How to. 2 or more motors on one axis. Gantry

- ikkuh

-

- Offline

- Elite Member

-

Less

More

- Posts: 272

- Thank you received: 47

11 Apr 2019 09:43 - 11 Apr 2019 09:46 #130652

by ikkuh

That would be me

rather frustrating that the people who seem to know all this stuff sometimes get tired of answering questions. I can not blame them if I think about it. But a better documentation would be nice. And then I mean documentation that can be used by people who are better at wood or metal then computers. LinuxCNC is a tool to make a machine work, not a project on itself for people like me. (remarks as saying why don't you write the documentation yourself then miss the point. If I could I would. I started exposing my current config files on an open git server for everyone to see and make adjustments ( git.cnckloon.nl/CNCZone/Mesa_2019 ), that is as far as I can help others at the moment.)

All the ingredients are there to make LinuxCNC the tool of choice for loads of people.

I am sure that if the documentation was easier to understand, more relevant examples for example, LinuxCNC would be much more used and the makers would get a lot more satisfaction of participating in the development. Technically the documentation is perfect, everything one needs to know is there. But that is not the purpose of software, I do not want to study or be an expert at understanding LinuxCNC setup. I want to use gmoccapy with a touchscreen and make nice things for other people in wood and metal. I honestly do not think I need to spend hours and hours exploring the documentation for things I do not even know they exist.

For my cheap Chinese BOB's I could start with stepconf, that worked quite well. Now I switched over to a Mesa card, a 7i96 that is supported but pncconf does not support my card. Kinda confusing at first, disappointing later.

The few examples that are around are mostly outdated, functionality that is great and a must have is hidden in pre-release versions and the documentation although very concise does not connect to the real world of the tired and frustrated woodworker who has invested a lot of money just to be able to use part of the OS movement.

Sometimes I wonder why I do not use Mach 3, but then I look at the specs and I know I am better of with LinuxCNC (if I get it working again).

I am happy and grateful that LinuxCNC exists and is being developed. But, as I said, it would be nice if it could be used by 'normal' people too.

This is by no means a flame towards all the knowledgeable people who donate their time and effort towards this great project. English is not my first language, I apologize if I offended anyone.

Replied by ikkuh on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

For those readers (like me) who are not totaly fluent in LinuxSpeak

That would be me

rather frustrating that the people who seem to know all this stuff sometimes get tired of answering questions. I can not blame them if I think about it. But a better documentation would be nice. And then I mean documentation that can be used by people who are better at wood or metal then computers. LinuxCNC is a tool to make a machine work, not a project on itself for people like me. (remarks as saying why don't you write the documentation yourself then miss the point. If I could I would. I started exposing my current config files on an open git server for everyone to see and make adjustments ( git.cnckloon.nl/CNCZone/Mesa_2019 ), that is as far as I can help others at the moment.)

All the ingredients are there to make LinuxCNC the tool of choice for loads of people.

I am sure that if the documentation was easier to understand, more relevant examples for example, LinuxCNC would be much more used and the makers would get a lot more satisfaction of participating in the development. Technically the documentation is perfect, everything one needs to know is there. But that is not the purpose of software, I do not want to study or be an expert at understanding LinuxCNC setup. I want to use gmoccapy with a touchscreen and make nice things for other people in wood and metal. I honestly do not think I need to spend hours and hours exploring the documentation for things I do not even know they exist.

For my cheap Chinese BOB's I could start with stepconf, that worked quite well. Now I switched over to a Mesa card, a 7i96 that is supported but pncconf does not support my card. Kinda confusing at first, disappointing later.

The few examples that are around are mostly outdated, functionality that is great and a must have is hidden in pre-release versions and the documentation although very concise does not connect to the real world of the tired and frustrated woodworker who has invested a lot of money just to be able to use part of the OS movement.

Sometimes I wonder why I do not use Mach 3, but then I look at the specs and I know I am better of with LinuxCNC (if I get it working again).

I am happy and grateful that LinuxCNC exists and is being developed. But, as I said, it would be nice if it could be used by 'normal' people too.

This is by no means a flame towards all the knowledgeable people who donate their time and effort towards this great project. English is not my first language, I apologize if I offended anyone.

Last edit: 11 Apr 2019 09:46 by ikkuh.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

11 Apr 2019 12:31 #130655

by pl7i92

Replied by pl7i92 on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

I try hard to get Videos off infos Updated

but nativ German speeking somtimes it is real hard to Explain

aspecial as there are significand changes from Version you use

YT Channel and Playlist English

the Men how did this in first place has deceased in 2018 so i need myself come over all this

but nativ German speeking somtimes it is real hard to Explain

aspecial as there are significand changes from Version you use

YT Channel and Playlist English

the Men how did this in first place has deceased in 2018 so i need myself come over all this

Please Log in or Create an account to join the conversation.

- ikkuh

-

- Offline

- Elite Member

-

Less

More

- Posts: 272

- Thank you received: 47

11 Apr 2019 19:34 #130690

by ikkuh

I am Dutch. so I can understand English as well as German. I enjoy the video's made by Talla83 ( www.youtube.com/channel/UCHDMxw4Oum-wKm5UpMt2lzA ) he is very knowledgeable and can explain the more special stuff very well. The original German video's by Nieson ( www.youtube.com/channel/UCulC7EkwdYkaIHPo6rlkGQw ) are very good too.

Seems that both Talla83 and Nieson fill quite a void in knowledge as far as using LinuxCNC goes. Glad that they try to explain stuff and show examples of working setups.

Replied by ikkuh on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

I try hard to get Videos off infos Updated

but nativ German speeking somtimes it is real hard to Explain

I am Dutch. so I can understand English as well as German. I enjoy the video's made by Talla83 ( www.youtube.com/channel/UCHDMxw4Oum-wKm5UpMt2lzA ) he is very knowledgeable and can explain the more special stuff very well. The original German video's by Nieson ( www.youtube.com/channel/UCulC7EkwdYkaIHPo6rlkGQw ) are very good too.

Seems that both Talla83 and Nieson fill quite a void in knowledge as far as using LinuxCNC goes. Glad that they try to explain stuff and show examples of working setups.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21171

- Thank you received: 7235

12 Apr 2019 01:29 #130709

by tommylight

Replied by tommylight on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

There is a tool to configure 7i96 made by JT, easy to use and works as it should.

gnipsel.com

Under the Linuxcnc section i think.

gnipsel.com

Under the Linuxcnc section i think.

Please Log in or Create an account to join the conversation.

- FedX

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 2

25 Aug 2019 11:26 #143133

by FedX

Replied by FedX on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

Hi,

I tried to set up a simulated configuration for my Gantry CNC (XYYZ), before i install LinuxCNC 2.9 on my machine.

Ive set up everything as described (except the homing part). But there seems to be a problem with joging the axis.. Key left and right is X Axis, Key Up and Downn is nothing, and pos Up and Down is the X Axis.. I cant move my Y Axis with to Joints.

When i have only 3 Joints in my ini File then everything works. Is that because only three joints are defined in sim_hardware.hal? I tried to configure all joints there but i dont really now how and always get error messages at startup

I tried to set up a simulated configuration for my Gantry CNC (XYYZ), before i install LinuxCNC 2.9 on my machine.

Ive set up everything as described (except the homing part). But there seems to be a problem with joging the axis.. Key left and right is X Axis, Key Up and Downn is nothing, and pos Up and Down is the X Axis.. I cant move my Y Axis with to Joints.

When i have only 3 Joints in my ini File then everything works. Is that because only three joints are defined in sim_hardware.hal? I tried to configure all joints there but i dont really now how and always get error messages at startup

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11635

- Thank you received: 3916

25 Aug 2019 12:15 #143139

by rodw

Replied by rodw on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

Any of the sims I've used for my gantry machine have just been an XYZ machine. This kinda makes sense becasue in a sim, Joints (motors) don't exist anyway.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

25 Aug 2019 12:40 #143142

by pl7i92

Replied by pl7i92 on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

@fedX

it is only importend on a real mashine

no ned to sim

and you can be shure it workes its proven multiple times

THe thing you shoudt ask is your hardware supportd to do the thing

WHAT system you are going to plan

DB25 Mesa Eth Stepper hybrid servo

it is only importend on a real mashine

no ned to sim

and you can be shure it workes its proven multiple times

THe thing you shoudt ask is your hardware supportd to do the thing

WHAT system you are going to plan

DB25 Mesa Eth Stepper hybrid servo

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

25 Aug 2019 15:28 - 25 Aug 2019 16:59 #143148

by dgarrett

Attached file (ok.ini) updates your sim ini to work.

Edits:

1) Make [TRAJ]COORDINATES agree with trivkins coordinates

2) use kinstype=both to clarify joint,axes distinctions

(recommended for any config with 2joints for an axis)

2) Specify HOME_SEQUENCE for all [JOINT_n] sections

to enable "Home All" and sync homing for joints 1,2

1) also, comment out unsupplied files:

custompanel.xml,custom.hal

Replied by dgarrett on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

I tried to set up a simulated configuration for my Gantry CNC (XYYZ)

Attached file (ok.ini) updates your sim ini to work.

Edits:

1) Make [TRAJ]COORDINATES agree with trivkins coordinates

2) use kinstype=both to clarify joint,axes distinctions

(recommended for any config with 2joints for an axis)

2) Specify HOME_SEQUENCE for all [JOINT_n] sections

to enable "Home All" and sync homing for joints 1,2

1) also, comment out unsupplied files:

custompanel.xml,custom.hal

Last edit: 25 Aug 2019 16:59 by dgarrett.

The following user(s) said Thank You: Jalfrezi19

Please Log in or Create an account to join the conversation.

- FedX

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 2

25 Aug 2019 20:12 #143170

by FedX

Replied by FedX on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

Great thank you! Now evereything works fine after "homing". Should i do theese changes also on the real machine or is it just a "cosmetic" effect?

Please Log in or Create an account to join the conversation.

- deemoss

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 0

30 Sep 2019 11:59 - 30 Sep 2019 12:04 #146706

by deemoss

Replied by deemoss on topic How to. 2 or more motors on one axis. Gantry LinuxCNC 2.8 Master

Hi Guys, thanks for the excellent write up.

1.

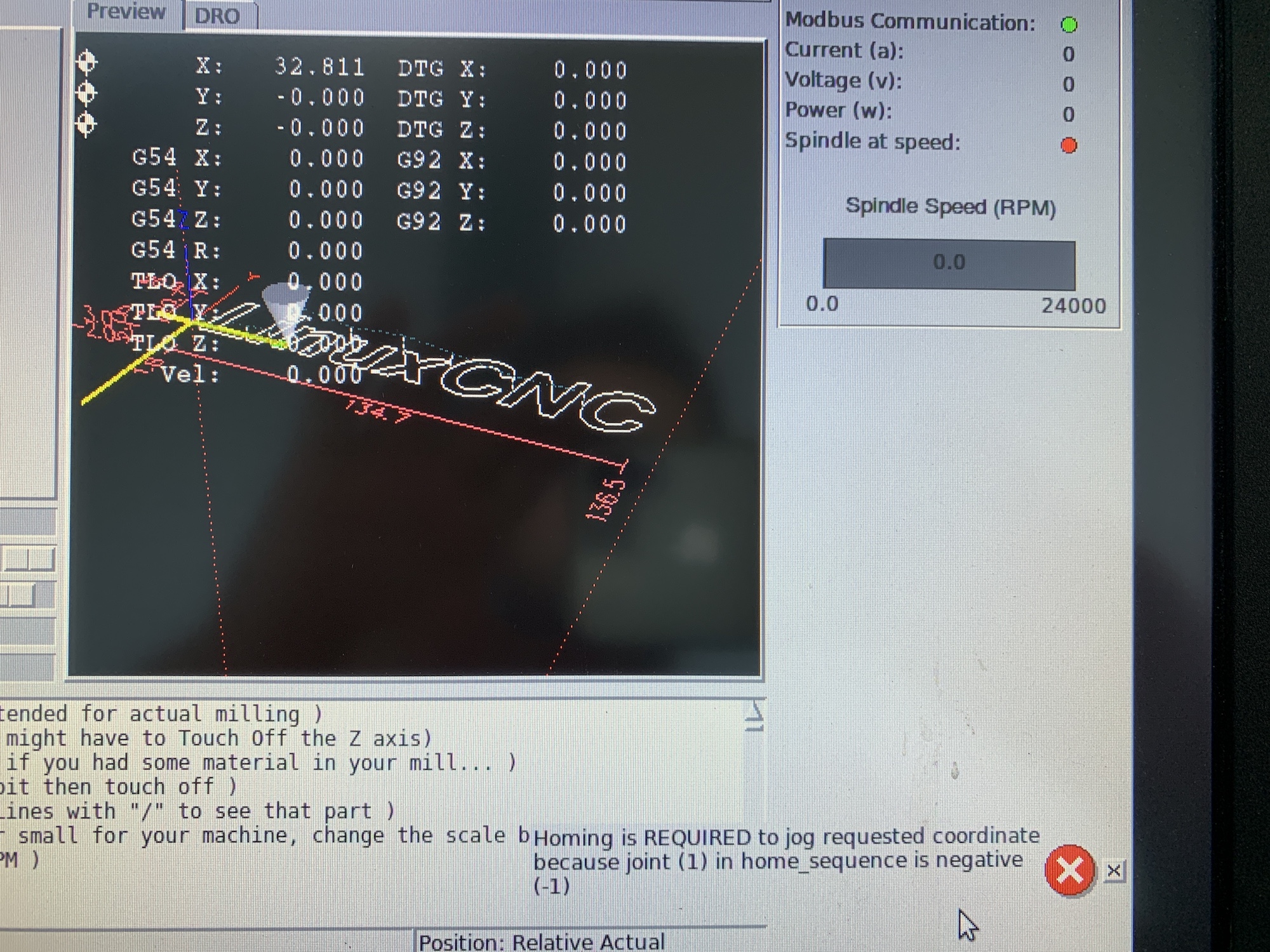

I have implemented the changes in 2.8pre and it seems that I am able to home the 2 joint Y gantry (Home ALL). As you can see in the screenshot 1, the router LOOKS homed. Then when I try to jog Y, I get this error (as if it hasn't been homed). Why could this be?

2.

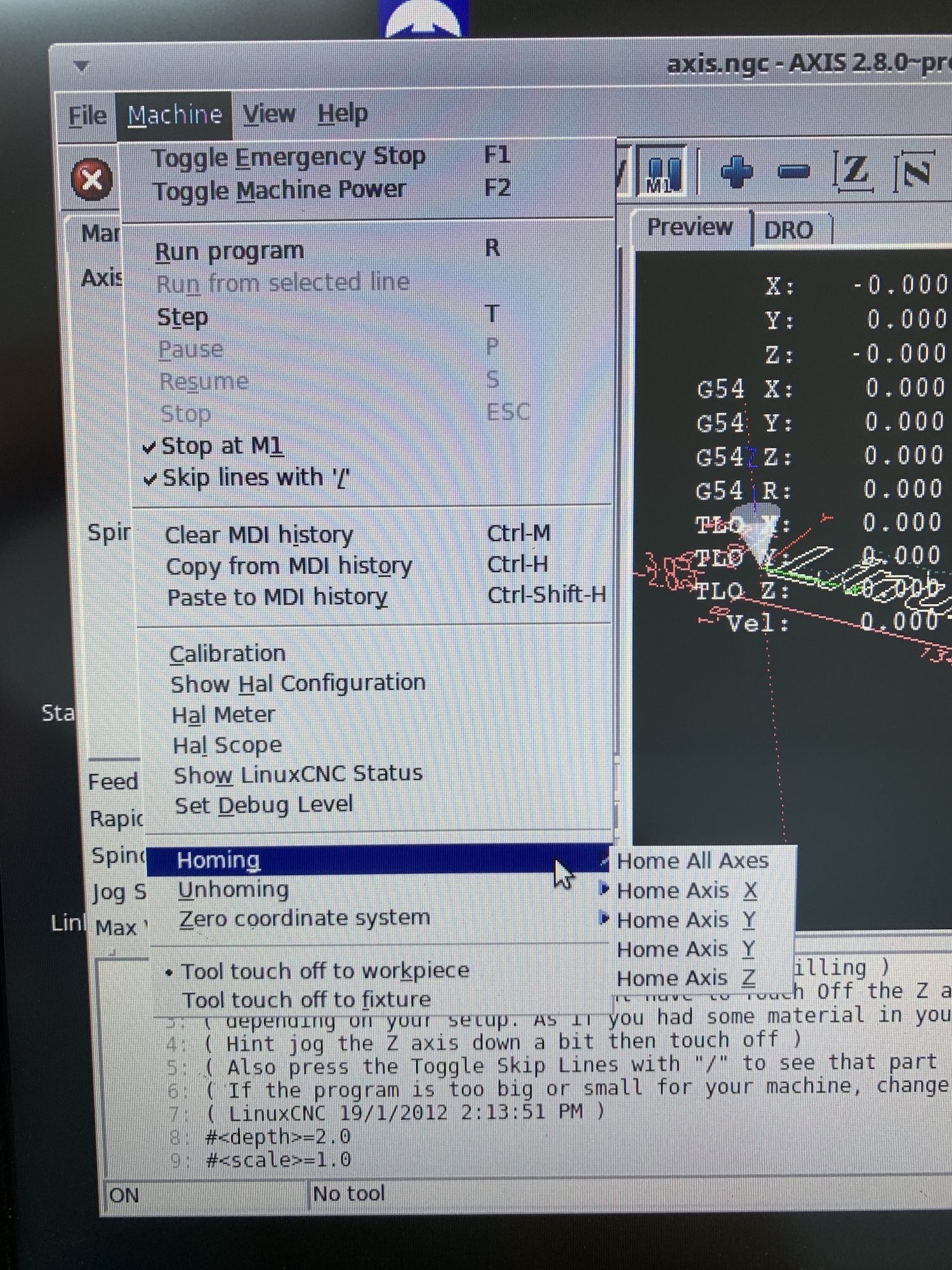

When (in Axis) going to Machine -> Homing I see two "Home Axis Y". If I try one of them does it mean that only one joint will start moving? Screenshot 2.

Cheers,

Dimos

1.

I have implemented the changes in 2.8pre and it seems that I am able to home the 2 joint Y gantry (Home ALL). As you can see in the screenshot 1, the router LOOKS homed. Then when I try to jog Y, I get this error (as if it hasn't been homed). Why could this be?

2.

When (in Axis) going to Machine -> Homing I see two "Home Axis Y". If I try one of them does it mean that only one joint will start moving? Screenshot 2.

Cheers,

Dimos

Last edit: 30 Sep 2019 12:04 by deemoss.

Please Log in or Create an account to join the conversation.

Time to create page: 0.452 seconds