servo dac offset

- PCW

-

- Away

- Moderator

-

- Posts: 17479

- Thank you received: 5107

As the tutorial states you must adjust FF1 so the feedback position neither leads nor lags the commanded position

You cannot just set a value you must adjust it till correct

If you want to scale in machine units you set the output scale (and limits) to the axis velocity in machine units per second at 10V

so if your axis moves 360 degrees per second with a 10V command to the servo drive, you would set

OUTPUT_SCALE = 360

OUTPUT_MIN_LIMIT = -360.0

OUTPUT_MAX_LIMIT = 360.0

and then FF1 should be 1.0

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 114

OUTPUT_SCALE = 1200

OUTPUT_MIN_LIMIT = -1200.0

OUTPUT_MAX_LIMIT = 1200.0

and I can set FF1 = 1.0 ... Is right?

At these point:

MAX_VELOCITY = 72000.0

MAX_ACCELERATION = 72000.0 (or more if possible)

Is right??

But stability of system decrease ..... whitch parameter can adjust for make more stable the servo motor at stop command?

regards

Giorgio

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19752

- Thank you received: 4584

Reduce P to make the system more stable. Increase P to make the system more responsive.

Add I to make the system more accurate, reduce I to stop the system over-shooting.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17479

- Thank you received: 5107

you set

OUTPUT_SCALE = 1200

OUTPUT_MIN_LIMIT = -1200.0

OUTPUT_MAX_LIMIT = 1200.0

and then FF1 = 1.0 will be _CLOSE_ but still need tuning

If your axis moves 1200 degrees per second at 10V, then the maximum velocity

_must_ be below this so there is headroom for the servo:

MAX_VELOCITY = 1000.0

Maximum acceleration depends in your drive/load capabilities and error budget though

72000 degrees per S^2 means you can get to full speed (1000 degrees per second) in about

14 milliseconds which is unlikely.

I would start with a gentler:

MAX_ACCELERATION = 5000.0

or 200 milliseconds to full speed (at least to start)

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 114

regards

Giorgio

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17479

- Thank you received: 5107

If the drives quadrature signals include index, and they are wired to the 7I77,

LinuxCNC can home to index

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 114

At last This my conf (ini file attach) .... it works quite good .... I change feedback signal to 2500ppr encoder direct ..... I have an other issue ... in pos move the machine go directly to quote ... in neg move it stop 8° first and than go to quote slowly ..... some reason or adjust to ini file for solve these??

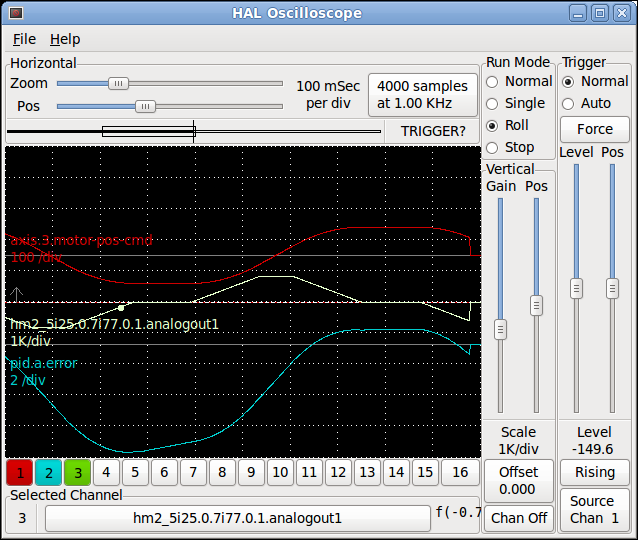

hal scope image during working (+90 to -90° continuosly ...)

in addition I have to keep ferror 50 otherwise I get error tracking .... I tried to lower to the acceleration ... but I would be forced to lower it too ......

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19752

- Thank you received: 4584

in pos move the machine go directly to quote ... in neg move it stop 8° first and than go to quote slowly ..... some reason or adjust to ini file for solve these??

Can you use the "Calibrate axis" option in the Axis menu? That is a much faster way to test PID settings than editing the INI file.

If the system takes too long to correct a static error then you probably want a bit of I-gain. But it might also be that the P-gain isn't high enough.

There is a reason that they call it PID "tuning", you need to try a number see if it is better, try a bit more or a bit less, try again.

You _could_ try the Ziegler-Nichols method which is mentioned in this general page about PID control.

it.wikipedia.org/wiki/Controllo_PID

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 114

in pos move the machine go directly to quote ... in neg move it stop 8° first and than go to quote slowly ..... some reason or adjust to ini file for solve these??

Ok but why only in one direction? How can make simmetric the error ? Because I move only +90° and -90° continuosly but only at -90° have a problem when go to +90° the axis stop perfect. On the the servo motor shaft is connected to anything . No load on servomotor shaft .... I expect an error identical on both directions.

regards

Giorgio

Please Log in or Create an account to join the conversation.

- bkt

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1110

- Thank you received: 114

regards

giorgio

Please Log in or Create an account to join the conversation.