Search Results (Searched for: 7i76e)

- AdelRTP

- AdelRTP

21 Jun 2025 14:09

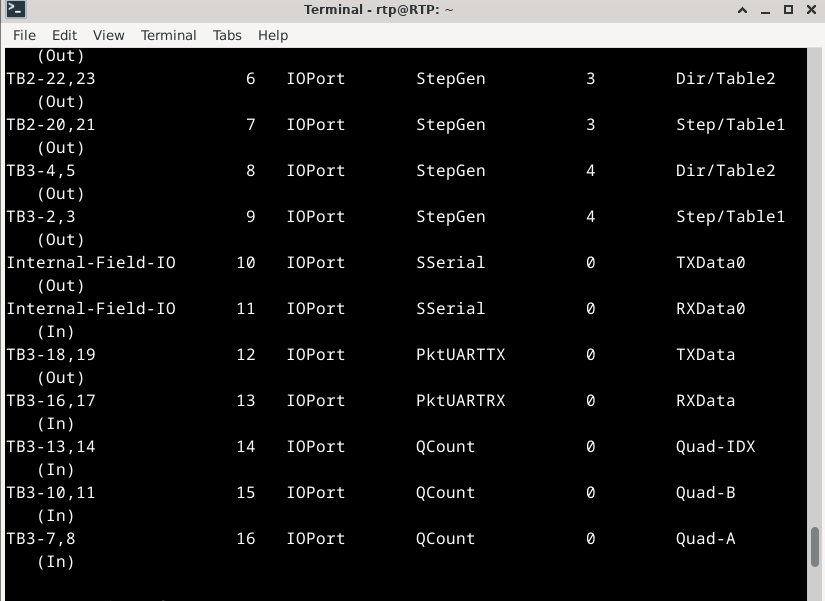

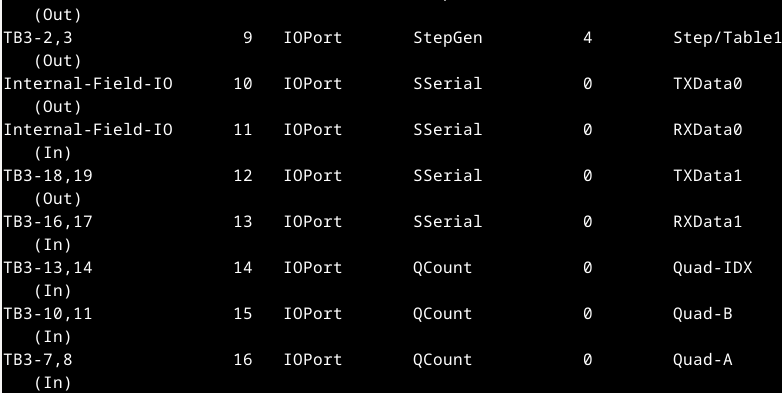

Modbus connection issue mesa 7i76eu pktUART was created by AdelRTP

Modbus connection issue mesa 7i76eu pktUART

Category: General LinuxCNC Questions

- AdelRTP

- AdelRTP

20 Jun 2025 21:34

- tommylight

20 Jun 2025 21:00

- AdelRTP

- AdelRTP

20 Jun 2025 20:54

- PCW

20 Jun 2025 20:49 - 20 Jun 2025 20:50

- AdelRTP

- AdelRTP

20 Jun 2025 20:34

- andypugh

20 Jun 2025 20:08

- tommylight

20 Jun 2025 19:56

- AdelRTP

- AdelRTP

20 Jun 2025 19:39

- tommylight

20 Jun 2025 15:57

- AdelRTP

- AdelRTP

20 Jun 2025 15:04

- knipknap

- knipknap

20 Jun 2025 11:09

Replied by knipknap on topic MESA 7i76E burning out issue

MESA 7i76E burning out issue

Category: Driver Boards

- bcorley

- bcorley

19 Jun 2025 16:49

Replied by bcorley on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- directandrew

- directandrew

16 Jun 2025 00:34

Replied by directandrew on topic New to linuxcnc, basic question for DRO modes with encoded handwheels

New to linuxcnc, basic question for DRO modes with encoded handwheels

Category: General LinuxCNC Questions

- SebastianM

- SebastianM

14 Jun 2025 16:44

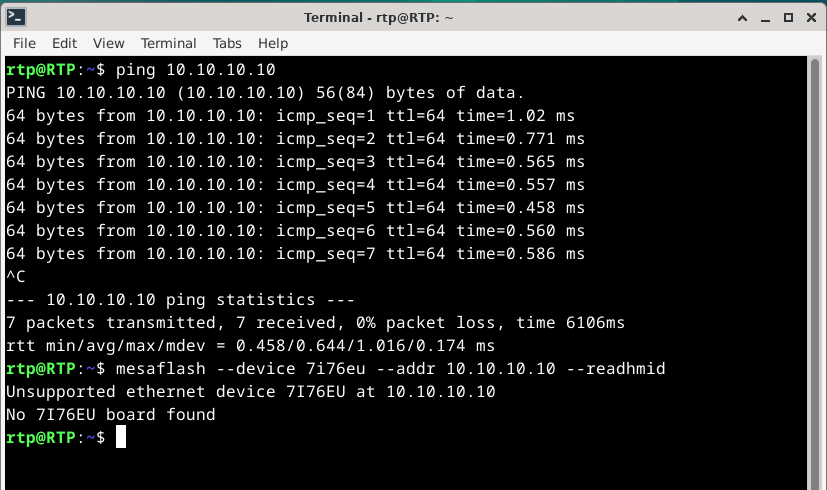

Error finishing read... *sigh* was created by SebastianM

Error finishing read... *sigh*

Category: Computers and Hardware

Time to create page: 0.625 seconds