with pnconfig and I see that FF1 at maximum I can set to 10000.0 ....

These confis is more soft .... only 360° max vel ans 1.2 max acc ..... Than I try tu run all with halmeter window open on hm2......01.analogue.out (my analog out ... I try to change out connector number... in case it is broken .... nothing change) ...

I see that analogue out go to 99.9 if go at minimum jog vel on axis (0.6 deg) .... and 9999.9 at max jog speed .... all ok. But in drive I see tha save velocity both???? is not possible I'm aspect to see 6rpm at 0.1volt and 600rpm at 10V ... why these ??? I try to control the i/o connector on drive but I suspect that the problem are in other land....

Some suggest??

These confis is more soft .... only 360° max vel ans 1.2 max acc ..... Than I try tu run all with halmeter window open on hm2......01.analogue.out (my analog out ... I try to change out connector number... in case it is broken .... nothing change) ...

I see that analogue out go to 99.9 if go at minimum jog vel on axis (0.6 deg) .... and 9999.9 at max jog speed .... all ok. But in drive I see tha save velocity both???? is not possible I'm aspect to see 6rpm at 0.1volt and 600rpm at 10V ... why these ??? I try to control the i/o connector on drive but I suspect that the problem are in other land....

Some suggest??

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17406

- Thank you received: 5070

06 Nov 2015 00:34 #64838

by PCW

Replied by PCW on topic servo dac offset

Can you post you current hal and ini files here?

maybe I can see if anything is obviously wrong

maybe I can see if anything is obviously wrong

The following user(s) said Thank You: bkt

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1110

- Thank you received: 113

06 Nov 2015 00:51 - 06 Nov 2015 01:02 #64839

by bkt

Replied by bkt on topic servo dac offset

for sure ....

Now I see that F in gcode (and with these conf) is equal to velocity on drive ... so if I set F60 drive go to 60rpm ... if set F600 drive go to 600rpm ....and so .... The vel that I set was too hight .... but there are other wrong setting ...

# Generated by PNCconf at Thu Nov 5 16:11:55 2015

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = test3

DEBUG = 0

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/k1/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 1.000000

MIN_LINEAR_VELOCITY = 0.010000

DEFAULT_ANGULAR_VELOCITY = 0.250000

MAX_ANGULAR_VELOCITY = 1.000000

MIN_ANGULAR_VELOCITY = 0.010000

EDITOR = gedit

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

SERVO_PERIOD = 1000000

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

[HAL]

HALUI = halui

HALFILE = test3.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

[TRAJ]

AXES = 4

COORDINATES = X Y Z A

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 2.50

MAX_LINEAR_VELOCITY = 25.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 10.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -0.01

MAX_LIMIT = 200.0

HOME_OFFSET = 0.0

#********************

# Axis Y

#********************

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 10.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -0.01

MAX_LIMIT = 200.0

HOME_OFFSET = 0.0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 10.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -100.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.0

#********************

# Axis A

#********************

[AXIS_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 100000000000000000.0

MIN_FERROR = 10000000000000.0

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 120.0

P = 1.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -27.7778

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -999999.0

MAX_LIMIT = 999999.0

HOME_OFFSET = 0.0

#********************

# Spindle

#********************

[SPINDLE_9]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

# Generated by PNCconf at Thu Nov 5 16:11:55 2015

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000xxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.a,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.a.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [AXIS_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [AXIS_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [AXIS_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd axis.0.motor-pos-cmd

net x-enable axis.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [AXIS_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => axis.0.motor-pos-fb

net x-index-enable axis.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net x-home-sw => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [AXIS_1]P

setp pid.y.Igain [AXIS_1]I

setp pid.y.Dgain [AXIS_1]D

setp pid.y.bias [AXIS_1]BIAS

setp pid.y.FF0 [AXIS_1]FF0

setp pid.y.FF1 [AXIS_1]FF1

setp pid.y.FF2 [AXIS_1]FF2

setp pid.y.deadband [AXIS_1]DEADBAND

setp pid.y.maxoutput [AXIS_1]MAX_OUTPUT

setp pid.y.error-previous-target true

setp pid.y.maxerror .0005

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [AXIS_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [AXIS_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [AXIS_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout2

net y-pos-cmd axis.1.motor-pos-cmd

net y-enable axis.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [AXIS_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.02.position

net y-vel-fb <= hm2_5i25.0.encoder.02.velocity

net y-pos-fb => axis.1.motor-pos-fb

net y-index-enable axis.1.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net y-home-sw => axis.1.home-sw-in

net y-neg-limit => axis.1.neg-lim-sw-in

net y-pos-limit => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror .0005

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout3-scalemax [AXIS_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout3-minlim [AXIS_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout3-maxlim [AXIS_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout3

net z-pos-cmd axis.2.motor-pos-cmd

net z-enable axis.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 0

setp hm2_5i25.0.encoder.03.scale [AXIS_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.03.position

net z-vel-fb <= hm2_5i25.0.encoder.03.velocity

net z-pos-fb => axis.2.motor-pos-fb

net z-index-enable axis.2.index-enable <=> hm2_5i25.0.encoder.03.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.03.rawcounts

# ---setup home / limit switch signals---

net z-home-sw => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# AXIS A

#*******************

setp pid.a.Pgain [AXIS_3]P

setp pid.a.Igain [AXIS_3]I

setp pid.a.Dgain [AXIS_3]D

setp pid.a.bias [AXIS_3]BIAS

setp pid.a.FF0 [AXIS_3]FF0

setp pid.a.FF1 [AXIS_3]FF1

setp pid.a.FF2 [AXIS_3]FF2

setp pid.a.deadband [AXIS_3]DEADBAND

setp pid.a.maxoutput [AXIS_3]MAX_OUTPUT

setp pid.a.error-previous-target true

setp pid.a.maxerror .0005

net a-index-enable <=> pid.a.index-enable

net a-enable => pid.a.enable

net a-pos-cmd => pid.a.command

net a-vel-cmd => pid.a.command-deriv

net a-pos-fb => pid.a.feedback

net a-output => pid.a.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [AXIS_3]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [AXIS_3]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [AXIS_3]OUTPUT_MAX_LIMIT

net a-output => hm2_5i25.0.7i77.0.1.analogout1

net a-pos-cmd axis.3.motor-pos-cmd

net a-enable axis.3.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [AXIS_3]ENCODER_SCALE

net a-pos-fb <= hm2_5i25.0.encoder.01.position

net a-vel-fb <= hm2_5i25.0.encoder.01.velocity

net a-pos-fb => axis.3.motor-pos-fb

net a-index-enable axis.3.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net a-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net a-home-sw => axis.3.home-sw-in

net a-neg-limit => axis.3.neg-lim-sw-in

net a-pos-limit => axis.3.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

setp pid.s.maxerror .0005

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net joint-select-d halui.joint.3.select

net a-is-homed halui.joint.3.is-homed

net jog-a-pos halui.jog.3.plus

net jog-a-neg halui.jog.3.minus

net jog-a-analog halui.jog.3.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---toolchange signals for custom tool changer---

net tool-number <= iocontrol.0.tool-prep-number

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-prepare-request <= iocontrol.0.tool-prepare

net tool-prepare-confirmed => iocontrol.0.tool-prepared

sorry for spoiler .... but BBCcode editor not work now on my pc.... but as you see the attachment upload hanyhow

My intention is make 60rpm at the and of servomotor .... after the motor I have a reducer 1/10 ... so for 60rpm at the end the motor make 600rpm .... I have divide the encoder feedback to 1/10 The motor have 2500 ppr encoder with 0 signal so the drive output a feedback of 250ppr .... I try these with halmeter .... 1RPM at the end of servomotor = 10000 pulse encoder (250*10*4) ... it seems ok ... but when run my g code :

the A axis go to 31000 and -31000 in while cicle (plus or less not see exactly) ....

Now I see that F in gcode (and with these conf) is equal to velocity on drive ... so if I set F60 drive go to 60rpm ... if set F600 drive go to 600rpm ....and so .... The vel that I set was too hight .... but there are other wrong setting ...

Warning: Spoiler!

# Generated by PNCconf at Thu Nov 5 16:11:55 2015

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = test3

DEBUG = 0

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/k1/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 1.000000

MIN_LINEAR_VELOCITY = 0.010000

DEFAULT_ANGULAR_VELOCITY = 0.250000

MAX_ANGULAR_VELOCITY = 1.000000

MIN_ANGULAR_VELOCITY = 0.010000

EDITOR = gedit

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

SERVO_PERIOD = 1000000

[HOSTMOT2]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

[HAL]

HALUI = halui

HALFILE = test3.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

[TRAJ]

AXES = 4

COORDINATES = X Y Z A

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 2.50

MAX_LINEAR_VELOCITY = 25.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 10.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -0.01

MAX_LIMIT = 200.0

HOME_OFFSET = 0.0

#********************

# Axis Y

#********************

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 10.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -0.01

MAX_LIMIT = 200.0

HOME_OFFSET = 0.0

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

P = 50.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = 10.0

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -100.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.0

#********************

# Axis A

#********************

[AXIS_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 100000000000000000.0

MIN_FERROR = 10000000000000.0

MAX_VELOCITY = 360.0

MAX_ACCELERATION = 120.0

P = 1.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

ENCODER_SCALE = -27.7778

OUTPUT_SCALE = 10.0

OUTPUT_MIN_LIMIT = -10.0

OUTPUT_MAX_LIMIT = 10.0

MIN_LIMIT = -999999.0

MAX_LIMIT = 999999.0

HOME_OFFSET = 0.0

#********************

# Spindle

#********************

[SPINDLE_9]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000

Warning: Spoiler!

# Generated by PNCconf at Thu Nov 5 16:11:55 2015

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000xxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.a,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.a.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# external input signals

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [AXIS_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [AXIS_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [AXIS_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd axis.0.motor-pos-cmd

net x-enable axis.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [AXIS_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => axis.0.motor-pos-fb

net x-index-enable axis.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net x-home-sw => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [AXIS_1]P

setp pid.y.Igain [AXIS_1]I

setp pid.y.Dgain [AXIS_1]D

setp pid.y.bias [AXIS_1]BIAS

setp pid.y.FF0 [AXIS_1]FF0

setp pid.y.FF1 [AXIS_1]FF1

setp pid.y.FF2 [AXIS_1]FF2

setp pid.y.deadband [AXIS_1]DEADBAND

setp pid.y.maxoutput [AXIS_1]MAX_OUTPUT

setp pid.y.error-previous-target true

setp pid.y.maxerror .0005

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [AXIS_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [AXIS_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [AXIS_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout2

net y-pos-cmd axis.1.motor-pos-cmd

net y-enable axis.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [AXIS_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.02.position

net y-vel-fb <= hm2_5i25.0.encoder.02.velocity

net y-pos-fb => axis.1.motor-pos-fb

net y-index-enable axis.1.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net y-home-sw => axis.1.home-sw-in

net y-neg-limit => axis.1.neg-lim-sw-in

net y-pos-limit => axis.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror .0005

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout3-scalemax [AXIS_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout3-minlim [AXIS_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout3-maxlim [AXIS_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout3

net z-pos-cmd axis.2.motor-pos-cmd

net z-enable axis.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 0

setp hm2_5i25.0.encoder.03.scale [AXIS_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.03.position

net z-vel-fb <= hm2_5i25.0.encoder.03.velocity

net z-pos-fb => axis.2.motor-pos-fb

net z-index-enable axis.2.index-enable <=> hm2_5i25.0.encoder.03.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.03.rawcounts

# ---setup home / limit switch signals---

net z-home-sw => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# AXIS A

#*******************

setp pid.a.Pgain [AXIS_3]P

setp pid.a.Igain [AXIS_3]I

setp pid.a.Dgain [AXIS_3]D

setp pid.a.bias [AXIS_3]BIAS

setp pid.a.FF0 [AXIS_3]FF0

setp pid.a.FF1 [AXIS_3]FF1

setp pid.a.FF2 [AXIS_3]FF2

setp pid.a.deadband [AXIS_3]DEADBAND

setp pid.a.maxoutput [AXIS_3]MAX_OUTPUT

setp pid.a.error-previous-target true

setp pid.a.maxerror .0005

net a-index-enable <=> pid.a.index-enable

net a-enable => pid.a.enable

net a-pos-cmd => pid.a.command

net a-vel-cmd => pid.a.command-deriv

net a-pos-fb => pid.a.feedback

net a-output => pid.a.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [AXIS_3]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [AXIS_3]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [AXIS_3]OUTPUT_MAX_LIMIT

net a-output => hm2_5i25.0.7i77.0.1.analogout1

net a-pos-cmd axis.3.motor-pos-cmd

net a-enable axis.3.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [AXIS_3]ENCODER_SCALE

net a-pos-fb <= hm2_5i25.0.encoder.01.position

net a-vel-fb <= hm2_5i25.0.encoder.01.velocity

net a-pos-fb => axis.3.motor-pos-fb

net a-index-enable axis.3.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net a-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net a-home-sw => axis.3.home-sw-in

net a-neg-limit => axis.3.neg-lim-sw-in

net a-pos-limit => axis.3.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

setp pid.s.maxerror .0005

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

net jog-y-pos halui.jog.1.plus

net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.jog.1.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net joint-select-d halui.joint.3.select

net a-is-homed halui.joint.3.is-homed

net jog-a-pos halui.jog.3.plus

net jog-a-neg halui.jog.3.minus

net jog-a-analog halui.jog.3.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---toolchange signals for custom tool changer---

net tool-number <= iocontrol.0.tool-prep-number

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-prepare-request <= iocontrol.0.tool-prepare

net tool-prepare-confirmed => iocontrol.0.tool-prepared

sorry for spoiler .... but BBCcode editor not work now on my pc.... but as you see the attachment upload hanyhow

My intention is make 60rpm at the and of servomotor .... after the motor I have a reducer 1/10 ... so for 60rpm at the end the motor make 600rpm .... I have divide the encoder feedback to 1/10 The motor have 2500 ppr encoder with 0 signal so the drive output a feedback of 250ppr .... I try these with halmeter .... 1RPM at the end of servomotor = 10000 pulse encoder (250*10*4) ... it seems ok ... but when run my g code :

G21 G90

#30 = 0

G0 F300 A0

o100 while [#30 LT 10]

G61 F300 A90

G4 P0.1

G61 F600 A-90

G4 P0.1

o100 endwhile

G61 F100 A50

M30the A axis go to 31000 and -31000 in while cicle (plus or less not see exactly) ....

Last edit: 06 Nov 2015 01:02 by bkt.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17406

- Thank you received: 5070

06 Nov 2015 01:03 #64842

by PCW

Replied by PCW on topic servo dac offset

OK for axis A a FF1 of 1 is probably about 30x too high

(FF1=1 _ONLY_ if the axis is scaled actual velocity = machine units per second at 10V to drive)

(FF1=1 _ONLY_ if the axis is scaled actual velocity = machine units per second at 10V to drive)

The following user(s) said Thank You: bkt

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1110

- Thank you received: 113

06 Nov 2015 01:27 - 06 Nov 2015 01:31 #64845

by bkt

Replied by bkt on topic servo dac offset

Sorry not understand very well ... actual velocity is velocity of motor (1) or final velocity after reducer(2)?

case 1 .... at 10V 600rpm ... 60°sec => 10

case 2 ... at 10V 60rpm ... 60°sec => 1

Anyhow ... with FF1 = 0.03 if move in gcode A = 90° obtain about 260/300° velocity decrease to 10%.... at 0.003 obtain about 150/200° but the velocity decrease to 1% .....

Regards

Giorgio

case 1 .... at 10V 600rpm ... 60°sec => 10

case 2 ... at 10V 60rpm ... 60°sec => 1

Anyhow ... with FF1 = 0.03 if move in gcode A = 90° obtain about 260/300° velocity decrease to 10%.... at 0.003 obtain about 150/200° but the velocity decrease to 1% .....

Regards

Giorgio

Last edit: 06 Nov 2015 01:31 by bkt.

Please Log in or Create an account to join the conversation.

Time to create page: 0.183 seconds