EtherCAT driver for a 6 axis robot

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

Some dots to connect now....

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

Not quite sure how to handle

1). the setting of bits on the slave during init() - active / home

2). the reading and writing of REAL to and from the slave

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

The Meca500 encoder is REAL format.

Using halType float does not return the correct value even if scaled.

However, if i set the ethercat pdo data as halType u32 ....

24 u32 OUT 0xC28A5415 lcec.0.encX.encoder.a1.raw

24 u32 OUT 0xC0B478C3 lcec.0.encY.encoder.a2.raw

24 u32 OUT 0x411BFEF1 lcec.0.encZ.encoder.a3.raw

24 u32 OUT 0xC2B59246 lcec.0.encA.encoder.a4.raw

24 u32 OUT 0xC2B11573 lcec.0.encB.encoder.a5.raw

24 u32 OUT 0xC1F06666 lcec.0.encC.encoder.a6.rawIf I use an online hex to float converter the values looks right

gregstoll.com/~gregstoll/floattohex/

Ie 0xC2B range is about -90 degrees, 0x42B about +90 - that aligns with the physical device.

Is there a conv for hex to float? Or a better way to read whatever REAL format Meca500 uses to float? [/code][/code]

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

If i uncomment L140 linux cnc fails to start. The PDO address and offset seem ok. I'm stumped!

github.com/djsftree/linuxcnc-ethercat/bl.../lcec_meca500.c#L140

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

[ 6938.151342] EtherCAT ERROR 0-0: SDO upload 0x0000:00 aborted.

[ 6938.151357] EtherCAT ERROR 0-0: SDO abort message 0x06020000: "This object does not exist in the object directory".

[ 6938.151362] EtherCAT ERROR 0-0: Failed to read number of mapped PDO entries.

[ 6938.151365] EtherCAT ERROR 0-0: Failed to read mapped PDO entries for PDO 0x0000.

[ 6938.156310] EtherCAT ERROR 0-0: SDO upload 0x0000:00 aborted.

[ 6938.156325] EtherCAT ERROR 0-0: SDO abort message 0x06020000: "This object does not exist in the object directory".

[ 6938.156331] EtherCAT ERROR 0-0: Failed to read number of mapped PDO entries.

[ 6938.156334] EtherCAT ERROR 0-0: Failed to read mapped PDO entries for PDO 0x0000.Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

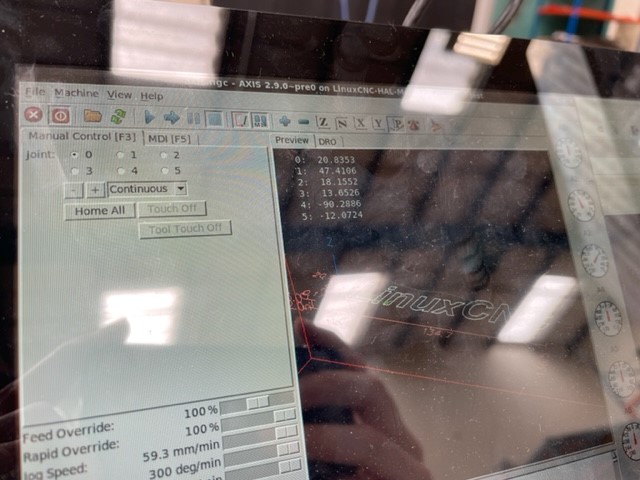

I am a little over my head setting up LinuxCNC with the Meca500 robot. I am looking for paid help as I am at impasse.

Is there anyone on here able to look at my LinuxCNC ini and hal files for a fee?

Here are my LinuxCNC project files

github.com/djsftree/linuxcnc-ethercat/tree/master/wip-meca500

I am struggling with the pid feedback, estop setup, axes setup, following errors when attempting to jog.

The only thing that appears to work so far are the six encoders correctly reporting the joint angles.

Image attached.

Some barriers to my thought and progress.

1). When coming out of estop and to activate the robot I need to send the following sequence with a few 10ms pause between each. How do I so that and where in a HAL LinuxCNC friendly way? I can do this manually using the "HAL Configuration" buttons.

lcec.0.Meca500.ctrl.deactivate 1

lcec.0.Meca500.ctrl.activate 1

lcec.0.Meca500.ctrl.home 1

The robot activation can be check with

lcec.0.Meca500.status.activated

all joints of the machine are then homed by the robot firmware - status check by

lcec.0.Meca500.status.homed

If anyone can help I would be much appreciated. Like I said, I'm happy to pay for your time if you think you can help.

Attachments:

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

- Posts: 790

- Thank you received: 276

-did you survive to get proper motion without pid, are the scaling correct ?

-does this descripe that everytime estop is raised, the robot lost its homing? does the robot send continous encoder values during its "own" homing sequence? this would raise a lot of following errors.

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

So, without any PID and just using the motion controller outputs

joint.0.vel-cmd => lcec.0.Meca500.vel-cmd.a1

joint.0.motor-pos-fb <= lcec.0.Meca500.encoder.a1

I was able to jog each axis ok (with following error after a few seconds).

At power-up, the Meca500 knows the approximate angle of each of its joints, with a couple of degrees of uncertainty. To find the exact joint angles with high accuracy, each motor must make one full revolution. This motion is the essential part of a procedure called homing. During homing, all joints rotate simultaneously. Each of joints 1, 2 and 3 rotates 3.6∘, joints 4 and 5 rotate 7.2∘ each, and joint 6 rotates 12∘. Then, all joints rotate back to their initial angles. The whole sequence lasts a few seconds.

Initially (at application startup) clear both the MoveID and SetPoint fields.

setp lcec.0.Meca500.motion.move-id 0

setp lcec.0.Meca500.motion.set-point 0

To start moving the robot

setp lcec.0.Meca500.vel-command 21

setp lcec.0.Meca500.motion.set-point 1

setp lcec.0.Meca500.motion.move-id 0

lcec.0.Meca500.vel-cmd.a1 thru a6 (degree/sec as REAL float)

To stop the robot, you must reset

setp lcec.0.Meca500.motion.set-point 0

absolute encoder positions (degree as REAL float) are read from

lcec.0.Meca500.encoder.a1 thru a6

joint velocities (degree/sec as REAL float) can be read from

lcec.0.Meca500.velocity.a1 thru a6

REAL floats was made possible by this commit

github.com/sittner/linuxcnc-ethercat/pull/114

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

Just checked, yes it does.does the robot send continous encoder values during its "own" homing sequence? this would raise a lot of following errors.

Please Log in or Create an account to join the conversation.

- ftree

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 10

-i would prefer to write a small c component for the initializing sequence

What would the C look like for setting the following at application startup?

lcec.0.Meca500.ctrl.deactivate 0

lcec.0.Meca500.ctrl.activate 0

lcec.0.Meca500.ctrl.home 0

lcec.0.Meca500.ctrl.reset-errror 0

lcec.0.Meca500.motion.move-id 0

lcec.0.Meca500.motion.set-point 0At what stage would you then "activate" , "robot home" and check for a sucessful home? Insert this routine to the power on button in the UI?

lcec.0.Meca500.ctrl.activate 1

wait 1 seconds

check that lcec.0.Meca500.status.activated = 1

lcec.0.Meca500.ctrl.home 1

wait 4 seconds

check for lcec.0.Meca500.status.homed = 1with an managed passthrough of the joints amp-enable-out and error pins...

Please Log in or Create an account to join the conversation.