Search Results (Searched for: 7i76e)

- PCW

07 Jul 2025 00:57

Replied by PCW on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- SjCNC

- SjCNC

06 Jul 2025 23:54

Replied by SjCNC on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- SjCNC

- SjCNC

06 Jul 2025 20:46

Replied by SjCNC on topic Please help with adding laser control

Please help with adding laser control

Category: Plasma & Laser

- SjCNC

- SjCNC

06 Jul 2025 16:26

Please help with adding laser control was created by SjCNC

Please help with adding laser control

Category: Plasma & Laser

- SebastianM

- SebastianM

04 Jul 2025 00:35 - 04 Jul 2025 02:01

- SebastianM

- SebastianM

29 Jun 2025 16:10 - 29 Jun 2025 16:14

Replied by SebastianM on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

- JT

29 Jun 2025 12:45

Replied by JT on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

- SebastianM

- SebastianM

29 Jun 2025 01:56 - 29 Jun 2025 01:57

Replied by SebastianM on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

- PCW

24 Jun 2025 16:12

Replied by PCW on topic New with questions on LinuxCNC and Mesa

New with questions on LinuxCNC and Mesa

Category: General LinuxCNC Questions

- PCW

22 Jun 2025 23:22

Replied by PCW on topic Modbus connection issue mesa 7i76eu pktUART

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

- AdelRTP

- AdelRTP

22 Jun 2025 22:20

Replied by AdelRTP on topic Modbus connection issue mesa 7i76eu pktUART

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

- PCW

22 Jun 2025 13:27

Replied by PCW on topic Modbus connection issue mesa 7i76eu pktUART

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

- tommylight

22 Jun 2025 12:48

Replied by tommylight on topic Modbus connection issue mesa 7i76eu pktUART

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

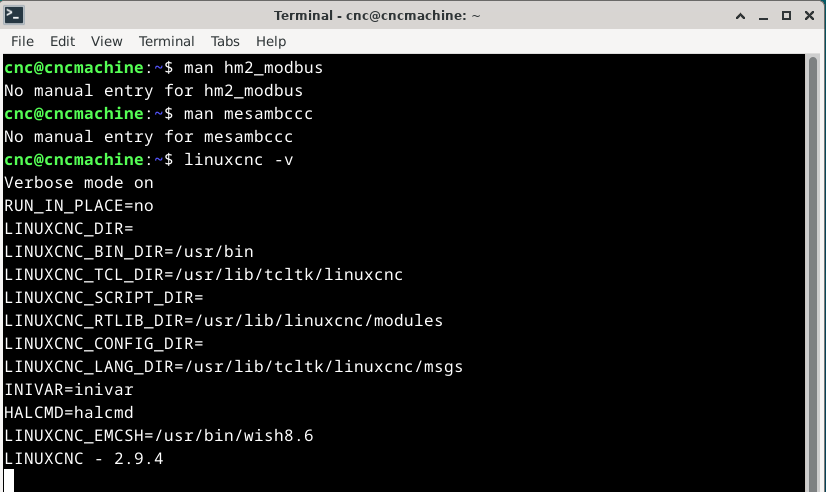

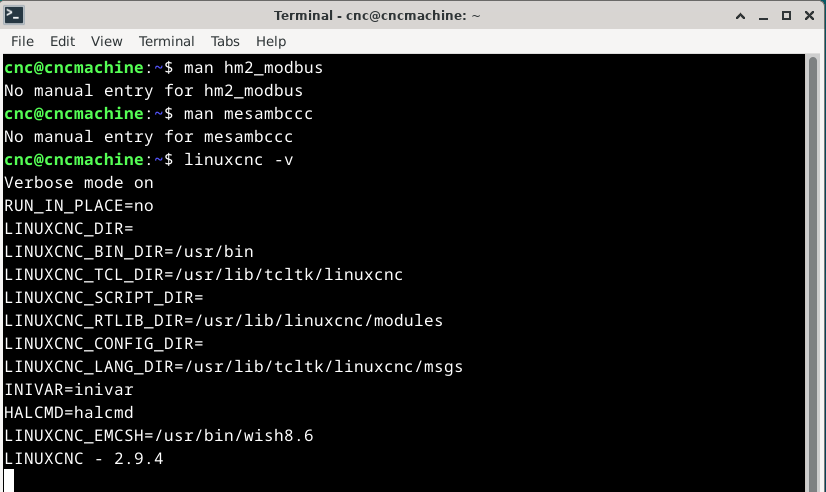

- AdelRTP

- AdelRTP

22 Jun 2025 10:50 - 22 Jun 2025 10:51

Replied by AdelRTP on topic Modbus connection issue mesa 7i76eu pktUART

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

- AdelRTP

- AdelRTP

22 Jun 2025 08:09

Replied by AdelRTP on topic Modbus connection issue mesa 7i76eu pktUART

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

Time to create page: 0.582 seconds